Abstract

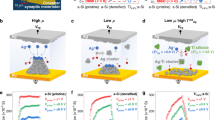

A memristor1 has been proposed as an artificial synapse for emerging neuromorphic computing applications2,3. To train a neural network in memristor arrays, changes in weight values in the form of device conductance should be distinct and uniform3. An electrochemical metallization (ECM) memory4,5, typically based on silicon (Si), has demonstrated a good analogue switching capability6,7 owing to the high mobility of metal ions in the Si switching medium8. However, the large stochasticity of the ion movement results in switching variability. Here we demonstrate a Si memristor with alloyed conduction channels that shows a stable and controllable device operation, which enables the large-scale implementation of crossbar arrays. The conduction channel is formed by conventional silver (Ag) as a primary mobile metal alloyed with silicidable copper (Cu) that stabilizes switching. In an optimal alloying ratio, Cu effectively regulates the Ag movement, which contributes to a substantial improvement in the spatial/temporal switching uniformity, a stable data retention over a large conductance range and a substantially enhanced programmed symmetry in analogue conductance states. This alloyed memristor allows the fabrication of large-scale crossbar arrays that feature a high device yield and accurate analogue programming capability. Thus, our discovery of an alloyed memristor is a key step paving the way beyond von Neumann computing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

23 June 2020

A Correction to this paper has been published: https://doi.org/10.1038/s41565-020-0735-0

References

Strukov, D. B., Snider, G. S., Stewart, D. R. & Williams, R. S. The missing memristor found. Nature 453, 80–83 (2008).

Xia, Q. & Yang, J. J. Memristive crossbar arrays for brain-inspired computing. Nat. Mater. 18, 309–323 (2019).

Burr, G. W. et al. Neuromorphic computing using non-volatile memory. Adv. Phys. X 2, 89–124 (2017).

Valov, I., Waser, R., Jameson, J. R. & Kozicki, M. N. Electrochemical metallization memories—fundamentals, applications, prospects. Nanotechnology 22, 254003 (2011).

Lübben, M. & Valov, I. Active electrode redox reactions and device behavior in ECM type resistive switching memories. Adv. Electron. Mater. 5, 1800933 (2019).

Jo, S. H. et al. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 10, 1297–1301 (2010).

Choi, S. et al. SiGe epitaxial memory for neuromorphic computing with reproducible high performance based on engineered dislocations. Nat. Mater. 17, 335–340 (2018).

Yang, Y. et al. Observation of conducting filament growth in nanoscale resistive memories. Nat. Commun. 3, 732–738 (2012).

Prezioso, M. et al. Training and operation of an integrated neuromorphic network based on metal-oxide memristors. Nature 521, 61–64 (2015).

Yao, P. et al. Face classification using electronic synapses. Nat. Commun. 8, 15199 (2017).

Wang, Z. et al. Fully memristive neural networks for pattern classification with unsupervised learning. Nat. Electron. 1, 137–145 (2018).

Li, C. et al. Efficient and self-adaptive in-situ learning in multilayer memristor neural networks. Nat. Commun. 9, 2385 (2018).

Cai, F. et al. A fully integrated reprogrammable memristor–CMOS system for efficient multiply–accumulate operations. Nat. Electron. 2, 290–299 (2019).

Shi, Y. et al. Neuroinspired unsupervised learning and pruning with subquantum CBRAM arrays. Nat. Commun. 9, 5312 (2018).

Ambrogio, S. et al. Neuromorphic learning and recognition with one-transistor–one-resistor synapses and bistable metal oxide RRAM. IEEE Trans. Electron Devices 63, 1508–1515 (2016).

Woo, J. & Yu, S. Resistive memory-based analog synapse: the pursuit for linear and symmetric weight update. IEEE Nanotechnol. Mag. 12, 36–44 (2018).

Dietrich, S. et al. A non-volatile 2Mbit CBRAM memory core featuring advanced read and program control. IEEE J. Solid-State Circuits 42, 839–845 (2007).

Otsuka, W. et al. A 4Mb conductive-bridge resistive memory with 2.3GB/s read-throughput and 216MB/s program-throughput. In IEEE International Solid-State Circuits Conference 210–211 (IEEE, 2011); https://doi.org/10.1109/ISSCC.2011.5746286

Valov, I., Waser, R., Jameson, J. R. & Kozicki, M. N. Electrochemical metallization memories—fundamentals, applications, prospects. Nanotechnology 22, 254003 (2011).

van den Hurk, J. et al. Physical origins and suppression of Ag dissolution in GeSx-based ECM cells. Phys. Chem. Chem. Phys. 16, 18217–18225 (2014).

