Abstract

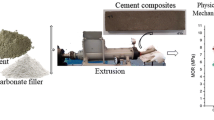

The main objective of this study was to investigate a zero-waste restoration and reprocessing method of carbon/epoxy prepreg. We studied a series of chemical and thermal treatments to reshape and re-strengthen pre-impregnated (prepreg) carbon fiber-reinforced polymer (CFRP) composite rolls that were cured over the shelf, never been used, and would otherwise be discarded. The proposed treatment method is of high interest in minimizing solid waste and reducing the environmental footprint of polymer composites. We used a series of solvents (water, ethanol, N, N- Dimethylformamide (DMF) and Sulfuric Acid) to induce ductility in the scrap already rigid self-cured specimens. The chemical treatments of the scraps using mixtures of DMF-Water or DMF-Ethanol enhanced the ductility of the samples without any negative impact on the mechanical properties. However, the chemical treatment of scarps using a mixture of sulfuric acid with other solvents, could not improve the ductility of the samples. Heat pressing the chemically treated samples further enhanced the ductility of the samples and flattened the scrap composites. The recovered strength and modulus of the recycled prepreg CFRP reached a promising value of over 65% of the original properties, where the samples treated with a mixture of DMF-ethanol preserved their mechanical properties better than other treated samples. The simple, safe, and zero-waste recycling technique presented in this study has proven to be effective for closing the life cycle of a thermoset polymer composite.

Similar content being viewed by others

References

Mangalgiri, P.D.: Composite materials for aerospace applications. Bull. Mater. Sci. 22, 657–664 (1999)

Adam, H.: Carbon fibre in automotive applications. Mater. Des. 18, 349–355 (1997)

Pimenta, S., Pinho, S.T.: Pinho. Recycling carbon fibre reinforced polymers for structural applications: technology review and market outlook. Waste Manag. 31, 378–392 (2011)

Schinner, G., Brandt, J., Richter, H.: Recycling carbon-fiber-reinforced thermoplastic composites. J. Thermoplast. Compos. Mater. 9(3), 239–245 (1996)

Li, H., Englund, K.: Recycling of carbon fiber reinforced thermoplastic composite wastes from the aerospace industry. J. Compos. Mater. 51(9), 1265–1273 (2017)

Fried, J.R.: Polymer Science & Technology. Pearson Education, United States of America: Hoboken, (2003)

Palmer, J., Ghita, O.R., Savage, L., Evans, K.E.: Successful closed-loop recycling of thermoset composites. Composites Part A. 40, 490–498 (2009)

Oliveux, G., Dandy, L., Leeke, G.: Current status of recycling of fibre reinforced polymers: review of technologies, reuse and resulting properties. Prog. Mater. Sci. 72, 61–99 (2015)

Liu, Y., Farnsworth, M., Tiwari, A.: A review of optimization techniques used in the composite recycling area: state-of-the-art and steps towards a research agenda. Clean. Prod. 140, 1775–1781 (2017)

Thomas, C., Borges, P.H.R., Panzera, T.H., Cimentada, A., Lombillo, I.: Epoxy composites containing CFRP powder wastes. Composites Part B. 59, 260–268 (2014)

Ogi, K., Shinoda, T., Mizui, M.: Strength in concrete reinforced with recycled CFRP pieces. Composites Part A. 36, 893–902 (2005)

Wong, K., Rudd, C., Pickering, S., Liu, X.L.: Composites recycling solutions for the aviation industry. Sci. China Technol. Sci. 60, 1291–1300 (2017)

Meyer, L.O., Schulte, K.: CFRP-recycling following a pyrolysis route: process optimization and potentials. Compos. Mater. 43, 1121–1132 (2009)

Pickering, S.J., Liu, Z., Turner, T.A., Wong, K.H.: Applications for carbon fibre recovered from composites. IOP Conf Ser Mater Sci Eng. 139, 012005 (2016)

Piñero-Hernanz, R., Dodds, C., Hyde, J., García-Serna, J., Poliakoff, M., Lester, E., Cocero, M.J., Kingman, S., Pickering, S., Wong, K.H.: Chemical recycling of carbon fibre reinforced composites in nearcritical and supercritical water. Composites Part A. 39, 454–461 (2008)

Feraboli, P., Kawakami, H., Wade, B., Gasco, F., DeOto, L., Masini, A.: Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 46(12), 1459–1473 (2011)

Xu, P., Li, J., Ding, J.: Chemical recycling of carbon fibre/epoxy composites in a mixed solution of peroxide hydrogen and N, N-dimethylformamide. Compos. Sci. Technol. 82, 54–59 (2013)

