Abstract

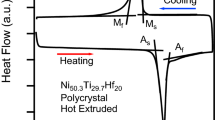

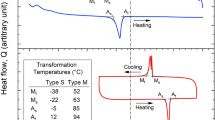

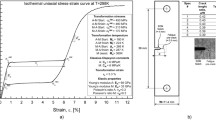

Superelastic NiTi shape memory alloy is characterized by phase transformation under loading. In this work, the effect of loading rate on fracture mechanics of NiTi is investigated. First, to characterize the behavior of the material, tensile experiments are conducted on dog-bone specimens at different quasi-static-range loading rates and the transformation stresses–strains are calculated. An increase in forward transformation stresses–strains, and a decrease in the reverse transformation stresses–strains with increasing loading rate is observed. Surface mean temperature is measured using a thermal camera, and an increase in temperature difference is observed with increasing loading rate. Displacement field and strain maps are obtained simultaneously using Digital Image Correlation (DIC). The strain maps show strain localizations that change with increasing loading rate. At higher loading rates, localized strain bands increase in number. Fracture experiments are then conducted under Mode I loading on plane stress Compact Tension (CT) specimens, and for further confirmation of the behavior, Finite Element Analysis (FEA) is used with a user defined subroutine to account for thermomechanical coupling. Crack mouth opening displacements (CMODs) are measured and an increase with increasing loading rate is observed. Stress Intensity Factors (SIFs) are calculated using ASTM E399 equations, the displacement data obtained from DIC, and FEA. In all cases, stress intensity factors show an increasing-decreasing trend with increasing loading rate. Results are summarized in a figure to show the trend. Austenite to martensite transformation region sizes around the crack tip are evaluated experimentally, analytically and computationally, and are found to be decreasing with increasing loading rate as well. An interesting but coherent behavior in change of fracture parameters with increasing loading rate is obtained. This study is expected to stimulate new discussions on the subject.

Similar content being viewed by others

References

Adharapurapu RR, Jiang F, Vecchio KS, Gray GT (2006) Response of niti shape memory alloy at high strain rate: a systematic investigation of temperature effects on tension-compression asymmetry. Acta Mater 54(17):4609–4620

Afshar A, Ardakani SH, Hashemi S, Mohammadi S (2015) Numerical analysis of crack tip fields in interface fracture of sma/elastic bi-materials. Int J Fract 195(1–2):39–52

Ahadi A, Sun Q (2016) Grain size dependence of fracture toughness and crack-growth resistance of superelastic niti. Script Mater 113:171–175

Ardakani SH, Ahmadian H, Mohammadi S (2015) Thermo-mechanically coupled fracture analysis of shape memory alloys using the extended finite element method. Smart Mater Struct 24(4):045031

Ardakani SH, Afshar A, Mohammadi S (2016) Numerical study of thermo-mechanical coupling effects on crack tip fields of mixed-mode fracture in pseudoelastic shape memory alloys. Int J Solids Struct 81:160–178

ASTM-E399 (2012) Standard test method for linear-elastic plane-strain fracture toughness kic of metallic materials. ASTM Standard

Auricchio F, Fugazza D, Desroches R (2008) Rate-dependent thermo-mechanical modelling of superelastic shape-memory alloys for seismic applications. J Intell Mater Syst Struct 19(1):47–61

Baxevanis T, Lagoudas D (2012) A mode i fracture analysis of a center-cracked infinite shape memory alloy plate under plane stress. Int J Fract 175(2):151–166

Baxevanis T, Chemisky Y, Lagoudas D (2012) Finite element analysis of the plane strain crack-tip mechanical fields in pseudoelastic shape memory alloys. Smart Mater Struct 21(9):094012

Baxevanis T, Parrinello A, Lagoudas D (2013) On the fracture toughness enhancement due to stress-induced phase transformation in shape memory alloys. Int J Plast 50:158–169

Baxevanis T, Landis CM, Lagoudas DC (2014a) On the effect of latent heat on the fracture toughness of pseudoelastic shape memory alloys. J Appl Mech 81(10):101006

Baxevanis T, Landis CM, Lagoudas DC (2014b) On the fracture toughness of pseudoelastic shape memory alloys. J Appl Mech 81(4):041005

Baxevanis T, Parrinello A, Lagoudas D (2016) On the driving force for crack growth during thermal actuation of shape memory alloys. J Mech Phys Solids 89:255–271

Brinson LC, Schmidt I, Lammering R (2002) Micro and macromechanical investigations of cualni single crystal and cualmnzn polycrystalline shape memory alloys. J Intell Mater Syst Struct 13(12):761–772

Creuziger A, Bartol L, Gall K, Crone W (2008) Fracture in single crystal niti. J Mech Phys Solids 56(9):2896–2905

Daly S, Miller A, Ravichandran G, Bhattacharya K (2007) An experimental investigation of crack initiation in thin sheets of nitinol. Acta Mater 55(18):6322–6330

Dayananda G, Rao MS (2008) Effect of strain rate on properties of superelastic niti thin wires. Mater Sci Eng A 486(1–2):96–103

Duerig T, Bhattacharya K (2015) The influence of the r-phase on the superelastic behavior of niti. Shape memory superelast 1(2):153–161

Freed Y, Banks-Sills L (2007) Crack growth resistance of shape memory alloys by means of a cohesive zone model. J Mech Phys Solids 55(10):2157–2180

