Abstract

Construction issues of high-speed rail infrastructures have been increasingly concerned worldwide, of which the subgrade settlement in soft soil area becomes a particularly critical problem. Due to the high compressibility and low permeability of soft soil, the post-construction settlement of the subgrade is extremely difficult to control in these regions, which seriously threatens the operation safety of high-speed trains. In this work, the significant issues of high-speed railway subgrades in soft soil regions are discussed. The theoretical and experimental studies on foundation treatment methods for ballasted and ballastless tracks are reviewed. The settlement evolution and the settlement control effect of different treatment methods are highlighted. Control technologies of subgrade differential settlement are subsequently briefly presented. Settlement calculation algorithms of foundations reinforced by different treatment methods are discussed in detail. The defects of existing prediction methods and the challenges faced in their practical applications are analyzed. Furthermore, the guidance on future improvement in control theories and technologies of subgrade settlement for high-speed railway lines and the corresponding challenges are provided.

Similar content being viewed by others

1 Introduction

The construction of high-speed railway tracks especially those throughout Europe, East Asia and North America has been growing rapidly over the last decade, as they aim to improve the capacity, availability and carbon footprints of national infrastructures. Train speeds have increased from 200 to 350 km/h, while the speed record for the rolling stock is approaching 600 km/h. To guarantee the operation safety of high-speed trains and the ride comfort of passengers, the criterion on the post-construction settlement [1] of the track infrastructure becomes more and more strict, which poses severe challenges to life cycle design theories and construction technologies of high-speed rail infrastructures. These challenges are more complicated for the constructions in soft soils with high compressibility, since the post-construction settlement control is difficult in these regions. For instance, in typical soft soil regions (e.g., Bohai Sea region, Yangtze River Delta region and Pearl River Delta region of China), many high-speed railway lines have been constructed. Due to the high compressibility and inhomogeneity of soft soils, the subgrade differential settlement in these regions is a serious issue.

To ensure the operation safety and reliability of high-speed railways, the criteria on the track geometry irregularity and infrastructure stability should be met. Large subgrade differential settlement induces additional stress in a monolithic track bed and significantly affects the track geometry irregularity [2,3,4]. The settlement-induced irregularity cannot be fully recovered by routine maintenance, especially for ballastless tracks. Furthermore, as subjected to long-term dynamic train loads, the track must have suffered from a series of track defects (e.g., structural cracks of the infrastructure) [5]. These defects accelerate the track deterioration and threaten the operation safety of high-speed trains. Consequently, the long-term stability and settlement control are significant to the high-speed railway infrastructures, and the related theoretical and practical technologies should be well studied.

This paper is organized in the following manner. Section 2 summarizes the significant issues of high-speed railway subgrade in soft soil regions. Section 3 presents the state-of-the-art review of high-speed railway subgrade settlement control. The studies on the foundation treatment methods for ballasted and ballastless track are reviewed in Sect. 3.1. Sections 3.2 and 3.3 present the design approaches of controlling the differential settlement of high-speed railway subgrade in soft soil area and the prediction methods of foundation settlements, respectively. Section 4 provides the unsolved issues and new challenges.

2 Main issues of high-speed railway subgrade in soft soil regions

2.1 Serviceability of foundation treatment methods to different grades of high-speed railway lines

Different evolution stages can be observed as to subgrade settlement, which can be described as a function of loading conditions and time. Among these settlement stages, the post-construction settlement of the track is mainly contributed by the settlement of subgrade fills and foundation soils. The compression settlement of subgrade fills is not obvious according to in situ measurement data [1]. As a result, the key of the track post-construction settlement control is to minimize the foundation settlement.

The foundation settlement depends on multiple factors, such as foundation types, soil properties, soil-filled height (embankment height), foundation reinforcement methods and time of construction. The settlement of soft foundation will last long time and accumulate to a substantial magnitude due to the high compressibility and low permeability of the soil. Therefore, the foundation reinforcement method plays an important role in the control of subgrade post-construction settlement.

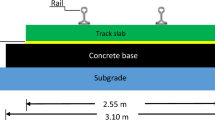

There are two main configurations of high-speed railway tracks, i.e., ballasted and ballastless tracks. The post-construction settlement criteria for these two types are different. For instance, in China with an operation speed of 250 km/h, the critical settlement criterion for ballasted tracks is 100 mm, while for the ballastless track it is 15 mm [2].

The widely used foundation treatment methods for tracks in soft soils include the plastic drainage plate combined with surcharge preloading, the vacuum preloading combined with surcharge preloading, deep cement mixed (DCM) columns with reinforcements, cement fly-ash gravel (CFG) piles with reinforcements and prestressed pipe piles with reinforcements [6]. Due to the spatial variability of soil properties, a unified foundation treatment approach with uniform parameters cannot satisfy the settlement control criteria. Consequently, the foundation treatment methods and technologies should optimize in both technical and economic aspects.

2.2 Difficulties of track differential settlement control

The track infrastructure is composed of the super-structure (track components) and sub-structure (foundation components). The track differential settlement is mainly located in the vicinity of the connections between different sub-structures due to structural differences and foundation treatment differences. Furthermore, the differential settlement also appears in the regions with foundation non-uniformities, connections between the filling section and cutting section and connections of different foundation treatment sections [5]. The differential settlement of the high-speed railway ballastless track is strictly defined in transition zones (e.g., bridge–embankment transition zones and tunnel–embankment transition zones). For instance, according to the Code for Design of High-speed Railway in China [2], the allowable subgrade differential settlement in transition zones should be smaller than 5 mm and the consequent bending angle of the rail should be limited to 1/1,000. Consequently, the differential settlement control of subgrade in soft soil area is tough.

2.3 Uncertainty of calculation precision with existing prediction methods

The prediction methods on foundation consolidation settlement can be summarized as analytical algorithms and numerical simulations. The total consolidation settlement of soft soil with drained consolidation can be calculated with the layer-wise summation method. Based on the drained consolidation principle [7], the post-construction foundation settlement can be obtained by deducting the consolidation settlement during construction process from the total settlement. Since the total consolidation settlement of the foundation with drained consolidation treatment is very large, the calculation precision of this method is acceptable for high-speed railway ballasted tracks. In terms of the composite foundation treatment, such as cement mixing piles, the total settlement is mainly predicated by the composite modulus method [8]. However, this method cannot provide a reliable estimate for the post-construction settlement of the composite foundation.

Some specially designed subgrade configurations, such as pile–net-supported embankments, pile–raft-supported embankments and pile–plank-supported embankments, are widely employed for the high-speed ballastless track in soft soil area. Although the bearing capacity ratio method and the pile foundation settlement method [9] were employed to predict the total subgrade settlement in these cases, the prediction results were not desirable. In practice, the prediction of the subgrade post-construction settlement highly depends on experimental estimations.

Numerical approaches based on the finite element method and finite difference method are frequently used in arbitrary boundary and loading conditions. The foundation non-uniformity and soil nonlinear properties can be considered in these methods. However, the prediction precision of numerical approaches is significantly affected by the material constitutive model and parameter selection. Furthermore, these methods are computationally intensive due to complicated boundary and loading conditions. As a result, the numerical methods are limited to the theoretical research and rarely applied to engineering practice.

In summary, the post-construction subgrade settlement cannot be exactly predicated in practice due to the complexity of soil properties and limitation of geological survey technologies.

3 State-of-the-art of high-speed railway subgrade settlement control

3.1 Theoretical and practical studies on foundation treatment methods

3.1.1 Foundation treatment methods for ballasted track

Excessive track settlement has been observed in lots of normal-speed railway lines in soft soil area, which also provide significant experiences for dealing with the settlement. The foundation reinforcement methods that have been proved to be effective include the drained consolidation method and the flexible composite foundation (e.g., stone column-reinforced foundation and DCM column-reinforced foundation). The principle for the drained consolidation method is to accelerate soil consolidation during railway construction process, while the flexible composite foundation can reduce the total subgrade settlement.

-

(1)

Theoretical studies

If railway construction lasts long, the drained consolidation method combined with surcharge preloading is an economic method to foundation soil with high water content, high compressibility and low strength [10]. As a typical drained consolidation method, the vacuum preloading combined with surcharge preloading method is developed from the vacuum preloading method and the surcharge preloading method for soft soil foundation reinforcement [11]. The combined effects of the vacuum preloading method over the surcharge preloading method can be achieved. If the foundation is applied with a considerable negative pressure by vacuum pumping, the foundation consolidation procedure will be accelerated.

