Abstract

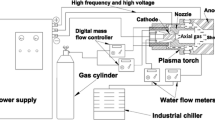

Plasma atomization technology is able to both melt and atomize a material which is fed into the converging plasma jets as a wire. Temperature and velocity distribution in a plasma jet obtained at the outer region of a plasma torch is very important to melt a solid wire and to disintegrate the liquid metal into fine spherical particles. In this study, a non-transferred arc plasma torch is designed and numerically solved for the determination of temperature and velocity distributions in the plasma jet. A high velocity nozzle attachment is assembled to plasma torches for increasing the jet velocity for atomization purposes. Results of numerical solutions with and without high velocity nozzle attachment are discussed and compared with experimental studies. It is found that high velocity nozzle attachment can be favourable in terms of the higher velocity and temperature distribution in the plasma jet at longer distances from the torch exit.

Similar content being viewed by others

References

Moulding MI, Kroeger J, Ap R, Raymor APC (2011) Leading the way with plasma atomised Ti spherical powders for MIM. Inject Mould Int 5:55–57

Larouche F, Balmayer M, Trudeau-Lalonde F (2017) Plasma atomization metal powder manufacturing processes and systems therefore. WO 2017/011900 A1

Boulos MI, Jurewicz JW, Auger A (2015) Process and apparatus for producing powder particles by atomization of a feed material in the form of an elongated member. WO 2015/135075 A1

Sun P, Fang ZZ, Zhang Y, Xia Y (2017) Review of the methods for production of spherical Ti and Ti alloy powder. JOM 69:1853–1860. https://doi.org/10.1007/s11837-017-2513-5

Entezarian M, Allaire F, Tsantrizos P, Drew RAL (1996) plasma atomization : a new process for the production of fine. Spherical Powders 48:53–55

Singh S, Ramakrishna S, Singh R (2017) Material issues in additive manufacturing: a review. J Manuf Process 25:185–200

Nickels L (2017) Plasma boost for 3D printing. Met Powder Rep 72:130–132. https://doi.org/10.1016/j.mprp.2017.03.040

Grenier S (1998) Plasma Atomization goes commercial. Met Powder Rep 53:26–28. https://doi.org/10.1016/S0026-0657(99)80007-1

Ti U, Tsantrizos P (1997) Plasma atomization gives unique spherical powders. Met Powder Rep, 34–37. https://ac.els-cdn.com/S0026065797871500/1-s2.0-S0026065797871500-main.pdf?_tid=0ca04de5-8321-4b7f-84d9-9ef194a2d9f8&acdnat=1525276632_136e1074e88d4bd4f285130c957221a7

Selvan B, Ramachandran K (2009) Comparisons between two different three-dimensional arc plasma torch simulations. J Therm Spray Technol 18:846–857. https://doi.org/10.1007/s11666-009-9343-0

Westhoff R, Szekely J (1991) A model of fluid, heat flow, and electromagnetic phenomena in a nontransferred arc plasma torch. J Appl Phys 70:3455–3466. https://doi.org/10.1063/1.349238

Paik S, Huang PC, Heberleinand J, Pfender E (1993) Determination of the arc-root position in a DC plasma torch. Plasma Chem Plasma Process 13:379–397. https://doi.org/10.1007/BF01465872

Bauchire JM, Gonzalez JJ, Gleizes A (1997) Modeling of a DC plasma torch in laminar and turbulent flow. Plasma Chem Plasma Process 17:409–432. https://doi.org/10.1023/A:1021847113956

Trelles JP, Pfender E, Heberlein JVR (2006) Multiscale finite element modeling of arc dynamics in a DC plasma torch. Plasma Chem Plasma Process 26:557–575. https://doi.org/10.1007/s11090-006-9023-5

Ramachandran K, Marques JL, Vaben R, Stöver D (2006) Modelling of arc behaviour inside a F4 APS torch. J Phys D Appl Phys 39:3323–3331. https://doi.org/10.1088/0022-3727/39/15/015

Wenxia P, Xian M, Teng L, Xi C, Chengkang W (2007) Comparative observation of Ar, Ar-H 2 and Ar-N 2 DC arc plasma jets and their arc root behaviour at reduced pressure. Plasma Sci Technol 9:152–157. https://doi.org/10.1088/1009-0630/9/2/07

Selvan B, Ramachandran K, Sreekumar KP, Thiyagarajan TK, Ananthapadmanabhan PV (2009) Numerical and experimental studies on DC plasma spray torch. Vacuum 84:444–452. https://doi.org/10.1016/j.vacuum.2009.09.009

Guo Z, Yin S, Liao H, Gu S (2015) Three-dimensional simulation of an argon-hydrogen DC non-transferred arc plasma torch. Int J Heat Mass Transf 80:644–652. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.059

Ghorui S, Das AK (2013) Arc plasma devices: evolving mechanical design from numerical simulation. Pramana 80:685–699. https://doi.org/10.1007/s12043-012-0491-2

Park J, Heberlein JVR, Pfender E, Candler G, Chang CH (2008) Two-dimensional numerical modeling of direct-current electric arcs in nonequilibrium. Plasma Chem Plasma Process 28:213–231. https://doi.org/10.1007/s11090-008-9120-8

