Abstract

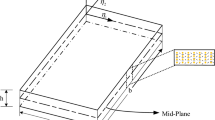

Background: Experimental modelling techniques are still rare for composite structures under complex thermal environments. Objective: In this paper, by taking a fibre-reinforced composite plate (FRCP) as an example, a lumped parameter model of the FRCP with temperature dependence is developed from an experimental perspective. Methods: Initially, a series of thermal vibration measurements are performed under different temperatures to characterize the temperature-dependent vibration behaviours of the FRCP, in which the natural frequencies and modal damping ratios are identified via the variational mode decomposition method. Then, according to the degree of freedom division criterion of the half-wave number, a mass-spring-damper lumped parameter model of this type of composite plate considering additional thermal stiffness is established. Finally, a novel method of determining the lumped stiffness and damping parameters in this model is proposed based on the above experimental data. Results: The developed model is verified by comparing the theoretical natural frequencies, modal shapes and resonant responses with the test results at 40, 120, 220 and 300 °C, for which the calculation errors are within an acceptable range. Conclusions: It has been found that the accuracy of this lumped parameter model can be further improved by applying a larger number of modes to inversely calculate the lumped stiffness and damping parameters. Meanwhile, the efficiency can also be increased by adopting an appropriate step size in the iterative calculation of the additional thermal stiffness.

Similar content being viewed by others

References

Vinson JR, Sierakowski RL (2006) The behavior of structures composed of composite materials[M]. Springer Science & Business Media, Heidelberg

Qin ZY, Yang ZB, Zu J et al (2018) Free vibration analysis of rotating cylindrical shells coupled with moderately thick annular plate. Int J Mech Sci 142–143:127–139

Kulkarni P, Dhoble A, Padole P (2018) A review of research and recent trends in analysis of composite plates[J]. Sadhana Academy Proceedings in Engineering Science. A review of research and recent trends in analysis of composite plates

Li H, Niu Y, Li Z, Xu Z, Han Q (2020) Modeling of amplitude-dependent damping characteristics of fiber reinforced composite thin plate[J]. Appl Math Model 80:394–407

Whitney JM, Ashton JE (1971) Effect of environment on the elastic response of layered composite plates[J]. AIAA J 9(9):1708–1713

Ram KSS, Sinha PK (1992) Hygrothermal effects on the free vibration of laminated composite plates[J]. J Sound Vib 158(1):133–148

Gilat R, Aboudi J (1996) Thermomechanical coupling effects on the dynamic inelastic response and buckling of metal matrix composite infinitely wide plates[J]. Compos Struct 35(1):49–63

Yang J, Shen HS (2002) Vibration characteristics and transient response of shear-deformable functionally graded plates in thermal environments [J]. J Sound Vib 255(3):579–602

Matsunaga H (2007) Free vibration and stability of angle-ply laminated composite and sandwich plates under thermal loading[J]. Compos Struct 77(2):249–262

Vangipuram P, Ganesan N (2007) Buckling and vibration of rectangular composite viscoelastic sandwich plates under thermal loads[J]. Compos Struct 77(4):419–429

Jeyaraj P, Padmanabhan C, Ganesan N (2008) Vibration and acoustic response of an isotropic plate in a thermal environment[J]. J Vib Acoust 130(5):051005

Geng Q, Li Y (2012) Analysis of dynamic and acoustic radiation characters for a flat plate under thermal environments[J]. Int J Appl Mech 4:1250028

Geng Q, Li Y (2014) Solutions of dynamic and acoustic responses of a clamped rectangular plate in thermal environments[J]. Journal of Vibration & Control

Gibson RF (2000) Modal vibration response measurements for characterization of composite materials and structures[J]. Compos Sci Technol 60(15):2769–2780

Melo JDD, Radford DW (2005) Time and temperature dependence of the viscoelastic properties of CFRP by dynamic mechanical analysis[J]. Compos Struct 70(2):240–253

Sefrani Y, Berthelot JM (2006) Temperature effect on the damping properties of unidirectional glass fibre composites[J]. Compos Part B 37(4):346–355

Yang HZ, Li HJ (2008) Experimental modal analysis of the composite laminates with temperature variation[J]. Acta Materiae Compositae Sinica 2(2):149–155

Zhao SG, Wang YW, Wu DF et al (2015) Experimental research on thermal-vibration for composite trilaminated wing structure[J]. Adv Mater Res 1061–1062:799–805

Zhang XL, Xu K, Bai YH et al (2015) Thermal vibration characteristics of fiber-reinforced mullite sandwich structure with ceramic foams core[J]. Compos Struct 131:99–106

Wu D, Wang Y, Shang L, Wang H, Pu Y (2016) Experimental and computational investigations of thermal modal parameters for a plate-structure under 1200 °C high temperature environment[J]. Measurement 94:80–91

Li H, Chang Y, Xu Z et al (2018) Modal shape measurement of fiber-reinforced composite plate with high efficiency and precision based on laser linear scanning method. Measurement and Control[J] 51(9–10):470–487

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition[J]. IEEE Trans Signal Process 62(3):531–544

Shi HT, Bai XT (2020) Model-based uneven loading condition monitoring of full ceramic ball bearings in starved lubrication[J]. Mech Syst Signal Process 139:106583

Liu Y, Zhao YL, Li JT, Ma H, Yang Q, Yan XX (2020) Application of weighted contribution rate of nonlinear output frequency response functions to rotor rub-impact[J]. Mech Syst Signal Process 136:106518

Funding

This study was funded by the National Natural Science Foundation of China (No. 51505070, No. 51970530 and U1708257), the Fundamental Research Funds for the Central Universities of China (No. N170302001, N180302004, N180703018, N180312012 and N180313006), the National Key Laboratory of Science and Technology on Advanced Composites in Special Environments, Harbin Institute of Technology (No. 6142905192512), and the Key Laboratory of Vibration and Control of Aero-Propulsion System Ministry of Education, Northeastern University (No. VCAME201603).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Liang, X., Wang, W. et al. A Lumped Parameter Model of a Fibre-Reinforced Composite Plate with Temperature Dependence Based on Thermal Vibration Measurements. Exp Mech 60, 949–967 (2020). https://doi.org/10.1007/s11340-020-00602-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00602-8