Mastali, M., et al.: The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Composites Part B. 92, 360–376 (2016)

Asmatulu, E., Twomey, J., Overcash, M.: Recycling of fiber-reinforced composites and direct structural composite recycling concept. Compos Mater. 48, 593–608 (2014)

Mamanpush, S.H., Li, H., Englund, K., Tabatabaei, A.T.: Dataset demonstrating physical properties of recycled wind turbine blade composites. Data Brief. 20, 658–661 (2018)

Souza, C., Opelt, C., Candido, G., Souza, S.D.B., Botelho, E., Marlet, J.M., Rezende, M.: Reuse of uncured carbon fibre/epoxy resin Prepreg scraps: mechanical behavior & environmental response. ACS Sustain. Chem. Eng. 7(2), 2200–2206 (2019)

Nilakantan, G., Nutt, S.: Reuse and upcycling of thermoset prepreg scrap: case study with out-of-autoclave carbon fiber/epoxy prepreg. J. Compos. Mater. 52(3), 341–360 (2018)

Nilakantan, G., Nutt, S.: Reuse and upcycling of aerospace prepreg scrap and waste. Reinf. Plast. 59(1), 44–51 (2015)

Adams, R.D., Collins, A., Cooper, D., Wingfield-Digby, M., Watts-Farmer, A., Laurence, A., Patel, K., Stevens, M., Watkins, R.: Recycling of reinforced plastics. Appl. Compos. Mater. 21, 263–284. Aug 2019 (2014)

Corcione, C.E., Freuli, F., Frigione, M.: Cold curing structural epoxy resins: analysis of the curing reaction as a function of curing time and thickness. Mater. 7, 6832–6842 (2017)

Gul, S., Shah, A.A., Bilal, S.: Calculation of activation energy of degradation of polyaniline-dodecylbenzene sulfonic acid salts via TGA. J Sci Innov Res. 2(3), 673–684 (2013)

ASTM: D3039 / D3039M-17, Standard test method for tensile properties of polymer matrix composite materials. ASTM International, West Conshohocken (2017) www.astm.org

Kong, E.S.: Physical aging in epoxy matrices and composites. In: Dusek, K. (ed.) Epoxy Resins and Composites IV, pp. 125–171 (2005)

Hepburn, D.M., Kemp, I.J., Shields, A.J., Cooper, J.: Degradation of epoxy resin by partial discharges. IEEE Proc. Sci. Meas. Technol. 147, 97–104 (2000)

Huang, Y., Ge, Z., Zhao, C., Dong, J., Shitian, M., Ma, W., Wang, G., Qian, X.: Solvothermal recovery of carbon fibers from thermoset polymer-based carbon fiber reinforced polymers. J. Reinf. Plast. Compos. 34(20), 1673–1683 (2015)

Sun, J., Li, H., Wang, C., Yuan, D., Stubbs, L.P., He, C.: The effect of residual solvent N, N′- Dimethylformamide on the curing reaction and mechanical properties of epoxy and lignin epoxy Composites. Macromol. Chem. Phys. 217, 1065–1073 (2016)

Lau, K., Lu, M., Lam, C., Cheung, H., Sheng, F., Li, H.: Thermal and mechanical properties of single-walled carbon nanotube bundle-reinforced epoxy nanocomposites: the role of solvent for nanotube dispersion. Compos. Sci. Technol. 65, 719–725 (2005)

Ren, Y.K., Liu, S.D., Duan, B., Xu, Y.F., Li, Z.Q., Huang, Y., Hu, L.H., Zhu, J., Dai, S.Y.: Controllable intermediates by molecular self-assembly for optimizing the fabrication of large-grain perovskite films via one-step spin coating. J. Alloys Compd. 705, 205–210 (2017)

Rodríguez-González, J.A., Rubio-González, C., Meneses-Nochebuena, C.A., González-García, P., Licea-Jiménez, L.: Enhanced interlaminar fracture toughness of unidirectional carbon fiber/epoxy composites modified with sprayed multi-walled carbon nanotubes. Compos Interface. 24, 883–896 (2017)

Acknowledgements

The authors would like to acknowledge the financial support of the National Council for Scientific Research – Lebanon (CNRS-L) and the University Research Board (URB) at the American University of Beirut.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ajam, A., Tehrani-Bagha, A., Mustapha, S. et al. Zero-Waste Recycling of Shelf-Cured Pre-Impregnated Carbon Fiber Reinforced Epoxy Laminae. Appl Compos Mater 27, 357–373 (2020). https://doi.org/10.1007/s10443-020-09821-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09821-7