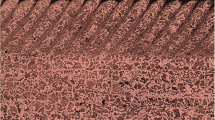

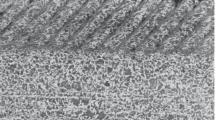

The effect of deforming cutting (DC) on structural and phase transformations in iron and steels 35 and U8 is studied with the help of scanning optical and transmission electron microscopy. It is shown that with an increase in carbon content test material structure and phase composition become more complex.

Similar content being viewed by others

References

Y. Guo and G. Janowski, “Microstructural characterization of white layers by hard turning and grinding,” Trans. NAMRI/SME, XXXII, 367 – 374 (2004).

Y. B. Guoanda and W. Warren, “Microscale mechanical behavior of the subsurface by finishing processes,” ASMEJ. Manuf. Sci. Eng., No. 127, 333 – 338 (2004)

S. Naik, C. Guo, S. Malkin, et al., “Experimental investigation of hard turning,” in: 2nd Int. Mach. & Grinding Conf. Dearborn, MI (1997), pp. 224 – 308.

J. Kundrak, A. Mamalis, K. Gyani, and V. Bana, “Surface layer microhardness changes with high-speed turning of hardened steels,” Int. J. Adv. Manuf. Technol., 53(1), 105 – 112 (2011).

E. Brinksmeier and T. Brockhoff, “Randschicht Wärmebehandlung durch Schleifen,” Härterei-Techn. Mitt., 49(5), 327 – 330 (1994).

G. Hyatt, “Integration of heat treatment into the process Chainofa Mill Turn Center by enabling external cylindrical grind-hardening,” Prod. Eng.-Res. Devel. (WGP Annals), 7(6), 571 – 584 (2013). (DOI: https://doi.org/10.1007/s11740-013-0465-3).

T. Nguyen, M. Liu, L. Zhang, et al., “An investigation of the grinding–hardening induced by traverse cylindrical grinding” ,ASME. Manuf. Sci. Eng., 136(5), 051008–1 – 05100-10 (2014) (DOI: https://doi.org/10.1115/1.4028058).

L. Zhanqiang, X. Ai, and Z. Wang, “Comparison study of surface hardening by grinding versus machining,” Key Engineering Materials, 304 – 305, 156 – 160 (2006).

X. Huang, Y. Ren, W. Wu, and T. Li, “Research on grind-hardening layer and residual stresses based on variable grinding forces,” Int. J. Adv. Manuf. Technol., 103, 1 – 11 (2019) doi: https://doi.org/10.1007/s00170-019-03329-6.

F. Klocke, Manufacturing Processes 1: Cutting, Springer-Verlag, Berlin, Germany (2011) (ISBN 978-3-642-11978-1; DOI https://doi.org/10.1007/978-3-642-11979-8).

N. Zubkov, V. Poptsov, S. Vasiliev, and A. D. Batako, “Steel case hardening using deformational cutting,” J. Manuf. Sci. Eng., Trans. Am. Soc. Mechan. Eng., 140(6), Art. No. 061013 (2018) (DOI: https://doi.org/10.1115/1.4039382).

N. N. Zubkov, S. G. Vasil’ev, and V. V. Poptsov, “RF Patent 2556897 MPK C21D 8_00. Method of surface hardening strengthening with a cutting and deforming tool,” Byull. Izobr. Polezn. Modeli, No. 20 (2015), claim 01.21.2014, publ. 07.22.2015.

N. N. Zubkov, S. G. Vasil’ev, and V. V. Poptsov, “Features of quenching deformation cutting,” Obrab. Met., 20(2), 35 – 49 (2018) (DOI: https://doi.org/10.17212/1994-6309-2018-20.2-35-49).

A. G. Degtyareva, O. M. Zhigalina, D. N. Khmelenin, and V. N. Simonov, “Specifics of steel 35 structure after hardening by deforming cutting,” Kristallografiya, 64(1), 120 – 126 (2019).

Structural studies were partly conducted on equipment of the Federal Scientific and Research Center “Crystallography and Photonics,” Russian Academy of Sciences, with financial support of the Ministry and Science and Higher education within the scope of performing work according to a state assignment FNITs “Crystallography and photonics” Russian Academy of Sciences in the section for performing research by electron microscopy methods.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 65 – 71, February, 2020.

Rights and permissions

About this article

Cite this article

Zhigalina, O.M., Degtyareva, A.G., Zubkov, N.N. et al. Effect of Carbon Content on the Structure and Microhardness of Steels Under Rapid Action by Deforming Cutting. Met Sci Heat Treat 62, 168–173 (2020). https://doi.org/10.1007/s11041-020-00530-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00530-3