Abstract

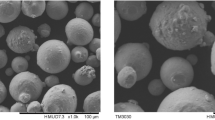

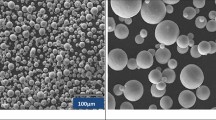

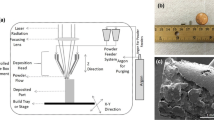

The adoption of selective laser melting (SLM) for fabrication of porous titanium has resulted in many new investigations into the complex design parameters associated with porous architecture of high spatial resolution. The development of meta-materials has included research into the effects of unit cell architecture (strut versus sheet), porosity, pore size, and other factors on the performance of metallic scaffolds. The current study examined the interactive effects of varying the gyroid sheet unit cell size and overall specimen size on the compressive behavior of Ti–6Al–4V ELI porous scaffolds manufactured via SLM. The increasing unit cell size relative to specimen geometry was found to decrease the compressive strength and stiffness of the overall structure and shift the material fracture mode. The understanding of the relationship between unit cell size and specimen geometry can be used to optimize mechanical properties of implants with constrained volumes and pore/wall size requirements to optimize properties of porous titanium implants for strength and osseointegration.

Similar content being viewed by others

References

L. Bai, C. Gong, X. Chen, Y. Sun, J. Zhang, L. Cai, S. Zhu, and S.Q. Xie: Additive manufacturing of customized metallic orthopedic implants: Materials, structures, and surface modifications. Metals 9, 1004 (2019).

R. Waulthle, S.M. Ahmadi, S.A. Yavari, M. Mulier, A.A. Zadpoor, and H. Weinans: Revival of pure titanium for dynamically loaded porous implants using additive manufacturing. Mater. Sci. Eng., C 54, 94–100 (2015).

L. Maini, A. Sharma, S. Jha, and A. Tiwari: Three-dimensional printing and patient-specific pre-contoured plate: Future of acetabulum fracture fixation? Eur. J. Trauma Emerg. Surg. 44, 215–224 (2018).

T.J. Dekker, J.R. Steele, and A.E. Federer: Use of patient-specific 3D-printed titanium implants for complex foot and ankle limb salvage, deformity correction, and arthrodesis procedures. Foot Ankle Int. 39, 916–921 (2018).

J. Ni, H. Ling, S. Zhang, Z. Wang, Z. Peng, C. Benyshek, R. Zan, A.K. Miri, Z. Li, X. Zhang, J. Lee, K-J. Lee, H-J. Kim, P. Tebon, T. Hoffman, M.R. Dokmeci, N. Ashammakhi, X. Li, and A. Khademhosseini: Three-dimensional printing of metals for biomedical applications. Mater. Today Bio 3, 100024 (2019).

L.M. Ricles, J.C. Coburn, and M. Di Prima: Regulating 3D-printed medical products. Sci. Transl. Med. 10, 461 (2018).

H.B. Rotaru, H. Stan, I.S. Florian, R. Schumacher, Y-T. Park, S-G. Kim, H. Chezan, N. Balc, and M. Baciut: Cranioplasty with custom-made implants: Analyzing the cases of 10 patients. J. Oral Maxillofac. Surg. 70, 169–176 (2012).

K.S. Hamid, S.G. Parekh, and S.B. Adams: Salvage of severe foot and ankle trauma with 3D printed scaffold. Foot Ankle Int. 37, 433–439 (2016).

K.B. Trauner: The emerging role of 3D printing in arthroplasty and orthopedics. J. Arthroplasty 33, 2352–2354 (2018).

D.K. Pattanayak, A. Fukuda, T. Matsushita, M. Takemoto, S. Fujibayashi, K. Sasaki, N. Nishida, T. Nakamura, and T. Kokubo: Bioactive Ti metal analogous to human cancellous bone: Fabrication by selective laser melting and chemical treatments. Acta Biomater. 7, 1398–1406 (2011).