Waleed Sunjuq WK, Yurtkuran E, Özsunar AK, Ünal R (2018) Investigation of the effect of gas flow rate and electric current on plasma jet temperature and velocity at torch exit by CFD analysis. J Fac Eng Archit Gazi Univ. https://doi.org/10.17341/gazimmfd.406807

Yurtkuran E, Unal R, Ozsunar A (2018) Numerical modeling of torch design for plasma atomization. Acta Phys Pol A. https://doi.org/10.12693/APhysPolA.134.292

Lek JY, Bhowmik A, Tan AWY, Sun W, Song X, Zhai W, Buenconsejo PJ, Li F, Liu E, Lam YM, Boothroyd CB (2018) Understanding the microstructural evolution of cold sprayed Ti-6Al-4V coatings on Ti-6Al-4V substrates. Appl Surf Sci 459:492–504. https://doi.org/10.1016/j.apsusc.2018.07.175

Selvan B, Ramachandran K, Sreekumar KP, Thiyagarajan TK, Ananthapadmanabhan PV (2009) Three-dimensional numerical modeling of an Ar-N2plasma Arc inside a non-transferred torch. Plasma Sci Technol 11:679–687. https://doi.org/10.1088/1009-0630/11/6/09

Guo R, Xu L, Wu J, Yang R, Zong BY (2015) Microstructural evolution and mechanical properties of powder metallurgy Ti-6Al-4 V alloy based on heat response. Mater Sci Eng, A 639:327–334. https://doi.org/10.1016/j.msea.2015.05.041

Alaya M, Chazelas C, Mariaux G, Vardelle A (2014) Arc-cathode coupling in the modeling of a conventional DC plasma spray torch. J Therm Spray Technol 24:3–10. https://doi.org/10.1007/s11666-014-0162-6

Tiwari N, Bhandari S, Ghorui S (2018) Stability and structures in atmospheric pressure DC non-transferred arc plasma jets of argon, nitrogen, and air. Phys Plasmas. doi 10(1063/1):5034397

Trelles JP, Heberlein JVR, Pfender E (2007) Non-equilibrium modelling of arc plasma torches. J Phys D Appl Phys 40:5937–5952. https://doi.org/10.1088/0022-3727/40/19/024

Li H, Pfender E (2007) Three dimensional modeling of the plasma spray process. J Therm Spray Technol 16:245–260. https://doi.org/10.1007/s11666-007-9023-x

Trelles JP, Chazelas C, Vardelle A, Heberlein JVR (2009) Arc plasma torch modeling. J Therm Spray Technol 18:728–752. https://doi.org/10.1007/s11666-009-9342-1

Liang P, Groll R (2018) Numerical study of plasma–electrode interaction during arc discharge in a DC plasma torch. IEEE Trans Plasma Sci 46:363–372. https://doi.org/10.1109/TPS.2017.2786079

Ansys® Academic Research, Release 18.1, Help System, User Guide, ANSYS, Inc

Murphy AB, Arundelli CJ (1994) Transport coefficients of argon, nitrogen, oxygen, argon-nitrogen, and argon-oxygen plasmas. Plasma Chem Plasma Process 14:451–490. https://doi.org/10.1007/BF01570207

Murphy AB (2000) Transport coefficients of hydrogen and argon–hydrogen plasmas. Plasma Chem Plasma Process 20:279–297. https://doi.org/10.1023/A:1007099926249

Inc. ANSYS (2013) ANSYS FLUENT theory guide. https://doi.org/10.1016/0140-3664(87)90311-2

Yurtkuran E, Unal R, Ozsunar A (2018) Numerical modeling of torch design for plasma atomization. Acta Phys Pol A 134:292–296. https://doi.org/10.12693/APhysPolA.134.292

Guildenbecher DR, López-Rivera C, Sojka PE (2009) Secondary atomization. Exp Fluids 46:371–402. https://doi.org/10.1007/s00348-008-0593-2

Gang XG, Fritsching U (2017) Process modeling pressure-swirl-gas-atomization for metal powder production. J Mater Process Technol 239:1–17. https://doi.org/10.1016/j.jmatprotec.2016.08.009

O’Rourke, PJ, Amsden AA (1987) The TAB method for numerical calculation of spray droplet breakup. SAE Technical Paper. https://doi.org/10.4271/872089

Reitz RD (1987) Modeling atomization processes in high-pressure vaporizing sprays. At Sprays Technol 3:309–337. https://doi.org/10.1111/jace.13860

Zeoli N, Gu S (2006) Numerical modelling of droplet break-up for gas atomisation. Comput. Mater. Sci. 38(2):282–292. https://doi.org/10.1016/j.commatsci.2006.02.012

Boulos MI, Jurewicz JW, Auger A (2015) Process and apparatus for producing powder particles by atomization of a feed material in the form of an elongated member. WO2015/135075 AI

Acknowledgements

This study was supported by the Scientific and Technological Research Council of Turkey (TÜBİTAK), Grant No: 215M895.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yurtkuran, E., Ünal, R. Numerical and Experimental Investigation on the Effects of a Nozzle Attachment to Plasma Torches for Plasma Atomization. Plasma Chem Plasma Process 40, 1127–1144 (2020). https://doi.org/10.1007/s11090-020-10095-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-020-10095-x