Abstract

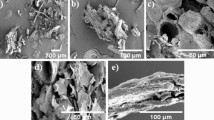

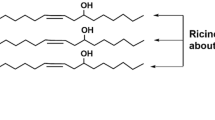

In this work, a castor-oil-based process for flexible polyurethane foam scrap decomposition was used to prepare a recycled-based polyurethane foam. Decomposed polyurethane (DP) and 4,4′ diphenylmethane diisocyanate (MDI) were polymerized at three distinct MDI/DP ratios (1.0/2.2, 1.0/2.7 and 1.0/3.2) and two curing times (15 and 50 min). The influence of castor oil on the decomposition process and subsequent synthesis of polyurethane foam were evaluated using Fourier transform infrared spectroscopy (FTIR). Further characterization of the final material was carried out through thermogravimetric analysis (TGA), scanning electron microscopy (SEM) and mechanical testing. FTIR assessment showed the presence of multi-functional hydroxyl groups as a result of the decomposition process. TGA confirmed three thermal degradation zones between 160 ℃ and 535 ℃ indicating the degradation of non-reacted compounds as well as the presence of oligomers, fatty acid chains, and urethane network. Mechanical evaluation evidenced that the MDI/DP ratios had a significant effect on tensile properties. The addition of DP increased the elongation at break and reduced the tensile strength with a slight variation of curing time. From the perspective of pore size, SEM micrographs exhibited that cell size apparently decreased with the addition of the DP.

Similar content being viewed by others

References

Cruz F, Boudaoud H, Hoppe S, Camargo M (2017) Polymer recycling in an open-source additive manufacturing context: mechanical issues. Addit Manuf 17:87–105

Huo S, Jin C, Liu G, Chen J, Wu G, Kong Z (2019) Preparation and properties of biobased autocatalytic polyols and their polyurethane foams. Polym Degrad Stab 159:62–69

Yang J, Yang W, Wang X, Dong M, Liu H, Wujcik EK, Guo Z (2019) Synergistically toughening polyoxymethylene by methyl methacrylate–butadiene–styrene copolymer and thermoplastic polyurethane. Macromol Chem Phys 220:1800567

Dong M, Li Q, Liu H, Liu C, Wujcik EK, Shao Q, Guo Z (2018) Thermoplastic polyurethane-carbon black nanocomposite coating: fabrication and solid particle erosion resistance. Polymer (Guildf) 158:381–390

Dong M, Wang C, Liu H, Liu C, Shen C, Zhang J, Guo Z (2019) Enhanced solid particle erosion properties of thermoplastic polyurethane-carbon nanotube nanocomposites. Macromol Mater Eng 304:1–11

Hang S, Liu H, Yang S, Shi X, Zhang D, Shan C, Guo Z (2019) Ultrasensitive and highly compressible piezoresistive sensor based on polyurethane sponge coated with a cracked cellulose nanofibril/silver nanowire layer. ACS Appl Mater Interfaces 11:10922–10932

Tantisattayakul T, Kanchanapiya P, Methacanon P (2018) Comparative waste management options for rigid polyurethane foam waste in Thailand. J Clean Prod 196:1576–1586

Moon J, Kwak SB, Lee JY, Kim D, Ha JU, Oh JS (2019) Synthesis of polyurethane foam from ultrasonically decrosslinked automotive seat cushions. Waste Manag 85:557–562

Członka S, Bertino MF, Strzelec K (2018) Rigid polyurethane foams reinforced with industrial potato protein. Polym Test 68:135–145

Yang W, Dong Q, Liu S, Xie H, Liu L, Li J (2012) Recycling and disposal methods for polyurethane foam wastes. Procedia Environ Sci 16:167–175

Cornille A, Auvergne R, Figovsky O, Boutevin B, Caillol S (2017) A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur Polym J 87:535–552

Datta J, Marcin W (2017) Recycling of polyurethanes. In: Polyurethane polymers, 1st edn. MPS limited, Chennai, pp 323–358

