Abstract

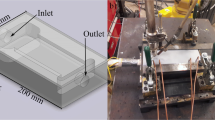

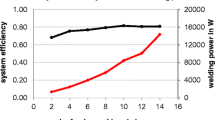

The thermal efficiency of arc welding influences the cooling rate, peak temperature, and microstructures of a weld, which affects the material properties of the welded joint. This work quantifies the uncertainty of thermal efficiency measurements on gas metal arc welds using low (2.5 kW) and high (9.5 kW) arc powers. In order to understand the effect of calorimeter parameters on the measured efficiency, a two-factor, two-level full factorial design was carried out for each arc power condition. In this study, the factors are flow rate (2 l/min and 5 l/min) and plate thickness (0.25 in. [6.35 mm] and 0.375 in. [9.53 mm]). The results show that the uncertainty in the thermal efficiency measurements increases when both higher flow rates and plate thickness are used. Moreover, the use of a thick plate causes the heat transfer regime to change, increasing the cooling rate and decreasing the observed thermal efficiency. Uncertainty is also influenced by the metal transfer mode during welding.

Similar content being viewed by others

References

Scotti A (2019) Cares to deal with heat input in arc welding: applications and modeling. Adv Weld Technol Process Dev:101–138. https://doi.org/10.1201/9781351234825-6

Liskevych O, Scotti A (2015) Determination of the gross heat input in arc welding. J Mater Process Technol 225:139–150. https://doi.org/10.1016/j.jmatprotec.2015.06.005

Liskevych O, Quintino L, Vilarinho LO, Scotti A (2013) Intrinsic errors on cryogenic calorimetry applied to arc welding. Weld World 57:349–357. https://doi.org/10.1007/s40194-013-0035-5

Pépe N, Egerland S, Colegrove PA, Yapp D, Leonhartsberger A, Scotti A (2011) Measuring the process efficiency of controlled gas metal arc welding processes. Sci Technol Weld Join 16:412–417. https://doi.org/10.1179/1362171810Y.0000000029

Haelsig A, Kusch M, Mayr P (2015) Calorimetric analyses of the comprehensive heat flow for gas metal arc welding. Weld World 59:191–199. https://doi.org/10.1007/s40194-014-0193-0

Haelsig A, Mayr P (2013) Energy balance study of gas-shielded arc welding processes. Weld World 57:727–734. https://doi.org/10.1007/s40194-013-0073-z

Haelsig A, Mayr P, Kusch M (2016) Determination of energy flows for welding processes. Weld World 60:259–266. https://doi.org/10.1007/s40194-016-0297-9

Hälsig A, Pehle S, Kusch M, Mayr P (2017) Reducing potential errors in the calculation of cooling rates for typical arc welding processes. Weld World 61:745–754. https://doi.org/10.1007/s40194-017-0462-9

Hurtig K, Choquet I, Scotti A, Svensson L-E (2016) A critical analysis of weld heat input measurement through a water-cooled stationary anode calorimeter. Sci Technol Weld Join 21:339–350. https://doi.org/10.1080/13621718.2015.1112945

ASME (2018) ASME PTC 19.1-2018 - test uncertainty. ASME, 81pp

Arevalo HDH, Vilarinho LO (2012) Desenvolvimento e avaliação de calorímetros por nitrogênio líquido e fluxo contínuo para medição de aporte térmico. Soldag e Insp 17:236–250. https://doi.org/10.1590/S0104-92242012000300008

Grong O (1997) Metallurgical modelling of welding, 2nd edn. The Institute of Materials, London

Sikström F (2015) Operator bias in the estimation of arc efficiency in gas tungsten arc welding. Soldag e Insp 20:128–133. https://doi.org/10.1590/0104-9224/SI2001.13

Kou S, Le Y (1984) Heat flow during the autogenous GTA welding of pipes. Metall Trans A, Phys Metall Mater Sci 15 A:1165–1171

Incropera FP (2007) Fundamentals of heat and mass transfer, 6th edn. John Wiley & Sons, Inc.

Joseph A, Harwig D, Farson DF, Richardson R (2003) Measurement and calculation of arc power and heat transfer efficiency in pulsed gas metal arc welding. Sci Technol Weld Join 8:400–406. https://doi.org/10.1179/136217103225005642

Radaj D (1992) Heat effects of welding, 1st edn. Springer, Berlin

Egerland S, Colegrove P (2011) Using solid state calorimetry for measuring gas metal arc welding efficiency. In: Sudnik W (ed) Arc welding, 1st edn. InTech, pp 265–280

Acknowledgments

The authors would like to thank the Centre for Advanced Materials Joining (CAMJ) in the University of Waterloo where all the experiments were performed. Additionally, Mr. P. D. C. Assunção would like to acknowledge the Coordination for the Improvement of Higher Education Personnel (CAPES) from the Brazilian Ministry of Education for a scholarship to visit the University of Waterloo.

Funding

This research study was funded by the TC Energy, Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Study Group 212 - The Physics of Welding

Rights and permissions

About this article

Cite this article

Ribeiro, R.A., Dos Santos, E.B.F., Assunção, P.D.C. et al. Uncertainty analysis of a water flow calorimeter while welding in short-circuit and spray transfer regimes. Weld World 64, 1615–1624 (2020). https://doi.org/10.1007/s40194-020-00931-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00931-1