Abstract

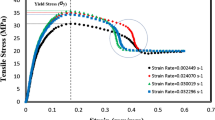

The crystalline and amorphous regions were alternately arranged in the hard elastic polypropylene (PP) films with row-nucleated lamellae. In this work, their structure evolution during stretching and recovery at room temperature was followed and the elastic recovery mechanism was discussed by twice cyclic tensile experiment. During the first stretching to 100%, the lamellae crystals are parallel separated and the intercrystallite crazing is formed at the first yield point. Many nano-cavities within the intercrystallite crazing appear when the strain reaches 20%. The strain-hardening process accompanies with the lamellae long period increasing and the intercrystallite crazing enlargement. After the secondary yield point, the lamellae cluster is further separated and more nano-cavities appear. The first and second recovery processes are complete overlap. During recovery, firstly, the energy elasticity provided by nano-cavities surface tension drives the shrinkage of material, and then the entropy elasticity related to amorphous chain relaxation plays a leading role when the strain is smaller than the secondary yield point. The elastic recovery process of hard elastic material is the co-contribution of energy elasticity and entropy elasticity. This work gives a clearer recognition about the source of hard elastic property and the role of amorphous region in material’s deformation.

Similar content being viewed by others

References

Cannon, S. L.; McKenna, G. B.; Statton, W. O. Hard-elastic fibers. A review of a novel state for crystalline polymers. J. Polym. Sci.: Macromol. Rev.1976, 11209–11275.

Park, I. K.; Noether, H. D. Crystalline “hard” elastic materials. Colloid Polym. Sci.1975, 253, 824–839.

Wittkop, M.; Kreitmeier, S.; Göuritz, D. On the deformation of hard elastic polymers—applicability of the coil-strand-transition model. Acta Polym.1995, 46, 319–327.

Hild, S.; Gutmannsbauer, W.; Lüthi, R.; Fuhrmann, J.; Guntherodt, H. J. A nanoscopic view of structure and deformation of hard elastic polypropylene with scanning force microscopy. J. Polym. Sci., Part B: Polym. Phys.1996, 34, 1953–1959.

Adams, W. W.; Yang, D.; Thomas, E. L. Direct visualization of microstructural deformation processes in polyethylene. J. Mater. Sci.1986, 21, 2239–2253.

Lei, C. H.; Xu, R. J. in Submicron porous materials. Springer, Cham, 2017, p. 81–105.

Hosemann, R.; Čačković, H. Adhäsive Reibungselastizität von hartelastischem Polypropylen (HEPP). Colloid Polym. Sci.1981, 259, 15–22.

Shimizu, Y.; Miyasaka, K.; Ishikawa, K. Analysis of small angle X-ray scattering intensity of hard elastic polypropylene under extension. Die Makromolekulare Chemie: Macromol. Chem. Phys.1981, 182, 199–208.

Quynn, R. G.; Brody, H. Elastic “hard” fibers. I. J. Macromol. Sci., Part B: Phys.1971, 5, 721–738.

Miles, M.; Petermann, J.; Gleiter, H. Structure and deformation of polyethylene hard elastic fibers. J. Macromol. Sci., Part B: Phys.1976, 12, 523–534.

Sprague, B. S. Relationship of structure and morphology to properties of “hard” elastic fibers and films. J. Macromol. Sci., Part B: Phys.1973, 8, 157–187.

Clark, E. S. in Structure and properties of polymer films. Springer, Boston, MA, 1973, p. 267–282.

Garber, C. A.; Clark, E. S. Morphology and deformation behavior of “row-nucleated” polyoxymethylene film. J. Macromo. Sci., Part B.1970, 4, 499–517.

Noether, H. D.; Whitney, W. in Aktuelle Probleme der Polymer-Physik IV. Steinkopff, 1973, p. 991–1005.

Lin, Y.; Li, X.; Meng, L.; Chen, X.; Lv, F.; Zhang, Q.; Li, L. Stress-induced microphase separation of interlamellar amorphous phase in hard-elastic isotactic polypropylene film. Polymer2018, 148, 79–92.

Lin, Y; Li, L. Deformation mechanisms of polyolefin hard-elastic films during uniaxial stretching. Bulletin of the American Physical Society, 2020.

Lin, Y.; Li, X.; Meng, L.; Chen, X.; Lv, F.; Zhang, Q.; Li, L. Structural evolution of hard-elastic isotactic polypropylene film during uniaxial tensile deformation: the effect of temperature. Macromolecules2018, 51, 2690–2705.

Lei, C.; Xu, R.; Tian, Z.; Huang, H.; Xie, J.; Zhu, X. Srretching-induced uniform micropores formation: an in situ SAXS/WAXS study. Macromolecules2018, 51, 3433–3442.

Ren, W. Hard elastic polypropylene-nature, internal friction, and surface energy. Colloid Polym. Sci.1992, 270, 943–955.

Chou, C. J.; Hiltner, A.; Baer, E. The role of surface stresses in the deformation of hard elastic polypropylene. Polyme.1986, 27, 369–376.

Kreitmeier, S.; Wittkop, M.; Wagner, T.; Göritz, D.; Zietz, R. Investigations of hard elastic polypropylene with respect to the coil-strand-transition model. Colloid Polym. Sci.1955, 273, 1008–1021.

Moet, A.; Palley, I.; Baer, E. Development of hard-elastic solids from glassy polymers. J. Appl. Phys.1980, 51, 5175–5183.

