Abstract

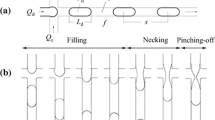

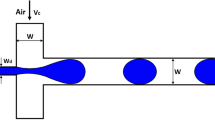

Droplet formation in a flow-focusing device was modeled using the open source CFD package, OpenFOAM, with the VOF model for two-phase flow. Predictions using the interFoam solver and a power-law non-Newtonian model were first validated against experimental data in the literature. Then, the formation of Newtonian fluid droplets in power-law fluids was modeled during tubing, squeezing, dripping and jetting. The effects of the continuous phase rheological parameters on the droplet formation were investigated by changing the power law index (n) and the consistency coefficient (K). The results show that the droplet length and the spacing between two droplets decrease as n or K increase. However, the formation frequency and droplet velocity in the main channel increase as n or K increase. The results also show that n has a greater effect than K on the droplet formation. A method was developed to calculate the capillary number of the power-law continuous phase in the squeezing and dripping regimes including the influences of n and K. For a given dispersed phase flow rate, the formation frequency is inversely proportional to the droplet volume. A scaling law was also developed to predict the formation frequency since the droplet volume is found to vary linearly with the non-dimensional droplet length. The present work is useful for controlling droplet formation and designing microfluidic devices in areas where non-Newtonian fluids are used as the continuous phase.

Similar content being viewed by others

Abbreviations

- a, a’, b, b’, ε, ε’, ω, ω’ :

-

fitting parameters

- C α :

-

compression factor

- d :

-

spacing between two droplets, μm

- d h :

-

channel hydraulic diameter, μm

- f :

-

droplet formation frequency, Hz

- f σ :

-

surface tension, N∙m−3

- g :

-

gravitational acceleration, m∙s−2

- K :

-

consistency coefficient of power-law fluids, Pa∙sn

- L :

-

droplet length, μm

- Lblock, Lsqueeze :

-

droplet length increase, μm

- L d :

-

characteristic length, μm

- L e :

-

channel flow development length, μm

- M w :

-

unit tangential vector

- n :

-

power-law index of power-law fluids

- N :

-

normal vector

- N w :

-

unit normal vector

- p :

-

pressure, Pa

- Q c :

-

continuous flow rate, μL/h

- Q d :

-

dispersed flow rate, μL/h

- r :

-

final droplet radius, μm

- S :

-

cross sectional area, μm2

- t :

-

time, s

- u :

-

velocity vector, m∙s−1

- u c :

-

average velocity of the continuous phase, m∙s−1

- u r :

-

interface-compression velocity, m∙s−1

- v :

-

droplet velocity, m∙s−1

- V :

-

droplet volume, m3

- W c :

-

channel width, μm

- α :

-

volume fraction

- γ :

-

rate-of-strain tensor, s−1

- μ :

-

volume-averaged viscosity, Pa∙s

- ρ :

-

volume-averaged density, kg∙m−3

- κ :

-

interfacial curvature

- σ :

-

surface tension coefficient, N∙m−1

- θ w :

-

contact angle, °

- ∆ρ :

-

density difference, kg∙m−3

- ∆t :

-

time step, s

- ∆x :

-

mesh spacing, μm

- *:

-

dimensionless parameter

- c:

-

continuous phase

- d:

-

dispersed phase

References

Sahin S, Bliznyuk O, Rovalino CA, Schroën K (2016) Microfluidic EDGE emulsification: the importance of interface interactions on droplet formation and pressure stability. Sci Rep 6:2–8. https://doi.org/10.1038/srep26407

Millman JR, Bhatt KH, Prevo BG, Velev OD (2005) Anisotropic particle synthesis in dielectrophoretically controlled microdroplet reactors. Nat Mater 4:98–102. https://doi.org/10.1038/nmat1270

Ahmadi F, Samlali K, Vo PQN, Shih SCC (2019) An integrated droplet-digital microfluidic system for on-demand droplet creation, mixing, incubation, and sorting. Lab Chip 19:524–535. https://doi.org/10.1039/C8LC01170B

Chou WL, Lee PY, Yang CL, Huang WY, Lin YS (2015) Recent advances in applications of droplet microfluidics. Micromachines 6:1249–1271. https://doi.org/10.3390/mi6091249

Tewhey R, Warner JB, Nakano M, Libby B, Medkova M, David PH, Kotsopoulos S, Samuels M, Hutchison JB, Larson JW, Topol EJ, Weiner MP, Harismendy O, Olson J, Link DR, Frazer KA (2009) Microdroplet-based PCR enrichment for large-scale targeted sequencing. Nat Biotechnol 27:1025–1031. https://doi.org/10.1038/nbt.1583

Zhu P, Wang L (2017) Passive and active droplet generation with microfluidics: a review. Lab Chip 17:34–75. https://doi.org/10.1039/C6LC01018K

Zhao Y, Chen G, Yuan Q (2006) Liquid-liquid two-phase flow patterns in a rectangular microchannel. AICHE J 52:4052–4060. https://doi.org/10.1002/aic.11029

