Abstract

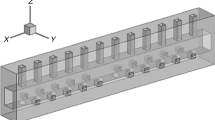

A unique boiling heat transfer study of wetting fluids in a vertical three-dimensional rectangle microchannel was carried out in this paper, to develop a novel passive three-dimensional chip stack cooling technology. The base liquids were deionized water and R113, and Sodium dodecagon sulfate (SDS) was used as a surfactant, which is added into the base fluids for developing wetting fluids. The length, gap, and width of rectangle channels were in the range of 30 mm to 100 mm,30 mm to 50 mm, and 0.4 mm to 4 mm, respectively. Metal wires with different numbers were laid in the rectangle channel along the flow direction for forming change in the width of the microchannel. The study results show that using wetting fluids can significantly enhance both heat transfer coefficients and maximum heat flux of thermosyphon boiling in three-dimensional microchannels compared with that found in pure liquids. The enhanced effects have significant relations with the three-dimensional geometric dimensions. The present experimental results provide significant technology support for passive three-dimensional chip cooling.

Similar content being viewed by others

Abbreviations

- D :

-

hydrodynamic equivalent diameter (m)

- g :

-

gravity (m/s2)

- h :

-

heat transfer coefficient (W/(m2 · K))

- h ag :

-

latent heat of evaporation (J/kg)

- L :

-

height of 3D channel (m)

- I :

-

electric current (A)

- P :

-

power (W)

- q :

-

heat flux (W/m2)

- q” :

-

critical heat flux (W/m2)

- S :

-

surface area (m2)

- T :

-

temperature (°C)

- \( \mathit{\Delta }\overline{T} \) :

-

mean super-heating (K)

- U :

-

voltage (V)

- W :

-

width of the 3D channel (m)

- Φ :

-

dimensionless heat flux

- β :

-

contact angle (°)

- ρ :

-

density (kg/m3)

- μ :

-

dynamic viscosity (Pa · s)

- σ :

-

surface tension coefficient (N/m)

- ω :

-

mass fraction

- 0 :

-

pure liquid

- s :

-

wetting liquid, or saturated temperature

- w :

-

heating surface

- loss :

-

heat loss

References

Moore GE (1998) Cramming more components onto integrated circuits[J]. Proc IEEE 86(1):82–85

Voutsinos CM, Judd RL (1975) Laser interferometric investigation of the microlayer evaporation phenomenon[J]. J Heat Transf 97(1):88–92

Xia C, Hu W, Guo Z (1996) Natural convective boiling in vertical rectangular narrow channels[J]. Exp Thermal Fluid Sci 12(3):313–324

Bonjour J, Lallemand M (1997) Effects of confinement and pressure on critical heat flux during natural convective boiling in vertical channels[J]. International communications in heat and mass transfer 24(2):191–200

Liu ZH, Chen YM (1999) Study of Critical Heat Flux during Natural Convective Boiling in Vertical Tubes and Vertical Annular Tubes Submerged in Saturated Liquids[J]. JSME International Journal Series B 42(4):731–736

Md CF, Kaminaga F (2002) Boiling heat transfer characteristics of R-113 in a vertical small diameter tube under natural circulation condition[J]. Int J Heat Mass Transf 45(24):4823–4829

Geisler KJL, Bar-Cohen A (2009) Confinement effects on nucleate boiling and critical heat flux in buoyancy-driven microchannels[J]. Int J Heat Mass Transf 52(11):2427–2436

Sang WN, Suh KY (2014) Critical heat flux in various inclined rectangular straight surface channels [J]. Experimental Thermal & Fluid Science 52(1):1–11

Misale M, Guglielmini G, Priarone A (2009) HFE-7100 pool boiling heat transfer and critical heat flux in inclined narrow spaces[J]. Int J Refrig 32((2)):235–245

Noh SW, Suh KY (2014) Critical heat flux in various inclined rectangular straight surface channels[J]. Exp Thermal Fluid Sci 52:1–11