Hajto, J., Owen, A. E., Snell, A. J., Comber, P. G. Le & Rose, M. J. Analogue memory and ballistic electron effects in metal–amorphous silicon structures. Philos. Mag. B 63, 349–369 (1991).

Snell, A. J. et al. Analogue memory effects in metal/a-Si:H/metal memory devices. J. Non-Cryst. Solids 137–138, 1257–1262 (1991).

Jo, S. H. & Lu, W. CMOS compatible nanoscale nonvolatile resistance switching memory. Nano Lett. 8, 392–397 (2008).

Jo, S. H., Kim, K.-H. & Lu, W. High-density crossbar arrays based on a Si memristive system. Nano Lett. 9, 870–874 (2009).

Rickert, H. Electrochemistry of Solids (Springer, 1982).

Fisher, D. J. Diffusion in Silicon: 10 Years of Research (Scitec, 1998).

Tsuruoka, T. et al. Effects of moisture on the switching characteristics of oxide-based, gapless-type atomic switches. Adv. Funct. Mater. 22, 70–77 (2012).

Valov, I. & Tsuruoka, T. Effects of moisture and redox reactions in VCM and ECM resistive switching memories. J. Phys. D 51, 413001 (2018).

Fehlner, F. P. Low-Temperature Oxidation: The Role of Vitreous Oxides (John Willey & Sons, Inc., 1986).

Zhang, L. et al. Atomic modeling for the initial stage of chromium passivation. Int. J. Miner. Metall. Mater. 26, 732–739 (2019).

Murarka, S. P. in Encyclopedia of Materials: Science and Technology (eds Buschowet, K. H. J. et al.) 1–14 (Elsevier, 2003).

Yang, X., Choi, B. J., Chen, A. B. K. & Chen, I.-W. Cause and prevention of moisture-induced degradation of resistance random access memory nanodevices. ACS Nano 7, 2302–2311 (2013).

Kang, S.-K. et al. Dissolution behaviors and applications of silicon oxides and nitrides in transient electronics. Adv. Funct. Mater. 24, 4427–4434 (2014).

Hu, M. et al. Memristor-based analog computation and neural network classification with a dot product engine. Adv. Mater. 30, 1705914 (2018).

Acknowledgements

This work is partially supported by MIT Research Support Committee funds, MIT-IBM Watson AI Lab, Samsung Global Research Laboratory and NSF-SRC-E2CDA. We thank J. J. Yang and Q. Xia of the University of Massachusetts for valuable help and fruitful discussion. We acknowledge the Texas Advanced Computing Center (TACC) for providing computation sources. This work was performed in part at the Micro Technology Laboratories (MTL) at the Massachusetts Institute of Technology, and in part at the Harvard University Center for Nanoscale Systems (CNS).

Author information

Authors and Affiliations

Contributions

H.Y. and J.K. conceived this work and J.K. supervised the team. H.Y., P.L., C.C. and J.K. designed the experiments and prepared the manuscript. H.Y., P.L., C.C., S.H.T., Y.P. and D.L. performed the device fabrication. H.Y. and C.C. conducted the d.c. switching measurements. C.C., P.L., S.K. and Y.P. performed the pulse-switching measurements. P.L. performed the array measurements. H.Y., C.C., F.X., B.G., H.W., H.Q. and Y.N. performed and analysed the ab initio calculations and kinetic Monte Carlo simulations. All the authors discussed and contributed to the discussion and analysis of the results regarding the manuscript at all stages.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Nanotechnology thanks Wei Lu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Process flow of depositing Ag-Cu films for active metals.

We have design step-by-step metal deposition process to drive Ag-Cu together into switching medium on the stage of forming. We first deposited ultrathin Ag islands on switching medium, where the thickness of Ag islands determines the opening area of Si (step1). Next, we deposited ultrathin Cu on top of Ag islands-deposited Si where Cu islands make the direct contact with the switching medium (step2). Last, we encapsulated Ag-Cu islands with 15 nm thick Ag film (step3). The amount of Cu involved in switching is determined by ‘Ag-Cu thickness ratio’. The thicker Ag film is deposited, The less Cu is contributing to the switching. The Ag-Cu alloying conduction channels are formed in the switching medium during forming process.

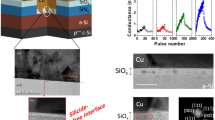

Extended Data Fig. 2 Ag-Cu alloy formation.

Scanning electron microscopy (SEM) images and energy dispersive X-ray (EDX) mapping of Ag-Cu alloying film on amorphous Si surface. Scale bars: 400 µm. When the total thickness was 2 ~ 4 nm, discontinuous metal films were formed and the metal clusters were uniformly distributed. A merging of metal clusters was observed at 7-nm-thick Ag with 2-nm-thick Cu film Source data.

