Abstract

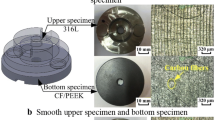

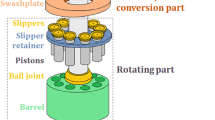

This study investigates tribological performance of MoS2 coating on slipper pair in axial piston pump. Firstly, the MoS2 coating on the surface of slipper pair was prepared by atmospheric plasma spraying treatment technology. Secondly, the tribological characteristics of slipper pair under various working conditions were evaluated on ring-on-block tester in oil lubrication. The original and worn surfaces of the specimens were analyzed with scanning electron microscope and energy dispersive spectrometer, and then the wear morphologies of the MoS2 coatings were imaged by X-ray photoelectron spectroscopy. The experimental results showed that the friction coefficients of Cu-based materials with MoS2 coating decreased by about 0.05 at 800 N. Especially, when the external load was set to 800 N, the wear rate of the ZY331608 decreased by about 16.4% after the substrates were treated by the MoS2 coating, which exhibited excellent anti-friction and wear resistance. The formation of the MoS2 lubricating film could be classified into four stages, including the initial friction stage, anchoring stage of MoS2 on friction surface, covering stage of the sliding surface by MoS2 and the formation stage of MoS2 film. The dominating wear mechanisms of Cu-based materials with MoS2 coating were adhesive wear and abrasive wear accompanied with oxidative wear.

摘要

本文研究了轴向柱塞泵滑靴副表面 MoS2 涂层的摩擦学性能. 首先, 利用等离子喷涂技术在滑靴副材料表面制备 MoS2 涂层. 其次, 采用环块摩擦磨损实验机考察材料在不同工况条件下的摩擦学性能. 最后, 基于能谱仪和扫描电子显微分析以及试件磨损表面 X 射线衍射分析, 探讨了滑靴副表面 MoS2 涂层的摩擦机理. 研究结果表明, 当外部载荷为 800 N 时, 含 MoS2 涂层的铜基体材料表面摩擦系数降低 0.05; 在 MoS2 涂层下的 ZY331608 试件具有优异的抗摩擦磨损性能, 其磨损率减少 16.4%; 铜基体材料表面形成 MoS2 润滑膜的过程分为四个阶段: 初始摩擦阶段、 MoS2 在摩擦表面的粘附阶段、 MoS2 在滑动表面的覆盖阶段以及 MoS2 润滑膜的形成阶段; 铜基体材料表面 MoS2 涂层的主要磨损机制是粘着磨损、 磨粒磨损和氧化磨损.

Similar content being viewed by others

Abbreviations

- μ :

-

Friction coefficient

- F :

-

Contact force

- T :

-

Friction torque

- f :

-

Friction force

- R c :

-

Outer radius of the lower specimen

- ω c :

-

Wear rate of the specimens

- m c1 :

-

Mass of the specimen before the test

- m c2 :

-

Mass of the specimen after the test

- ρ :

-

Density of the specimen

- v c :

-

Velocity of the ring

- t :

-

Testing time

References

CANBULUT F, SINANOGLU C, KOC E. Experimental analysis of frictional power loss of hydrostatic slipper bearings [J]. Industrial Lubrication & Tribology, 2009, 61(3): 123–131. DOI: 10.1108/00368790910953631.

TANG H S, YIN Y B, ZHANG Y, LI J. Parametric analysis of thermal effect on hydrostatic slipper bearing capacity of axial piston pump [J]. Journal of Central South University, 2016, 23(2): 333–343. DOI: 10.1007/s11771-016-3078-0.

XU B, HU M, ZHANG J H, MAO Z B. Distribution characteristics and impact on pump’s efficiency of hydro-mechanical losses of axial piston pump over wide operating ranges [J]. Journal of Central South University, 2017, 24(3): 609–624. DOI: 10.1007/s11771-017-3462-4.

