Abstract

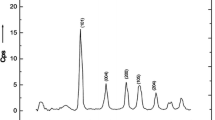

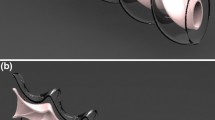

In this experimental study, the influence of combined passive technique on heat transfer, friction factor, and thermal performance factor are investigated in a double pipe heat exchanger fitted with different turbulators and GO-Water nanofluid. Experiments were conducted for a fixed flow rate of (Re = 2500) in the inner tube (hot fluid); for varying flow rates (500 ≤ Re ≤ 5000) and volume concentrations (0.05%–0.15%) of GO-Water nanofluid in the outer tube (cold fluid), under uniform heat flux condition, using i) circular finned twisted tape inserts with TR = 20, 13.3 and 9.8 ii) frequently spaced helically twisted inserts with the number of helices = 5, 7, 9). The experimental results showed that the Nusselt number and Thermal Performance Factor (TPF) were increased with decreased twist ratio and increased helices and volume concentration of nanofluid. The enhancement of heat transfer was 21.35% and 22.21%, respectively, whereas the enhancement in the Thermal Performance Factor (TPF) was 7.16% and 8.06%, respectively, for the above two test conditions. The augmentation was maximum for configurations corresponding to the circular finned twisted tape insert with TR = 9.8 and frequently spaced helical screw-tape with 9 helices in 0.15% volume concentrations of GO-water nanofluid as compared to other combinations, with a slight penalty in pressure drop.

Similar content being viewed by others

Abbreviations

- V:

-

Velocity, m s−1

- d:

-

Diameter, m

- L:

-

Length, m

- T:

-

Temperature, OC

- Cp :

-

Specific Heat, J.kg−1 K−1

- Q:

-

Heat transfer

- K:

-

Thermal conductivity, W.m−1 K−1

- h:

-

Heat transfer coefficient, W.m−2 K−1

- Re:

-

Reynolds Number

- Nu:

-

Nusselt Number

- Pr:

-

Prandtl Number

- f:

-

Friction factor

- ΔP:

-

Pressure Drop, bar

- D:

-

Tape width, m

- H:

-

Pitch length of tape, m

- U:

-

Uncertainty

- X:

-

Sample mean

- n:

-

Sample size

- ρ:

-

Density, kg m−3

- μ:

-

Dynamic Viscosity, kg.m s−1

- ϕ:

-

Volume concentration

- σ:

-

Standard Deviation

- nf:

-

Nanofluid

- bf:

-

Base fluid

- f:

-

Fluid

- P:

-

Particle

- W:

-

Water

- m:

-

Mass

- h:

-

Hot fluid

- c:

-

Cold fluid

- hi:

-

Hot fluid inlet

- ho:

-

Hot fluid outlet

- ci:

-

Cold fluid inlet

- co:

-

Cold fluid outlet

- DPHE:

-

Double Pipe Heat Exchanger

- TR:

-

Twist Ratio

- LMTD:

-

Logarithmic Mean Temperature Difference

- TPF:

-

Thermal Performance Factor

References

Anoop K, Cox J, Sadr R (2013) Thermal evaluation of nanofluids in heat exchangers. Int Commun Heat Mass Transf 49:5–9

Maddah H, Alizadeh M, Ghasemi N, Alwi SRW (2014) Experimental study of Al2O3/water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int J Heat Mass Transf 78:1042–1054

Rabienataj Darzi AA, Farhadi M, Sedighi K (2013) Heat transfer and flow characteristics of AL2O3-water nanofluid in a double tube heat exchanger. Int Commun Heat Mass Transf 47:105–112

Omidreza S, Mohammed HA, Marjan B-N, Wahid MA (2016) Heat transfer and nanofluid flow characteristics through a circular tube fitted with helical tape inserts. Int Commun Heat Mass Transf 71:234–244

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. J Heat Transf 125(ASME):567–574

Notter RH, Rouse MW (1972) A solution the Graetz problem-III. Fully developed region heat transfer rates. Chem Eng Sci 27:2073–2093

Choi SUS (1995) Enhancing thermal conductivity of fluid with nanoparticles. In: Signer DA, Wang HP (eds) Developments and applications of non-newtonian flows, FED-V.231/MD-V.66. ASME, New York, pp 99–105

Bhuiya MMK, Chowdhury MSU, Shahabuddin M, Saha M, Memon LA (2013) Thermal characteristics in a heat exchanger tube fitted with triple twisted tape inserts. Int Commun Heat Mass Transf 48:124–132

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2010) Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int Commun Heat Mass Transf 37:39–46

Seemawute P, Eiamsa-ard S (2010) Thermohydraulics of turbulent flow through a round tube by a peripherally-cut twisted tape with an alternate axis. Int Commun Heat Mass Transf 37:652–659

Eiamsa-ard S, Wong SR, Promvonge P (2009) Turbulent convection in round tube equipped with propeller type swirl generators. Int Commun Heat Mass Transf 36:357–364

