Abstract

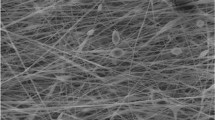

The current research presents the optimization of the parameters involved in the production of polyacrylonitrile (PAN) nanofibers via the needleless electrospinning system. The experiments were designed using the Taguchi method to investigate the morphological, physical, and mechanical properties of the nanofibers. The single-wall carbon nanotubes (CNT) were used in order to improve the mechanical properties of the electrospun nanofibers. The diameter of the PAN nanofibers in the needleless system was less than 300 nm, which was smaller than that in the conventional system. The results showed that the concentration had the greatest impact on the fiber diameter than other parameters in both PAN and PAN/CNT nanofibers. The specific stress of the nanofibers produced by the needleless electrospinning system was lower than that created by the conventional electrospinning system. Addition of The CNT caused to improve the specific stress of the PAN/CNT nanofibers compared with the PAN nanofibers. However, excessive amounts of CNT had a negative effect on the elongation and modulus because of the aggregation of CNT inside the nanofibers. The X-ray diffraction analysis was used to study the crystalline behavior of the PAN nanofibers produced via the needleless electrospinning system. The results showed that the PAN nanofibers had amorphous structure compared with the conventional PAN nanofibers.

Similar content being viewed by others

References

X. Wang and T. Lin, “Needleless Electrospinning of Nanofibers: Technology and Applications”, 1st ed., pp.1–17, CRC Press, Taylor & Francis Group, New York, 2013.

P. Supaphol, C. Mituppatham, and M. Nithitanakul, Macromol. Mater. Eng., 290, 933 (2005).

S. Alborzi, L. T. Lim, and Y. Kakuda, J. Food Sci., 75, C100 (2010).

L. M. Bellan, G. W. Coates, and H. G. Craighead, Macromol. Rapid Commun., 27, 511 (2006).

I. Keun Kwon, S. Kidoaki, and T. Matsuda, Biomaterials, 26, 3929 (2005).

S. R. Givens, K. H. Gardner, J. F. Rabolt, and D. B. Chase, Macromolecules, 40, 608 (2007).

H. Niu and T. Lin, J. Nanomater., 2012, 725950 (2012).

N. Amiraliyan, M. Nouri, and M. H. Kish, J. Appl. Polym. Sci., 113, 226 (2009).

N. Sasithorn and L. Martinová, J. Nanomater., 2014, 947315 (2014).

R. M. Nerem and A. Sambanis, Tissue Eng., 1, 3 (1995).

J. J. Stankus, L. Soletti, K. Fujimoto, Y. Hong, D. A. Vorp, and W. R. Wagner, Biomaterials, 28, 2738 (2007).

H. Niu, T. Lin, and X. Wang, J. Appl. Polym. Sci., 114, 3524 (2009).

E. R. Kenawy, J. M. Layman, J. R. Watkins, G. L. Bowlin, J. A. Matthews, D. G. Simpson, and G. E. Wnek, Biomaterials, 24, 907 (2003).