Hiltner, Anne. In Structure-property relationships of polymeric solids, Vol. 22. Springer Science & Business Media, 2012.

Goritz, D.; Müller, F. H. Mechanism of torque restoration of elastic molded fibers. Colloid Polym. Sci.1974, 252, 862–870.

Goritz, D.; Müller, F. H. Structure and properties of commercial polymer. Colloid Polym. Sci.1975, 253, 844–864.

Samuels, R. J. High strength elastic polypropylene. J. Polym. Sci:,Part B: Polym. Phys.1979, 17, 535–568.

Ren, W. Inverse relaxation-model and relation to recovery internal friction. Colloid Polym. Sci.1992, 270, 990–998.

Hashimoto, T.; Nagatoshi, K.; Todo, A.; Kawai, H. Deformation mechanism of’ hard elastic polyethylene films. Polymer1976, 17, 1063–1074.

Crist, B. Microfibril dimensions from small-angle X-ray scattering. J. Appl. Crystallogr.1979, 12, 27–33.

Fraser, R. D. B. Interpretation of infrared dichroism in axially oriented polymers. J. Chem. Phys.1958, 28, 1113–1115.

Samuels, R. J. Infrared dichroism, molecular structure, and deformation mechanisms of isotactic polypropylene. Die Makromolekulare Chemie: Macromol. Chem. Phys.1881, 4, 241–270.

Yu, T.; Du, Q.; Hu, J. Elasticity of hard elastic polypropylene fibre and surface energy. Polym. Commun.1985, 3, 35–41.

Xie, J.; Xu, R.; Lei, C. Uniaxial stretching induced pore nucleation and growth in row-nucleated crystalline hard-elastic polypropylene film: the effect of activation volume and stretching work. Polymer2018, 158, 10–17.

Matsui, K.; Hosaka, N.; Suzuki, K.; Shinohara, Y.; Amemiya, Y. Microscopic deformation behavior of hard elastic polypropylene during cold-stretching process in fabrication of microporous membrane as revealed by synchrotron X-ray scattering. Polymer2015, 70, 215–221.

Rozanski, A.; Galeski, A.; Debowska, M. Initiation of cavitation of polypropylene during tensile drawing. Macromolecules2010, 44, 20–28.

Pawlak, A.; Galeski, A. Plastic deformation of crystalline polymers: the role of cavitation and crystal plasticity. Macromolecules2005, 38, 9688–9697.

Pawlak, A.; Galeski, A. Cavitation during tensile deformation of polypropylene. Macromolecules2008, 41, 2839–2851.

Yarysheva, A. Y.; Bagrov, D. V.; Bakirov, A. V.; Yarysheva, L. M.; Chvalun, S. N.; Volynskii, A. L. Effect of initial polypropylene structure on its deformation via crazing mechanism in a liquid medium. Eur. Polym. J.2018, 100, 233–240.

Volynskii, L.; Bakeev, N. F. Surface phenomena in the structural and mechanical behaviour of solid polymers. CRC Press, 2018.

Walton, K.; Moet, A.; Baer, E. In Contemporary topics in polymer science. Springer, 1984, p. 977–1003.

Yefimov, A. V.; Bulayev, V. M.; Ozerin, A. N.; Rebrov, A. V.; Godovskii, Y. K.; Bakeyev, N. F. Formation of crazes in isotactic polypropylene and accompanying changes of energy. Polym. Sci. USSR.1986, 28, 1951–1958.

Xu, J. Z.; Xu, L.; Liang, Y. Y.; Zhong, G. J.; Lei, J.; Li, Z. M. Temperature dependence of molecular conformation in uniaxially deformed isotactic polypropylene investigated by combination of polarized FTIR spectroscopy and 2D correlation analysis. J. Polym. Sci., Part B: Polym. Phys.2015, 53, 673–684.

Parthasarthy, G.; Sevegney, M.; Kannan, R. M. Rheooptical Fourier transform infrared spectroscopy of the deformation behavior in quenched and slow-cooled isotactic polypropylene films. J. Polym. Sci., Part B: Polym. Phys.2002, 40, 2539–2551.

Noda, I.; Ozaki, Y. in Two-dimensional correlation spectroscopy: applications in vibrational and optical spectroscopy. Wiley Online Library, 2004.

Maekawa, H.; Ge, N. H. Comparative study of electrostatic models for the amide-I and -II modes: linear and two-dimensional infrared spectra. J. Phys. Chem. B2010, 114, 1434–1446.

Acknowledgments

The work was financially supported by the National Natural Science Foundation of China (Nos. 51773044 and 51603047), Research and Development Plan for Key Areas in Guangdong Province (No. 2019B090914002), Guangdong Province Science and Technology Plan Project (No. 2016A010103030), the PhD Start-up Fund of Natural Science Foundation of Guangdong Province, China (No. 2016A030310344).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Information

10118_2020_2432_MOESM1_ESM.pdf

Origin of high elastic recovery of hard-elastic polypropylene film at room temperature: The mixed contribution of energy elasticity and entropy elasticity

Rights and permissions

About this article

Cite this article

Xie, JY., Xu, RJ. & Lei, CH. Origin of High Elastic Recovery of Hard-elastic Polypropylene Film at Room Temperature: the Mixed Contribution of Energy Elasticity and Entropy Elasticity. Chin J Polym Sci 38, 1325–1334 (2020). https://doi.org/10.1007/s10118-020-2432-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2432-8