Abstract

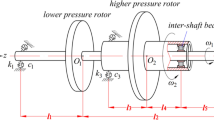

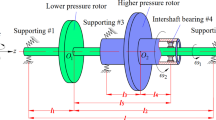

This paper proposes a new theoretical method to investigate the thermal behaviors of the inter-shaft bearing considering the nonlinear dynamic characteristics of a dual-rotor system by combining heat transfer and nonlinear dynamics. The nonlinearities of the inter-shaft bearing, including the Hertzian contact and the radial clearance, are considered during the dynamic modeling for the system. The dynamic load of the inter-shaft bearing is defined according to the nonlinear dynamic responses of the system. Therefore, some fundamental nonlinear phenomena, i.e., jump and bi-stable phenomena happen to the dynamic load. It makes the dynamic load more appropriate to describe the actual load of the inter-shaft bearing than the static load. Furthermore, a steady-state heat transfer model for the inter-shaft bearing subjected to the dynamic load can be set up with the help of Palmgren’s empirical formula. The variation of temperatures with the rotation speed is obtained by using the Gauss–Seidel iteration. Temperatures of the inter-shaft bearing also show nonlinear thermal behaviors, i.e., jump and bi-stable phenomena. It implies the nonlinear dynamic behaviors of the system have a great impact on the thermal behaviors of the inter-shaft bearing. Moreover, an exhaustive parametric analysis for temperatures and nonlinear thermal behaviors of the inter-shaft bearing affected by dynamic parameters (including the rotation speed ratio, unbalances of rotors, the radial clearance, the stiffness and the roller number of the inter-shaft bearing) and thermal parameters (including the lubricant viscosity and the ambient temperature) is carried out. The results show that the rotation speed ratio has a significant influence on both temperatures and nonlinear thermal behaviors, other dynamic parameters mainly affect nonlinear thermal behaviors, while thermal parameters only affect temperatures. This unique discovery indicates the thermal behaviors of the inter-shaft bearing could be much more complex because of the nonlinear dynamic characteristics of the dual-rotor system. The obtained results will contribute to a better understanding of the nonlinear thermal behaviors of bearings and profoundly reveal the mechanism of the nonlinear thermal behaviors of bearings.

Similar content being viewed by others

Abbreviations

- M :

-

Total friction torque

- M l :

-

Friction torque due to the load

- M ν :

-

Friction torque due to the viscosity

- Q :

-

Total FH

- Q l :

-

Load FH

- Q ν :

-

Viscosity FH

- Q r :

-

FH distributed to rollers

- Q i :

-

FH distributed to inner race

- Q o :

-

FH distributed to outer race

- f l :

-

A coefficient depends on the type of roller bearing

- f ν :

-

A coefficient depends on the type of roller bearing and the type of lubrication

- r LP :

-

Inner radius of LP rotor

- d :

-

Nominal bore

- r i :

-

Radius of inner race

- D m :

-

Pitch diameter

- r o :

-

Radius of outer race

- D :

-

Nominal outside diameter

- r HP :

-

Outside radius of HP outer

- d r :

-

Roller diameter

- a r :

-

Roller length

- K b :

-

Stiffness of the inter-shaft bearing

- B :

-

Width of the inter-shaft bearing

- A :

-

Area

- ∑ ρ i :

-

Curvature sum of rollers-inner race contact pair

- ∑ ρ o :

-

Curvature sum of rollers-outer race contact pair

- e 1 :

-

LP rotor’s unbalance

- h :

-

Convective heat transfer coefficient

- ε m :

-

Aspect ratio

- V :

-

Line speed

- k steel :

-

Thermal conductivity of steel

- ν :

-

Kinematic viscosity of the lubricant

- α :

-

Thermal diffusivity

- α steel :

-

Thermal diffusivity of steel

- Adown :

-

“Jump point”

- Bdown :

-

“Jump point”

- \( \omega_{{{\text{A}}_{\text{down}} }} \) :

-

“Frequency of jump point”

- \( \omega_{{{\text{B}}_{\text{down}} }} \) :

-

“Frequency of jump point”

- \( \Delta T_{{{\text{A}}_{\text{down}} }} \) :

-

“Jump amplitude”

- \( \Delta T_{{{\text{B}}_{\text{down}} }} \) :

-

“Jump amplitude”

- \( \Delta \omega_{\text{A}} \) :

-

“Bi-stable interval”

- T :

-

Common temperature

- T L :

-

Temperature of lubricant

- T r :

-

Temperature of rollers

- T i :

-

Temperature of inner race

- T o :

-

Temperature of outer race

- T LP :

-

Temperature of the portion of LP rotor contact inner race

- T HP :

-

Temperature of the portion of HP rotor contact outer race

- T ∞ :

-

Ambient temperature

- R ri :

-

Thermal resistance of rollers-inner race

- R ro :