Lashkaripour A, Rodriguez C, Ortiz L, Densmore D (2019) Performance tuning of microfluidic flow-focusing droplet generators. Lab Chip 19:1041–1053. https://doi.org/10.1039/C8LC01253A

Garstecki P, Stone HA, Whitesides GM (2005) Mechanism for flow-rate controlled breakup in confined geometries: A route to monodisperse emulsions. Phys Rev Lett 2005;94:164501–1–164501-4. https://doi.org/10.1103/PhysRevLett.94.164501

Gao W, Liu M, Chen S, Zhang C, Zhao Y (2019) Droplet microfluidics with gravity-driven overflow system. Chem Eng J 362:169–175. https://doi.org/10.1016/j.cej.2019.01.026

Huang H, He X (2015) Fluid displacement during droplet formation at microfluidic flow-focusing junctions. Lab Chip 15:4197–4205. https://doi.org/10.1039/c5lc00730e

Thorsen T, Roberts RW, Arnold FH, Quake SR (2001) Dynamic pattern formation in a vesicle-generating microfluidic device. Phys Rev Lett 86:4163–4166. https://doi.org/10.1103/PhysRevLett.86.4163

Wu Z, Cao Z, Sundén B (2017) Liquid-liquid flow patterns and slug hydrodynamics in square microchannels of cross-shaped junctions. Chem Eng Sci 174:56–66. https://doi.org/10.1016/j.ces.2017.08.032

Fu T, Wu Y, Ma Y, Li HZ (2012) Droplet formation and breakup dynamics in microfluidic flow-focusing devices: from dripping to jetting. Chem Eng Sci 84:207–217. https://doi.org/10.1016/j.ces.2012.08.039

Steegmans ML, Schroën CGP, Boom RM (2009) Generalised insights in droplet formation at T-junctions through statistical analysis. Chem Eng Sci 64:3042–3050. https://doi.org/10.1016/j.ces.2009.03.010

Steijn VV, Kleijn CR, Kreutzer MT (2010) Predictive model for the size of bubbles and droplets created in microfluidic T-junctions. Lab Chip 10:2513–2518. https://doi.org/10.1039/c002625e

Yagodnitsyna AA, Kovalev AV, Bilsky AV (2016) Flow patterns of immiscible liquid-liquid flow in a rectangular microchannel with T-junction. Chem Eng J 303:547–554. https://doi.org/10.1016/j.cej.2016.06.023

Xu JH, Luo GS, Li SW, Chen GG (2006) Shear force induced monodisperse droplet formation in a microfluidic device by controlling wetting properties. Lab Chip 6:131–136. https://doi.org/10.1039/b509939k

Xu JH, Li SW, Tan J, Wang YJ, Luo GS (2006) Preparation of highly monodisperse droplet in a T-junction microfluidic device. AICHE J 52:3005–3010. https://doi.org/10.1002/aic.10924

Nekouei M, Vanapalli SA (2017) Volume-of-fluid simulations in microfluidic T-junction devices: influence of viscosity ratio on droplet size. Phys fluids 29:032007-1-032007-10. https://doi.org/10.1063/1.4978801

Lee W, Walker LM, Anna SL (2009) Role of geometry and fluid properties in droplet and thread formation processes in planar flow focusing. Phys Fluids 21: 032103–1–032103-14. https://doi.org/10.1063/1.3081407

Anna SL, Bontoux N, Stone HA (2003) Formation of dispersions using “flow focusing” in microchannels. Appl Phys Lett 82:364–366. https://doi.org/10.1063/1.1537519

Zhao CX, Middelberg APJ (2011) Two-phase microfluidic flows. Chem Eng Sci 66:1394–1411. https://doi.org/10.1016/j.ces.2010.08.038

Roumpea E, Kovalchuk NM, Chinaud M, Nowak E, Simmons MJH, Angeli P (2019) Experimental studies on droplet formation in a flow-focusing microchannel in the presence of surfactants. Chem Eng Sci 195:507–518. https://doi.org/10.1016/j.ces.2018.09.049

Liu H, Zhang Y (2011) Droplet formation in microfluidic cross-junctions. Phys fluids 23:082101-1-082101-12. 10.1063/1.3615643

Gupta A, Matharoo HS, Makkar D, Kumar R (2014) Droplet formation via squeezing mechanism in a microfluidic flow-focusing device. Comput Fluids 100:218–226. https://doi.org/10.1016/j.compfluid.2014.05.023

Qiu D, Silva L, Tonkovich AL, Arora R (2010) Micro-droplet formation in non-Newtonian fluid in a microchannel. Microfluid Nanofluidics 8:531–548. https://doi.org/10.1007/s10404-009-0487-5

Fu T, Ma Y, Funfschilling D, Zhu C, Li HZ (2012) Breakup dynamics of slender bubbles in non-Newtonian fluids in microfluidic flow-focusing devices. AICHE J 58:3560–3567. https://doi.org/10.1002/aic.13723

Sontti SG, Atta A (2017) CFD analysis of microfluidic droplet formation in non–Newtonian liquid. Chem Eng J 330:245–261. https://doi.org/10.1016/j.cej.2017.07.097

