Abstract

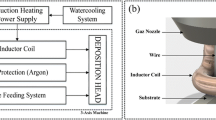

The modern domestic installations used for the additive laser technologies based on layer-by-layer melting of metal powders are considered. An installation was developed and manufactured for the selective melting of metal powders by laser radiation scanned along a given contour. The installation is equipped with an automatic control system and makes it possible to grow 110 × 110 × 110 mm parts with an accuracy of 20 μm and a growth rate up to 10 cm3/h. A KLP-400 installation was created for growing large-sized parts. The principle of operation of the installation is based on layer-by-layer laser facing with metal powders supplied coaxially with laser radiation. The installation can be used to produce parts 400 × 400 × 400 mm in size and about 500 kg in weight. The accuracy of the manufactured parts is 0.1–0.5 mm.

Similar content being viewed by others

REFERENCES

A. G. Grigor’yants, I. N. Shiganov, et al., Laser Additive Technologies in Mechanical Engineering (Izd. MGTU, Moscow, 2018).

A. Yakovlev, “Laser-assisted direct manufacturing of functionally graded 3D objects,” Surf. Coat. Technol. 190 (1), 15–24 (2005).

J. Gibson, Additive Manufacturing Technologies (Springer, New York, 2015).

M. A. Zilenko, A. A. Popovich, and I. N. Mutylina, Additive Technologies in Mechanical Engineering: Textbook for Universities (Izd. Politekh. Univ., St. Petersburg, 2013).

V. A. Valetov, Additive Technologies: Textbook for Universities (Izd. Univ. ITMO, St. Petersburg, 2015).

M. Rombouts, Selective Laser Sintering/Melting Iron-Based Powders: PhD Thesis (Heverlee, 2006).

I. V. Shishkovskii, Laser Synthesis of Functional Mesostructures and Bulk Products Izd. Fizmatlit, Moscow, 2009).

I. Smurov, “Laser cladding and laser assisted direct manufacturing,” Surf. Coat. Technol. 202 (18), 4496–4502 (2008).

A. G. Grigor’yants, I. N. Shiganov, and A. I. Misyurov, Technological Processes of Laser Processing: Textbook for Universities (Izd. MGTU, 2008).

A. V. Bogdanov and Yu. V. Golubenko, Fiber Lasers and Their Application (Lan’, St. Petersburg, 2018).

N. Keller and V. Ploshikhin, “New method for fast predictions of residual stress and distortion of AM parts,” in Airbus Endowed Chair for Integrative Simulation and Engineering of Materials and Processes (University of Bremen, Bremen, 2014), Vol. 96, pp. 1229–1237.

L. Han, F. W. Liou, and K. M. Phatak, “Modeling of laser cladding with powder injection,” Metall. Mater. Trans. B 35 (6), 1139–1150 (2004).

M. Doubenskaia et al., “Optical monitoring in direct metal deposition,” in Proceedings of the 5th International WLT-Conference on Lasers in Manufacturing LIM-2009 (Munich, 2009), pp. 591–596.

T. A. Mai and G. C. Lim, “Micromelting and its effects on surface topography and properties in laser polishing of stainless steel,” J. Laser Appl., 132–140 (2004).

Funding

This work was supported by the Ministry of Education and Science of the Russian Federation, project no. 95051.2017/8.9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Grigor’yants, A.G., Shiganov, I.N. Development of Domestic Equipment for Laser Additive Technologies by Melting Metallic Powders. Russ. Metall. 2020, 649–653 (2020). https://doi.org/10.1134/S0036029520060099

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520060099