Abstract

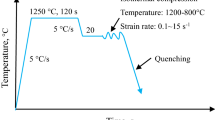

The correlation between hardening and softening in an ASTM F-1586 stainless steel used as biomaterial was investigated by means of hot torsion simulations. Multi-pass deformation under continuous cooling was employed to simulate industrial hot rolling. Samples were subjected to 17 deformation passes of strains of 0.20 and 0.30, strain rate of 1.0 s−1 in a temperature range of 1250 to 930 °C. Interpass times (tp) of 5.0, 10, 20, 40, and 80 s were used. The obtained results showed direct dependence of the mean flow stress (MFS) and all applied thermomechanical parameters. The work hardening rate associated with the degree of stress accumulation (Δσ) inhibited the metadynamic recrystallization. This led to the variation of the non-recrystallization temperature (Tnr), associated with intense static recovery in the material. From the experimental data, a constitutive function of the mean flow stress (MFS) obtained through multiple nonlinear regression technique was proposed. The study aimed to have a better understanding of the physical metallurgy behind the thermomechanical behavior of the steel under a multi-pass process. The results allowed to monitor the recrystallized fraction (X) and the grain size (d) during the simulated conditions.

Graphic Abstract

Similar content being viewed by others

References

L.L. Hench, J.M. Polak, Third-generation biomedical materials. Science 295, 1014–1017 (2002). https://doi.org/10.1126/science.1067404

E.J. Giordani, A.M. Jorge Jr., O. Balancin, Evidence of strain-induced precipitation on a Nb and N-bearing austenitic stainless steel biomaterial. Mater. Sci. For. 500, 179–186 (2005). https://doi.org/10.4028/www.scientific.net/MSF.500-501.179

E.J. Giordani, V.A. Guimarães, T.B. Pinto, I. Ferreira, Effect of precipitates on the corrosion–fatigue crack initiation of ISO 5832-9 stainless steel biomaterial. Int. J. Fatigue 26, 1129–1136 (2004). https://doi.org/10.1016/j.ijfatigue.2004.03.002

C. Örnhagen, J.O. Nilsson, H. Vannevik, Characterization of a nitrogen-rich austenitic stainless steel used for osteosynthesis devices. J. Biol. Mater. Res. 31, 97–103 (1996). https://doi.org/10.1002/(SICI)1097-4636(199605)31:1%3c97:AID-JBM12%3e3.0.CO;2-J

M. Navarro, A. Michiardi, O. Castaño, J.A. Planell, Biomaterials in orthopaedics. J. R. Soc. Interface 5(27), 1137–1158 (2008). https://doi.org/10.1098/rsif.2008.0151

International Organization for Standardization, Switzerland, 5832-9; Implants for surgery—Metallic materials—Part 9: Wrought high nitrogen stainless steel. Switzerland (1997)

F.R. Bernardes, S.F. Rodrigues, E.S. Silva, G.S. Reis, M.B.R. Silva, A.M. Moreira Jr., O. Balancin, Analytical modeling of the thermomechanical behavior of ASTM F-1586 high nitrogen austenitic stainless steel used as a biomaterial under multipass deformation. Mater. Sci. Eng. C Mater. Biol. Appl. 51, 87–98 (2015). https://doi.org/10.1016/j.msec.2015.02.040

M.B.R. Silva, J. Galleno, J.M. Cabrera, O. Balancin, A.M. Moreira Jr., Interaction between recrystallization and strain-induced precipitation in a high Nb- and N-bearing austenitic stainless steel: influence of the interpass time. Mater. Sci. Eng., A 637, 189–200 (2015). https://doi.org/10.1016/j.msea.2015.04.049

ASTM_International. Standard ASTM F-1586, Specification for Wrought Nitrogen Strengthened 21Chromium–10Nickel–3Manganese–2.5Molybdenum Stainless Steel Alloy Bar for Surgical Implants (UNS S31675) (2013)

A.J. DeArdo, Modern thermomechanical processing of microalloyed steel: a physical metallurgy perspective. In: Proceedings of International Conference on Microalloying’95, Pittsburgh, PA, pp 15–33 (1995)

B. Dutta, E.J. Palmiere, C.M. Sellars, Modelling the kinetics of strain induced precipitation in Nb microalloyed steels. Acta Mater. 49(5), 785–794 (2001). https://doi.org/10.1016/S1359-6454(00)00389-X