-

Thermal resistance of rollers-outer race

- R Lr :

-

Thermal resistance of lubricant rollers

- R Li :

-

Thermal resistance of lubricant-inner race

- R Lo :

-

Thermal resistance of lubricant-outer race

- R i :

-

Thermal resistance of inner race-LP rotor

- R o :

-

Thermal resistance of outer race-HP rotor

- R LP :

-

Thermal resistance of LP rotor-ambient

- R HP :

-

Thermal resistance of HP rotor-ambient

- F b :

-

Dynamic load of the inter-shaft bearing

- F n :

-

Normal force between roller and races

- 2δ0 :

-

Radial clearance of the inter-shaft bearing

- N b :

-

Roller number of the inter-shaft bearing

- n b :

-

Stressed roller number

- ω 1 :

-

Rotation speed of LP rotor

- ω 2 :

-

Rotation speed of HP rotor

- λ :

-

Rotation speed ratio

- e 2 :

-

HP rotor’s unbalance

- Nu:

-

Nusselt number

- Re:

-

Reynolds number

- Pr:

-

Prandtl number

- Ta:

-

Taylor number

- Bi:

-

Biot number

- Pe:

-

Peclet number

- Pe* :

-

Modified Peclet number

- Aup :

-

“Jump point”

- Bup :

-

“Jump point”

- \( \omega_{{{\text{A}}_{\text{up}} }} \) :

-

“Frequency of jump point”

- \( \omega_{{{\text{B}}_{\text{up}} }} \) :

-

“Frequency of jump point”

- \( \Delta T_{{{\text{A}}_{\text{up}} }} \) :

-

“Jump amplitude”

- \( \Delta T_{{{\text{B}}_{\text{up}} }} \) :

-

“Jump amplitude”

- \( \Delta \omega_{\text{B}} \) :

-

“Bi-stable interval”

References

Li, Q.H., Hamilton, J.F.: Investigation of the transient response of a dual-rotor system with intershaft squeeze-film damper. J. Eng. Gas Turb. Power 108, 613–618 (1985)

Holmes, R., Dede, M.M.: Non-linear phenomena in aero-engine rotor vibration. Arch. Proc. Inst. Mech. Eng. Part A J. Power Eng. 203(11), 25–34 (1989)

Yamamoto, T.: On critical speeds of a shaft supported by a ball bearing. Trans. JSME 21, 182–192 (1955)

Fukata, S., Gad, E.H., Kondou, T., Ayabe, T., Tamura, H.: On the radial vibrations of ball bearings (computer simulation). Bull. JSME 28(239), 899–904 (1985)

Mevel, B., Guyader, J.L.: Routes to chaos in ball bearings. J. Sound Vib. 162(3), 471–487 (1993)

Tiwari, M., Gupta, K., Prakash, O.: Effect of radial internal clearance of a ball bearing on the dynamics of a balanced horizontal rotor. J. Sound Vib. 238(5), 723–756 (2000)

Tiwari, M., Gupta, K., Prakash, O.: Dynamic response of an unbalanced rotor supported on ball bearings. J. Sound Vib. 238(5), 757–779 (2000)

Ghafari, S.H., Abdel-Rahman, E.M., Golnaraghi, F., Ismail, F.: Vibrations of balanced fault-free ball bearings. J. Sound Vib. 329(9), 1332–1347 (2010)

Bai, C.Q., Zhang, H.Y., Xu, Q.Y.: Subharmonic resonance of a symmetric ball bearing-rotor system. Int. J. Non-Linear Mech. 50, 1–10 (2013)

Zhang, Z.Y., Chen, Y.S., Cao, Q.J.: Bifurcations and hysteresis of varying compliance vibrations in the primary parametric resonance for a ball bearing. J. Sound Vib. 350, 171–184 (2015)

Zhang, Z.Y., Chen, Y.S., Li, Z.G.: Influencing factors of the dynamic hysteresis in varying compliance vibrations of a ball bearing. Sci. China Technol. Sci. 58(5), 775–782 (2015)

Palmgren, A., Ruley, B.: Ball and Roller Bearing Engineering. SKF Industries, inc., Philadelphia (1945)

T.A. Harris, M.N. Kotzalas. Essential Concepts of Bearing Technology. Taylor & Francis, London, 2006, pp. 133–135

Winer, W.O., Bair, S., Gecim, B.: Thermal resistance of a tapered roller bearing. Tribol. Trans. 29(4), 539–547 (1986)

DeMul, J.M., Vree, J.M., Maas, D.A.: Equilibrium and associated load distribution in ball and roller bearings loaded in five degrees of freedom while neglecting friction—art I: general theory and application to ball bearings. J. Tribol. (1989). https://doi.org/10.1115/1.3261864

