Abstract

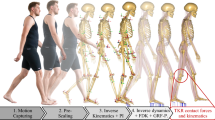

A new approach of coupling multibody dynamics and fluid dynamics is developed to model hydrodynamic lubrication of spherical clearance joints with thin fluid film and relative multidirectional motion. The model accounts for dynamics motion of articulating components as well as both squeeze- and wedge-film actions of the synovial fluid. Multibody dynamics methodology is employed to derive the motion equations and Reynolds equation governs the fluid dynamics. The finite difference method is utilized to discretize the governing equation of lubricant and the multi-grid method augments computational efficiency to acquire outcomes employing a Gauss–Seidel relaxation scheme. Fluid–structure interaction is incorporated into the methodology using a partitioned formulation embedded in a high-order Runge–Kutta time integrators for integrating the nonlinear equations of the coupled system over time of interest. A demonstrative example of total hip arthroplasty is considered and the developed model is assessed against outcomes available in the literature. The effect of initial conditions on the pressure, film thickness and dynamics of the lubricated spherical joint is analyzed and discussed. It is illustrated that maximum fluid pressure is undergone by the hip implant at the first walking cycle of movement due to an unstable state, which is strongly dependent upon the initial condition. Finally, the approach presented in this research work is a robust dynamic model to study hydrodynamic lubrication of spherical joints.

Similar content being viewed by others

Abbreviations

- Cl :

-

Clearance size

- D :

-

Non-dimensional hydrodynamic parameter

- \({\mathbf {e}}=\left( e_{x}{,}e_{y}{,}e_{z} \right) \) :

-

The eccentricity vector in Cartesian coordinate system

- \(e=\left\| {\mathbf {e}} \right\| \) :

-

The size of eccentricity vector

- \({\dot{e}}\) :

-

The time rate of the size of the eccentricity vector

- \({\mathbf {e}}_{r_{e}}\), \({\mathbf {e}}_{\theta _{e}}\) and \({\mathbf {e}}_{\varphi _{e}}\) :

-

The local orthogonal unit vectors at the head center

- \({\mathbf {e}}_{r}\), \({\mathbf {e}}_{\theta }\), \({\mathbf {e}}_{\varphi }\) :

-

The local orthogonal unit vectors

- \({\mathbf {F}}\) :

-

The force vector

- \({\mathbf {f}=}\left( f_{x}{,}f_{y}{,}f_{z} \right) \) :

-

Physiological force vector and its components

- \({\mathbf {f}}^{\mu }=\left( f_{x}^{\mu }{,}f_{y}^{\mu }{,}f_{z}^{\mu } \right) \) :

-

Friction force vector

- \({\mathbf {f}}^{L}=\left( f_{x}^{L}{,}f_{y}^{L}{,}f_{z}^{L} \right) \) :

-

Resultant fluid force vector

- h :

-

Fluid-film thickness

- \(h_{{\min }}\) :

-

Minimum film thickness

- \({\bar{H}}\) :

-

The element size of the coarse mesh

- L :

-

An operator

- \({\mathbf {M}}\) :

-

The mass matrix of the system

- \(O_{b}\) and \(O_{c}\) :

-

Centers of the femoral head and cup, respectively

- P :

-

Fluid pressure

- \({\bar{P}} \) :

-

A constant pressure

- P :

-

Normalized fluid pressure

- \({}_{i}^{n} p,i=1\ldots 6\) :

-

The normalized pressure profile at time \(t_{n}\) and the ith increment calculation in the Cash–Karp method

- \(\ddot{\mathbf{q}}\) :

-

The acceleration vector

- \(Q_{h}\) and \(Q_{c}\) :

-

The points on the head and cup surfaces, respectively

- \(R_{c}\) :

-

The radius of the cup

- \(\mathbf {r}_{{i}{,}{j}}^{{\bar{h}}}\) :

-

Residual magnitude

- t :

-

Time (s)

- \(U_{\theta }\) and \(U_{\varphi }\) :

-

The tangential velocity components at any point, e.g. \(Q_{h}\)

- \(v_{i{,}j}^{{\bar{h}}}\) :

-

Error magnitude

- \({\mathbf {V}}_{O_{h}}\) :

-

The velocity vector of the head center

- \({\mathbf {V}}_{Q_{h}}\) :