Vertical drains, first introduced in 1948 [12], are generally employed to accelerate the consolidation of soft soils. This method provides an additional drainage path in the radial direction and decreases the length of the drainage path. Yoshikuni and Nakanodo [13] presented an analytical solution for soil consolidation by vertical drain wells considering the well resistance. Zhu and Yin [14] found a new analytical solution for soil consolidation under ramp load by employing a new normalized time factor. Leo [15] developed a series of closed-form solutions for equal-strain consolidation in the presence of a vertical drain. In his study, the smear effect and well resistance were analyzed. Walker and Indraratna [16] proposed a spectral method model to analyze the consolidation of soils with multilayers subjected to the surcharge and vacuum loading. Lu et al. [17] developed the foundation consolidation analytical solution by considering the vertical distribution of the soil permeability coefficient, well resistance and the distribution shape of the additional soil stress. Lei et al. [18] derived a simplified analytical solution from the generalized governing equations of equal-strain consolidation assuming uniform and constant material properties. Ho and Behzad [19] realized the limited analysis of the 2D plane strain consolidation system and introduced a closed-form analytical solution to predict the dissipation of excess pore-air and pore-water pressures. Indraratna et al. [20] derived an analytical solution for vacuum consolidation of a circular foundation, which was validated by an FE model. This numerical model was utilized to analyze the settlement of a test embankment. Contrary to the most conventional theories, Lu et al. [21] proposed a new analytical model for the consolidation of soils by including multiple vertical drains in the cylindrical unit cell. Tian et al. [22] derived the analytical solutions for vacuum preloading consolidation by incorporating the linear decay pattern of vacuum pressure with the elliptical cylinder model. Jang and Chung [23] performed an elasto-viscoplastic FE analysis on the long-term settlement of partially PVD-improved thick clay deposits with a macro-element technique. Yuan and Zhong [24] employed the weak form quadrature element method (QEM) to analyze the consolidation of non-homogeneous soil foundation. Numerical examples with this method were presented and the results were examined by the analytical solutions and the FE simulations. Chai et al. [25] predicted the performance of two embankment cases on PVD-improved subsoils in Australia by using a plane strain FEA method. The prediction results were compared with the measured data.

In the last decades, the soil consolidation theory has been advanced on the basis of the Terzaghi consolidation equation and the Biot’s consolidation equation. More accurate and complicated soil constitutive models, stratum distributions, boundaries, drainage and time-dependent loading conditions were obtained within the developed analytical models. Additional to analytical algorithms, semi-analytical approaches and numerical simulation methods were employed to solve highly nonlinear problems.

The flexible composite foundation method has also been widely employed in soft soil deposits to improve the bearing capacity and to reduce the post-construction settlement of the foundation. Wang et al. [26] presented an analytical solution for the consolidation of soft soil foundations reinforced by stone columns under time-dependent loadings. Lu et al. [27] developed an analytical solution by considering a time- and depth-dependent stress increment for the consolidation of a composite foundation stabilized by impervious columns. According to the consolidation theory of a double-layer subsoil ground, Yang et al. [28] developed an analytical solution for the consolidation of a composite ground reinforced by a partially penetrated impervious column. Liu and Rowe [29] adopted a 3D FE method to investigate the influence of reinforcement viscosity on the post-construction performance of DCM column-supported embankments. Wonglert and Jongpradist [30] carried out a parametric study on the bearing capacity of a stiffened DCM column-reinforced foundation by using an FE method combined with physical model tests. Due to the complexities of column–soil interactions and of boundary conditions, the existing research works on the long-term performance of flexible composite foundations mainly employed numerical simulations together with model tests and in situ measurements.

-

(2)

Laboratory and in situ tests

The existing studies on laboratory and in situ tests of consolidation methods mainly focus on building and pavement foundations. Long et al. [31] conducted four trial sections to investigate the performance of soft ground improvement, in which different vacuum consolidation methods (VCMs) and PVD thicknesses were considered. Bergado et al. [32] introduced a series of in situ tests to investigate the performance of different soft foundation treatment technologies (i.e., prefabricated vertical drain with surcharge, vacuum and heat preloading, DCM and stiffened DCM methods). Chai et al. [33] conducted a series of laboratory radial drainage odometer and triaxial tests to investigate the deformation behavior of clayey soils under combined vacuum pressure and surcharge loads. Wang et al. [34] performed contrasting laboratory tests in two identical experimental tanks. Their results show that the two-stage vacuum preloading method could achieve a better consolidation effect than that of the one-stage method. Shen et al. [35] investigated the DCM columns induced property changes of the surrounding clay in the field. Liu et al. [36] carried out field tests on the performances of a T-shaped DCM column-supported embankment and a conventional DCM column-supported embankment. The test results revealed that the former had considerable advantages over the latter.

For experimental and practical studies on high-speed railway foundation reinforcement in soft soils, a series of outdoor and in situ tests have been carried out in China. Zhou [9] evaluated the feasibility of the foundation treatment method with plastic drainage plates for high-speed railways in soft soil regions with a series of in situ experiments. The settlement law of the soft soil foundation with the treatment of plastic drainage plates was recorded and analyzed [9].

In 2002, a series of in situ tests on the subgrade reinforcement method of high-speed railways were undertaken following the framework of the project entitled “Design parameters of earthworks and bridges in soft soil area” [38]. The test section was located on the high-speed railway line between Beijing and Shanghai with a length of 845 m. The embankment height varies between 4.3 and 5.9 m. The soft soil depth ranges from 4.0 to 16.5 m. Since it was designed as the ballasted track with an operation speed of 300 km/h, the criterion of the subgrade post-construction settlement was selected as 5 cm. To satisfy the settlement criterion, three foundation reinforcement methods were employed and tested, i.e., the plastic drainage plate with surcharge preloading, the plastic drainage plate with the vacuum preloading and the composite foundation with DCM columns.

Figure 1 shows the foundation settlement changing with time for three treatment methods. It is found that the total settlement of the drained consolidation method is larger than that of DCM column method. For the plastic drainage plate with the vacuum preloading method, the settlement generated in the vacuum preloading procedure was 195 cm, and after that, the settlement rate decreased significantly [37]. The subgrade settlement in the composite foundation of DCM columns was only 15 cm.

To achieve the criterion of the post-construction settlement of 5 cm, the required minimum static durations after construction are 17 months for the plastic drainage plate with surcharge preloading method, 10 months for the plastic drainage plate with the vacuum preloading method and 6 months for the composite foundation of cement mixing piles method, respectively [38].

The in situ test results indicate that the conventional drained consolidation method and the composite foundation method of DCM columns can be employed for the reinforcement of high-speed ballasted track subgrades in soft soil area when the thickness of the soft soil is limited to 15 m and the embankment height is smaller than 5 m. Furthermore, the sufficient construction duration is also expected in this case.

3.1.2 Foundation treatment methods for ballastless track

In China, the construction duration of high-speed railway infrastructures is generally very limited and the requirement of the post-construction settlement is very strict. This is especially true for the ballastless tracks. Thus, the drained consolidation method and the DCM column method do not adapt to ballastless tracks in soft soils. New foundation treatment methods and technologies, such as pile–net-supported embankments, pile–raft-supported embankments and pile–plank-supported embankments (Figs. 2, 3, 4), have been developed to satisfy the strict settlement criterion of the high-speed ballastless tracks.

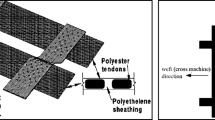

As shown in Fig. 2, the pile–net-supported embankment is a composite system composed of piles (normally with caps), nets (i.e., geotextiles) and subgrade soils between piles, where CFG piles and prestressed pipe piles are generally employed. In some special cases, the bored piles can also be utilized. The pile caps are widely used in the design of the pile–net structure in China [39], in order to increase the bearing ratio of the pile to soil. As a result, the pile spacing can also be increased to reduce construction costs. The cap can be shaped into square or round with a diameter of 1.0–2.0 m and a thickness no larger than 0.4 m. The piles should be penetrated through the soft soil stratum into the bearing stratum with a relatively high bearing capacity. The in-plane distribution of the piles is normally square or quincunx. The cushion thickness ranges between 40 and 60 cm. To increase the bearing efficiency, the geotextiles should be installed close to the pile top. For double layers of geotextiles, the recommended distance between layers is 15–30 cm.