J. A. Matthews, G. E. Wnek, D. G. Simpson, and G. L. Bowlin, Biomacromolecules, 3, 232 (2002).

A. Valipouri, S. A. Hosseini Ravandi, A. Pishevar, and E. I. Pǎrǎu, J. Text. Polym., 3, 20 (2015).

R. Zhu, C. Y. Jiang, X. Z. Liu, B. Liu, A. Kumar, and S. Ramakrishna, Appl. Phys. Lett., 93, 013102 (2008).

S. Chen, P. Hu, A. Greiner, C. Cheng, H. Cheng, F. Chen, and H. Hou, Nanotechnology, 19, 015604 (2007).

Y. Wu, W. Jia, Q. An, Y. Liu, J. Chen, and G. Li, Nanotechnology, 20, 245101 (2009).

D. G. Yu, X. X. Shen, C. Branford-White, K. White, L. M. Zhu, and S. W. A. Bligh, Nanotechnology, 20, 055104 (2009).

S. E. Kim, D. N. Heo, J. B. Lee, J. R. Kim, S. H. Park, S. H. Jeon, and I. K. Kwon, Biomed. Mater., 4, 044106 (2009).

E. Santala, M. Kemell, M. Leskelä, and M. Ritala, Nanotechnology, 20, 035602 (2009).

F. Dabirian, S. H. Ravandi, and A. Pishevar, Fiber. Polym., 14, 1497 (2013).

A. Valipouri, S. A. H. Ravandi, A. Pishevar, and E. I. Pǎrǎu, Int. J. Multiphase Flow, 69, 93 (2015).

T. Ondarcuhu and C. Joachim, Europhys. Lett., 42, 215 (1998).

L. Feng, S. Li, H. Li, J. Zhai, Y. Song, L. Jiang, and D. Zhu, Angew. Chem., Int. Ed., 41, 1221 (2002).

C. R. Martin, Chem. Mater., 8, 1739 (1996).

G. J. Liu, J. F. Ding, L. J. Qiao, A. Guo, B. P. Dymov, J. T. Gleeson, T. Hashimoto, and K. Saijo, Chem. Eur. J., 5, 2740 (1999).

C. Huang, H. Niu, J. Wu, Q. Ke, X. Mo, and T. Lin, J. Nanomater., 2012, 473872 (2012).

D. Li and Y. Xia, Adv. Mater., 16, 1151 (2004).

M. D. Pierschbacher and E. Ruoslahti, Nature, 309, 30 (1984).

A. Karthick Selvam and G. Nallathambi, Fiber. Polym., 16, 1327 (2015).

R. Purwar, K. S. Goutham, and C. M. Srivastava, Fiber. Polym., 17, 1206 (2016).

H. Ebrahimnezhad-Khaljiri and R. Eslami-Farsani, Fiber. Polym., 16, 2445 (2015).

H. Ebrahimnezhad-Khaljiri, R. Eslami-Farsani, and K. Abbas Banaie, Fiber Polym., 18, 296 (2017).

A. L. Yarin and E. Zussman, Polymer, 45, 2977 (2004).

O. Jirsak, F. Sanetrnik, D. Lukas, V. Kotek, L. Martinova, and J. Chaloupek, U. S. Patent, 7585437 (2005).

Y. Liu and J. H. He, Int. J. Nonlinear Sci. Numer. Simul., 8, 393 (2007).

X. Wang, H. Niu, X. Wang, and T. Lin, J. Nanomater., 2012, 548389 (2012).

X. Wang, H. Niu, T. Lin, and X. Wang, Polym. Eng. Sci., 49, 1582 (2009).

N. M. Thoppey, J. R. Bochinski, L. I. Clarke, and R. E. Gorga, Polymer, 51, 4928 (2010).

S. Tang, Y. Zeng, and X. Wang, Polym. Eng. Sci., 50, 2252 (2010).

B. Lu, Y. Wang, Y. Liu H. Duan, J. Zhou, Z. Zhang, Y. Wang, X. Li, W. Wang, W. Lan, and E. Xie, Small, 6, 1612 (2010).

D. Wu, X. Huang, X. Lai, D. Sun, and L. Lin, J. Nanosci. Nanotechnol., 10, 4221 (2010).

N. M. Thoppey, J. R. Bochinski, L. I. Clarke, and R. E. Gorga, Nanotechnology, 22, 345301 (2011).

F. K. Zafarulla Khan, H. Z. Shafi, F. Nufaiei, S. A. Furquan, and A. Matin, Int. J. Adv. Eng. Nano Technol., 2, 2347 (2015).

P. Heikkilä and A. Harlin, Express Polym. Lett., 3, 437 (2009).

L. Huang, J. T. Arena, S. S. Manickam, X. Jiang, B. G. Willis, and J. R. McCutcheon, J. Membr. Sci., 460, 241 (2014).

S. A. Hosseini, N. Pan, and F. Ko, Text. Res. J., 87, 2193 (2016).

D. G. Yu, N. P. Chatterton, J. H. Yang, X. Wang, and Y. Z. Liao, Macromol. Mater. Eng., 297, 395 (2011).

R. Eslami Farsani, S. Raissi, A. Shokuhfar, and A. Sedghi, World Acad. Sci. Eng. Technol., 50, 430 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi, Z., Ravandi, S.A.H., Haghighat, F. et al. Enhancement of the Mechanical Properties of PAN Nanofiber/Carbon Nanotube Composite Mats Produced via Needleless Electrospinning System. Fibers Polym 21, 1200–1211 (2020). https://doi.org/10.1007/s12221-020-9726-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9726-x