D. Samantaray, S. Mandal, M. Jayalakshmi, C.N. Athreya, A.K. Bhaduri, V.S. Sarma, New insights into the relationship between dynamic softening phenomena and efficiency of hot working domains of a nitrogen enhanced 316L (N) stainless steel. Mater. Sci. Eng., A 598, 368–375 (2014). https://doi.org/10.1016/j.msea.2013.12.105

S.F. Medina, The influence of niobium on the static recrystallization of hot deformed austenite and on strain induced precipitation kinetics. Scr. Met. Mater. 32(1), 43–48 (1995). https://doi.org/10.1016/S0956-716X(99)80009-0

F. Boratto, S. Yue, J.J. Jonas, T.H. Lawrence, Design of schedules for the production of high strength microalloyed steel strip in a hot steckel mill. I. Tamura (Ed.), Proceedings of International Conference on Physics Metallurgy of Thermomechanical Processing of Steels and other Metals (Thermec-88), Iron and Steel Institute of Japan, Tokyo (Japan), pp 519–526 (1988)

T.M. Maccagno, J.J. Jonas, Correcting for the effects of static and metadynamic recrystallization during the laboratory simulation of rod rolling. ISIJ Int. 34, 607–614 (1994). https://doi.org/10.2355/isijinternational.34.607

A. Laasraoui, J.J. Jonas, Prediction of temperature distribution, flow stress and microstructure during the multipass hot rolling of steel plate and strip. ISIJ Int. 31, 95–105 (1991). https://doi.org/10.2355/isijinternational.31.95

F. Boratto, R. Barbosa, S. Yue, J.J. Jonas, Effect of chemical composition on the critical temperatures of microalloyed steels. In: Tamura (Ed.), Proceedings of International Conference on Physical Metallurgy of Thermomechanical Processing of Steels and Other Metals (Thermec-88), Iron and Steel Institute of Japan, Tokyo (Japan): 383–390 (1988)

D.Q. Bai, S. Yue, W.P. Sun, J.J. Jonas, Effect of deformation parameters on the No-recrystallization temperature in Nb-bearing steels. Met. Trans. A 24, 2151–2159 (1993). https://doi.org/10.1007/BF02648589

M. Gomes, L. Rancel, B.J. Fernandez, S.F. Medina, Evolution of austenite static recrystallization and grain size during hot rolling of a V-microalloyed steel. Mater. Sci. Eng., A 501, 188–196 (2009). https://doi.org/10.1016/j.msea.2008.09.074

M. Arribas, B. Lopes, J.M. Rodriguez-Ibabe, Additional grain refinement in recrystallization controlled rolling of Ti-microalloyed steels processed by near-net-shape casting technology. Mater. Sci. Eng., A 485, 383–394 (2008). https://doi.org/10.1016/j.msea.2007.08.015

N. Radović, D. Drobnjak, K. Raić, Determination of activation energy for static recrustallization using multipass continuous cooling torsion test. Ass. Met. Eng. Ser. AMES 15(2), 99–104 (2009)

E.S. Silva, R.C. Sousa, A.M. Jorge Jr., O. Balancin, Hot deformation behavior of an Nb- and N-bearing austenitic stainless steel biomaterial. Mater. Sci. Eng., A 543, 69–75 (2012). https://doi.org/10.1016/j.msea.2012.02.048

L. Rauch, R. Jacolot, K. Bzowski, M. Pietrzyk, Physical and numerical simulation of the multipass AHSS strip rolling, cooling and coiling. Proc. Manuf. 27, 118–123 (2019). https://doi.org/10.1016/j.promfg.2018.12.053

M.I. Vega, S.F. Medina, A. Quispe, M. Gomez, P.P. Gomez, Influence of TiN particle precipitation state on static recrystallisation in structural steels. ISIJ Int. 45(2005), 1878–1886 (2005). https://doi.org/10.2355/isijinternational.45.1878

F. Siciliano, K. Minami, T.M. Maccagno, J.J. Jonas, Mathematical modeling of the mean flow stress, fractional softening and grain size during the hot strip rolling of C–Mn steels. ISIJ Int. 36, 1500–1506 (1996). https://doi.org/10.2355/isijinternational.36.1500