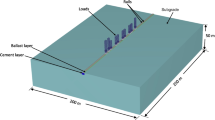

For the pile–raft-supported embankment, the cushion layer with a thickness of 15–20 cm is constructed on top of the piles and a reinforced concrete raft with a thickness of 40–60 cm lies on the cushion layer, as shown in Fig. 3. Since the stiffness of the concrete raft and that of piles are much higher than that of the soil between piles, the compression deformation of the soil is larger than that of the piles during the initial loading process. Due to the deformation difference between the piles and soil, the dead load on the raft is mainly supported by piles. With the increase in the load concentrated in the vicinity of the piles, the top of the pile may gradually penetrate into the cushion layer and the cushion layer particles are laterally squeezed out into the regions on the top of the soils between piles. In this way, the cushion layer in these areas is still in contact with the raft. Finally, the balanced load distribution between the piles and soil is reached. In this system, the soil between piles supports the super-structure load and the cushion balances the distribution of the loads on the piles and the soil.

The pile–plank-supported embankment (Fig. 4) is composed of reinforced concrete piles and planks (or reinforced concrete piles, joists and planks). According to the connection type and buried depth, the pile–plank-supported embankment is divided into three types, i.e., non-buried, shallow buried and deep buried. For the high-speed railways in soft soil area, the most frequently used type is the deep-buried pile–plank structure. The reinforced concrete plank generally adopts a concrete grade of C30 and a thickness of 50 cm.

-

(1)

Theoretical studies on pile-supported embankment

Based on the yield design theory, Bouassida et al. [40] derived a lower-bound solution for the bearing capacity of a column-reinforced foundation. Castro and Sagaseta [41] presented an analytical solution for the radial consolidation of stone column-reinforced foundations subjected to a constant surcharge load. Both the vertical and radial deformation was considered. The accuracy of this analytical solution was validated by comparing with the finite element method [42, 43]. Huang et al. [44] conducted a three-dimensional coupled mechanical and hydraulic modeling by using FLAC3D to consider consolidation and three-dimensional arrangement of columns. Zhang et al. [45] proposed a new ground improvement technique, referred to as the fixed-geosynthetic-reinforced and pile-supported embankment (called FGT embankment), and investigated its performance by using a two-dimensional finite element model. Zhuang et al. [46] presented a simplified model for an embankment of granular fill on soft ground supported by reinforcement and piles. Bhasi and Rajagopal [47] numerically investigated the performance of geosynthetic-reinforced embankments supported on end bearing as well as floating piles considering the pile–soil and geosynthetic–soil interaction. Yu et al. [48] proposed a modified unit cell approach to model column-supported embankments supported by deep mixed column walls. Zhao et al. [49] analyzed the load transfer mechanism within a column-supported embankment by using a simplified mathematical model. Yu et al. [50] examined column-supported embankments using a full-width model with small- and large-strain modes in FLAC. The results were subsequently compared with those obtained by a typical unit cell model. Huang et al. [51] presented three-dimensional numerical analyses of a column-supported embankment case history using the finite difference method. Xie et al. [52] developed a more rigorous theoretical solution to compute the degree of consolidation for column-reinforced composite foundations.

Research works with regard to the pile-supported embankment focus on the load transfer and load sharing mechanism that is influenced by multiple factors. A large number of axisymmetric, two-dimensional or three-dimensional unit cells have been employed for parametric studies. Most of them considered long-term or short-term behavior with drained or undrained strength parameters. However, the time-dependent behavior of these embankments due to the consolidation of soft soil was not fully considered.

-

(2)

Laboratory and in situ tests

To test and investigate the mechanical properties of the pile-supported embankment, a large number of indoor experiments and in situ tests were carried out. Chen et al. [53] monitored the earth pressures, settlements and pore-water pressures for three cases of pile-supported embankments over soft soil. Hong et al. [54] performed two types of model tests to investigate the configuration of the punching shear and the loads transferred onto a pile cap beam in pile-supported embankments. Jiang et al. [55] conducted shaking table model tests to investigate the performance of CFG pile–net composite foundation in soft soil deposits of the Beijing–Shanghai high-speed railway. Briançon and Simon [56] carried out a series of full-scale experiments of pile-supported embankments on soft soils to improve the design theory of highway and railway embankments. Xing et al. [57] compared the results of two well-instrumented large-scale tests of pile-supported earth platform with and without geogrid reinforcement. Wang et al. [58] performed centrifugal model tests on settlement control effects of pile–raft structure-supported embankments for high-speed railways. Fagundes et al. [59] introduced a series of centrifuge tests on pile-supported embankments with basal geosynthetic reinforcement. The effects of pile spacing, embankment height, pile cap size and geosynthetic stiffness on the load transfer mechanism and surface settlements were investigated. Chai and Rondonuwu [33] designed a test embankment that was built on a clay layer and improved by the installation of floating soil–cement columns. McGuire and Filz [60] developed an extensive bench-scale testing program to investigate the settlement of column-supported embankments affected by multiple factors. Zhang et al. [61] carried out a series of centrifugal modeling tests to investigate the performance of an SDM column-supported embankment over soft clay. Zheng et al. [62] monitored two CFG pile-supported high-speed railway embankment cases constructed over the soft marine clay in China. The field measurement data on the embankment service performance (i.e., the load distribution discipline, excess pore pressure, settlement and lateral displacement) were investigated. Marinda et al. [63] carried out a laboratory test on the influence of the encasement on stone columns. The soil–column stress distribution, soil settlement and pore pressure dissipation were measured.

In 2002, a series of experiments on settlement control effect of CFG pile–net-supported embankment were conducted at Tongji University [9]. The experimental results were applied to the design of the CFG piles of high-speed railway line in soft soils.

Following the work of Ref. [9], a series of experiments with regard to the reinforcement effect of the pile–net-supported embankment and the pile–raft-supported embankment were undertaken in Liyao, China, in 2007 [64]. The experimental results indicate that both the pile–net-supported embankment and the pile–raft-supported embankment can satisfy the critical post-construction settlement of 15 mm with a static duration of 6 months after the completion of the subgrade filling if the pile supporting stratum has sufficient bearing capacity. Some additional surcharge preloading treatments will further reduce the post-construction settlement of the foundation. The experimental results were used to design the soft soil foundation reinforcement of Beijing–Shanghai high-speed railway. In 2010, the pile–net-supported embankment, pile–raft-supported embankment and pile–plank-supported embankment were incorporated into the Technical Code for Ground Treatment of Railway Engineering [65].

3.2 Differential settlement control technologies

The differential settlement of the high-speed railway subgrade in soft soils can be obviously observed in the longitudinal and lateral directions of the subgrade. The differential settlement of the subgrade along track direction is mainly concentrated in the vicinity of the connection between the earthwork and structures, such as bridge and tunnel. In addition, the longitudinal differential settlement is also observed in the area where the soft soil stratum distributes unevenly, the connection between the filling section and cutting section, and the connection between different foundation treatments, etc. The lateral subgrade differential settlement is mainly induced by the non-uniformity of the load and abrupt variation of geology conditions. Furthermore, when a newly constructed high-speed railway track is incorporated into an existing high-speed railway track, the existing subgrade needs to be broadened to guarantee space for new constructed infrastructures. The substantial differential settlement may therefore be induced between the old subgrade and new constructed one in lateral direction. The track geometry irregularity induced by the subgrade differential settlement may drastically amplify the wheel–rail contact force, thereby threatening the stability of high-speed trains and track service performance.

The longitudinal differential settlement of the track is mainly concentrated in bridge–embankment transition zones. Research works on transition zone problems focused on the vehicle–track dynamics influenced by track geometry irregularity and track stiffness variations [66,67,68,69,70,71]. The distribution of differential settlement in transition zones was investigated using in situ measurements and laboratory model tests [72,73,74,75]. In soft soil area, the bored piles are generally employed for bridge supporting foundation. The piles used to support bridges are much longer than those used for subgrade (CFG piles and pipe piles), resulting in the smaller long-term settlement of the bridge foundation than that of the subgrade. To guarantee the operation safety of high-speed trains, the track differential settlement should be limited to an allowable value. A specially designed transition zone configuration between the bridge abutment and the subgrade is an available mitigation. The foundation reinforcement of the transition zone is basically more strengthening than the treatment of normal subgrade section. A number of effective treatments [76, 77] have been employed in practice to reduce the differential settlement between the bridge abutment and the subgrade, such as increasing pile length in transition zones, reducing space between piles and using strengthened foundation reinforcement. Furthermore, the increase in soil stack height for surcharge preloading treatment in transition zones can efficiently reduce the post-construction differential settlement between the bridge and subgrade [78].