Zhang K-L, Liu Z-H, Zheng B-c (2016) A new 3D chip cooling technology using microchannels thermosyphon with super-moist fluids and nanofluids. Energy Convers Manag 128:44–56

Li S-F, Liu Z-H, Zhang K-l (2018) Effect of Nano-Structure Coating on Thermal Performance of Thermosyphon Boiling in Microchannels. Int J Heat Mass Transf 124:463–474

Huang J-H, Li S-f, Liu Z-H (2019) Experimental study on thermosyphon boiling in three-dimensional microchannels. Int J Heat Mass Transf 131:1260–1269

Kedzierski MA (2000) Enhancement of R123 pool boiling by the addition of hydrocarbons. Int J Refrig 23(2):89–100

Yong HJ, Chang WJ, Chang SH (2008) Wettability of heated surfaces under pool boiling using surfactant solutions and nano-fluids. Int J Heat Mass Transf 51(11–12):3025–3031

Chen RH, Phuoc TX, Martello D (2011) Surface tension of evaporating nanofluid droplets. Int J Heat Mass Transf 54(11):2459–2466

Mahbubul SS, Shahrul IM (2013) Effect of particle concentration, temperature and surfactant on surface tension of nanofluids. International Communications in Heat & Mass Transfer 49(4):110–114

Sarafraz MM, Hormozi F (2016) Critical heat flux and pool boiling heat transfer analysis of Synthesized Zirconia aqueous nano-fluids [J]. International Communications in Heat & Mass Transfer 70(4):75–83

Marcel C, Clausse A, Frankiewicz C, Betz A (2017) Numerical investigation into the effect of surface wettability in pool boiling heat transfer with a stochastic-automata model. D Attinger International Journal of Heat and Mass Transfer 111:657–665

Peng H, Ding G, Hu H (2011) Effect of surfactant additives on nucleate pool boiling heat transfer of refrigerant-based nanofluid. Exp Thermal Fluid Sci 35:960–970

Fadhl B et al (2015) CFD modelling of a two-phase closed thermosyphon charged with R134a and R404a. Appl Therm Eng 78:482–490

Alizadehdakhel A et al (2010) CFD modeling of flow and heat transfer in a thermosyphon Int. Commun Heat Mass Transfer 37:312–318

Zhou Z, Shi J, Chen H-H, Schafer SR, Chen C-L (2014) Two-phase flow over flooded micro-pillar structures with engineered wettability pattern. International Journal of Heat and Mass Transfer 71:593–605

Zhao Z, Zhang J, Jia D, Zhao K, Zhang X, Jiang P (2017) Thermal performance analysis of pool boiling on an enhanced surface modified by the combination of microstructures and wetting properties. Applied Thermal Engineering 117:417–426

Marcel C, Clausse A, Frankiewicz C, Betz A, Attinger D (2017) Numerical investigation into the effect of surface wettability in pool boiling heat transfer with a stochastic-automata model. Int J Heat Mass Transf 111:657–665

Marcel C, Bonetto F, Clausse A (2011) Simulation of boiling heat transfer in small heaters by a coupled cellular and geometrical automata. Heat Mass Transf 47:13–25

Acknowledgments

This work was supported by the national natural science foundation of China under grant No. 51876121.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• A new wetting fluids as the medium was used in Thermosyphon boiling of 3 D microchannels.

• The new medium significantly improve CHF and HTC in 3-D microchannels.

• The influence of dimensions of 3-D microchannel on the CHF and HTC are very complex.

• Experimental results provide significant technology support for passive 3-D chip cooling.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 808 kb)

Rights and permissions

About this article

Cite this article

Wang, PY., Zhao, XL. & Liu, ZH. Experimental study on boiling performance of wetting fluids in three-dimensional rectangle microchannels. Heat Mass Transfer 56, 2639–2652 (2020). https://doi.org/10.1007/s00231-020-02883-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02883-0