DeMul, J.M., Vree, J.M., Maas, D.A.: Equilibrium and associated load distribution in ball and roller bearings loaded in five degrees of freedom while neglecting friction—part II: application to roller bearings and experimental verification. J. Tribol. (1989). https://doi.org/10.1115/1.3261865

Jorgensen, B.R., Shin, Y.C.: Dynamics of machine tool spindle/bearing systems under thermal growth. J. Tribol. 119(4), 875–882 (1997)

Stein, J.L., Tu, J.F.: A state-space model for monitoring thermally induced preload in anti-friction spindle bearings of high-speed machine tools. J. Dyn. Syst. Meas. Contr. 116(3), 372–386 (1994)

Sun, G., Palazzolo, A., Provenza, A., Lawrence, C., Carney, K.: Long duration blade loss simulations including thermal growths for dual-rotor gas turbine engine. J. Sound Vib. 316, 147–163 (2008)

Takabi, J., Khonsari, M.M.: Experimental testing and thermal analysis of ball bearings. Tribol. Int. 60, 93–103 (2013)

Ai, S.Y., Wang, W., Wang, Y., Zhao, Z.: Temperature rise of double-row tapered roller bearings analyzed with the thermal network method. Tribol. Int. 87, 11–22 (2015)

Than, V.T., Huang, J.H.: Nonlinear thermal effects on high-speed spindle bearings subjected to preload. Tribol. Int. 96, 361–372 (2016)

Wang, N.F., Liu, C., Jiang, D.X., Behdinan, K.: Casing vibration response prediction of dual-rotor-blade-casing system with blade-casing rubbing. Mech. Syst. Signal Pr. 118, 61–77 (2019)

Lu, Z.Y., Chen, Y.S., Li, H.L., Hou, L.: Reversible model-simplifying method for aero-engine rotor systems. J. Aerosp. Power 31(1), 57–64 (2016)

Sun, C.Z., Chen, Y.S., Hou, L.: Steady-state response characteristics of a dual-rotor system induced by rub-impact. Nonlinear Dyn. 86(1), 91–105 (2016)

Gao, P., Hou, L., Yang, R., Chen, Y.S.: Local defect modelling and nonlinear dynamic analysis for the inter-shaft bearing in a dual-rotor system. Appl. Math. Model. 68, 29–47 (2019)

Gao, P., Hou, L., Chen, Y.S.: Nonlinear vibration characteristics of a dual-rotor system with inter-shaft bearing. J. Vib. Shock 38(15), 1–10 (2019)

Yang, R., Jin, Y.L., Hou, L., Chen, Y.S.: Study for ball bearing outer race characteristic defect frequency based on nonlinear dynamics analysis. Nonlinear Dyn. 90, 781–796 (2017)

Hou, L., Chen, Y.S., Fu, Y.Q., Chen, H.Z., Lu, Z.Y., Liu, Z.S.: Application of the HB-AFT method to the primary resonance analysis of a dual-rotor system. Nonlinear Dyn. 88(4), 2531–2551 (2017)

Holman, J.P.: Heat Transfer, 10th edn, pp. 51–52. McGraw Hill, New York (2010)

Muzychka, Y.S., Yovanovich, M.M.: Thermal resistance models for non-circular moving heat sources on a half space. J. Heat Transf. 123(4), 624–632 (2001)

Fand, R.M.: Heat transfer by forced convection from a cylinder to water in crossflow. J. Heat Mass. Transf. 8(7), 995–1010 (1965)

Gazley, C.: Heat-transfer characteristics of the rotational and axial flow between concentric cylinders. Trans. ASME 108, 79–90 (1958)

Yang, Z.L., Zhuo, X.R., Yang, C., Song, Y.Z.: An experimental research on convective heat transfer on the surface of horizontal cylinder rotating with high speed. Ind. Heat. 5, 17–20 (2002)

Ruhe, A.: Properties of a matrix with a very ill-conditioned eigenproblem. Numer. Math. 15(1), 57–60 (1970)

Hu, Q.H., Deng, S.E., Teng, H.F.: Optimization of rotor-bearing system with nonlinear dynamics considering internal clearance. J. Aerosp. Power 26(9), 2154–2160 (2011)

Acknowledgements

The authors are very grateful for the financial supports from the National Major Science and Technology Projects of China (Grant No. 2017-IV-0008-0045), the National Basic Research Program of China (973 Program) (Grant No. 2015CB057400) and the National Natural Science Foundation of China (Grant Nos. 11972129 and 11602070).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The coefficient matrix A is a symmetric matrix, which is shown as follows:

Rights and permissions

About this article

Cite this article

Gao, P., Chen, Y. & Hou, L. Nonlinear thermal behaviors of the inter-shaft bearing in a dual-rotor system subjected to the dynamic load. Nonlinear Dyn 101, 191–209 (2020). https://doi.org/10.1007/s11071-020-05753-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-020-05753-w