The control methods of subgrade lateral differential settlements can be grouped into three types. The first method is to construct the pile–raft structure in subgrade central part and the pile–net structure on both sides, as shown in Fig. 5. The second method is to use the piles with different types, lengths and intervals. This method was applied to the Jinan west station subgrade with a width of 160 m, which was reinforced by the combination of the pile–net structure and the pile–raft structure with different pile types (pipe piles and CFG piles) and pile lengths (Fig. 6). Figure 7 presents the third method, in which the pile–plank structure is used for the new broadened subgrade region (or combined with light fill materials).

3.3 Settlement prediction methods

3.3.1 Calculation algorithms of foundation settlements

For the soft soil foundation reinforced by drainage consolidation methods, the post-construction subgrade settlement can be calculated by utilizing the consolidation theory, while the composite modulus method is usually employed to predict the post-construction settlement of the composite foundation with flexible columns (e.g., stone columns and DCM columns). For the rigid composite foundation, the settlement of the reinforced area results from the penetration of piles into the soil.

-

(1)

Drainage consolidation methods

Indraratna et al. [79] proposed an analytical model of vertical drains incorporating vacuum preloading in both axisymmetric and plane strain conditions to calculate the consolidation settlement. Mohamedelhassan and Shang [80] developed a vacuum and surcharge combined one-dimensional consolidation model to calculate the excess pore-water pressure and the consolidation settlement. Ho and Behzad [19] introduced an analytical solution of an unsaturated soil stratum settlement by utilizing a two-dimensional (2D) plane strain model. The time-dependent loadings were considered.

With the deep understanding of the soil consolidation settlement, the analytical model of the foundation was developed from one soil layer with homogeneous behavior to multilayers with inhomogeneous soil properties. The smear effect and well resistance are also included. Based on these analytical approaches, a large number of numerical algorithms have been developed to calculate the consolidation settlement of the foundation in highly complicated situations. Since various aspects play a role in the soft soil consolidation procedure (e.g., the fluid–solid coupling, stratum distribution, geological environment and seepage flow), the accuracy of the numerical simulation results highly depends on the calculation algorithm and parameter selection.

-

(2)

Flexible composite foundation

As for the flexible composite foundation, Castro and Sagaseta [42] presented a new analytical solution for a column–soil unit cell to analyze the settlement of stone column-reinforced foundations. The influence of governing parameters on the settlement was evaluated. Yapage and Liyanapathirana [81] presented a parameter study on the total and differential settlements of geosynthetic-reinforced DCM column-supported embankments by using an FE method. They indicated that the column spacing and diameter and the elastic modulus of soft soil were the most important parameters. Liu and Rowe [82] employed a 3D FE model to calculate the post-construction settlement of the DCM floating-column-supported embankment with and without prefabricated vertical drains. The results showed that the combined use of PVDs and surcharge preloading substantially reduced the post-construction settlement. Filz et al. [83] proposed a load–displacement compatibility method to estimate the transfer of vertical loads and the settlement of column-supported embankments. With this method, the critical embankment height was recommended. Phutthananon et al. [84] utilized small-scale model tests combined with FE method to investigate the load transfer and settlement behaviors of T-shaped DCM column-supported embankments.

Since the settlement of the reinforced area for the flexible composite foundation is equal to the pile compression deformation, the simplified calculation methods are widely employed in engineering practice to determine the composite compression modulus of the flexible composite foundation \(E_{\text{cs}}\) [65]:

where m is the area displacement ratio; \(E_{\text{P}}\) is the pile compression modulus; and \(E_{\text{s}}\) is the soil compression modulus. With the composite modulus, the foundation settlement can be obtained by using layer-wise summation method.

-

(3)

Rigid composite foundation

The deformation mechanism of the rigid composite foundation (e.g., pile–net structure, pile–raft structure and pile–plank structure) is entirely different from that of the flexible composite foundation. In the flexible composite foundation, the piles can be compressed and will not obviously penetrate into the covering layer and the supporting layer. However, the compression deformation of piles in the rigid composite foundation can be neglected. The settlement of the reinforced area is provided by the penetration of the piles into the soil. Consequently, the calculation algorithm used for the flexible composite foundation cannot be applied to the settlement prediction of the rigid composite foundation.

Chen et al. [85] proposed a 1D model to calculate the settlement of a pile-supported embankment. The soil arching, negative skin friction of the pile and the foundation settlement were taken into account. Xu et al. [86] proposed a simplified solution to calculate time-dependent settlement for rigid composite foundations with multiple piles subjected to surface loads. Li et al. [87] presented a semi-analytical approach to predict the time-dependent bearing performance of an axially loaded jacked pile in saturated clay strata.

Generally, the total settlement (S) is equal to the sum of the settlement of the reinforcement area (S1) and the settlement of pile supporting layer (S2). The synthetic modulus method [65] is applied to calculate the settlement S1. In this method, the synthetic modulus of the reinforced area is calculated first. The compression settlement in this area can subsequently be obtained by using the layer-wise summation method. The synthetic modulus of the composite foundation (\(E_{\text{sp}}\)) was expressed as [88]:

where \(\zeta\) denotes the amplification factor; \(E_{\text{s}}\) is the foundation soil compression modulus; \(f_{\text{ak}}\) is the criterion of the natural foundation bearing capacity; and \(f_{{{\text{sp}},{\text{k}}}}\) is the criterion of the composite foundation bearing capacity:

in which \(f_{\text{pk}}\) is the criterion of the bearing capacity of single pile; \(f_{\text{sk}}\) is the criterion of the bearing capacity of the reinforced soil between piles; and \(\beta\) is the reduction factor of the bearing capacity of the reinforced soil between piles.

For the rigid composite foundation, the compression deformation of the pile is much smaller than that of soil. The composite modulus of the rigid composite foundation calculated with the weighted average of the pile modulus and the soil modulus will be hundreds of times larger than general soil modulus. This is why the foundation settlement is underestimated. For this reason, the diffuser angle method, Boussinesq method and the L/3 method [89] were developed to calculate the compression deformation of the pile supporting layer (S2).

An empirical factor ms is introduced to revise the prediction results, as shown in Eq. (4). Table 1 lists the value of the empirical factor ms as a function of the modulus \(\bar{E}_{\text{s}}\), which is determined by the measurement data of the local foundation settlement and the engineering specifications

In a project entitled “Calculation theories and design methods of the rigid pile composite foundation” [64], the calculation method of the settlement of the pile–net-supported embankment was studied. Based on the pile–soil interaction principle, the stress solutions of Boussinesq method and Mindlin method were integrated as an algorithm for predicting the settlement of the pile–net-supported embankment, which is called the Mindlin–Boussinesq combined algorithm. Since the superstructures are supported by both piles and soils, the additional stress in the foundation is composed of two parts, i.e., the additional stress induced by loads on piles and the additional stress induced by loads on soil between piles.

Since the soil arching plays an important role in load distribution between piles and soil, various soil arching models were proposed and improved. The arching models proposed by Hewlett and Randolph [90] and Zaeske [91] were validated and used in design codes like British Standard [92], Nordic Handbook [93], Japan Specifications [94] and Recommendations of Germany [95]. The Chinese technical code for the application of geosynthetics (GB/T 50290-2014) employs the Marston’s formula [96] from British Standard (8006-2010) to estimate the ratio of the vertical stress exerted on top of the pile caps to the average vertical stress at the base of the embankment. van Eekelen et al. [97, 98] proposed and validated the novel concentric arching (CA) model, which was adopted in Dutch code CUR 226 [99]. According to the laboratory model tests [100, 101], the degradation of the soil arching effect may occur with low embankment and high dynamic train load level. Therefore, the dynamic evolution of the arching effect is one of the research highlights in this field. For instance, Zhuang et al. [102] presented an analytical solution under traffic loads. Some researcher also focused on the systematic behavior of the pile–net structure. Lu and Miao [103] created a simplified systematic model for pile–net-supported embankments. Feng et al. [104] and Rui et al. [105] proposed evolutionary 2D arching models. Zhang et al. [106] proposed a 3D arching model for triangular arrangement of piles. Several configurations of soil arching models are illustrated in Fig. 8.

