Abstract

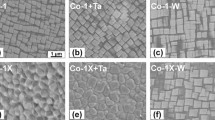

The feasibility of a cost-efficient method to produce carbon coated Al-foams in a single-step heating process is investigated. In this context, a dissolution-sintering process for manufacturing metal foams is developed using raw cane sugar as both the space holder material and the carbon generating medium. The structural characteristics of the produced carbon coated Al-foams were evaluated by XRD, Raman and SEM analyses. Static compression tests were conducted to determine the mechanical response of the produced carbon coated Al-foams. The produced carbon coated Al-foams were fully covered with an external carbon layer having a relatively uniform thickness, despite the inherent complex 3D surface of the foam. The carbon deposition process led to a significant increase of the compression strength of the Al-foam. A strain softening behavior was observed for the carbon coated Al-foams attributed to micro-cracking of aluminum carbides. The produced carbon coated Al-foams can potentially be used as a catalyst support structure.

Similar content being viewed by others

Data availability

Not applicable.

References

H.P. Degischer, B. Kriszt, Handbook of cellular metals: production, processing, applications (Wiley-VCH, Weinheim, 2002)

Sh Song, M. Wu, Y. Liu, Q. Zhu, P. Tsiakaras, Y. Wang, Electrochim. Acta 176, 811–818 (2015)

E.D. Banús, V.G. Milt, E.E. Miró, M.A. Ulla, Appl. Catal. A 379, 95–104 (2010)

T. Knorr, P. Heinl, J. Schwerdtfeger, C. Körner, R.F. Singer, B.J.M. Etzol, Chem. Eng. J. 181–182, 725–733 (2012)

F. Lali, S. Gärtner, S. Haase, R. Lange, Chem. Eng. Technol. 38, 1353–1361 (2015)

T. Knorr, A. Schwarz, B.J.M. Etzold, Chem. Eng. Technol. 37, 453–461 (2014)

A. Kennedy, in Powder Metallurgy, ed. by Dr. Katsuyoshi Kondoh, (InTech, 2012) p.31

B. Jiang, N.Q. Zhao, C.S. Shi, X.W. Du, J.J. Li, H.C. Man, Mater. Lett. 59, 3333–3336 (2005)

L. Stanev, M. Kolev, B. Drenchev, L. Drenchev, ASME. J. Manuf. Sci. Eng. 139, 050801 (2017)

M. Maurer, L. Zhao, E. Lugscheider, Adv. Eng. Mater. 4, 791–797 (2002)

B. Yuttanant, A.S. Christopher, C.D. David, Scr. Mater. 59, 336–339 (2008)

L. Jiaan, Z. Xianyong, S. Jothi, G. Fei, F. Pibo, Int. J. Electrochem. Sci. 7, 5951–5961 (2012)

T. Abdulla, A. Yerokhin R. Goodall. Mater. Des. 32, 3742–3749 (2011)

L. Jiaan, Z. Xianyong, H. Zhiqiu, Y. Sirong, Y. Xizhen, J. Coat. Technol. Res. 9, 357–363 (2012)

S.R. Yu, Y.R. Luo, J.A. Liu, Mater. Sci. Eng. A 487, 394–399 (2008)

T. Abdulla, A. Yerokhin, R. Goodall, Scr. Mater. 75, 38–41 (2014)

N. Michailidis, F. Stergioudi, Mater. Des. 32, 1559–1564 (2011)

N. Michailidis, F. Stergioudi, D.N. Tsipas, Adv. Eng. Mater. 13(3), 29–32 (2011)

F. örsi, J. Therm. Anal., 5 (1973), pp. 329–335

E. Hugot, Handbook of cane sugar engineering, 3rd edn. (Elsevier Science, New York, 1986)

M.I. Abd-Elrahman, S.M. Ahmed, Int. J. Polym. Mater. 58, 322–335 (2009)

F. Stergioudi, C.A. Vogiatzis, K. Gkrekos, N. Michailidis, S.M. Skolianos, Corros. Sci. 91, 151–159 (2015)

A.C. Ferrari, J. Robertson, Phys. Rev. B 61, 14095 (2000)

C.E. Foerster, S.L.R. da Silva, T. Fitz, T. Dekorsy, F. Prokert, U. Kreiβig, E. Richter, W. Möller, C.M. Lepienski, C.J.de M. Siqueira, Surf. Coat Technol., 200 (2006), pp.5210–5219

Y. Zhao, F. Han, T. Fung, Mater. Sci. Eng. A 364, 117–125 (2004)

R. Surace, L.A.C. De Filippis, A.D. Ludovico, G. Boghetich, Mater. Des. 30, 1878–1885 (2009)

N. Michailidis, F. Stergioudi, A. Tsouknidas, E. Pavlidou, Mater. Sci. Eng. A 528, 1662–1667 (2011)

Q.M. Li, I. Magkiriadis, J.J. Harrigan, J. Cell. Plast. 42, 371–392 (2006)

M. Besterci, O. Velgosová, J. Ivan, T. Kvačkaj, Acta Metall. Slov. 14, 7–16 (2008)

B. Pichler, C. Hellmich, H.A Mang: Int. J. Numer. Anal. Methods Geomech., 31 (2007), pp. 111–132

Acknowledgements

The author would like to express its deepest gratitude to Prof. Georgios Vourlias and Prof. Dimitrios Christofilos for technical support and assistance with the XRD and Raman studies.

Funding

This research received no funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There is no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Stergioudi, F. Production of carbon coated Al-foams and evaluation of their mechanical response. J Porous Mater 27, 1399–1407 (2020). https://doi.org/10.1007/s10934-020-00916-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-020-00916-x