Ghozatloo A, Rashidi A, Shariaty-Niassar M (2014) Convective heat transfer enhancement of graphene nanofluids in shell and tube heat exchanger. Exp Thermal Fluid Sci 53:136–141

Reddy MCS, Rao VV (2014) Experimental investigation of heat transfer coefficient and friction factor of ethylene glycol water-based TiO2 nanofluid in a double pipe heat exchanger with and without helical coil inserts. Int Commun Heat Mass Transf 50:68–76

Wongcharee K, Eiamsa-ard S (2012) Heat transfer enhancement by using CuO/water nanofluid in corrugated tube equipped with twisted tape. Int Commun Heat Mass Transf 39:251–257

Ravi Kumar NT, Bhramara P, BirhanuMulat A, SyamSundar L, Singh MK, Sousa ACM (2017) Heat transfer, friction factor and effectiveness analysis of Fe3O4/water nanofluid flow in a double pipe heat exchanger with return bend. Int Commun Heat Mass Transf 81:155–163

P.V. Durga Prasad and A. V. S. S. K. S. Gupta, (2012) Augmentation of heat transfer and pressure drop characteristics inside a double pipe U-Tube heat exchanger by using twisted tape inserts, emerging trends in science, engineering and technology, lecture notes in mechanical engineering, https://doi.org/10.1007/978-81-322-1007-83, Springer India

Hegde RN, Rao SS, Reddy R (2012) Flow visualization and study of critical heat flux enhancement in pool boiling with Al2O3-water nano-fluids. Therm Sci 16(2):445–453

Kline SJ, McClintock F (1953) Describing uncertainties in single-sample experiments. Mech Eng 75(1):3–8

Arya H, Sarafraz MM, Pourmehran O, Arjomandi M (2019) Heat transfer and pressure drop characteristics of MgO nanofluid in a double pipe heat exchanger. Heat Mass Transf, Springer Berlin Heidelberg 55(6):1769–1781

Qi C, Liu M, Tang J (2019) Influence of triangle tube structure with twisted tape on the thermohydraulic performance of nanofluids in heat-exchange system based on thermal and exergy efficiency. Energy Convers Manag 192:243–268. https://doi.org/10.1016/j.enconman.2019.04.047

Ranjbarzadeh R, Isfahani AHM, Hojaji M (2018) Experimental investigation of heat transfer and friction coefficient of the water/graphene oxide nanofluid in a pipe containing twisted tape inserts under air cross-flow. Exp Heat Transf, A Journal of Thermal Energy Generation, Transport, Storage, and Conversion 31:373–390. https://doi.org/10.1080/08916152.2018.1431736

Rashidi S, Eskandarian M, Mahian O, Poncet S (2018) Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim 135:437–460. https://doi.org/10.1007/s10973-018-7070-9

Bahiraeia M, Salmia HK, Safaeib MR (2019) Effect of employing a new biological nanofluid containing functionalized graphene nanoplatelets on thermal and hydraulic characteristics of a spiral heat exchanger. Energy Convers Manag 180:72–82. https://doi.org/10.1016/j.enconman.2018.10.098

Aghayari R, Maddah H, Ashori F, Hakiminejad A, Aghili M (2015) Effect of nanoparticles on heat transfer in mini double-pipe heat exchangers in turbulent flow. Heat Mass Transf, Springer-Verlag Berlin Heidelberg 51:301–306. https://doi.org/10.1007/s00231-014-1415-0

Hegde RN, Rao SS, Reddy RP (2012) Investigations on heat transfer enhancement in pool boiling with water-CuO nanofluids. J Therm Sci, Springer-Science Press 21(2):179–183

Choi SUS (1998) “Nanofluid technology,” current status and future research. Argonne National Lab, Lemont

Heris SZ, Nasr Esfahany M, Etemad G (2007) Numerical investigation of nanofluid laminar convective heat transfer through a circular tube. Numer Heat Transf A Appl 52(11):1043–1058

Hazbehian M, Maddah H, Mohammadiun H, Alizadeh M (2016) Experimental investigation of heat transfer augmentation inside double pipe heat exchanger equipped with reduced width twisted tapes inserts using polymeric nanofluid. Heat Mass Transf, Springer-Verlag Berlin Heidelberg 52:2515–2529

Acknowledgements

The authors acknowledge VGST (Vision Group on Science and Technology), State Government of Karnataka, India, for the funding granted under the KFIST- L1 scheme bearing GRD No 476.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Uncertainty Calculations

Appendix: Uncertainty Calculations

1.1 Reynolds number

1.2 Heat transfer coefficient

1.3 Nusselt Number

1.4 Friction factor

1.5 Overall uncertainty

Rights and permissions

About this article

Cite this article

Murthy, H.M.S., Hegde, R.N. Investigations on thermal characteristics in a double pipe fitted with circular finned and frequently spaced helical twisted inserts and Graphene oxide nanofluid. Heat Mass Transfer 56, 2667–2679 (2020). https://doi.org/10.1007/s00231-020-02890-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02890-1