M.B.R. Silva, J.M. Cabrera, O. Balancin, A.M. Moreira Jr., Thermomechanical controlled processing to achieve very fine grains in the ISO 5832-9 austenitic stainless steel biomaterial. Mater. Charact. 127, 153–160 (2017). https://doi.org/10.1016/j.matchar.2017.02.026

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater Sci. 60, 130–207 (2014). https://doi.org/10.1016/j.pmatsci.2013.09.002

M.C. Mataya, C.A. Perkins, S.W. Thompson, D.K. Matlock, Flow stress and microstructural evolution during hot working of alloy 22Cr–13 Ni–5Mn–0.3N austenitic stainless steel. Met. Mater. Trans. A 27, 1251–1266 (1996). https://doi.org/10.1007/BF02649862

E.J. Giordani, A.M. Jorge Jr., O. Balancin, Proportion of recovery and recrystallization during interpass times at high temperatures on a Nb- and N-bearing austenitic stainless steel biomaterial. Scr. Mater. 55, 743–746 (2006). https://doi.org/10.1016/j.scriptamat.2006.05.015

X. Liu, J.K. Solberg, R. Gjengedal, A.O. Kluken, Modelling of interaction between recrystallisation and precipitation during multipass rolling of niobium microalloyedsteels. Mater. Sci. Technol. 5, 469–473 (1995). https://doi.org/10.1179/mst.1995.11.5.469

S.H. Mousavi Anijdan, S. Yue, The necessity of dynamic precipitation for the occurrence of no-recrystallization temperature in Nb-microalloyed steel. Mater. Sci. Eng., A 528, 803–807 (2011). https://doi.org/10.1016/j.msea.2010.09.101

J. Erneman, M. Schwind, P. Liu, J.O. Nilsson, H.O. Andren, J. Agren, Precipitation reactions caused by nitrogen uptake during service at high temperatures of a niobium stabilised austenitic stainless steel. Acta Mater. 52, 4337–4350 (2004). https://doi.org/10.1016/j.actamat.2004.06.001

Y. Cheng, H. Du, Y. Wei, L. Hou, B. Liu, Metadynamic recrystallization behavior and workability characteristics of HR3C austenitic heat-resistant stainless steel with processing map. J. Mater. Process. Technol. 235, 134–142 (2016). https://doi.org/10.1016/j.jmatprotec.2016.04.026

A. Paggi, G. Angella, R. Donnini, Strain induced grain boundary migration effects on grain growth of an austenitic stainless steel during static and metadynamic recrystallization. Mater. Charact. 107, 174–181 (2015). https://doi.org/10.1016/j.matchar.2015.07.003

R.C. Souza, E.S. Silva, A.M. Jorge Jr., J.M. Cabrera, O. Balancin, Dynamic recovery and dynamic recrystallization competition on a Nb- and N-bearing austenitic stainless steel biomaterial: influence of strain rate and temperature. Mater. Sci. Eng., A 582, 96–107 (2013). https://doi.org/10.1016/j.msea.2013.06.037

K. Huang, K. Marthinsen, Q. Zhao, R.E. Loge, The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials. Prog. Mater Sci. 92, 284–359 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.004

S.R.J.B. Leitão Filho, E.S. Silva, S.F. Rodrigues, C. Aranas Jr., E.J.P. Miranda Jr., G.S. Reis, O. Balancin, Delay in the static softening kinetics of a Nb–N-bearing austenitic stainless steel. Mater. Res. Exp. 6(11), 65f3 (2019). https://doi.org/10.1088/2053-1591/ab3e27

Acknowledgements

The authors are grateful for the technical collaboration of Prof. J.M. Cabrera from the Materials Research Group from Polytechnic University of Catalonia (UPC/Barcelona/ESP), financial support from the Research and Support Foundation of Maranhão (FAPEMA), CAPES and CNPq.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos Filho, N.L.C., Silva, E.S., Aranas, C. et al. Constitutive Analysis of the Mean Flow Stress of a Nb- and N-Bearing Austenitic Stainless Steel Biomaterial. Met. Mater. Int. 27, 4768–4779 (2021). https://doi.org/10.1007/s12540-020-00777-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00777-8