-

The velocity vector at point \(Q_{h}\)

- \({\mathbf {V}}_{Q_{h}}^{n}\) :

-

Normal velocity vector at point \(Q_{h}\)

- \({\mathbf {V}}_{Q_{h}}^{t}\) :

-

Tangential velocity vector at point \(Q_{h}\)

- \({\mathbf {V}}_{Q_{h}{/}O_{h}}\) :

-

The velocity vector of point \(Q_{h}\) with respect to the head center

- \(e_{x}\), \(e_{y}\), \(e_{z}\) :

-

Coordinates of the center of the femoral head

- \(\mathbf{y }_{n}\) :

-

The state variable of the system at time \(t_{n}\)

- \(\beta \) :

-

The cup angle

- \(\theta \) and \(\varphi \) :

-

Azimuthal and polar angles

- \(\theta _{e}\) and \(\varphi _{e}\) :

-

Azimuthal and polar angles of the eccentricity vector

- \(\Delta \theta \) and \({\Delta }\varphi \) :

-

Element size in azimuthal and polar directions

- \({\Delta }t\) :

-

The size of time step

- \({\varvec{\Omega }} =(\omega _{x},\omega _{y},\omega _{z})\) :

-

Angular velocity vector

- \(\mu \) :

-

Lubricant viscosity

- \(\tau _{\theta }\) and \(\tau _{\varphi }\) :

-

Shear stresses

- \({\varvec{\nabla }} \) :

-

Del (nabla) in the spherical coordinate system

References

Shabana, A.A.: Computational Dynamics, 3rd edn. Wiley, New York (2010)

Nikravesh, P.E.: Computer-Aided Analysis of Mechanical Systems. Prentice-Hall, Englewood Cliffs (1988)

Zhao, B., Cui, Y., Xie, Y., Zhou, K.: Dynamics and lubrication analyses of a planar multibody system with multiple lubricated joints. Proc. IMechE Part J: J. Eng. Tribol. 232(3), 326–346 (2018)

Pinkus, O., Sternlicht, S.A.: Theory of Hydrodynamic Lubrication. McGraw-Hill, New York (1961)

Daniel, G.B., Machado, T.H., Cavalca, K.L.: Investigation on the influence of the cavitation boundaries on the dynamic behavior of planar mechanical systems with hydrodynamic bearings. Mech. Mach. Theory 99, 19–36 (2016)

Tian, Q., Lou, J., Mikkola, A.: A new elastohydrodynamic lubricated spherical joint model for rigid-flexible multibody dynamics. Mech. Mach. Theory 107, 210–228 (2017)

Reynolds, O.: On the theory of lubrication and its application to Mr. Beauchamp Tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. R. Soc. Lond. (1886)

Hamrock, B.J.: Fundamentals of Fluid Film Lubrication. McGraw-Hill, New York (1994)

Hou, G., Wang, J., Layton, A.: Numerical methods for fluid-structure interaction—a review. Commun. Comput. Phys. 12(2), 337–377 (2012)

Dowell, E.H., Hall, K.C.: Modeling of fluid–structure interaction. Annu. Rev. Fluid Mech. 33, 445–490 (2001)

Chakrabarti, S.K.: Numerical Models in Fluid Structure Interaction, Advances in Fluid Mechanics, vol. 42. WIT Press, Cambridge (2005)

Malvandi, A., Ghasemi, A., Nikbakhti, R., Ghasemi, A., Hedayati, F.: Modeling and parallel computation of the non-linear interaction of rigid bodies with incompressible multi-phase flow. Comput. Math. Appl. 72, 1055–1065 (2016)

Flores, P., Ambrósio, J., Claro, J.P.: Dynamic analysis for planar multibody mechanical systems with lubricated joints. Multibody Syst. Dyn. 12, 47–74 (2004)

Tian, Q., Zhang, Y.Q., Chen, L.P., Flores, P.: Dynamics of spatial flexible multibody systems with clearance and lubricated spherical joints. Comput. Struct. 87, 913–929 (2009)

Flores, P., Lankarani, H.M.: Spatial rigid-multi-body systems with lubricated spherical clearance joints: modeling and simulation. Nonlinear Dyn. 60(1–2), 99–114 (2010)

