Abstract

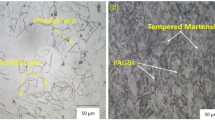

To explore the influence of wire feed rate (WFR) to speed ratio on arc stability, interfacial microstructure and mechanical properties, cold metal transfer (CMT) weld-brazed lap joints of aluminium alloy (AA5052) to dual-phase (DP780) steel were formed at a constant optimized heat input of 80 J/mm. Cyclic representation of recorded voltage and current showed that joining process was comparatively less stable at high WFR to speed combinations. At high WFR and higher speed combinations, greater spatial variations in intermetallic compound (IMC) layer thickness due to spilling of τ5-Fe2Al7.4Si phase and higher porosity in the bead reduced the resistance to failure of the joints especially in the case of AlSi12 filler. Addition of Si successfully increased the wettability of the joints and also reduced the average thickness of the IMC layer at the interface. Formation of hard and brittle orthorhombic η-Fe2Al5 and monoclinic θ-FeAl3 compounds was observed for pure Al filler whereas less brittle ternary Fe-Al-Si intermetallic phases formed with Si-enriched fillers. Three modes of failure, in the Al heat-affected zone (HAZ) (due to softening), bead (due to porosity) and interface (due to poor wettability/increased brittleness), were observed during shear tensile testing. The joints formed using AlSi5 filler at lower joining speed and low WFR combinations, i.e. high WFR/speed ratio, showed higher and consistent mechanical properties.

Similar content being viewed by others

References

Wang PF, Chen XZ, Pan QH, Madigan B, Long JQ (2016) Laser welding dissimilar materials of aluminum to steel: an overview. Int J Adv Manuf Technol 87(9-12):3081–3090. https://doi.org/10.1007/s00170-016-8725-y

Qin GL, Su YH, Meng XM, Fu BL (2015) Numerical simulation on MIG arc brazing-fusion welding of aluminum alloy to galvanized steel plate. Int J Adv Manuf Technol 78:1917–1925. https://doi.org/10.1007/s00170-014-6529-5

Singh J, Arora KS, Shukla DK (2019) Dissimilar MIG-CMT weld-brazing of aluminium to steel: a review. J Alloys Compd 783:753–764. https://doi.org/10.1016/j.jallcom.2018.12.336

Meco S, Pardal G, Ganguly S, Miranda RM, Quintino L, Williams S (2013) Overlap conduction laser welding of aluminium to steel. Int J Adv Manuf Technol 67:647–654. https://doi.org/10.1007/s00170-012-4512-6

Pouranvari M, Abbasi M (2018) Dissimilar gas tungsten arc weld-brazing of Al/steel using Al-Si filler metal: microstructure and strengthening mechanisms. J Alloys Compd 749:121–127. https://doi.org/10.1016/j.jallcom.2018.03.224

Agudo L, Eyidi D, Schmaranzer CH, Arenholz E, Jank N, Bruckner J, Pyzalla AR (2007) Intermetallic FexAly-phases in a steel/Al-alloy fusion weld. J Mater Sci 42(12):4205–4214. https://doi.org/10.1007/s10853-006-0644-0

Yang S, Zhang J, Lian J, Lei Y (2013) Welding of aluminum alloy to zinc coated steel by cold metal transfer. Mater Des 49:602–612. https://doi.org/10.1016/j.matdes.2013.01.045

Basak S, Das H, Pal TK, Shome M (2016) Characterization of intermetallics in aluminum to zinc coated interstitial free steel joining by pulsed MIG brazing for automotive application. Mater Charact 112:229–237. https://doi.org/10.1016/j.matchar.2015.12.030

Jácome LA, Weber S, Leitner A, Arenholz E, Bruckner J, Hackl H, Pyzalla AR (2009) Influence of filler composition on the microstructure and mechanical properties of steel-aluminum joints produced by metal arc joining. Adv Eng Mater 11(5):350–358. https://doi.org/10.1002/adem.200800319

Lin SB, Song JL, Ma GC, Yang CL (2009) Dissimilar metals TIG welding-brazing of aluminium alloy to galvanized steel. Front Mater Sci China 3(1):78–83. https://doi.org/10.1007/s11706-009-0007-2

Potesser M, Schoeberl T, Antrekowitsch H, Bruckner J (2006) The Characterization of the intermetallic Fe-Al layer of steel-aluminum weldings. EPD Congress, 167, Texas, USA: San Antonio.