Beneš H, Černá R, Ďuračková A, Látalová P (2012) Utilization of natural oils for decomposition of polyurethanes. J Polym Environ 20:175–185

Zia KM, Bhatti HN, Bhatti IA (2007) Methods for polyurethane and polyurethane composites, recycling and recovery: a review. React Funct Polym 67:675–692

Li Y, Lv L, Wang W, Zhang J, Lin J, Zhou J, Dong M, Yuanfa G, Seok I, Guo Z (2020) Effects of chlorinated polyethylene and antimony trioxide on recycled polyvinyl chloride/acryl-butadiene-styrene blends: Flame retardancy and mechanical properties. Polymer 190:122198

Cho SJ, Kim KH, Jung HY, Kwon OJ, Seo YC (2010) Characteristics of products and PCDD/DF emissions from a pyrolysis process of urethane/styrofoam waste from electrical home appliances. J Mater Cycles Waste Manag 12:98–102

Badawy SM (2013) Vacuum pyrolysis of polymeric wastes containing hazardous cyano groups. J Mater Cycles Waste Manag 15:218–222

Li Y, Lv L, Wang W, Zhang J, Lin J, Zhou J, Guo Z (2020) Effects of chlorinated polyethylene and antimony trioxide on recycled polyvinyl chloride/acryl-butadiene-styrene blends: flame retardancy and mechanical properties. Polymer (Guildf) 190:122198

Kong Y, Li Y, Hu G, Cao N, Ling Y, Pan D, Guo Z (2018) Effects of polystyrene-b-poly(ethylene/propylene)-b-polystyrene compatibilizer on the recycled polypropylene and recycled high-impact polystyrene blends. Polym Adv Technol 29:2344–2351

Kong Y, Li Y, Hu G, Lin J, Pan D, Dong D, Guo Z (2018) Preparation of polystyrene-b-poly(ethylene/propylene)-b-polystyrene grafted glycidyl methacrylate and its compatibility with recycled polypropylene/recycled high impact polystyrene blends. Polymer (Guildf) 145:232–241

Li Y, Wu X, Song J, Li J, Shao Q, Cao N, Guo Z (2017) Reparation of recycled acrylonitrile-butadiene-styrene by pyromellitic dianhydride: reparation performance evaluation and property analysis. Polymer (Guildf) 124:41–47

Simón D, Borreguero AM, De Lucas A, Molero C, Rodríguez JF (2014) (2014) Novel polyol initiator from polyurethane recycling residue. J Mater Cycles Waste Manag 16:525–532

Molero C, De Lucas A, Romero F, Rodríguez JF (2009) Glycolysis of flexible polyurethane wastes using stannous octoate as the catalyst. J Mater Cycles Waste Manag 11:130–132

Carriço CS, Fraga T, Pasa VMD (2016) Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur Polym J 85:53–61

Aguado A, Martínez L, Moral A, Fermoso J, Irusta R (2011) Chemical Recycling of Polyurethane Foam Waste Via Glycolysis. Chem Eng Trans 24:1069–1074

Dalen MB, Ibrahim AQ, Adamu HM (2014) Effects of low castor oil on mechanical properties of polyurethane foams. Br J Appl Sci Technol 4:2661–2683

Borreguero AM, De Lucas A, Rodríguez JF, Sim D (2015) Valorization of crude glycerol as a novel transesterification agent in the glycolysis of polyurethane foam waste. Polym Degrad Stabil 121:126–136

Bene H, Rais D (2013) Recycling of waste poly (ethylene terephthalate) with castor oil using microwave heating Hynek Bene. Polym Degrad Stabil 98:2232–2243

Risti IS, Cincovi MM, Stojiljkovi DT, János CJ, Miroslav CJ, Stamenkovi JV (2015) Progress in organic coatings glycolyzed poly (ethylene terephthalate) waste and castor oil-based polyols for waterborne polyurethane adhesives containing hexamethoxymethyl melamine. Prog Org Coat 78:357–368