Daniel, G.B., Cavalca, K.L.: Analysis of the dynamics of a slider-crank mechanism with hydrodynamic lubrication in the connecting rod-slider joint clearance. Mech. Mach. Theory 46, 1434–1452 (2011)

Zhang, H., Zhang, X., Zhan, Z., Yang, L.: Dynamic modeling and comparative analysis of a 3-PRR parallel robot with multiple lubricated joints. Int. J. Mech. Mater. Des. (2019). https://doi.org/10.1007/s10999-019-09479-5

Fang, C., Meng, X., Lu, Z., Wue, G., Tang, D., Zhao, B.: Modeling a lubricated full-floating pin bearing in planar multibody systems. Tribol. Int. 131, 222–237 (2016)

Zhuang, X., Afshari, S.S., Yu, T., Liang, X.: A hybrid model for wear prediction of a single revolute joint considering a time-varying lubrication condition. Wear (2019). https://doi.org/10.1016/j.wear.2019.203124

Denni, M., Biboulet, N., Abousleiman, V., Lubrecht, A.A.: Dynamic study of a roller bearing in a planetary application considering the hydrodynamic lubrication of the roller/cage contact. Tribol. Int. (2019). https://doi.org/10.1016/j.triboint.2019.03.054

Andersen, M.S., Damsgaard, M., MacWilliams, B., Rasmussen, J.: A computationally efficient optimisation-based method for parameter identification of kinematically determinate and over-determinate biomechanical systems. Comput. Methods Biomech. Biomed. Eng. 13, 171–183 (2010)

Ambrosio, J.: Rigid and flexible multibody dynamics tools for the simulation of systems subjected to contact and impact conditions. Eur. J. Solids A/Solids 19, S23–44 (2000)

Stops, A., Wilcox, R., Jin, Z.: Computational modelling of the natural hip: a review of finite element and multibody simulations. Comput. Methods Biomech. Biomed. Eng. 15(9), 963–979 (2012)

Askari, E., Flores, P., Dabirrahmani, D., Appleyard, R.: Dynamic modeling and analysis of wear in spatial hard-on-hard couple hip replacements using multibody systems methodologies. Nonlinear Dyn. 82, 1039–1058 (2015)

Askari, E., Flores, P., Dabirrahmani, D., Appleyard, R.: Nonlinear vibration and dynamics of ceramic on ceramic artificial hip joints: a spatial multibody modelling. Nonlinear Dyn. 76(2), 1365–1377 (2014)

Kang, J.: Numerical calculation of hip squeak over the normal gait cycle. Int. J. Precis. Eng. Manuf. 20, 2205–2214 (2019)

Kurtz, S., Ong, K., Lau, E., Mowat, F., Halpern, M.: Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. J. Bone Joint Surg. 89(4), 780–785 (2007)

Canadian Joint Replacement Registry: Annual Report. Canadian institute for health information, Canada (2014)

NJR 10th Annual Report 2013, National Joint Registry UK

Askari, E., Flores, P., Dabirrahmani, D., Appleyard, R.: A review of squeaking in ceramic total hip prostheses. Tribol. Int. 93, 239–256 (2016)

Goenka, P.K., Booker, J.F.: Spherical bearings: static and dynamics analysis via the finite element method. ASME J. Lubr. Technol. 102(7), 308–319 (1980)

Ai, X., Cheng, H.S.: Hydrodynamic lubrication analysis of metallic hip joint. Tribol. Trans. 39(1), 103–111 (1996)

Jin, Z.M., Dowson, D.: A full numerical analysis of hydrodynamic lubrication in artificial hip joint replacements constructed from hard materials. Proc. IMECHE J. Mech. Eng. 213(4), 355–370 (1999)

Jagatia, M., Jin, Z.M.: Elastohydrodynamic lubrication analysis of metal-on-metal hip prostheses under steady state entraining motion. Proc. IMECHE J. Eng. Med. 215(H6), 531–541 (2001)

Jagatia, M., Jalali-Vahid, D., Jin, Z.M.: Elastohydrodynamic lubrication analysis of UHMWPE hip joint replacements under squeeze-. lm motion. Proc. Inst. Mech. Eng. Part H: J. Eng. Med. 215(H2), 141–152 (2001)

Gao, L., Dowson, D., Hewson, R.W.: A numerical study of non-Newtonian transient elastohydrodynamic lubrication of metal-on-metal hip prostheses. Tribol. Int. 93, 486–494 (2016)