A. Yanez, A. Cuadrado, O. Martel, H. Afonso, and D. Monopoli: Gyroid porous titanium structures: A versatile solution to be used as scaffolds in bone defect construction. Mater. Des. 140, 21–29 (2018).

A.T. Sidambe: Biocompatibility of advanced manufactured titanium implants—A review. Materials 7, 8168–8188 (2014).

M. Niinomi: Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng., A 243, 231–236 (1998).

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia: Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 54, 397–425 (2009).

T.B. Sercombe: Failure modes in high strength and stiffness to weight scaffolds produced by selective laser melting. Mater. Des. 67, 501–508 (2015).

Y. Chen, J.E. Frith, A. Dehghan-Manshadi, H. Attar, D. Kent, N.D.M. Soro, M.J. Bermingham, M.S. Dargusch: Mechanical properties and biocompatibility of porous titanium scaffolds for bone tissue engineering. J. Mech. Behav. Biomed. Mater. 75, 169–174 (2017).

J. Kadkhodapour, H. Montazerian, A.C. Darabi, A. Zargarian, and S. Schmauder: The relationship between deformation mechanisms and additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 70, 28–42 (2017).

M. Niinomi, Y. Liu, M. Nakai, H. Liu, and H. Li: Biomedical titanium alloys with Young's moduli close to that of cortical bone. Regener. Biomater. 3, 173–185 (2016).

B. Vamsi Krishna, S. Bose, and A. Bandyopadhyay: Low stiffness porous Ti structures for load-bearing implants. Acta Biomater. 3, 997–1006 (2007).

C.N. Kelly, J. Francovich, S. Julmi, D. Safranski, R.E. Guldberg, H.J. Maier, and K. Gall: Fatigue behavior of As-built selective laser melted titanium scaffolds with sheet-based gyroid microarchitecture for bone tissue engineering. Acta Biomater. 94, 610–626 (2019).

D. Barba, E. Alabort, and R.C. Reed: Synthetic bone: Design by additive manufacturing. Acta Biomater. 97, 637–656 (2019).

O. Alketan, R. Rowshan, and R.K. Abu Al-Rub: Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 19, 167–183 (2018).

C. Yan, L. Hao, A. Hussein, P. Young, J. Huang, and W. Zhu: Microstructure and mechanical properties of aluminum alloy cellular lattice structures by direct metal laser sintering. Mater. Sci. Eng., A 628, 238–246 (2015).

L. Yuan, S. Ding, and C. Wen: Additive manufacturing technology for porous metal implant applications and triply minimal surface structures: A review. Bioact. Mater. 4, 56–70 (2019).

S.M. Ahmadi, G. Campoli, S. Amin Yavari, B. Sajadi, R. Wauthle, J. Schrooten, H. Weinans, and A.A. Zadpoor: Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J. Mech. Behav. Biomed. Mater. 34, 106–115 (2014).

A. Cheng, A. Humayun, B.D. Boyan, and Z. Schwartz: Enhanced osteoblast response to porosity and resolution of additively manufactured Ti–6Al–4V constructs with trabeculae-inspired porosity. 3D Print. Addit. Manuf. 3, 10–21 (2016).

C.N. Kelly, A.T. Miller, S.J. Hollister, R.E. Guldberg, and K. Gall: Design and structure-function characterization of 3D printed synthetic porous biomaterials for tissue engineering. Adv. Healthcare Mater. 7, 1701905 (2017).

H. Karcher: The triply periodic minimal surfaces of alan schoen and their constant mean curvature companions. Manuscripta Math. 64, 291–357 (1989).

A.H. Schoen: Infinite Periodic Minimal Surfaces Without Self-Intersections (National Aeronautics and Space Administration, Electronics Research Center Cambridge, Massachusetts, 1970).