According to the soil arching model of Zaeske [91], Eqs. (5) and (6) can be utilized to calculate the pressure on the soil between piles and the pressure on the top of the pile, respectively:

where \(\chi = \frac{{d\left( {K_{\text{krit}} - 1} \right)}}{{\lambda_{2} s}}\); \(\lambda_{1} = \frac{1}{8}(s - d)^{2}\); \(\lambda_{2} = \frac{{s^{2} + 2sd - d^{2} }}{{2s^{2} }}\); \(K_{\text{krit}} = \tan^{2} \left( {45^{\circ} + \frac{{\phi_{\text{k}}^{ \prime} }}{2}} \right)\) is the coefficient of Rankine’s passive earth pressure; \(\phi_{\text{k}}^{\prime}\) is the internal friction angle of the subgrade filler (°); \(\gamma\) is the weight of the subgrade filler (kN/m3); \(h\) is the subgrade height (m); \(q_{0}\) is the additional load on the subgrade surface (kN/m2); \(h_{\text{g}}\) is the height of the soil arching: \(h_{\text{g}} = s/2\) (\(h \ge s/2\)), \(h_{\text{g}} = h\) (\(h < s/2\)); \(d\) is the diameter of the pile (or pile cap); if the shape of the pile cap is not round, the equivalent diameter can be obtained as \(d = \sqrt {4A_{\text{s}} /\uppi }\), where \(A_{\text{s}}\) is the pile cap area; and \(s\) is the distance between adjacent piles.

where \(\gamma h + p_{\text{k}}\) is the average stress in pile treatment area; \(A_{\text{p}}\) is the area of the pile cross section; and \(A_{\text{E}}\) is the pile treatment area.

The Boussinesq solution can be used to calculate the addition stress of the foundation generated by loads acting on soils between piles, while the additional stress of the foundation induced by loads applied to piles can be calculated by the Mindlin solution. In this way, the final additional stress in the foundation can be obtained by the Mindlin–Boussinesq combined algorithm. The layer-wise summation method combined with the e-lgp curve can subsequently be utilized to calculate the settlement of the composite foundation. The Mindlin–Boussinesq combined algorithm is available to reveal the additional stress distribution in the composite foundation and the foundation settlement discipline as a function of the depth measured from the foundation surface. The settlement calculated by this method was in accordance with the measured results in engineering practice [107].

Since piles are fixed with the plank in the pile–plank-supported embankment, the settlement of the plank is equal to the settlement of the pile foundation. The settlement of the pile foundation can be calculated with deep massive foundation method recommended in the design code on subsoil and foundation of railway bridge and culvert [108].

For the design of the pile–net and pile–raft structure with reinforced cement piles, the dead load of the embankment is basically assumed to be completely supported by piles. This design philosophy is validated from field monitoring. In reality, some substantial voids and gaps beneath the pile caps and nets have been widely observed in existing pile–net-supported embankments of high-speed railways in soft soil area. In this case, the embankment loads are not supported by the soils between piles. Consequently, the settlement calculation methods for pile foundations [65] (e.g., deep massive foundation method and L/3 method) are applicable for the settlement prediction of pile–net and pile–raft-supported embankments. Furthermore, the Mindlin solution method is also suitable for the calculation of pile foundation settlements.

3.3.2 Prediction of the foundation post-construction settlement

The point of the foundation treatment technology of the high-speed subgrade is to control the post-construction settlement, which is time dependent. In engineering practice, a total foundation settlement is estimated with one or multiple prediction methods previously. An approximate evaluation of the foundation post-construction settlement can subsequently be obtained by the ratio of the post-construction settlement to the total settlement. This ratio depends on foundation soil properties, foundation reinforcement methods, design parameters, load amplitudes, construction duration and static duration after construction.

Another prediction method is based on the in situ measurement of the foundation settlement from the initial construction stage. As the measured load and settlement are functions of time, the long-term foundation settlement can be predicated by utilizing machine learning methodologies, e.g., the artificial neural network [109, 110], the gray prediction theory [111, 112] and the ant colony algorithm [113, 114]. Based on the prediction results, the treatment method can be evaluated and the construction parameters of the treatment can be optimized. In this way, the loading and unloading durations and the reasonable time for the track installation can be determined.

As an alternative, the curve-fitting method (mathematical method) based on the in situ measured data can be applied to predict the final settlement of the foundation, such as the hyperbola method [115, 116], the exponential method [117, 118], the Hoshino method [119] and the Asaoka method [120, 121]. However, three application rules for these methods should be followed [122]:

-

(1)

To guarantee the precision of the regression analysis based on the in situ measurement data, the correlation coefficient of the curve regression should be larger than 0.92.

-

(2)

To validate the settlement prediction method, the difference between the results of adjacent two predictions with an interval of 3–6 months should be smaller than 8 mm.

-

(3)

The basic accuracy requirement of the prediction method should be met before the track installation.

3.3.3 Prediction of train-load-induced settlement

Two types of computational algorithms can be used to evaluate the cumulative plastic deformation of the subgrade subjected to dynamic train loads. One is the constitutive model method, in which the yield criterion, hardening rules and flow rules are included [123,124,125,126,127]. Numerical analysis methods combined with soil constitutive models have been employed to calculate the subgrade soil plastic deformation induced by the train cyclic load. This method is useful in reflecting the deformation mechanism of the subgrade soil subjected to the train cyclic load. This method, however, is computationally intensive even with small number of loading cycles. Therefore, it is impractical to use this method to predict the long-term differential settlement of the subgrade after millions of loading cycles.

The other type of computational algorithm is based on empirical models. Several methods of predicting the settlement of the ballasted track were developed on the basis of the triaxial tests, reduced scale models or statistical analysis of in situ measurements [128,129,130,131]. The track settlement can be directly drawn as a function of the cyclic load condition from these models. Furthermore, considering the deformation of the subgrade soil, the models that reflect the relationship between cumulative plastic strain of the soil and the number of cyclic load applications have been obtained from laboratory tests [85, 132,133,134,135]. The accumulative subgrade deformation can be calculated by the integration of the soil strain along the depth. The characteristics of cyclic loads (e.g., frequency, amplitude and number of cycles), soil properties (e.g., types and consolidation ratio) and the soil stress state can be considered overall in this method. Compared with the constitutive model method, the empirical model method has the advantages of simple operation and high efficiency. Several empirical model methods were proposed [136, 137] to evaluate the long-term subgrade settlement. However, the soil dynamic stress distribution kept constant with soil strain in those methods, which was not in agreement with real track conditions. As the subgrade cumulative plastic deformation increases, the track geometry irregularity is aggravated, thereby affecting the wheel–rail contact force and the soil stress distribution.

To simulate the dynamic interaction process, Vale and Calçada [138] employed a 1D vehicle–track interaction model for simulating the evolution of the vertical track profile and assessing the track response during the degradation process. An iterative procedure was proposed to predict the track settlement including the deformation of the ballast layer and of the subgrade. Mauer [139] presented an iterative model to calculate the track settlement under various initial geometric and parametric conditions. The model consists of a dynamic vehicle model, a nonlinear static track model and an empirical roadbed settlement model. Ford [140] presented a prediction model for track profile deterioration, which considered the interaction between the track profile evolution and the dynamic vehicle loads as well as the effect of the previous load history of the ballast. Varandas et al. [75] proposed a methodology to predict the differential settlement of the ballast track in transition zones by coupling a dynamic vehicle–track interaction model to an incremental settlement model of the ballast. Wang and Markine [141] proposed a similar iteration methodology to predict the permanent settlement of track transition zones. The vehicle–track interactions and the evolution of the ballast settlement were considered. Shan et al. [142] proposed an iterative computation method of the train-load-induced differential subgrade settlement in transition zones. The evolution process of the differential settlement of the transition zone was investigated. Guo and Zhai [3, 4] adopted an iterative methodology with a vehicle–track coupling model to predict the system dynamic response due to subgrade differential settlement evolution. In this study, the evolution of subgrade differential settlement was evaluated and the corresponding rail deflection under track weight was calculated.

The increase in the operation speed of the high-speed train exacerbates train-induced settlement of the subgrade. Although a number of iterative algorithms have been proposed for considering the vehicle–track interaction and the variation of the dynamic stress field in the subgrade, the calculation efficiency of these methods cannot fully meet the requirements of engineering practice. Minimizing the calculation time and increasing the prediction accuracy are targets for future studies.

