Abstract

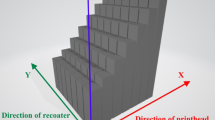

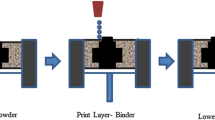

3D sand printing is an emerging technology that is enabling new possibilities in metal casting with respect to part complexity, casting design, and rapid mold production. The 3D printing technology, also known as additive manufacturing, is a binder jetting process which involves selectively depositing a furan-based binder into a sand bed one thin layer at a time. Over the course of the process, layers are subsequently added until the entire part has been fabricated. Although the use of 3D-printed sand molds in the foundry industry is growing, significant hesitation to widespread implementation remains. In this work, an investigation was conducted to determine the influence of machine settings on the physical characteristics of 3D-printed sand. Two factorial matrices were constructed to directly measure the significance of six settings that change the resin content and compaction characteristics of the bonded sand. Factors include: X-resolution, printhead voltage, layer thickness, and the frequency, speed, and angle of the recoater blade. Responses include: density, permeability, strength, scratch hardness, loss on ignition, and print resolution. Several relationships are reported between machine settings and physical properties of the product. These results will help inform mold manufacturing as the foundry industry continues to adopt additive technologies.

Similar content being viewed by others

References

R. Singh, Three dimensional printing for casting applications: a state of art review and future perspectives. In Advanced materials research 2010 (Vol. 83, pp. 342–349). Trans Tech Publications

J. Thiel, S. Ravi, N. Bryant, Advancements in materials for three-dimensional printing of molds and cores. Inter. Metalcast. 11, 3–13 (2017). https://doi.org/10.1007/s40962-016-0082-y

P. Beeley, Foundry Technology (Elsevier, 2001)

E.M. Sachs, Three dimensional printing techniques. United States Patent No. 5204055 (1993)

E. Sachs, M. Cima, J. Cornie, D. Brancazio, J. Bredt, A. Curodeau, M. Esterman, T. Fan, C. Harris, K. Kremmin, S.J. Lee, Dimensional printing: rapid tooling and prototypes directly from CAD representation. In International Solid Freeform Fabrication Symposium, Austin, TX 1990 (pp. 27–47)

D. Bak, Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem. Autom. 23(4), 340–345 (2003)

C.W. Lee, C.K. Chua, C.M. Cheah, L.H. Tan, C. Feng, Rapid investment casting: direct and indirect approaches via fused deposition modelling. Int. J. Adv. Manuf. Technol. 23(1–2), 93–101 (2004)

K. Woods, Sand distribution effect on three dimensional printed sand properties (2018). Electronic theses and dissertations. 534

D. Snelling, C. Williams, A. Druschitz, A comparison of binder burnout and mechanical characteristics of printed and chemically bonded sand molds. In SFF Symposium, Austin, TX (2014)

J. Thiel, Thermal expansion of chemically bonded silica sand. AFS Trans. 119, 369–378 (2011)

D. Snelling, C. Williams, A. Druschitz, Mechanical and Material Properties of Castings produced via 3d printed molds. Addit. Manuf. (2019)

E. Bassoli, A. Gatto, L. Iuliano, Violante M. Grazia, 3D printing technique applied to rapid casting. Rapid Prototyp. J. 13(3), 148–155 (2007)

H. Miyanaji, S. Zhang, L. Yang, A new physics-based model for equilibrium saturation determination in binder jetting additive manufacturing process. Int. J. Mach. Tools Manuf. 124, 1 (2018)

J. Walker, E. Harris, C. Lynagh, A. Beck, R. Lonardo, B. Vuksanovich, J. Thiel, K. Rogers, B. Conner, E. MacDonald, 3D printed smart molds for sand casting. Inter. Metalcast. 12, 785–796 (2018). https://doi.org/10.1007/s40962-018-0211-x

J.M. Walker, A. Prokop, C. Lynagh, B. Vuksanovich, B. Conner, K. Rogers, J. Thiel, E. MacDonald, Real-time process monitoring of core shifts during metal casting with wireless sensing and 3D sand printing. Addit. Manuf. 27, 54–60 (2019)

J. Kobliska, P. Ostojic, X. Cheng, X. Zhang, H. Choi, Y. Yang, X. Li, Rapid fabrication of smart tooling with embedded sensors by casting in molds made by three dimensional printing. In Proc. of Solid Freeform Fabrication Symposium 2005 (pp. 468–475)

D. Snelling, H. Blount, C. Forman, K. Ramsburg, A. Wentzel, C. Williams, A. Druschitz, The effects of 3D printed molds on metal castings. In Proceedings of the Solid Freeform Fabrication Symposium 2013 (pp. 827–845)

D. Snelling, Q. Li, N. Meisel, C.B. Williams, R.C. Batra, A.P. Druschitz, Lightweight metal cellular structures fabricated via 3D printing of sand cast molds. Adv. Eng. Mater. 17(7), 923–932 (2015)

Y.F. Liu, M.H. Tsai, Y.F. Pai, W.S. Hwang, Control of droplet formation by operating waveform for inks with various viscosities in piezoelectric inkjet printing. Appl. Phys. A 111(2), 509–516 (2013)

T.M. Liou, C.Y. Chan, K.C. Shih, Effects of actuating waveform, ink property, and nozzle size on piezoelectrically driven inkjet droplets. Microfluid. Nanofluid. 8(5), 575–586 (2010)

Acknowledgements

This effort was performed through the National Center for Defense Manufacturing and Machining under the America Makes Program entitled “Maturation of Advanced Manufacturing for Low Cost Sustainment (MAMLS)—Additional Work for Research Project #1, Phase 1” and is based on research sponsored by Air Force Research Laboratory under Agreement Number FA8650-16-2-5700.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bryant, N., Frush, T., Thiel, J. et al. Influence of Machine Parameters on the Physical Characteristics of 3D-Printed Sand Molds for Metal Casting. Inter Metalcast 15, 361–372 (2021). https://doi.org/10.1007/s40962-020-00486-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00486-3