Ogunniyi DS (2006) Castor oil: a vital industrial raw material. Bioresour Technol 97:1086–1091

Calvo-Correas T, Eceiza A, Datta J (2016) Synthesis and characterisation of polyurethane elastomers with semi-products obtained from polyurethane recycling. Eur Polym J 85:26–37

Trzebiatowska PJ, Deuter I, Datta J (2017) Cast polyurethanes obtained from reactive recovered polyol intermediates via crude glycerine decomposition process. React Funct Polym 119:20–25

Hummel DO (2002) Atlas of plastics additives analysis by spectrometric methods. Springer and Business Media, Berlin Heidelberg

Szycher M (2013) Szycher’s handbook of polyurethanes Second. CRC Press Taylor & Francis Group, Boca Raton

Stuart BH (2004) Spectral analysis Infrared spectroscopy: fundamentals and applications. John Wiley Sons Ltd, Hoboken

Asefnejad A, Khorasani MT, Behnamghader A, Farsadzadeh B, Bonakdar S (2011) Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method : physical properties and in vitro assay. Int J Nanomed 6:2375–2384

Cinelli P, Anguillesi I, Lazzeri A (2013) Green synthesis of flexible polyurethane foams from liquefied lignin. Eur Polym J 49(6):1174–1184

Pulido JE, Cabrera JM, Navas KJ, Valero MF (2007) Síntesis y caracterización de elastómeros de poliuretano a partir de poliol-suspensiones de aceite de higuerilla y almidón de yuca. Rev Fac Ing 39:100–111

Valero MF, Pulido JE, Ramírez Á, Higuita LE, Arias SM, Gonzáles CS (2010) Poliuretanos elastoméricos obtenidos a partir de aceite de ricino y almidón de yuca original y modificado con anhídrido propiónico: síntesis, propiedades fisicoquímicas y fisicomecánicas. Quím Nova 33(4):850–854

Kraitape N, Thongpin C (2016) Influence of recycled polyurethane polyol on the properties of flexible polyurethane foams. Energy Procedia 89:186–197

Maheo L, Viot P, Bernard D, Chirazi A, Ceglia G, Schmitt V, Mondain-Monval O (2013) Composites : part B elastic behavior of multi-scale, open-cell foams. Compos Part B 44(1):172–183

Rampf M, Speck O, Speck T, Luchsinger RH (2012) Structural and mechanical properties of flexible polyurethane foams cured under pressure. J Cell Plast 48(1):53–69

Hinrichsen G (1994) Polyurethane handbook. Edited by G. Oertel, Hanser Publishers, Munich 1993, 770 pp., DM 358, ISBN 3‐446‐17198‐3. Acta Polym 45(5):398–398

Rojek P, Prociak A (2012) Effect of different rapeseed-oil-based polyols on mechanical properties of flexible polyurethane foams. J Appl Polym Sci 125(4):2936–2945

Jiao C, Shao Q, Wu M, Zheng B, Guo Z, Yi J, Guo Z (2020) 2-(3,4-Epoxy) ethyltriethoxysilane-modified waterborne acrylic resin: preparation and property analysis”. Polymer (Guildf) 190:122196

Gu H, Zhang H, Ma C, Xu X, Wang Y, Wang Z, Mai X (2019) Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: simultaneously strengthening and toughening epoxy. Carbon N Y 142:131–140

Hu Z, Zhang D, Lu F, Yuan W, Xu X, Zhang Q, Huang Y (2018) Multistimuli-responsive intrinsic self-healing epoxy resin constructed by host-guest interactions. Macromolecules 51(14):5294–5303

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Valle, V., Aguirre, C., Aldás, M. et al. Recycled-based thermosetting material obtained from the decomposition of polyurethane foam wastes with castor oil. J Mater Cycles Waste Manag 22, 1793–1800 (2020). https://doi.org/10.1007/s10163-020-01068-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01068-5