4 Conclusions and suggestions

After decades of research works and engineering practices, the subgrade settlement control theories and technologies for high-speed railway tracks have deeply developed. For future improvement in this area, several discussions and prospects are drawn:

-

(1)

There is a need for developing an advanced method for predicting the settlement of the pile–net structure foundation with high calculation precision and efficiency. The pile–raft-supported embankment and pile–plank-supported embankment widely used in high-speed railways are employed in industrial and civil architecture foundation treatments. The settlement mechanics and the calculation methods of these two configurations have been studied in depth. However, for the pile–net-supported embankment, further works are needed to study the pile–soil–net interaction, the load transfer principle and the corresponding settlement prediction methods. Among the existing methods, the empirical factor method is widely adopted in rail engineering design. A huge number of in situ tests and settlement measurement data for railways in low/intermediate compressible soil area have been recorded. The corresponding empirical factors that depend on construction conditions (i.e., the soil properties, foundation treatment methods and the subgrade static duration after the construction) in those areas have been obtained. However, the empirical factors for rail subgrade settlement prediction in soft soil area still need to be accumulated and explored.

-

(2)

The soil arching theory for pile–net structure needs to be further evaluated in engineering practice. The bearing load distribution between piles and soils and the tensile force of geotextile in cushion layer under the static embankment load and the dynamic train load are the most significant design parameters of the pile–net-supported embankment. However, these parameters determined by different soil arching theories are not unified due to different assumptions. Further works are needed to verify the adopted soil aching model for pile–net-supported embankments in soft soils. In addition, according to the laboratory model tests, the degradation of the soil arching effect may occur with low embankment and dynamic train load of high amplitudes. Consequently, using the pile–net structure with low embankment in soft soil area should be further investigated.

-

(3)

Further studies on the design theory and method of subgrade settlement control in deep soft soils are still required. The in situ measurement data and numerical simulation results reveal that the long-term settlement of the pile–net-supported embankment is larger than the settlement of the pile–raft/plank-supported embankment with the same pile length and distance as well as the differential settlement in the lateral direction [143]. However, an obvious advantage of the pile–net structure is the relatively low construction cost. In addition, some key design parameters for the foundation treatment method of ballastless tracks, such as the pile distance and material parameters of the cushion layer, are determined by engineering experience rather than theoretical base. Consequently, the design theories of these soft soil foundation treatment structures should be further studied from a combined perspective of technology and economics.

-

(4)

There is an urgent need on technical standards for the application of light fill in embankments. Since the density of light fill is only 1/5–1/3 of the normal embankment fill, the dead weight of the embankment filled with light fill is much smaller than that of the embankment with normal fill as well as the consequent foundation settlement. Consequently, the application of light fill has significant advantages in settlement control of soft soil foundation, especially for transition zones and lateral broadened embankments. The application of light fill in the high-speed railway embankment is still in experimental stage. The long-term dynamic properties and service performance of light fill should be explored further, and its technical standard for application should be launched with urgency.

-

(5)

With the rapid mileage increase of high-speed railways lines in soft soil area, the long-term settlement of subgrade can only be mitigated due to the limitations in the survey, design and construction as well as the environment variations. Consequently, as the high-speed railway operation should be uninterrupted, the rapid defect treatment methods and deformation repair technologies of the subgrade are targets for future studies.

References

Wang BL, Yang XW, Zhou Y et al (2015) Subgrade and track engineering of high speed railway. Tongji University Press, Shanghai (in Chinese)

National Railway Administration (2014) Code for design of high speed railway (TB10621-2014). China Railway Press, Beijing (in Chinese)

Guo Y, Zhai WM, Sun Y (2018) A mechanical model of vehicle–slab track coupled system with differential subgrade settlement. Struct Eng Mech 66(1):15–25

Guo Y, Zhai WM (2018) Long-term prediction of track geometry degradation in high-speed vehicle–ballastless track system due to differential subgrade settlement. Soil Dyn Earthq Eng 113:1–11

Zhai WM, Zhao CF, Xia H et al (2014) Basic scientific issues on dynamic performance evolution of the high-speed railway infrastructure and its service safety. Sci Sin (Technol) 44(7):645–660 (in Chinese)

Gong XN (2002) Application of composite foundation theory and engineering. China Construction Industry Press, Beijing (in Chinese)

Biot MA (1955) Theory of elasticity and consolidation for a porous anisotropic solid. J Appl Phys 26(2):182–185

Wang X (2006) Prediction and control of settlement of high speed railway soft subgrade treated with cement powder mixing piles. Dissertation of Ph.D., Tongji University, Shanghai (in Chinese)

Zhou SH (2003) Experimental research on control methods on settlements of subgrade and bridge pile. Research Report, Tongji University, Shanghai (in Chinese)

Yin ZZ (1999) Status and prospects of soil mechanics development. J Hohai Univ 27(1):1–5

Liu HL, Zhao MH (2016) Review of ground improvement technical and its application in China. China Civ Eng J 49(1):96–115 (in Chinese)

Barron RA (1948) Consolidation of fine-grained soils by drain wells. Trans Am Soc Civ Eng 113(1):718–742

Yoshikuni H, Nakanodo H (1974) Consolidation of soils by vertical drain wells with finite permeability. Soils Found 14(2):35–46

Zhu GF, Yin JH (2001) Consolidation of soil with vertical and horizontal drainage under ramp load. Géotechnique 51(4):361–367

Leo CJ (2004) Equal strain consolidation by vertical drains. J Geotech Geoenviron Eng 130(3):316–327

Walker R, Indraratna B (2009) Consolidation analysis of a stratified soil with vertical and horizontal drainage using the spectral method. Géotechnique 59(5):439–449

Lu MM, Xie KH, Wang SY (2011) Consolidation of vertical drain with depth-varying stress induced by multi-stage loading. Comput Geotech 38(8):1096–1101

Lei GH, Zheng Q, Wang CW et al (2015) An analytical solution for consolidation with vertical drains under multi-ramp loading. Géotechnique 65(7):531–547

Ho L, Behzad F (2015) Analytical solution for the two-dimensional plane strain consolidation of an unsaturated soil stratum subjected to time-dependent loading. Comput Geotech 67:1–16

Indraratna B, Kan ME, Potts D et al (2016) Analytical solution and numerical simulation of vacuum consolidation by vertical drains beneath circular embankments. Comput Geotech 80:83–96

Lu MM, Sloan SW, Indraratna B et al (2016) A new analytical model for consolidation with multiple vertical drains. Int J Numer Anal Methods Geomech 40:1623–1640

Tian Y, Wu WB, Jiang GS et al (2019) Analytical solutions for vacuum preloading consolidation with prefabricated vertical drain based on elliptical cylinder model. Comput Geotech 116:103202

Jang WY, Chung SG (2014) Long-term settlement analysis of partially improved thick clay deposit. Geotext Geomembr 42(6):620–628

Yuan S, Zhong H (2014) Consolidation analysis of non-homogeneous soil by the weak form quadrature element method. Comput Geotech 62:1–10

Chai JC, Shen JSL, Liu MD et al (2018) Predicting the performance of embankments on PVD-improved subsoils. Comput Geotech 93:222–231

Wang GC (2009) Consolidation of soft clay foundations reinforced by stone columns under time-dependent loadings. J Geotech Geoenviron Eng 135(12):1922–1931

Lu MM, Xie KH, Wang SY et al (2013) Analytical solution for the consolidation of a composite foundation reinforced by an impervious column with an arbitrary stress increment. Int J Geomech 13(1):33–40

Yang T, Yang JZ, Ni J (2014) Analytical solution for the consolidation of a composite ground reinforced by partially penetrated impervious columns. Comput Geotech 57:30–36

Liu KW, Rowe RK (2015) Numerical study of the effects of geosynthetic reinforcement viscosity on behaviour of embankments supported by deep-mixing-method columns. Geotext Geomembr 43(6):567–578

Wonglert A, Jongpradist P (2015) Impact of reinforced core on performance and failure behavior of stiffened deep cement mixing piles. Comput Geotech 69:93–104

Long PV, Nguyen LV, Bergado DT et al (2015) Performance of PVD improved soft ground using vacuum consolidation methods with and without airtight membrane. Geotext Geomembr 43(6):473–483

Bergado DT, Long PV, Chaiyaput S et al (2018) Prefabricated vertical drain (PVD) and deep cement mixing (DCM)/stiffened DCM (SDCM) techniques for soft ground improvement. In: Bui QB, Cajka R, Tran MT, Trinh TA, Yasar AUH, Wets G, Woloszyn M (eds) IOP conference series: earth and environmental science, 2nd international conference on sustainable development in civil, urban and transportation engineering (CUTE 2018), vol 143, pp 1–31. IOP Publishing, Bristol