E. Yang, M. Leary, B. Lozanovski, D. Downing, M. Mazur, A. Sarker, A. Khorasani, A. Jones, T. Maconachie, S. Bateman, M. Easton, M. Qian, P. Choong, and M. Brandt: Effect of geometry on the mechanical properties of Ti–6Al–4V gyroid structures fabricated via SLM: A numerical study. Mater. Des. 184, 108165 (2019).

S. Ma, Q. Tang, Q. Feng, J. Song, X. Han, and F. Guo: Mechanical behaviours and mass transport properties of bone-mimicking scaffolds consisted of gyroid structures manufactured using selective laser melting. J. Mech. Behav. Biomed. Mater. 93, 158–169 (2019).

C. Yan, L. Hao, A. Hussein, and P. Young: Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 51, 61–73 (2015).

F.S.L. Bobbert, K. Lietaert, A.A. Eftekhari, B. Pouran, S.M. Ahmadi, H. Weinans, and A.A. Zadpoor: Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties. Acta Biomater. 53, 572–584 (2017).

A.A. Zadpoor, R. Uyttendaele, L.E. Fratila-Apachitei, and S. Callens: Substrate curvature as a cue to guide spatiotemporal cell and tissue organization. Biomaterials 232, 119739 (2020).

X.P. Tan, Y.J. Tan, C.S.L. Chow, S.B. Tor, and W.Y. Yeong: Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng., C 76, 1328–1343 (2017).

C.N. Kelly, N.T. Evans, C.W. Irvin, S.C. Chapman, K. Gall, and D.L. Safranski: The effect of surface topography and porosity on the tensile fatigue of 3D printed Ti–6Al–4V fabricated by selective laser melting. Mater. Sci. Eng., A 98, 726–736 (2019).

E.W. Andrews, G. Gioux, P. Onck, and L.J. Gibson: Size effects in ductile cellular solids. Part II: Experimental results. Int. J. Mech. Sci. 43, 701–713 (2001).

L. Zhang, S. Feih, S. Daynes, S. Chang, M.Y. Wang, J. Wei, and W.F. Lu: Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading. Addit. Manuf. 23, 505–515 (2018).

M. Ashby, T. Evans, N. Fleck, and J. Hutchinson: Metal Foams: A Design Guide (Butterworth-Heinemann, Boston, Massachusetts, 2000).

I. Maskery, N.T. Aboulkhair, A.O. Aremu, C.J. Tuck, and I.A. Ashcroft: Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 16, 24–29 (2017).

C. Yan, L. Hao, A. Hussein, and D. Raymont: Evaluations of cellular lattice structures manufactured using selective laser melting. Int. J. Mach. Tool Manufact. 62, 32–38 (2012).

N. Taniguchi, S. Fujibayashi, M. Takemoto, K. Sasaki, B. Otsuki, T. Nakamura, T. Matsushita, T. Kokubo, and S. Matsuda: Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater. Sci. Eng., C 59, 690–701 (2016).

J.P. Li, P. Habibovic, M. van den Doel, C.E. Wilson, J.R. de Wijn, C.A. van Blitterswijk, and K. de Groot: Bone ingrowth in porous titanium implants produces by 3D fiber deposition. Biomaterials 28, 2810–2820 (2007).

S. Arabnejad, R. Burnett Johnston, J.A. Pura, B. Singh, M. Tanzer, and D. Pasini: High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater. 30, 345–356 (2016).

B. Zhang, X. Pei, C. Zhou, Y. Fan, Q. Jiang, A. Ronca, U. D’Amora, Y. Chen, H. Li, Y. Sun, and X. Zhang: The biomimetic design and 3D printing of customized mechanical properties porous Ti6Al4V scaffold for load-bearing bone reconstruction. Mater. Des. 152, 30–39 (2018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pham, A., Kelly, C. & Gall, K. Free boundary effects and representative volume elements in 3D printed Ti–6Al–4V gyroid structures. Journal of Materials Research 35, 2547–2555 (2020). https://doi.org/10.1557/jmr.2020.105

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.105