Abstract

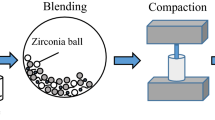

In this study, \(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\) and graphene-reinforced aluminium matrix composites (AMCs) with various contents (\(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\): 1, 3, 6, 9 wt%; graphene: 0.1, 0.3, 0.5 wt%) were produced by the powder metallurgy method. The phase and microstructure analyses of the composites were performed by X-ray diffractometry and scanning electron microscopy, respectively. To investigate the tribological behaviour of Al–\(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\) and Al–\(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\)–graphene composites, pin-on-disc experiments were conducted with different loads (\(F = 10\), 20 and 30 N) at a constant sliding speed (200 rpm). Thus, the effects of \(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\) and graphene contents on microstructure, Vickers hardness, apparent density, porosity, wear rate and friction coefficient of AMCs were investigated. Test results reveal that the highest Vickers hardness (\(66 \pm 1\hbox { HV}\)), the lowest porosity (5.6%), wear rate (\(3.1 \times 10^{\mathrm {-5}}\hbox { mm}^{\mathrm {3}}\hbox { N}^{\mathrm {-1}}\) \(\hbox {m}^{\mathrm {-1}})\) and friction coefficient (0.13) were obtained for Al–9\(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\)–0.1 graphene. After attaining 0.1% graphene content, agglomeration was detected from the microstructure images of \(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\)–graphene-reinforced AMCs. It was concluded that \(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\) had an outstanding wear resistance and graphene was a good solid lubricant for AMCs.

Similar content being viewed by others

References

Rajmohan T and Palanikumar K 2012 J. Compos. Mater. 46 869

Saboori A, Novara C, Pavese M, Badini C, Giorgis F and Fino P 2017 J. Mater. Eng. Perform. 26 993

Alizadeh A, Taheri-Nassaj E and Baharvandi H R 2011 Bull. Mater. Sci. 34 1039

Neikow O G, Naboychenko S S and Dawson G 2009 Handbook of non-ferrous metal powders – technologies and applications (Oxford: Elsevier Ltd)

Ramesh B and Senthilvelan T 2010 Int. J. Eng. Technol. 2 1

Sharma P, Sharma S and Kandhuja D 2015 J. Asian Ceram. Soc. 3 352

Geim A K and Novoselov K S 2007 Nat. Mater. 6 183

Savage N 2012 Nature 482 30

Randviir E P, Brownson D A C and Banks C E 2014 Mater. Today 17 426

Singh V, Joung D, Zhai L, Das S, Khondaker S I and Seal S 2012 Prog. Mater. Sci. 56 1178

Saboori A, Pavese M, Badini C and Fino P 2017 Acta Metall. Sin. (Engl. Lett.) 30 675

Saboori A, Dadkhak M and Pino P 2018 Metals 8 423

Rashad M, Pan F, Yu Z, Asif M, Lin H and Pan R 2015 Prog. Nat. Sci. Mater. Int. 25 460

Wang J, Li Z, Fan G, Pan H, Chen Z and Zhang D 2012 Scr. Mater. 66 594

Li J L, Xiong Y C, Wang X D, Yan S J, Yang C, He W W et al 2015 Mater. Sci. Eng. A 626 400

Li G and Xiong B 2017 J. Alloys Compd. 697 31

Bartolucci S F, Paras J, Rafiee M A, Rafiee J, Lee S, Kapoor D et al 2011 Mater. Sci. Eng. A 528 7933

An Y, Yang S, Wu H, Zhao E and Wang Z 2017 Mater. Des. 134 44

Rashad M, Pan F, Tang A and Asif M 2014 Prog. Nat. Sci. Mater. Int. 24 101

Bastwros M, Kim G Y, Zhu K, Zhang K, Wang S, Tang X et al 2014 Compos. Part B 60 111

Berman D, Erdemir A and Sumant A V 2014 Mater. Today 17 31

Iacob G, Ghica V G, Buzatu M, Buzatu T and Petrescu M I 2015 Compos. Part B 69 603

Zhai W, Shi X, Yao J, Ibrahim A M M, Xu Z, Zhu Q et al 2015 Compos. Part B 70 149

Kumar N M, Kumaran S S and Kumaraswamidhas L A 2016 Alexandria Eng. J. 55 19

Ul Haq M I and Anand A 2018 Silicon 10 1819

Ambigai R and Prabhu S 2017 Trans. Nonferrous Met. Soc. China 27 986

Kumar H G P and Xavior M A 2016 Trans. Indian Inst. Met. 69 415

Tabandeh-Khorshid M, Omrani E, Menezes P L and Rogathi P K 2016 Eng. Sci. Technol. 19 463

Zeng X, Yu J, Fu D, Zhang H and Teng J 2018 Vacuum 155 364

Zhang J, Chen Z, Wu H, Zhao J and Jiang Z 2019 Surf. Coat. Technol. 358 907

Fathy A, Abu-Oqail A and Wagih A 2018 Ceram. Int. 44 22135

Şenel M C, Gürbüz M and Koç E 2018 Mater. Sci. Technol. Ser. 34 1980

Gürbüz M, Şenel M C and Koç E 2018 J. Compos. Mater. 52 553

Şenel M C, Gürbüz M and Koç E 2018 Compos. Part B 154 1

Varol T and Canakci A 2015 Met. Mater. Int. 21 704

Rahimian M, Ehsani N, Parvin N and Baharvandi H R 2009 J. Mater. Process. Technol. 209 5387

Li J, Zhang X and Geng L 2019 Compos. Part A 121 487

Liu R and Li D Y 2001 Wear 251 956

Acknowledgements

The authors acknowledge Black Sea Advanced Technology Research and Application Center (KITAM) in Ondokuz Mayıs University (OMU) for SEM and XRD analyses. This work was supported by the Scientific Researched Project Department of Ondokuz Mayıs University under grant numbers PYO.MUH.1902.15.001 and grant number PYO.MUH.1904.16.002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Şenel, M.C., Gürbüz, M. Microstructure and wear behaviour of graphene–\(\hbox {Si}_{\mathrm {3}}\hbox {N}_{\mathrm {4}}\) binary particle-reinforced aluminium hybrid composites. Bull Mater Sci 43, 148 (2020). https://doi.org/10.1007/s12034-020-02124-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02124-4