Chai JC, Rondonuwu SG (2015) Surcharge loading rate for minimizing lateral displacement of PVD improved deposit with vacuum pressure. Geotext Geomembr 43(6):558–566

Wang J, Cai YQ, Fu HT et al (2018) Experimental study on a dredged fill ground improved by a two-stage vacuum preloading method. Soils Found 58(3):766–775

Shen SL, Han J, Du YJ (2008) Deep mixing induced property changes in surrounding sensitive marine clays. J Geotech Geoenviron Eng 134(6):845–854

Liu SY, Du YJ, Yi YL et al (2012) Field investigations on performance of T-shaped deep mixed soil cement column-supported embankments over soft ground. J Geotech Geoenviron Eng 138(6):718–727

Wang BL, Yang LC, Gong QM et al (2006) Experimental study on soft soil reinforced by vacuum combined with fill preloading. J Tongji Univ (Nat Sci) 34(4):499–503 (in Chinese)

China Railway Fourth Survey and Design Institute Group Co., Ltd (2005) Evaluation on calculation methods of soft subgrade settlement treated with different reinforced measures. China Railway Fourth Survey and Design Institute Group Co., Ltd, Wuhan (in Chinese)

Cai DG, Ye YS, Zhang QL et al (2009) Field test study on the mechanical behaviors of the geosynthetic-reinforced pile-supported embankment and the deformation of the reinforced bedding. China Railw Sci 30(5):1–8 (in Chinese)

Bouassida M, Buhan PD, Dormieux L (1995) Bearing capacity of a foundation resting on a soil reinforced by a group of columns. Géotechnique 45(1):25–34

Castro J, Sagaseta C (2009) Consolidation around stone columns. Influence of column deformation. Int J Numer Anal Methods Geomech 33(7):851–877

Castro J, Sagaseta C (2011) Consolidation and deformation around stone columns: numerical evaluation of analytical solutions. Comput Geotech 38(3):354–362

Castro J, Sagaseta C (2011) Deformation and consolidation around encased stone columns. Geotext Geomembr 29(3):268–276

Huang J, Han J (2009) 3D coupled mechanical and hydraulic modeling of a geosynthetic-reinforced deep mixed column-supported embankment. Geotext Geomembr 27(4):272–280

Zhang J, Zheng JJ, Chen BG et al (2013) Coupled mechanical and hydraulic modeling of a geosynthetic reinforced and pile-supported embankment. Comput Geotech 52:28–37

Zhuang Y, Wang KY, Liu HL (2014) A simplified model to analyze the reinforced piled embankments. Geotext Geomembr 42(2):154–165

Bhasi A, Rajagopal K (2015) Numerical study of basal reinforced embankments supported on floating/end bearing piles considering pile soil interaction. Geotext Geomembr 43(6):524–536

Yu Y, Bathurst RJ, Damians IP (2016) Modified unit cell approach for modelling geosynthetic-reinforced column-supported embankments. Geotext Geomembr 44(3):332–343

Zhao LS, Zhou WH, Yuen KV (2017) A simplified axisymmetric model for column supported embankment systems. Comput Geotech 92:96–107

Yu Y, Bathurst RJ (2017) Modelling of geosynthetic-reinforced column-supported embankments using 2D full-width model and modified unit cell approach. Geotext Geomembr 45(2):103–120

Huang ZY, Ziotopoulou K, Filz GM (2019) 3D numerical limiting case analyses of lateral spreading in a column-supported embankment. J Geotech Geoenviron Eng 145(11):04019096

Xie KH, Lu MM, Hu AF et al (2009) A general theoretical solution for the consolidation of a composite foundation. Comput Geotech 36(1–2):24–30

Chen RP, Xu ZZ, Chen YM et al (2010) Field tests on pile-supported embankments over soft ground. J Geotech Geoenviron Eng 136(6):777–785

Hong WP, Hong S, Song JS (2011) Load Transfer by Punching Shear in Pile-Supported Embankments on Soft Grounds. Mar Georesour Geotechnol 29(4):279–298

Jiang GL, Liu XF, Zhang JW et al (2006) Shaking table test of composite foundation reinforcement of saturated silty soil ground for high speed railway. J Southwest Jiaotong Univ 41(2):190–196 (in Chinese)

Briançon L, Simon B (2012) Performance of pile-supported embankment over soft soil: full-scale experiment. J Geotech Geoenviron Eng 138(4):551–561

Xing HF, Zhang Z, Liu HB et al (2014) Large-scale tests of pile-supported earth platform with and without geogrid. Geotext Geomembr 42(6):586–598

Wang CD, Wang BL, Guo PJ et al (2015) Experimental analysis on settlement controlling of geogrid-reinforced pile-raft-supported embankments in high-speed railway. Acta Geotech 15(9):231–242

Fagundes DF, Almeida MSS, Thorel L et al (2017) Load transfer mechanism and deformation of reinforced piled embankments. Geotext Geomembr 45(2):1–10

McGuire MP, Filz GM (2017) Bench-scale test apparatus for modeling column-supported embankments. Geotech Test J 40(5):731–745

Zhang Z, Ye GB, Cai YY et al (2019) Centrifugal and numerical modeling of stiffened deep mixed column-supported embankment with slab over soft clay. Can Geotech J 56(10):1418–1432

Zheng G, Jiang Y, Han J et al (2011) Performance of cement-fly ash-gravel pile-supported high-speed railway embankments over soft marine clay. Mar Georesour Geotechnol 29(2):145–161

Miranda M, Costa AD, Castro J et al (2017) Influence of geotextile encasement on the behaviour of stone columns: laboratory study. Geotext Geomembr 45(1):14–22

China Railway Design Group Co., Ltd (2009) Experimental research on settlements of high speed railway subgrade reinforced with CFG piles. Research Report, China Railway Design Group Co., Ltd, Tianjin (in Chinese)

National Railway Administration (2010) Technical code for ground treatment of railway engineering (TB10106-2010). China Railway Press, Beijing (in Chinese)

Galvín P, Domínguez J (2007) High-speed train-induced ground motion and interaction with structures. J Sound Vib 307(3–5):755–777

Shan Y, Albers B, Savidis SA (2013) Influence of different transition zones on the dynamic response of track-subgrade systems. Comput Geotech 48:21–28

Shan Y, Shu Y, Zhou SH (2017) Finite-infinite element coupled analysis on the influence of material parameters on the dynamic properties of transition zones. Constr Build Mater 148:548–558

Varandas JN, Hölscher P, Silva MAG (2016) Three-dimensional track–ballast interaction model for the study of a culvert transition. Soil Dyn Earthq Eng 89:116–127

Mishra D, Qian Y, Huang H et al (2014) An integrated approach to dynamic analysis of railroad track transitions behavior. Transp Geotech 1(4):188–200

Faragau AB, Metrikine AV, van Dalen KN (2019) Transition radiation in piecewise-linear and infinite one-dimensional structure—a Laplace transform method. Nonlinear Dyn 98(4):2435–2461

Shi C, Zhao C, Zhang X et al (2020) Analysis on dynamic performance of different track transition forms using the discrete element/finite difference hybrid method. Comput Struct 230:1–11

Read D, Li D (2006) Design of track transitions. Research Results Digest 79, Transit Cooperative Research Program, Transportation Research Board, National Academies

Mishra D, Tutumluer E, Kazmee H et al (2014) Use of multi-depth deflectometers and strain gauges to investigate the differential movement at railway bridge approaches. In: Pombo J (ed) Proceedings of the second international conference on railway technology: research, development and maintenance. Civil-Comp Press; Paper 229

Varandas JN, Hölscher P, Silva MAG (2014) Settlement of ballasted track under traffic loading: application to transition zones. Proc IMechE Part F J Rail Rapid Transit 228(3):242–259

Hu YF, Li NF (2010) Theory of ballastless track-subgrade for high speed railway. China Railway Publishing House, Beijing (in Chinese)

Li DQ, Hyslip J, Sussmann T et al (2016) Railway geotechnics. CRC Press, Taylor & Francis Group, Boca Raton

Xiao JH, Wang BL, Wang CD et al (2015) Differential settlement of subgrade and its control for high speed railway. Tongji University Press, Shanghai (in Chinese)