Williams NT, Parker JD (2004) Review of resistance spot welding of steel sheets. Part 2. Factors influencing electrode life. Int Mater Rev 49(2):77–108. https://doi.org/10.1179/095066004225010541

Yuan R, Deng S, Cui H, Chen Y, Lu F (2019) Interface characterization and mechanical properties of dual beam laser welding-brazing Al/steel dissimilar metals. J Manuf Process 40:37–45. https://doi.org/10.1016/j.jmapro.2019.03.005

Pang J, Hu S, Shen J (2016) Arc characteristics and metal transfer behavior of CMT + P welding process. J Mater Process Technol 238:212–217. https://doi.org/10.1016/j.jmatprotec.2016.07.033

Cao R, Yu G, Chen JH, Wang PC (2013) Cold metal transfer joining aluminum alloys-to-galvanized mild steel. J Mater Process Technol 213(10):1753–1763. https://doi.org/10.1016/j.jmatprotec.2013.04.004

Niu S, Chen S, Dong H, Zhao D, Zhang X, Guo X, Wang G (2016) Microstructure and properties of lap joint between aluminum alloy and galvanized steel by CMT. J Mater Eng Perform 25(5):1839–1847. https://doi.org/10.1007/s11665-016-2035-2

Shi Y, Shao L, Huang J, Gu Y (2013) Effects of Si and Mg elements on the microstructure of aluminum–steel joints produced by pulsed DE-GMA welding–brazing. Mater Sci Technol 29(9):1118–1124. https://doi.org/10.1179/1743284713Y.0000000291

Song JL, Lin SB, Yang CL, Fan CL (2009) Effects of Si additions on intermetallic compound layer of aluminum-steel TIG welding-brazing joint. J Alloys Compd 488(1):217–222. https://doi.org/10.1016/j.jallcom.2009.08.084

Roulin M, Luster JW, Karadeniz G, Mortensen A (1999) Strength and structure of furnace-brazed joints between aluminum and stainless steel. Weld Res 78:151–155

Qin G, Su Y, Wang S (2014) Microstructures and properties of welded joint of aluminum alloy to galvanized steel by Nd:YAG laser + MIG arc hybrid brazing-fusion welding. Trans Nonferrous Metals Soc China 24(4):989–995. https://doi.org/10.1016/S1003-6326(14)63153-8

Milani AM, Paidar M, Khodabandeh A, Nategh S (2016) Influence of filler wire and wire feed speed on metallurgical and mechanical properties of MIG welding-brazing of automotive galvanized steel/5754 aluminum alloy in a lap joint configuration. Int J Adv Manuf Technol 82:1495–1506. https://doi.org/10.1007/s00170-015-7505-4

Pépe N, Egerland S, Colegrove PA, Yapp D, Leonhartsberger A, Scotti A (2011) Measuring the process efficiency of controlled gas metal arc welding processes. Sci Technol Weld Join 16:412–417. https://doi.org/10.1179/1362171810Y.0000000029

Lin QL, Mao GJ, Huang Q, Cao R, Chen JH (2016) Effect of Zn vaporization on wetting of Al-galvanized steel in cold metal transfer process. J Iron Steel Res Int 23(6):566–572. https://doi.org/10.1016/S1006-706X(16)30089-9

Feng JC, He P, Hackl H (2007) Distribution of Zn and interfacial microstructure of Braze-welding CMT joints between aluminium and galvanized steel sheets. Solid State Phenom 127:43–48. https://doi.org/10.4028/www.scientific.net/SSP.127.43

Lemmens B, Springer H, Duarte MJ, Graeve ID, Strycker JD, Raabe D, Verbeken K (2016) Atom probe tomography of intermetallic phases and interfaces formed in dissimilar joining between Al alloys and steel. Mater Charact 120:268–272. https://doi.org/10.1016/j.matchar.2016.09.008

Zhang HT, Feng JC, Heb P, Zhang BB, Chen JM, Wang L (2009) The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater Sci Eng A 499:111–113. https://doi.org/10.1016/j.msea.2007.11.124

Qin GL, Yang J, Ma H, Ao Z (2017) Effect of modified flux on MIG arc brazing fusion welding of aluminum alloy to steel butt joint. J Mater Process Technol 245:115–121. https://doi.org/10.1016/j.jmatprotec.2017.02.022

Yang J, Li YL, Zhang H, Guo W, David W, Zhou N (2015) Dissimilar laser welding/brazing of 5754 aluminum alloy to DP980 steel: mechanical properties and interfacial microstructure. Metal Mater Trans A 46(11):5149–5157. https://doi.org/10.1007/s11661-015-3079-x

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, J., Arora, K.S., Shajan, N. et al. Influence of wire feed rate to speed ratio on arc stability and characteristics of cold metal transfer weld–brazed dissimilar joints. Int J Adv Manuf Technol 108, 3491–3505 (2020). https://doi.org/10.1007/s00170-020-05637-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05637-8