ZHANG J H, CHAO Q, WANG Q N, XU B, CHEN Y, LI Y. Experimental investigations of the slipper spin in an axial piston pump [J]. Measurement, 2017, 102(5): 112–120. DOI: 10.1016/j.measurement.2017.01.035.

HASHEMI S, FRIEDRICH, BOBACH L, BARTEL D. Validation of a thermal elastohydrodynamic multibody dynamics model of the slipper pad by friction force measurement in the axial piston pump [J]. Tribology International, 2017, 115(10): 319–337. DOI:10.1016/j.triboint.2017.05.013.

KUMAR S, BERGADA J M, WATTON J. Axial piston pump grooved slipper analysis by CFD simulation of three-dimensional NVS equation in cylindrical coordinates [J]. Computer & Fluids, 2009, 38(3): 648–663. DOI: 10.1016/j.compfluid.2008.06.007.

SCHENK A, IVANTYSYNOVA M. A transient thermoelastohydrodynamic lubrication model for the slipper/swashplate in axial piston pump [J]. Journal of Tribology, 2015, 137(3): 031701–031711. DOI: 10.1115/1.4029674.

YE S G, TANG H S, REN Y, XIANG J W. Study on the load-carrying capacity of surface textured slipper bearing of axial piston pump [J]. Applied Mathematical Modelling, 2020, 77(1): 554–584. DOI: https://doi.org/10.1016/j.apm. 2019.07. 058.

LUO J, ZHU M H, WANG Y D, ZHENG J F, MO J L. Study on rotational fretting wear of bonded MoS2 solid lubricant coating prepared on medium carbon steel [J]. Tribology International, 2011, 44(11): 1565–1570. DOI: 10.1016/j.triboint.2010.10.011.

SHEN M X, CAI Z B, PENG J F, PENG X D, ZHU M H. Antiwear properties of bonded MoS2 solid lubricant coating under dual-rotary fretting conditions [J]. ASLE Transactions, 2016, 60(2): 217–225. DOI: 10.1080/10402004.2016. 1158338.

FIELD S K, JARRATT M, TEER D G. Tribological properties of graphite-like and diamond-like carbon coatings [J]. Tribology International, 2004, 37(11): 949–956. DOI: 10.1016/j.triboint. 2004.07.012.

ZHANG Z H, NIE S L, YUAN S H, LIAO W J. Comparative evaluation of tribological characteristics of CF/PEEK and CF/PTFE/Graphite filled PEEK sliding against AISI630 steel for seawater hydraulic piston pump/motors [J]. Tribology Transactions, 2015, 58(6): 1096–1104. DOI: 10.1080/10402004.2015.1045651.

KONG X L, ZHOU B, WANG J X, LI W P. Engineering research of DLC coating in piston pins and bucket tappets [J]. Industrial Lubrication and Tribology, 2016, 68(5): 530–535. DOI: 10.1108/ILT-09-2015-0132.

ZHU M H, ZHOU Z R. An investigation of molybdenum disulfide bonded solid lubricant coatings in fretting conditions [J]. Surface & Coating Technology, 2001, 141(2): 240–245. DOI: 10.1016/S0257-8972(01)01194-X.

YE Y P, CHEN J M, ZHOU H D. An investigation of friction and wear performances of bonded molybdenum disulfide solid film lubricants in fretting conditions [J]. Wear, 2009, 266(7, 8): 859–864. DOI: 10.1016/j.wear.2008.12.012.

RAMESH R, GNANAMOORTHY R. An investigation on fretting wear behaviour of MoS2-bonded coating on AISI 4340 Steel [J]. Proceedings of the Institution of Mechanical Engineers-Part J: Journal of Engineering Tribology, 2007, 221(1): 41–47. DOI: 10.1243/13506501jet171.

XU J, ZHU M H, ZHOU Z R, KAPSA P H, VINCENT L. An investigation on fretting wear life of bonded MoS2 solid lubricant coatings in complex condition [J]. Wear, 2003, 255(1): 253–358. DOI: 10.1016/s0043-1648(03)00053-x.

