Abstract

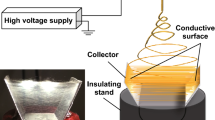

Following recent insights on structure-cell-function interactions and the critical role of the extracellular matrix (ECM), the latest biofabrication approaches have increasingly focused on designing materials with biomimetic microarchitecture. Divergence electrospinning is a novel fabrication method for three-dimensional (3D) nanofiber scaffolds. It is introduced to produce 3D nanofiber mats that have numerous applications in regenerative medicine and tissue engineering. One of the most important characteristics of 3D nanofiber mats is the density gradient. This study provides a statistical analysis and response surface modeling framework based on experimental data to evaluate the manner by which the geometric designs of double-bevel collectors influence the fiber density gradient. Specifically, variance of analysis and sensitivity analysis were performed to identify parameters that had significant effects, and a response surface model embedded with seven location indicators was developed to predict the spatial distribution of fiber density for different collector designs. It was concluded that the collector height, bevel angle, and their interactions were significant factors influencing the density gradient. This study revealed the sensitivity of system configuration and provided an optimization tool for process controllability of microstructure gradients.

Similar content being viewed by others

References

Jin G, He R, Sha B et al (2018) Electrospun three-dimensional aligned nanofibrous scaffolds for tissue engineering. Mater Sci Eng C 92:995–1005

Cui W, Zhou Y, Chang J (2010) Electrospun nanofibrous materials for tissue engineering and drug delivery. Sci Technol Adv Mater 11(1):014108

Kowalewski TA, Barral S, Kowalczyk T (2009) Modeling electrospinning of nanofibers. In: Proceedings of the IUTAM symposium on modelling nanomaterials and nanosystems, Aalborg, Denmark, 19–22 May 2008, pp 279–292

Šimko M, Lukáš D (2016) Mathematical modeling of a whipping instability of an electrically charged liquid jet. Appl Math Model 40(21/22):9565–9583

Taylor GI (1969) Electrically driven jets. Proc R Soc Lond A 313(1515):453–475

Li WJ, Laurencin CT, Caterson EJ et al (2002) Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res 60(4):613–621

Rezvani Z, Venugopal JR, Urbanska AM et al (2016) A bird’s eye view on the use of electrospun nanofibrous scaffolds for bone tissue engineering: current state-of-the-art, emerging directions and future trends. Nanomed Nanotechnol Biol Med 12(7):2181–2200

Rim NG, Shin CS, Shin H (2013) Current approaches to electrospun nanofibers for tissue engineering. Biomed Mater 8(1):014102

Park JS (2011) Electrospinning and its applications. Adv Nat Sci Nanosci Nanotechnol 1(4):043002. https://doi.org/10.1088/2043-6262/1/4/043002

Jiang T, Carbone EJ, Lo KWH et al (2015) Electrospinning of polymer nanofibers for tissue regeneration. Prog Polym Sci 46:1–24

Zhou Y, Hu Z, Du D et al (2018) The effects of collector geometry on the internal structure of the 3D nanofiber scaffold fabricated by divergent electrospinning. Int J Adv Manuf Technol 100:3045–3054

Zhou Y, Tan GZ (2018) Generation of 3D nanofiber structure by divergence electrospinning for tissue engineering scaffold. In: The 13th international manufacturing science and engineering conference, American Society of Mechanical Engineers, College Station, Texas, USA

Tan GZ, Zhou Y (2018) Tunable 3D nanofiber architecture of polycaprolactone by divergence electrospinning for potential tissue engineering applications. Nano Micro Lett 10(4):73. https://doi.org/10.1007/s40820-018-0226-0

Montgomery DC (2017) Design and analysis of experiments. Wiley, New York

Wu CJ, Hamada MS (2011) Experiments: planning, analysis, and optimization. Wiley, New York

Jeff CFH (2009) Experiments: planning, analysis, and optimization. Wiley, New York

Becker W, Tarantola S, Deman G (2018) Sensitivity analysis approaches to high-dimensional screening problems at low sample size. J Stat Comput Simul 88(11):2089–2110

Becker W, Rowson J, Oakley J et al (2011) Bayesian sensitivity analysis of a model of the aortic valve. J Biomech 44(8):1499–1506

Subia B, Kundu J, Kundu S (2010) Biomaterial scaffold fabrication techniques for potential tissue engineering applications. Tissue Engineering, London

Lund AW, Yener B, Stegemann JP et al (2009) The natural and engineered 3D microenvironment as a regulatory cue during stem cell fate determination. Tissue Eng B Rev 15(3):371–380

Michel G, Tonon T, Scornet D et al (2010) The cell wall polysaccharide metabolism of the brown alga Ectocarpus siliculosus. Insights into the evolution of extracellular matrix polysaccharides in Eukaryotes. New Phytol 188(1):82–97

Alberts B, Bray D, Hopkin K et al (2013) Essential cell biology. Garland Science, New York

Ahn H, Kim KJ, Park SY et al (2014) 3D braid scaffolds for regeneration of articular cartilage. J Mech Behav Biomed Mater 34:37–46

