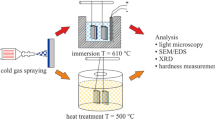

Processes of intermetallic phase formation in functional coatings prepared by cold gas-dynamic spraying of Ni – Al, Ni – Ti – Al, Ti – Al, and Ni – Ti powder mixtures are studied. On heating of the coatings containing Al, the main phase transformations proceed in the range of 450 – 750°C, and phase formation processes in the coatings based on the Ni – Al and Ni – Ti – Al systems develop in a similar manner. Transformations do not develop in Ni – Ti coatings in the temperature range studied. Phase transformations in the coatings are identified.

Similar content being viewed by others

References

S. C. Deevi and V. K. Sikka, “Nickel and iron aluminides: an overview on properties, processing, and applications,” Intermetallics, 5(4), 357–364 (2008).

M. I. Kolesnikov, Catalysis and Catalyst Production [in Russian], Tekhnika, Moscow (2004)

I. P. Muklenov, E. I. Dobkina, V. I. Deryuzhkina, and V. E. Soroko, Catalyst Technology [in Russian], Khimiya, Moscow (1989).

P. I. Begun, Flexible Elements and Medical Systems [in Russian], Politekhnika, St. Petersburg (2002).

K. Warden, New Intermetallic Materials and Structures. Properties and Applications [Russian translation], Tekhnosfera, Moscow (2006).

B. P. Sereda, K. V. Belokon’, G. B. Kozhemyakin, and Yu. A. Belokon’, “Study of the effect of modifying Ni – Al alloys and their catalytic properties,” Vestn. KhNADu, 52, 110 – 116 (2011).

A. S. Oryshchenko and D. A. Gerashchenkov, “Aluminum matrix functional coatings with high microhardness on the basis of Al – Sn + Al2O3 composite powders fabricated by cold gas dynamic spraying,” Inorg. Mater.: Appl. Res., 7(6), 863 – 867 (2016).

D. A. Gerashchenkov, B. V. Farmakovskii, A. F. Vasil’ev, and A. Ch. Mashek, “Study of flow temperature during cold gas-dynamic spraying of functional coatings,” Vopr. Materialoved., No. 1(77), 87 – 96 (2014).

R. E. Shalin, I. L. Svetlov, E. B. Kachanov, et al., Nickel Heat-Resistant Alloy Single Crystals [in Russian], Mashinostroenie, Moscow (12997).

Yu. P. Tarasenko, I. N. Tsareva, O. K. Levanov, et al., “Possibility of preparing a protective coating of intermetallic composition by powder gas-dynamic spraying,” Vopr. Materialoved., No. 3(83), 91 – 99 (2015).

Acknowledgement

Experimental research was conducted on equipment of the Center for Collective Usage of Scientific Equipment “Composition, structure, and properties of structural and functional materials” NITs Kurchatov Institute – TsNII KM Prometei with state financial support in the name of the Ministry of Education and Science within the framework of an agreement No. 14.595.21.0004, unique identifier RFMEF159517X0004.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 89 – 93, January, 2020.

Rights and permissions

About this article

Cite this article

Gerashchenkov, D.A., Askinazi, A.Y., Fedoseev, M.L. et al. Formation of Intermetallic Phases in Functional Coatings Prepared by Cold Gas-Dynamic Spraying. Met Sci Heat Treat 62, 90–94 (2020). https://doi.org/10.1007/s11041-020-00518-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00518-z