Abstract

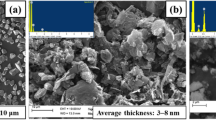

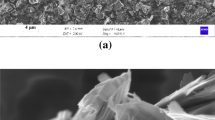

In this paper, it is intended to analyze the influence of coarse grain (CG) phase on mechanical properties and wear performance of Al–2Cu-4 wt% B4C trimodal composite. Trimodal ultra-fine grained (UFG) composites with 30 and 50 wt% aluminum coarse grains (4-66-30) and (4-46-50) were prepared using powder metallurgy and hot extrusion. Wear tests were conducted for normal loads of 20 and 50 N at a sliding velocity of 0.6 m/s at room temperature. Results revealed that there was a direct relationship between the CG content and the plastic deformation of worn subsurface. Moreover, by adding 50 wt% CG, wear rate reached to around 0.02 × 10−3 (mm3/m) and plastic deformation increased significantly. Investigations on the microstructure indicated that wear mechanisms of the trimodal samples were a combination of abrasive, adhesive, and delamination wear in the tribological layer.

Similar content being viewed by others

References

D. Witkin, Bing q. Han, Enrique J. Lavernia, Room-Temperature Mechanical Behavior of Cryomilled Al Alloys, Metallurgical and materials transactions A. 37A (2006) 186-194

N. Radhika, R. Raghu, Dry Sliding Wear Behaviour of Aluminium Al–Si12Cu/TiB2 Metal Matrix Composite Using Response Surface Methodology, Tribol Lett (2015) 59:2

Aleksandar Vencl, Ilija Bobic, Milan T. Jovanovic, Miroslav Babic, Slobodan Mitrovic, Microstructural and Tribological Properties of A356 Al-Si Alloy Reinforced with Al2O3 Particles, Tribol Lett (2008) 32:159–170

T.D. Topping, B. Ahn, Y. Li, S. R. Nutt, E. J. Lavernia, Influence of Process Parameters on the Mechanical Behavior of an Ultrafine-Grained Al Alloy, Metall Trans A. 43 [2] (2011) 505-519

A.P. Newbery, B. Ahn, R.W. Hayes, P.S. Pao, S.R. Nutt, E.J. Lavernia, Consolidation and Forging Methods for a Cryomilled Al Alloy, Metall. Trans. A 39 [9] (2008) 2193-2205

F. Tang, F. Tang a, X. Wu b, S. Gec, J. Ye a, H. Zhu, M. Hagiwara d, J. M. Schoenung, Dry sliding friction and wear properties of B4C particulate-reinforced Al-5083 matrix composites, Wear 264 (2008) 555–561

A. Canakci, F. Erdemir, T. Varol, R. Dalmıs¸, Ozkaya S, Effects of a new pre-milling coating process on the formation and properties of a Fe-Al intermetallic coating, powder technology. 268 (2014) 110-117

E.J. Lavernia, B.Q. Han, J.M. Schoenung, Cryomilled nanostructured materials: Processing and properties, Materials Science and Engineering A. 493 (2008) 207–214

B.Q. Han, J.Y. Huang b, Y.T. Zhu c, E.J. Lavernia, Strain rate dependence of properties of cryomilled bimodal 5083 Al alloys, Acta Materialia 54 (2006) 3015–3024

A. Abdollahi, A. Alizadeh, H. R. Baharvandi., Dry sliding tribological behavior and mechanical properties of Al2024–5 wt%B4C nanocomposite produced by mechanical milling and hot extrusion, Materials, and Design. 55 (2014) 471–481

B. Yao, B. Yao a, C. Hofmeister a, T. Patterson a, Y. H. Sohn a, M. V. D. Bergh b, T. Delahanty c, K. Cho, Microstructural features influencing the strength of Trimodal Aluminum Metal-Matrix-Composites, Composites: Part. A 41 (2010) 933–941

A. Abdollahi, A. Alizadeh, H. R. Baharvandi, Comparative studies on the microstructure and mechanical properties of bimodal and trimodal Al2024 based composites, Materials Science & Engineering A. 608 (2014) 139–148

M. Sameezadeh, M. Emamy, H. Farhangi, Effects of particulate reinforcement and heat treatment on the hardness and wear properties of AA 2024-MoSi2 nanocomposites, Materials and Design 32 (2011) 2157–2164

A. Alizadeh, E. Taheri-Nassaj, Mechanical properties and wear behavior of Al–2 wt% Cu alloy composites reinforced by B4C nanoparticles and fabricated by mechanical milling and hot extrusion, Materials Characterization. 67 (2012) 119–128

Witkin, D. B., Lavernia, E. J., 2006. Synthesis and mechanical behavior of nanostructured materials via cryomilling. Progress in Materials Science, vol. 5, pp. 11-60.

Han, B. Q., Mohamed, F.A., Bampton, C. C., Lavernia, E. J., 2005. Improvement of toughness and ductility of a cryomilled Al-Mg alloy via microstructural modification. Metallurgical and Materials Transactions A, vol. 36A, pp. 2081-2091.

Bing Q. H., Enrique, J. L., Farghalli, A. M., 2005. Mechanical properties of nanostructured materials. Reviews of Advanced Materials Science, vol. 9, pp. 1-16.

Ma, E., 2003. Instabilities and ductility of nanocrystalline and ultrafine-grained metals Scripta Materialia, vol. 49, pp. 663-668

Dhokey, N. B., Paretkar, R. K., 2008. Study of wear mechanisms in copper-based SiCp (20%by volume) reinforced composite. Wear, vol. 265, pp. 117–133.

B.Q. Han, J. Ye, F. Tang, J. Schoenung, E. J. Lavernia, Processing and behavior of nanostructured metallic alloys and composites by cryomilling, Mater.Sci. 42(2007) 1660–1672.

Z. Lee, D.B. Witkin, V. Radmilovic, E.J. Lavernia, S.R. Nutt, Bimodal microstructure and deformation of cryomilled bulk nanocrystalline Al–7.5 Mg alloy, Materials Science and Engineering A 410–411 (2005) 462–467

H. Yang, T. D. Topping, K. Wehage, L. Jiang, E. J. Lavernia, J. M. Schoenung, Tensile behavior and strengthening mechanisms in a submicron B4C reinforced Al trimodal composite, Materials Science & Engineering. A 616 (2014) 35–43

S.L. Rice, H. Nowotny, S.F. Wayne, A survey of the development of subsurface zones in the wear of materials. In Key Engineering Materials (Vol. 33, pp. 77–100). Trans Tech Publications Ltd. https://doi.org/10.4028/www.scientific.net/KEM.33.77

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alizadeh, A., Maleki, M. & Saessi, M. The Influence of Adding Coarse Grain Phase on the Tribo-Wear Characteristics and Mechanical Properties of Ultra-Fine Grained Al-2Cu-B4C Trimodal Composite at Room Temperature. Trans Indian Inst Met 73, 1985–1997 (2020). https://doi.org/10.1007/s12666-020-02012-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02012-9