Tamayol A, Akbari M, Annabi N et al (2013) Fiber-based tissue engineering: progress, challenges, and opportunities. Biotechnol Adv 31(5):669–687

Younesi M, Islam A, Kishore V et al (2014) Tenogenic induction of human MSCs by anisotropically aligned collagen biotextiles. Adv Func Mater 24(36):5762–5770

Pedde RD, Mirani B, Navaei A et al (2017) Emerging biofabrication strategies for engineering complex tissue constructs. Adv Mater 29(19):1606061. https://doi.org/10.1002/adma.201606061

Cui L, Zhang N, Cui W et al (2015) A novel nano/micro-fibrous scaffold by melt-spinning method for bone tissue engineering. J Bionic Eng 12(1):117–128

Puppi D, Mota C, Gazzarri M et al (2012) Additive manufacturing of wet-spun polymeric scaffolds for bone tissue engineering. Biomed Microdevice 14(6):1115–1127

Jun Y, Kang E, Chae S et al (2014) Microfluidic spinning of micro-and nano-scale fibers for tissue engineering. Lab Chip 14(13):2145–2160

Khalili S, Nouri Khorasani S, Razavi M et al (2018) Nanofibrous scaffolds with biomimetic structure. J Biomed Mater Res A 106(2):370–376

Choi JS, Lee SJ, Christ GJ et al (2008) The influence of electrospun aligned poly (epsilon-caprolactone)/collagen nanofiber meshes on the formation of self-aligned skeletal muscle myotubes. Biomaterials 29(19):2899–2906

Yeo M, Kim GH (2018) Anisotropically aligned cell-laden nanofibrous bundle fabricated via cell electrospinning to regenerate skeletal muscle tissue. Small 14(48):1803491. https://doi.org/10.1002/smll.201803491

Ghasemi-Mobarakeh L, Prabhakaran MP, Morshed M et al (2008) Electrospun poly (ɛ-caprolactone)/gelatin nanofibrous scaffolds for nerve tissue engineering. Biomaterials 29(34):4532–4539

Gnavi S, Fornasari B, Tonda-Turo C et al (2018) In vitro evaluation of gelatin and chitosan electrospun fibres as an artificial guide in peripheral nerve repair: a comparative study. J Tissue Eng Regen Med 12(2):679–694

Kitsara M, Agbulut O, Kontziampasis D et al (2017) Fibers for hearts: a critical review on electrospinning for cardiac tissue engineering. Acta Biomater 48:20–40

Sahoo S, Ouyang H, Goh JCH et al (2006) Characterization of a novel polymeric scaffold for potential application in tendon/ligament tissue engineering. Tissue Eng 12(1):91–99

Vaquette C, Sudheesh Kumar P, Petcu EB et al (2018) Combining electrospinning and cell sheet technology for the development of a multiscale tissue engineered ligament construct (TELC). J Biomed Mater Res B Appl Biomater 106(1):399–409

Shalumon K, Sheu C, Chen CH et al (2018) Multi-functional electrospun antibacterial core-shell nanofibrous membranes for prolonged prevention of post-surgical tendon adhesion and inflammation. Acta Biomater 72:121–136

Li WJ, Tuli R, Okafor C et al (2005) A three-dimensional nanofibrous scaffold for cartilage tissue engineering using human mesenchymal stem cells. Biomaterials 26(6):599–609

Girão AF, Semitela Â, Ramalho G et al (2018) Mimicking nature: fabrication of 3D anisotropic electrospun polycaprolactone scaffolds for cartilage tissue engineering applications. Compos B Eng 154:99–107

Therapeutic Category, and Segment Forecasts, 2018–2025 (2017) Regenerative medicine market analysis by product (therapeutics {primary cell-based, stem cell-based, immunotherapies, and gene therapies}, tools, banks, and services). Grand View Research

Tseng Q, Duchemin-Pelletier E, Deshiere A et al (2012) Spatial organization of the extracellular matrix regulates cell–cell junction positioning. Proc Natl Acad Sci 109(5):1506–1511

Geckil H, Xu F, Zhang X et al (2010) Engineering hydrogels as extracellular matrix mimics. Nanomedicine 5(3):469–484

He J, Qin T, Liu Y et al (2014) Electrospinning of nanofibrous scaffolds with continuous structure and material gradients. Mater Lett 137:393–397

Samavedi S, Horton CO, Guelcher SA et al (2011) Fabrication of a model continuously graded co-electrospun mesh for regeneration of the ligament–bone interface. Acta Biomater 7(12):4131–4138

Singh M, Dormer N, Salash JR et al (2010) Three-dimensional macroscopic scaffolds with a gradient in stiffness for functional regeneration of interfacial tissues. J Biomed Mater Res A 94(3):870–876

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaman, M.A.U., Sooriyaarachchi, D., Zhou, YG. et al. Modeling the density gradient of 3D nanofiber scaffolds fabricated by divergence electrospinning. Adv. Manuf. 9, 414–429 (2021). https://doi.org/10.1007/s40436-020-00307-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-020-00307-0