Indraratna B, Rujikiatkamjorn C, Sathananthan I (2005) Analytical and numerical solutions for a single vertical drain including the effects of vacuum preloading. Can Geotech J 42(4):994–1014

Mohamedelhassan E, Shang J (2002) Vacuum and surcharge combined onedimensional consolidation of clay soils. Can Geotech J 39(5):1126–1138

Yapage NNS, Liyanapathirana DS (2014) A parametric study of geosynthetic-reinforced column-supported embankments. Geosynth Int 21(3):213–232

Liu KW, Rowe RK (2015) Numerical modelling of prefabricated vertical drains and surcharge on reinforced floating column-supported embankment behaviour. Geotext Geomembr 43(6):493–505

Filz GM, Sloan JA, McGuire MP et al (2019) Settlement and vertical load transfer in column-supported embankments. J Geotech Geoenviron Eng 145(10):04019083

Phutthananon C, Jongpradist P, Jamsawang P (2019) Influence of cap size and strength on settlements of TDM-piled embankments over soft ground. Mar Georesour Geotechnol. https://doi.org/10.1080/1064119X.2019.1613700

Chen Y, Huang B, Chen Y (2008) Reliability analysis of high level backfill based on chaotic optimization. Chin J Geotech Eng 30(5):764–768 (in Chinese)

Xu MJ, Ni PP, Mei GX et al (2018) Time effects on settlement of rigid pile composite foundation: simplified models. Int J Comput Methods 15(1):1850066

Li L, Li JP, Sun DA, Gong WB (2017) Semi-analytical approach for time-dependent load-settlement response of a jacked pile in clay strata. Can Geotech J 54(12):1682–1692

Wang BL, Yang LC, Zhou SH et al (2006) Experimental study on the settlement control of high-speed railway subgrade over deep soft clay reinforced by CFG piles. J China Railw Soc 28(6):112–116 (in Chinese)

Lam LG, Bergado DT, Voottipruex P et al (2014) Performance of PVDs improvement with and without vacuum preloading for soft ground. In: Proceedings of the 9th international symposium on lowland technology, Japan, pp 313–317

Hewlett WJ, Randolph MA (1988) Analysis of piled embankments. Ground Eng 21(3):12–18

Zaeske D (2001) On the effect of unreinforced and reinforced mineral base courses over pile-like foundation elements. Schriftenreihe Geotechnik. Dissertation, Universität Kassel (in German)

BS8006-1 (2010) Code of practice for strengthened/reinforced soils and other fills. British Standards Institution, London

Rogbeck Y, Alén C, Franzén G et al (2003) Nordic guidelines for reinforced soils and fills. Nordic Geosynthetic Group of the Nordic Geotechnical Societies, Nordic Industrial Fund, Shanghai

Railway Institute of Integrated Technology (2001) Design and construction guide for mixing foundation (mechanical mixing mode). Institute of Integrated Railway Technology, Tokyo (in Japanese)

The German Geotechnical Society (DGGT) (2011) Recommendations for design and analysis of earth structures using geosynthetic reinforcements—EBGEO (DGGT/recommendations) embankments on soft soils. Ernst & Sohn, Hoboken

Spangler MG, Handy RL (1973) Soil Engineering. Intext Educational Publishers, New York

van Eekelen SJM, Bezuijen A, van Tol AF (2013) An analytical model for arching in piled embankments. Geotext Geomembr 39:78–102

van Eekelen SJM, Bezuijen A, van Tol AF (2015) Validation of analytical models for the design of basal reinforced piled embankments. Geotext Geomembr 43(1):56–81

van Eekelen SJM, Vollmert L (2018) The design guideline basal reinforced piled embankments; the Dutch CUR226: 2016 and the German EBGEO: 2010; a comparison of design models and safety approaches. In: Proceedings of 11 ICG, Korea

Han GX, Gong QM, Zhou SH (2015) Soil arching in a piled embankment under dynamic load. Int J Geomech 15(6):04014094

Bi ZQ, Gong QM, Zhou SH et al (2016) Shakedown analysis of soil arch in piled embankment of high-speed railway. J China Railw Soc 38(11):102–110 (in Chinese)

Zhuang Y, Cheng X, Wang K (2019) Analytical solution for geogrid-reinforced piled embankments under traffic loads. Geosynth Int. https://doi.org/10.1680/jgein.19.00023

Lu W, Miao L (2015) A simplified 2-D evaluation method of the arching effect for geosynthetic-reinforced and pile-supported embankments. Comput Geotech 65:97–103

Feng SJ, Ai SG, Chen HX (2017) Estimation of arching effect in geosynthetic-reinforced structures. Comput Geotech 87:188–197

Rui R, van Tol F, Xia YY et al (2018) Evolution of soil arching: 2D analytical models. Int J Geomech 18(6):04018056

Zhang C, Jiang G, Liu X et al (2016) Arching in geogrid-reinforced pile-supported embankments over silty clay of medium compressibility: field data and analytical solution. Comput Geotech 77:11–25

Wang CD, Wang BL, Zhou SH et al (2013) Calculation method of settlement of rigid pile-geogrid composite foundation of high-speed railways and comparisons with measured data. J China Railw Soc 35(8):80–87 (in Chinese)

National Railway Administration (2017) Code for design on subsoil and foundation of railway bridge and culvert (TB10093-2017). China Railway Press, Beijing (in Chinese)

Chik Z, Aljanabi QA, Kasa A et al (2014) Tenfold cross validation artificial neural network modeling of the settlement behavior of a stone column under a highway embankment. Arab J Geosci 7(11):4877–4887

Qi CQ, Wu QB, Shi B et al (2007) Application of BP neural network on deformation prediction for permafrost embankment. Hydrogeol Eng Geol 34(4):27–30

Feng Z, Xu ZY, Wang LJ et al (2004) Grey Prediction of embankment settlement and its application. J North Jiaotong Univ 27(4):23–26 (in Chinese)

Du YL, Lai J, Liu XF (2009) Grey prediction model for construction settlement forecast of embankment of high-speed railway and its application. J Railw Sci Eng 6(1):36–40 (in Chinese)

Wei K, Gong QM, Zhou SH (2009) Ant colony algorithms of long-term uneven settlement prediction in tunnel. Journal of Tongji University (Natural Science) 37(8):993–998 (in Chinese)

Wei K, Gong QM, Zhou SH (2008) Forecast of long-term settlement of metro tunnel on the basis of ant colony optimization. J China Railw Soc 30(4):79–83 (in Chinese)

Tan TS, Inoue T, Lee SL (1991) Hyperbolic method for consolidation analysis. J Geotech Eng ASCE 117(11):1723–1737

Tan SA, Chew SH (1996) Comparison of the hyperbolic and Asaoka observational method of monitoring consolidation with vertical drains. Soils Found 36(3):31–42

Chen SX, Wang XY, Xu XC et al (2011) Three-point modified exponential curve method for predicting subgrade settlements. Rock Soil Mech 32(11):3355–3360

Wang W, Sun BX, Lu TH (2008) 3-parameter prediction model of post-construction settlement for soft soil foundation under highway embankment. China J Highw Transp 21(2):12–17 (in Chinese)

Hoshino K (1962) The latest problems on soils and foundations. J Japan Soc Civil Eng 47(7):63–67 (in Japanese)

Asaoka A (1978) Observational procedure of settlement prediction. Soils Found 18(4):87–101

Asaoka A (1984) An inverse problem approach to settlement prediction of multi-dimensional condition behavior. Soils Found 24(1):49–62

Engineering Management Center of the Ministry of Railways (2009) Technical manual for deformation observation and evaluation of passenger dedicated railways. China Railway Press, Beijing (in Chinese)

Dafalias YF (1986) Bounding surface plasticity (I): mathematical formulation and hypoplasticity. J Eng Mech ASCE 112(9):966–987

Prevost JH (1985) A simple plasticity theory for frictional cohesionless soils. Int J Soil Dyn Earthq Eng 4(1):9–17

Zienkiewicz C, Leung KH, Pastor M (1985) Simple model for transient soil loading in earthquake analysis (I): basic model and its application. Int J Numer Anal Methods Geomech 9(5):453–476

Suiker SJ, Borst R (2003) A numerical model for the cyclic deterioration of railway tracks. Int J Numer Methods Eng 57(4):441–470

Dahlberg T (2001) Some railroad settlement models—a critical review. Proc IMechE Part F J Rail Rapid Transit 215(4):289–300