Shi Y, Tang GH (2015) Lattice boltzmann simulation of droplet formation in non-Newtonian fluids. Commun Comput Phys 17:1056–1072. https://doi.org/10.4208/cicp.2014.m333

Rostami B, Morini GL (2019) Experimental characterization of a micro cross-junction as generator of Newtonian and non-Newtonian droplets in silicone oil flow at low capillary numbers. Exp Thermal Fluid Sci 103:191–200. https://doi.org/10.1016/j.expthermflusci.2019.01.008

Shah RK, London AL (1978) Laminar flow forced convection in ducts. Academic, New York

Mastiani M, Mosavati B, Kim M (2017) Numerical simulation of high inertial liquid-in-gas droplet in a T-junction microchannel. RSC Adv 7:48512–48525. https://doi.org/10.1039/c7ra09710g

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100:335–354. https://doi.org/10.1016/0021-9991(92)90240-y

Hoang DA, Steijn VV, Portela LM, Kreutzer MT, Kleijn CR (2013) Benchmark numerical simulations of segmented two-phase flows in microchannels using the volume of fluid method. Comput Fluids 86:28–36. https://doi.org/10.1016/j.compfluid.2013.06.024

Weller HG (2008) A new approach to VOF-based interface capturing methods for incompressible and compressible flow. Caversham, the United Kingdom

Mora AEM, De LESALF, De LESSMM (2019) Numerical study of the dynamics of a droplet in a T-junction microchannel using OpenFOAM. Chem Eng Sci 196:514–526. https://doi.org/10.1016/j.ces.2018.11.020

Greenshields CJ (2017) OpenFOAM User Guide Version 6. OpenFOAM Found Ltd. https://cfd.direct/openfoam/user-guide/. Accessed 12 February 2020

Fu T, Ma Y, Li HZ (2016) Breakup dynamics for droplet formation in shear-thinning fluids in a flow-focusing device. Chem Eng Sci 144:75–86. https://doi.org/10.1016/j.ces.2015.12.031

Fu T, Carrier O, Funfschilling D, Ma Y, Li HZ (2016) Newtonian and non-Newtonian flows in microchannels: inline rheological characterization. Chem Eng Technol 39:987–992. https://doi.org/10.1002/ceat.201500620

Liu C, Zhang Q, Zhu C, Fu T, Ma Y, Li HZ (2018) Formation of droplet and “string of sausages” for water-ionic liquid ([BMIM][PF6]) two-phase flow in a flow-focusing device. Chem Eng Process Process Intensif 125:8–17. https://doi.org/10.1016/j.cep.2017.12.017

Liu C, Zhu C, Fu T, Ma Y, Li HZ (2018) Interfacial dynamics of the core-annular flow for glycerol-water solution/ionic liquid ([BMIM][PF6]) two-phase flow in a microfluidic flow-focusing junction. J Taiwan Inst Chem Eng 98:45–52. https://doi.org/10.1016/j.jtice.2018.04.033

Du W, Fu T, Zhu C, Ma Y, Li HZ (2016) Breakup dynamics for high-viscosity droplet formation in a flow-focusing device: symmetrical and asymmetrical ruptures. AICHE J 62:325–337. https://doi.org/10.1002/aic.15043

Wu Z, Cao Z, Sunden B (2019) Flow patterns and slug scaling of liquid-liquid flow in square microchannels. Int J Multiph Flow 112:27–39. https://doi.org/10.1016/j.ijmultiphaseflow.2018.12.009

Xu JH, Li SW, Tan J, Luo GS (2008) Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping. Microfluid Nanofluidics 5:711–717. https://doi.org/10.1007/s10404-008-0306-4

Garstecki P, Fuerstman MJ, Stone HA, Whitesides GM (2006) Formation of droplets and bubbles in a microfluidic T-junction - scaling and mechanism of break-up. Lab Chip 6:437–446. https://doi.org/10.1039/B510841A

Tan J, Xu JH, Li SW, Luo GS (2008) Drop dispenser in a cross-junction microfluidic device: scaling and mechanism of break-up. Chem Eng J 136:306–311. https://doi.org/10.1016/j.cej.2007.04.011

Tan J, Li SW, Wang K, Luo GS (2009) Gas-liquid flow in T-junction microfluidic devices with a new perpendicular rupturing flow route. Chem Eng J 146:428–433. https://doi.org/10.1016/j.cej.2008.10.024

Cao Z, Wu Z, Sundén B (2018) Dimensionless analysis on liquid-liquid flow patterns and scaling law on slug hydrodynamics in cross-junction microchannels. Chem Eng J 344:604–615. https://doi.org/10.1016/j.cej.2018.03.119

Lindner A, Bonn D, Meunier J (2000) Viscous fingering in a shear-thinning fluid. Phys Fluids 12:256–261. https://doi.org/10.1063/1.870303

Funding

This study was funded by the National Natural Science Foundation of China (No. 51706125).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Q., Li, J., Song, Y. et al. Modeling of Newtonian droplet formation in power-law non-Newtonian fluids in a flow-focusing device. Heat Mass Transfer 56, 2711–2723 (2020). https://doi.org/10.1007/s00231-020-02899-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02899-6