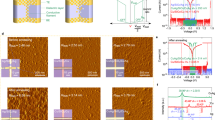

Extended Data Fig. 3 Ag-Cu alloying ratio effect on DC switching uniformity and retention.

Normalized on/off uniformity with respect to nominal thickness of (i) Ag and (ii) Cu layers. 15-nm-thick additional Ag layer was applied after the step-by-step evaporation. At each alloying condition, best-performed-device during 100 cycles at compliance current of 5 mA was selected for this mapping. Furthermore, DC switching curves with temporal on/off conductance variations and room temperature retention results are included. When Cu was evaporated even for 1 nm in advance to Ag, devices showed irreversible breakdown behavior that is similar results with pure Cu devices (20-nm-thick Cu layer). As Ag thickness increased under fixed Cu thickness (1 nm), switching performance dynamically modulated and Ag (2 nm)/Cu (1 nm) layers drove optimized switching performance: highly uniform switching with stable retention behavior at multi-level states. As Ag-Cu ratio was deviated from 2 nm-1nm, non-uniform switching with poor retention was observed (7 nm-1 nm) or on/off degradation occurred, although stable data retention was obtained (2 nm-2 nm). These results strongly suggest that Cu additives into Ag active electrode significantly affect the switching performance, even though the amount of Cu is too small to form continuous film on Si surface. Furthermore, the role of Cu can be summarized as follows. (1) Cu enhances stability of Ag-based conduction channel, but decreases maximum on/off ratio due to residual Cu elements bound to Si switching medium (called backbone of the conduction channel). (2) Excess Cu in Ag active electrode deteriorates on/off window with increasing cycle number. However, optimized Ag-Cu ratio can drive uniform switching with relatively stable data retention Source data.

Extended Data Fig. 4 Crossbar layout for alloy arrays with metal capping.

Metal capping for p+ Si bottom electrodes is preferred to reduce the line resistance in large array implementations. A new process was developed to make alloy array with gold capping layer. (a) formation of isolated a-Si/p+ Si line patterns on SOI wafer by photolithography and dry etching. The protrusions on the line patterns are active device areas. (b) capping Au on top of the p+ line patterns to reduce line resistance. The active areas remain intact. (c) passivation of the bottom electrodes while exposing the active areas. (d) patterning the top electrodes to finish device arrays.

Extended Data Fig. 5 Demonstration of the stability of Ag-Cu alloy memristor array for inference.

(a) four convolutional kernels shown in (b) were programmed into four columns of the 32 × 32 array for parallel kernel operation. Two memristors are used as differential pair to represent both positive and negative weights.

Supplementary information

Supplementary Information

Supplementary Notes 1–4, Figs. 1–21, Tables 1 and 2, Video 1 and refs. 1–39.

Supplementary Video 1

Kinetic Monte Carlo simulation of resistive switching dynamics based on a Ag–Cu alloy.

Source data

Source Data Fig. 1

Ag and Ag-Cu: DC switching curves, switching uniformity, and retention.

Source Data Fig. 2

Ag-Ti, Ag-Cr and Ag-Ni: DC switching curves, switching uniformity, and retention.

Source Data Fig. 3

Analogue switching performance of Ag and Ag-Cu devices.

Source Data Fig. 4

Image programming and convolutional kernel processing in Si memristor arrays.

Source Data Extended Data Fig. 2

Scanning electron microscopy (SEM) images and energy dispersive X-ray (EDX) mapping data of Ag-Cu film.

Source Data Extended Data Fig. 3

Ag-Cu alloying effect: DC switching curves, on/off uniformity, and retention.

Rights and permissions

About this article

Cite this article

Yeon, H., Lin, P., Choi, C. et al. Alloying conducting channels for reliable neuromorphic computing. Nat. Nanotechnol. 15, 574–579 (2020). https://doi.org/10.1038/s41565-020-0694-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-020-0694-5

This article is cited by

-

Highly-scaled and fully-integrated 3-dimensional ferroelectric transistor array for hardware implementation of neural networks

Nature Communications (2023)

-

Open-loop analog programmable electrochemical memory array

Nature Communications (2023)

-

Multifilamentary switching of Cu/SiOx memristive devices with a Ge-implanted a-Si underlayer for analog synaptic devices

NPG Asia Materials (2023)

-

Parallel in-memory wireless computing

Nature Electronics (2023)

-

Ultrathin quasi-2D amorphous carbon dielectric prepared from solution precursor for nanoelectronics

Communications Engineering (2023)