Abstract.

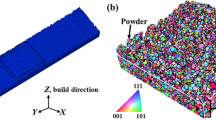

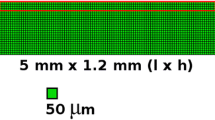

Electron beam additive manufacturing (EBAM) is an emerging additive manufacturing technology with extremely high energy beam. The rapid solidification in the molten pool is of interest but not fully understood. In EBAM, with both large thermal gradient and cooling rate, the microstructure evolution during solidification is difficult to be described. The quantitative multi-phase-field model provides an effective way to reveal the dynamic evolution of dendrites in the molten pool of EBAM. In this study, the thermal profile is interpolated from the macroscale simulation at each time-step, to couple the realistic thermal evolution in the molten pool. The microstructure evolution and competitive growth have been investigated in details. Simulations of dendrite arrays with the same orientation showed how the growth velocity and the primary spacing of columnar dendrites depend on thermal gradient and cooling rate. The results are in agreement with theoretical models qualitatively. Moreover, the Gaussian nucleation model was introduced so as to give a better prediction of the microstructure in EBAM.

Graphical abstract

Similar content being viewed by others

References

C. Körner, Int. Mater. Rev. 61, 361 (2016)

L.E. Murr et al., Mater. Charact. 60, 96 (2009)

S. Das, Adv. Eng. Mater. 5, 701 (2003)

P.J. Prescott, F.P. Incropera, in Advances in Heat Transfer, edited by D. Poulikakos (Elsevier, 1996) p. 231

V.R. Voller, A.D. Brent, C. Prakash, Int. J. Heat Mass Transfer 32, 1719 (1989)

X. He, J. Elmer, T. Debroy, J. Appl. Phys. 97, 084909 (2005)

W. Kurz, D.J. Fisher, R. Trivedi, Int. Mater. Rev. 64, 311 (2019)

J. Parthasarathy, B. Starly, S. Raman, A. Christensen, J. Mech. Behav. Biomed. Mater. 3, 249 (2010)

R. Cunningham, S.P. Narra, T. Ozturk, J. Beuth, A.D. Rollett, JOM 68, 765 (2016)

S. Bontha, N.W. Klingbeil, P.A. Kobryn, H.L. Fraser, Mater. Sci. Eng. A 513-514, 311 (2009)

S.M. Gaytan, L.E. Murr, F. Medina, E. Martinez, M.I. Lopez, R.B. Wicker, Mater. Technol. 24, 180 (2009)

P. Heinl, A. Rottmair, C. Koerner, R.F. Singer, Adv. Eng. Mater. 9, 360 (2010)

M. Koike, K. Martinez, L. Guo, G. Chahine, R. Kovacevic, T. Okabe, J. Mater. Process. Technol. 211, 1400 (2011)

W.J. Boettinger, J.A. Warren, C. Beckermann, A. Karma, Annu. Rev. Mater. Res. 32, 163 (2002)

A. Karma, W.-J. Rappel, Phys. Rev. E 57, 4323 (1998)

S.G. Kim, W.T. Kim, T. Suzuki, Phys. Rev. E 60, 7186 (1999)

Z. Wang, J. Wang, G. Yang, Scr. Mater. 61, 915 (2009)

C.A. Gandin, M. Rappaz, Acta Mater. 45, 2187 (1997)

H. Yin, S.D. Felicelli, L. Wang, Acta Mater. 59, 3124 (2011)

C. Guo, J. Li, H. Yu, Z. Wang, X. Lin, J. Wang, Acta Mater. 136, 148 (2017)

D. Montiel, L. Liu, L. Xiao, Y. Zhou, N. Provatas, Acta Mater. 60, 5925 (2012)

V. Fallah, M. Amoorezaei, N. Provatas, S.F. Corbin, A. Khajepour, Acta Mater. 60, 1633 (2012)

Z. Wang, T. Jing, H. Dong, IOP Conf. Ser.: Mater. Sci. Eng. 529, 012003 (2019)

X. Gong, K. Chou, JOM 67, 1176 (2015)

S. Sahoo, K. Chou, Addit. Manuf. 9, 14 (2016)

L. Wu, J. Zhang, JOM 70, 2392 (2018)

J.D. Hunt, Solidification and Casting of Metals (The Metal Society, 1979) p. 3

M.H. Burden, J.D. Hunt, J. Cryst. Growth 22, 99 (1974)

I. Steinbach, F. Pezzolla, B. Nestler, M. Seeßelberg, R. Prieler, G. Schmitz, J. Rezende, Physica D: Nonlin. Phenom. 94, 135 (1996)

J. Eiken, B. Böttger, I. Steinbach, Phys. Rev. E 73, 066122 (2006)

S.G. Kim, Acta Mater. 55, 4391 (2007)

S. Gyoon Kim, W. Tae Kim, T. Suzuki, M. Ode, J. Cryst. Growth 261, 135 (2004)

C. Guo, J. Li, Z. Wang, J. Wang, Mater. Des. 151, 141 (2018)

J. Li, Z. Wang, Y. Wang, J. Wang, Acta Mater. 60, 1478 (2012)

L. Nastac, J.S. Chou, Y. Pang, International Symposium on Liquid Metals Processing and Casting, edited by A. Mitchell, L. Ridgway, M. Baldwin (TMS, Warrendale, PA, 1999) p. 207

L. Nastac, CFD Modeling and Simulation in Materials Processing (Wiley-TMS, New York, 2012) pp. 123--130

Y. Qian, W. Yan, F. Lin, Engineering 5, 746 (2019)

W. Yan, Y. Qian, W. Ge, S. Lin, W.K. Liu, F. Lin, G.J. Wagner, Mater. Des. 141, 210 (2018)

Z. Wang, J. Li, J. Wang, J. Cryst. Growth 328, 108 (2011)

C.A. Gandin, M. Eshelman, R. Trivedi, Metall. Mater. Trans. A 27, 2727 (1996)

M. Rappaz, C.A. Gandin, Acta Metall. Mater. 41, 345 (1993)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

The EPJ Publishers remain neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chu, S., Guo, C., Zhang, T. et al. Phase-field simulation of microstructure evolution in electron beam additive manufacturing. Eur. Phys. J. E 43, 35 (2020). https://doi.org/10.1140/epje/i2020-11952-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epje/i2020-11952-1