Gao, L., Fisher, J., Jin, Z.: Effect of walking patterns on the elastohydrodynamic lubrication of metal-on-metal total hip replacements. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 225, 515–525 (2011)

Gao, L., Wang, F.C., Yang, P.R., Jin, Z.M.: Effect of 3D physiological loading and motion on elastohydrodynamic lubrication of metal-on-metal total hip replacements. Med. Eng. Phys. 31, 720–729 (2009)

Sonntag, R., Reinders, J., Rieger, J.S., Heitzmann, D.W.W., Kretzer, J.P.: Hard-on-hard lubrication in the artificial hip under dynamic loading conditions. PLoS ONE 8, e71622 (2013)

Jin, Z.M.: Theoretical studies of elastohydrodynamic lubrication of artificial hip joints. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 220, 719–727 (2006)

Jalali-Vahid, D., Jin, Z.M.: Transient elastohydrodynamic lubrication analysis of UHMWPE hip joint replacements. J. Mech. Eng. Sci. Proc. Inst. Mech. Eng. 216(C4), 409–420 (2002)

Liu, F., Jin, Z.M., Grigoris, P., Hirt, F., Rieker, C.: Steady-state elastohydrodynamic lubrication analysis of a metal-on-metal hip implant employing a metallic cup with an ultra-high molecular weight polyethylene backing. J. Eng. Med. Proc. Inst. Mech. Eng. 218, 261–270 (2004)

Wang, F.C., Jin, Z.M.: Prediction of elastic deformation of acetabular cup and femoral head for lubrication analysis of artificial hip joints. J. Eng. Tribol. Proc. Inst. Mech. Eng. 218, 201–209 (2004)

Askari, E., Andersen, M.S.: A modification on velocity terms of Reynolds equation in a spherical coordinate system. Tribol. Int. 131, 15–23 (2019)

Ruggiero, A., Sicilia, A.: Lubrication modeling and wear calculation in artificial hip joint during the gait. Tribol. Int. 142, 105993 (2020)

Weiss, C., Hothan, A., Huber, G., Morlock, M., Hoffmann, N.: Friction-induced whirl vibration: root cause of squeaking in total hip arthroplasty. J. Biomech. 45, 297–303 (2012)

Askari, E., Flores, P., Dabirrahmani, D., Appleyard, R.: Study of the friction-induced vibration and contact mechanics of artificial hip joints. Tribol. Int. 70, 1–10 (2014)

Bergmann, G., Bender, A., Dymke, J., Duda, G., Damm, P.: Standardized loads acting in hip implants. PloS ONE 11(5), e0155612 (2016)

Bergmann, G., Deuretzbacher, G., Heller, M., Graichen, F., Rohlmann, A., Strauss, J., et al.: Hip contact forces and gait patterns from routine activities. J. Biomech. 34(7), 859–871 (2001)

Damm, P., Bender, A., Duda, G., Bergmann, G.: In vivo measured joint friction in hip implants during walking after a short rest. Plos ONE 12(3), E0174788 (2017)

Askari, E., Andersen, M.S.: A closed-form formulation for the conformal articulation of metal-on-polyethylene hip prostheses: contact mechanics and sliding distance. Proc. Inst. Mech. Eng. H J. Eng. Med. 232(12), 1–13 (2018)

Askari, E., Andersen, M.S.: A dynamic model of polyethylene damage in dry total hip arthroplasties: wear and creep. Multibody Syst. Dyn. 45, 403–429 (2019)

Szeri, A.Z.: Fluid Film Lubrication: Theory and Design. Cambridge University Press, Cambridge (1998)

Lubrecht, A.A., Ten Napel, W.E., Bosma, R.: Multigrid, an alternative method for calculating film thickness and pressure profiles in elastohydrodynamically lubricated line contacts. J. Tribol. Trans. ASME 108(4), 551–558 (1986)

Brandt, A.: Multi-level adaptive solutions to boundary-value problems. Math. Comput. 31(138), 333–390 (1977)

Venner, CH.: Multilevel solution of the EHL line and point contact problems. PhD thesis, University of Twente, Enschede (N.L.) (1991)

Kapitza, P.L.: Hydrodynamic theory of lubrication during rolling. Zh. Tekh. Fiz. 25(4), 747–762 (1955)

