Abstract

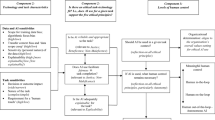

The introduction of automation to mining has great potential to reduce safety and health risks by removing people from hazardous situations. However, automation changes the tasks performed by people and may introduce new tasks. For the system to function optimally, these tasks must be designed taking human abilities and limitations into account. Human-systems integration refers to systems engineering processes that ensure that human-related issues are adequately considered during system planning, design, development, and evaluation. During procurement of automated systems, a human-systems integration program plan should be prepared that describes the human-systems integration activities that will be performed to address each of the six core domains of human-systems integration: staffing, personnel, training, human factors engineering, safety, and health.

Similar content being viewed by others

Notes

“Manpower” in previous HSI documents

References

Horberry T, & Lynas D (2012) Human interaction with automated mining equipment: the development of an emerging technologies database. Ergonomics Australia, 8:1

Rogers WP, Kahraman MM, Drews FA, Powell K, Haight JM, Wang Y, Baxla K, Sobalkar M (2019) Automation in the mining industry: review of technology, systems, human factors, and political risk. Mining Metall Explor 36:607–631

McGagh J (2014) Autonomous haulage: an owner/operator story. IMARC presentation. https://fellows.atse.org.au/Documents/Events/qld/mining-automation/pre-autonomous-haulage-mcgagh.pdf. Retrieved June 1, 2020

Lynas D, Horberry T (2011) Human factor issues with automated mining equipment. Ergon Open J 4(1):74–80

National Transportation Safety Board (2018) Preliminary report: Highway HWY18MH010. Retrieved from https://www.ntsb.gov/investigations/AccidentReports/Reports/HWY18MH010-prelim.pdf

Sheridan TB, Parasuraman R (2005) Human-automation interaction. Rev Human Factors Ergon 1:89–129

Endesley M (2011) Designing for situation awareness: an approach to user-centred design, 2nd edn. CRC Press, Boca Raton

Lee JD, Seppelt BD (2012) Human factors and ergonomics in automation design. In: Salvendy G (ed) Handbook of Human Factors and Ergonomics, 4th edn, pp 1615–1642

Wiener EL (1989) Human factors of advanced technology (“glass cockpit”) transport aircraft. NASA Contractor Report 177528, NASA Ames Research Center

Hancock PA, Billings DR, Schaefer KE, Chen JYC, de Visser E, Parasuraman RA (2011) Meta-analysis of factors affecting trust in human-robot interaction. Hum Factors 53:517–527

Western Australian Department of Mines and Petroleum Resources Safety (2015) Collision between an autonomous haul truck and manned water cart. Significant report 226

MSHA (2017) Fatality #8 - June 13, 2017 - Final Report. Retrieved from https://www.msha.gov/data-reports/fatality-reports/2017/fatality-8-june-13-2017/final-report

Leveson NG (2012) Engineering a safer world: systems thinking applied to safety. MIT Press

International Council on Systems Engineering (2015). INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities. Wiley. (pp 237–241)

Booher H (2003) Handbook of human systems integration. Wiley, New York

Folds D (2015) Systems engineering perspective on human systems integration. In: BoehmDavis D, Durso F, Lee J (eds) APA handbook of human systems integration. American Psychological Association, Washington, DC

Department of Defence (2008) Instruction 5000.02

Strauch B (2017) The automation-by-expertise-by-training interaction: why automation-related accidents continue to occur in sociotechnical systems. Hum Factors 59:204–228

Gordon SE (1994) Systematic training program design: maximising effectiveness and minimizing liability. Prentice Hall, Englewood Cliffs

Clark RE, Estes F (1996) Cognitive task analysis for training. Int J Educ Res 25:403–417

Salas E, Cannon-Bowers J (2001) The science of training: a decade of progress. Annu Rev Psychol 52:471–499

Horberry T, Burgess-Limerick R, Steiner L (2011) Human factors for the design, operation and maintenance of mining equipment. CRC Press, Boca Raton

Horberry T, Burgess-Limerick R, Steiner L (2018) Human-centered design for mining equipment and new Technology. CRC Press, Boca Raton

International Standards Organisation (2010). Ergonomics of human-system interaction Part 210: Human-centred design for interactive systems. ISO9241-210. p. 9

Burgess-Limerick R, Horberry T, Cronin J, & Steiner L (2017) Mining automation human-systems integration: a case study of success at CMOC-Northparkes. 13th AusIMM underground operators’ conference 2017, Gold Coast, 16-18 October, 2017

International Standards Organisation (2017) Earth-moving machinery and mining - autonomous and semi-autonomous machine system safety. ISO 17757

Department of Mines and Petroleum (2015) Safe mobile autonomous mining in Western Australia – code of practice. Resources Safety, Department of Mines and Petroleum, Western Australia

Leveson NG & Thomas JP (2018) STPA handbook. MIT

International Standards Organisation (2010) Safety of machinery - general principles for design - risk assessment and risk reduction. ISO 12100

Burgess-Limerick R, Joy J, Cooke T, Horberry T (2012) EDEEP - an innovative process for improving the safety of mining equipment. Minerals 2:272–282

NASA (2015) Space flight human-system standard. Volume 2: human factors, habitability, and environmental health. NASA-STD-3001, volume 2, revision a

Melnik G, Roth E, Multer J, Safar H, & Isaacs M (2018) An acquisition approach to adopting human systems integration in the railroad industry. US DOT. DOT/FRA/ORD-18/05

Western Australian Department of Mines and Petroleum (2015) Safe mobile autonomous mining in Western Australia – code of practice

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Burgess-Limerick, R. Human-Systems Integration for the Safe Implementation of Automation. Mining, Metallurgy & Exploration 37, 1799–1806 (2020). https://doi.org/10.1007/s42461-020-00248-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00248-z