Abstract

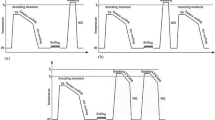

This study investigates the effect of solution treatment (at 470 °C for 0–48 h) on the microstructural evolution, tensile properties, and impact properties of an Al–5.0Mg–3.0Zn–1.0Cu (wt%) alloy prepared by permanent gravity casting. The results show that the as-cast microstructure consists of α-Al dendrites and a network-like pattern of T-Mg32(AlZnCu)49 phases. Most of the T-phases were dissolved within 24 h at 470 °C; and a further prolonging of solution time resulted in a rapid growth of α-Al grains. No transformation from the T-phase to the S-Al2CuMg phase was discovered in this alloy. Both the tensile properties and impact toughness increased quickly, reached a maximum peak value, and decreased gradually as the solution treatment proceeded. The impact toughness is more closely related to the elongation, and the relationship between impact toughness and elongation appears to obey an equation: \({\text{IT}} = 8.43{\text{EL}} - 3.46\). After optimal solution treatment at 470 °C for 24 h, this alloy exhibits excellent mechanical properties with the ultimate tensile strength, yield strength, elongation and impact toughness being 431.6 MPa, 270.1 MPa, 19.4% and 154.7 kJ/m2, which are comparable to that of a wrought Al–6.0Mg–0.7Mn alloy (5E06, a 5xxx aluminum alloy). Due to its excellent comprehensive combination of mechanical properties, this cast alloy has high potential for use in components which require medium strength, high ductility and high toughness.

Similar content being viewed by others

References

B. Lin, W. Zhang, Z. Lou, D. Zhang, Y. Li, Mater. Des. 59, 10 (2014)

H. Tang, Q. Wang, C. Lei, B. Ye, K. Wang, H. Jiang, W. Ding, X. Zhang, Z. Lin, J. Zhang, J. Alloys Compd. 801, 596 (2019)

Q. Wang, L. Xiao, W. Liu, H. Zhang, W. Cui, Z. Li, G. Wu, Mater. Sci. Eng. A 705, 402 (2017)

H. Tang, Q. Wang, C. Lei, K. Wang, B. Ye, H. Jiang, W. Ding, Acta Metall. Sin. (Engl. Lett.) 32, 1549 (2019)

J.R. Davis, Aluminum and Aluminum Alloys (ASM International, Cleveland, 1993)

J. Shin, T. Kim, D. Kim, D. Kim, K. Kim, J. Alloys Compd. 698, 577 (2017)

D.G. Eskin, L.K. Suyitno, Prog. Mater Sci. 49, 629 (2004)

Y. Liu, D. Jiang, W. Xie, J. Hu, B. Ma, Mater. Charact. 93, 173 (2014)

Z. Wang, H. Li, F. Miao, B. Fang, R. Song, Z. Zheng, Mater. Sci. Eng. A 607, 313 (2014)

Y. Han, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Mater. Des. 58, 426 (2014)

X. Fan, D. Jiang, Q. Meng, L. Zhong, Mater. Lett. 60, 1475 (2006)

C. Mondal, A.K. Mukhopadhyay, Mater. Sci. Eng. A 391, 367 (2005)

D. Xu, Z. Li, G. Wang, X. Li, X. Lv, Y. Zhang, Y. Fan, B. Xiong, Mater. Charact. 131, 285 (2017)

B. Li, Q. Pan, C. Chen, H. Wu, Z. Yin, J. Alloys Compd. 664, 553 (2016)

G.S. Peng, K.H. Chen, S.Y. Chen, H.C. Fang, Mater. Sci. Eng. A 641, 237 (2015)

M. Amne Elahi, S.G. Shabestari, Trans. Nonferrous Met. Soc. China 26, 956 (2016)

Y.M. Peng, H. Huang, Y. Wang, H.M. Li, Z.R. Nie, P.P. Zhang, Sci. Technol. Eng. 11, 1671 (2011)

P. Jia, Y. Cao, Y. Geng, L. He, N. Xiao, J. Cui, Mater. Sci. Eng. A 612, 335 (2014)

X. Lv, E. Guo, Z. Li, G. Wang, Rare Met. 30, 664 (2011)

X. Yuan, D. Yin, X. Yu, K. Pan, S. Lu, T. Hu, Z. Lv, Z. Zhu, Chin. J. Nonferrous Metal. 27, 459 (2017)

D.K. Xu, P.A. Rometsch, N. Birbilis, Mater. Sci. Eng. A 534, 244 (2012)

Y. Shi, Q. Pan, M. Li, Z. Liu, Z. Huang, Trans. Nonferrous Met. Soc. China 25, 3560 (2015)

L. Hai, C. Dahu, W. Zhixiu, Z. Ziqiao, J. Mater. Sci. 43, 1583 (2008)

C. Hua, Y.G. Zhang, X.W. Li, B.H. Zhu, F. Wang, B.Q. Xiong, Chin. J. Rare Met. 32, 803 (2008)

Y. Xiao, Q. Pan, W. Li, X. Liu, Y. He, Chin. J. Mater. Sci. Eng. 28, 919 (2010)

H. Wu, S. Wen, J. Lu, Z. Mi, X. Zeng, H. Huang, Z. Nie, Trans. Nonferrous Met. Soc. China 27, 1476 (2017)

L. He, X. Li, P. Zhu, Y. Cao, Y. Guo, J. Cui, Mater. Charact. 71, 19 (2012)

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Acta Mater. 62, 141 (2014)

X.Y. Liu, Q.L. Pan, Z.L. Lu, S.F. Cao, Y.B. He, W.B. Li, Mater. Des. 31, 4392 (2010)

Acknowledgements

The authors are grateful to the United Fund of National Natural Science Foundation of China and Yunnan Province (No. U1902220) and the National Natural Science Foundation of China (No. 51674166).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Tang, HP., Wang, QD., Luo, C. et al. Effects of Solution Treatment on the Microstructure, Tensile Properties, and Impact Toughness of an Al–5.0Mg–3.0Zn–1.0Cu Cast Alloy. Acta Metall. Sin. (Engl. Lett.) 34, 98–110 (2021). https://doi.org/10.1007/s40195-020-01077-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01077-1