Tank, P.W., Gest, T.R.: Lippincott Williams and Wilkins Atlas of Anatomy. Wol-ters Kluwer Health/Lippincott Williams & Wilkins (2009)

Mattei, L., Di Puccio, F., Piccigallo, B., Ciulli, E.: Lubrication and wear modelling of artificial hip joints: a review. Tribol. Int. 44(5), 532–549 (2011)

Stachowiak, G.W., Batchelor, A.W.: Engineering Tribology. Elsevier, Amsterdam (1993)

Stewart, T.D.: Tribology of artificial joints. Orthop. Trauma 24(6), 435–440 (2010)

Acknowledgements

The authors would express their gratitude to Fundação para a Ciência e a Tecnologia (FCT) for the project “POCI-01-0145-FEDER-028424”, by FEDER funds through the COMPETE 2020 - Programa Operacional Competitividade e Internacionalização. They would also acknowledge FCT for the project with the reference number “UID/EEA/04436/2019”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Matrices in Eq. (6)

where

Appendix B: The multi-grid method

A fine mesh is commonly constructed to compute the lubricant pressure and film thickness using a relaxation method, e.g. Gauss-Seidel iterative method. However, such a solution method has two drawbacks: (1) a very slow convergence of the relaxation process especially for a large number of nodes; and (2) incapability to suppress error components in the solution that have wavelengths larger than the mesh size. The multigrid method allows us to accelerate the convergence of the relaxation process as well as suppress high wavelength errors by making use of coarse meshes within the original fine mesh. For further information about the multigrid method, the reader is referred to the following references [52,53,54]. The matrix form of Eq. (6) for a fine mesh with an even mesh size as \( \Delta \theta = \Delta \varphi ={{\bar{h}}}\), is recast as follows:

where superscript (\({{\bar{h}}})\) is to characterize its mesh size. Equation (B1) is commonly solved using a relaxation method, namely the Gauss-Seidel iterative methodology. Assume after a few sweeps, e.g. 2 or 3, an approximation, \({\tilde{p}}^{\bar{h}}\), to the solution \(p^{{{\bar{h}}}}\) is achieved. The corresponding residual is calculated as follows:

Assuming an exact solution for Eq. (B1) is \(p^{{{\bar{h}}}}\), the operator L is approximated in a proximity of \({\tilde{p}}\) as given by

As we are interested in the exact solution, \({\bar{p}}\), and know that the operator L is linear, the equation is recast as follows:

in which the error is defined as \(v={\bar{p}}-{\tilde{p}}\). After discretizing the cup surface with a uniform mesh of the size \({{\bar{h}}}\), the error and residual can be written on the grid as

Substituting Eqs. (B5) and (B6) into Eq. (B4), the following equation can be written for the error

The right side of Eq. (B7) is known, so it would be solved for the error \(v_{i,j}^{{{\bar{h}}}} \) on the mesh grid. Using the Multigrid method enables us to solve Eq. (B7) for the error by switching the mesh from a fine mesh with the element size of \({{\bar{h}}}\) to a coarse mesh with the element size of 2\({{\bar{h}}}\) that is called \({\bar{H}}\). Numbers of nodes are converted using the following relations, \(i=2I-1\) and \(j=2J-1\), in order to obtaining the \(r_{I,J}^{{\bar{H}}} \), \((C_{6}^{{\bar{H}}} )_{I,J} \) and finally \((L\left( {{\tilde{p}}} \right) ^{{\bar{H}}})_{I,J} \) to rewrite Eq. (B7) in the coarse mesh grid, Eq. (B8).

Equation (B8) is solved using the Gauss–Seidel iterative method until it converges and obtains the solution for the error, \({\bar{v}}^{{\bar{H}}}\). By this time, the error is written in the fine mesh grid using the following relations

Knowing \({\bar{v}}_{i,j}^{\bar{h}}\), the obtained error is added to the approximation for the solution, Eq. (B10). This process is repeated until the solution for Eq. (B1) converges.

Rights and permissions

About this article

Cite this article

Askari, E., Flores, P. Coupling multi-body dynamics and fluid dynamics to model lubricated spherical joints. Arch Appl Mech 90, 2091–2111 (2020). https://doi.org/10.1007/s00419-020-01711-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01711-5