PIMENTEL J V, POLCAR T, CAVALEIRO A. Structural, mechanical and tribological properties of Mo-S-C solid lubricant coating [J]. Surface & Coating Technology, 2011, 205(10): 3274–3279. DOI: 10.1016/j.surfcoat.2010.11.043.

SHTERTSER A, MUDERS C, VESELOV S, ZLOBIN S. ULIANITSKY V, JIANG X, BATAEVC V. Computer controlled detonation spraying of WC/Co coatings containing MoS2 solid lubricant [J]. Surface & Coating Technology, 2012, 206(23): 4763–4770. DOI: 10.1016/j.surfcoat.2012.03.043.

ARSLAN E, BULBUL F, ALSARAN A, CELIK A, EFEOGLU I. The effect of deposition parameters and Ti content on structural and wear properties of MoS2-Ti coatings [J]. Wear, 2005, 259(7): 814–819. DOI: 10.1016/j.wear.2005.03.004.

DU H, SUN C, HUA W, WANG T, GONG J, JIANG X, LEE S W. Structure, mechanical and sliding wear properties of WCCo/MoS2Ni coatings by detonation gun spray [J]. Materials Science & Engineering A, 2007, 445-446(2): 122–134. DOI: 10.1016/j.msea.2006.09.011.

QIN X, KE P, WANG A, KIM K H. Microstructure, mechanical and tribological behaviors of MoS2-Ti composite coatings deposited by a hybrid HIPIMS method [J]. Surface & Coatings Technology, 2013, 228(9): 275–281. DOI: 10.1016/j.surfcoat.2013.04.040.

MESGARNEJAD A, KHONSARI M M. On the tribological behavior of MoS2-coated thrust ball bearings operating under oscillating motion [J]. Wear, 2010, 269(7): 547–556. DOI: 10.1016/j.wear.2010.05.010.

QIU M, LU J J, LI Y C, LV G S. Investigation on MoS2 and graphite coatings and their effects on the tribological properties of the radial spherical plain bearings [J]. Chinese Journal of Mechanical Engineering, 2016, 29(4): 844–851. DOI: 10.3901/CJME.2016.0331.043.

MARTINS R C, MOURA P S, SEABRA J O. MoS2/Ti low-friction coating for gears [J]. Tribology International, 2006, 39(12): 1686–1697. DOI: 10.1016/j.triboint.2006.02. 065.

HWANG B, LEE S, AHN J. Correlation of microstructure and wear resistance of molybdenum blend coatings fabricated by atmospheric plasma spraying [J]. Materials Science & Engineering A, 2004, 366(1): 152–163. DOI: 10.1016/j.msea.2003.09.062.

MATSUNAGA M. Handbook of solid lubrication [M]. Beijing: Machinery Industry Press, 1986: 93–94. (in Chinese)

MARTIN J M, DONNET C, MOGNE T L. Superlubricity of molybdenum disulphide [J]. Physical Review B: Condensed Matter, 1993, 48(14): 10584–10588. DOI: 10.1103/PhysRevB.48.10583.

SAVAN A, PFLUGER E, VOUMARD P, SCHROER A. Modern solid lubrication: Recent developments and applications of MoS2 [J]. Lubrication Science, 2002, 12(2): 85–203. DOI: 10.1002/ls.3010120206.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51805376) supported by the National Natural Science Foundation of China; Project(LQ17E050003) supported by the Zhejiang Provincial Natural Science Foundation of China; Project(GZKF-201719) supported by the Open Foundation of the State Key Laboratory of Fluid Power and Mechatronic Systems, China; Project(G20180019) supported by the Basic Scientific Research Projects Foundation of Wenzhou, China

Rights and permissions

About this article

Cite this article

Tang, Hs., Ren, Y. & Zhang, Xl. Tribological performance of MoS2 coating on slipper pair in axial piston pump. J. Cent. South Univ. 27, 1515–1529 (2020). https://doi.org/10.1007/s11771-020-4387-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4387-x