Frenzel J, Wieczorek A, Opahle I, Maaß B, Drautz R, Eggeler G (2015) On the effect of alloy composition on martensite start temperatures and latent heats in ni-ti-based shape memory alloys. Acta Mater 90:213–231

Gall K, Yang N, Sehitoglu H, Chumlyakov YI (2001) Fracture of precipitated niti shape memory alloys. Int J Fract 109(2):189–207

Gollerthan S, Young M, Baruj A, Frenzel J, Schmahl WW, Eggeler G (2009a) Fracture mechanics and microstructure in niti shape memory alloys. Acta Mater 57(4):1015–1025

Gollerthan S, Young M, Neuking K, Ramamurty U, Eggeler G (2009b) Direct physical evidence for the back-transformation of stress-induced martensite in the vicinity of cracks in pseudoelastic niti shape memory alloys. Acta Mater 57(19):5892–5897

Grabe C, Bruhns OT (2008) On the viscous and strain rate dependent behavior of polycrystalline niti. Int J Solids Struct 45(7–8):1876–1895

Haghgouyan B, Shafaghi N, Aydıner CC, Anlas G (2016) Experimental and computational investigation of the effect of phase transformation on fracture parameters of an sma. Smart Mater Struct 25(7):075010

Haghgouyan B, Hayrettin C, Baxevanis T, Karaman I, Lagoudas DC (2019) Fracture toughness of niti-towards establishing standard test methods for phase transforming materials. Acta Mater 162:226–238

Hazar S, Zaki W, Moumni Z, Anlas G (2015) Modeling of steady-state crack growth in shape memory alloys using a stationary method. Int J Plast 67:26–38

Hazar S, Anlas G, Moumni Z (2016) Evaluation of transformation region around crack tip in shape memory alloys. Int J Fract 197(1):99–110

He Y, Sun Q (2010) Frequency-dependent temperature evolution in niti shape memory alloy under cyclic loading. Smart Mater Struct 19(11):115014

Holtz R, Sadananda K, Imam M (1999) Fatigue thresholds of ni-ti alloy near the shape memory transition temperature. Int J Fatig 21:S137–S145

Huang H, Saletti D, Pattofatto S, Shi F, Zhao H (2013) Experimental observation of phase transformation front of sma under impact loading. In: 13th International conference of fracture, vol. 4, pp 2658–2666

Iadicola MA, Shaw JA (2004) Rate and thermal sensitivities of unstable transformation behavior in a shape memory alloy. Int J Plast 20(4–5):577–605

Iliopoulos A, Steuben J, Kirk T, Baxevanis T, Michopoulos J, Lagoudas D (2017) Thermomechanical failure response of notched niti coupons. Int J Solids Struct 125:265–275

Imanol F, Javier Z, Laurentzi A, Germán C, Jon A, Idoia U (2008) Constitutive model taking into account the strain rate for uniaxial niti shape memory alloy under low velocity impact conditions. Smart Mater Struct 17(6):065033

Jape S, Baxevanis T, Lagoudas D (2016) Stable crack growth during thermal actuation of shape memory alloys. Shape Memory Superelast 2(1):104–113

Jape S, Baxevanis T, Lagoudas D (2018) On the fracture toughness and stable crack growth in shape memory alloy actuators in the presence of transformation-induced plasticity. Int J Fract 209(1–2):117–130

Jiang F, Vecchio KS (2007) Fracture of nitinol under quasistatic and dynamic loading. Metallurg Mater Trans A 38(12):2907–2915

Kadkhodaei M, Rajapakse R, Mahzoon M, Salimi M (2007) Modeling of the cyclic thermomechanical response of sma wires at different strain rates. Smart Mater Struct 16(6):2091

Kan Q, Yu C, Kang G, Li J, Yan W (2016) Experimental observations on rate-dependent cyclic deformation of super-elastic niti shape memory alloy. Mech Mater 97:48–58

Katanchi B, Choupani N, Khalil-Allafi J, Tavangar R, Baghani M (2018) Mixed-mode fracture of a superelastic niti alloy: experimental and numerical investigations. Eng Fract Mech 190:273–287

Kim K (2013) Effects of crystallographic texture and applied strain rate on the cyclic behavior of nickel-titanium. PhD thesis, University of Michigan

Kim S, Cho M (2010) A strain rate effect of ni-ti shape memory alloy wire. Jpn J Appl Phys 49(11R):115801

Lagoudas DC (2008) Shape memory alloys. Springer, Berlin

Loughran G, Shield T, Leo P (2003) Fracture of shape memory cualni single crystals. Int J Solids Struct 40(2):271–294

Luo J, He J, Wan X, Dong T, Cui Y, Xiong X (2016) Fracture properties of polycrystalline niti shape memory alloy. Mater Sci Eng A 653:122–128

Maletta C (2012) A novel fracture mechanics approach for shape memory alloys with trilinear stress-strain behavior. Int J Fract 177(1):39–51

Maletta C, Furgiuele F (2010) Analytical modeling of stress-induced martensitic transformation in the crack tip region of nickel-titanium alloys. Acta Mater 58(1):92–101

Maletta C, Sgambitterra E, Furgiuele F (2013) Crack tip stress distribution and stress intensity factor in shape memory alloys. Fatig Fract Eng Mater Struct 36(9):903–912

Maletta C, Bruno L, Corigliano P, Crupi V, Guglielmino E (2014) Crack-tip thermal and mechanical hysteresis in shape memory alloys under fatigue loading. Mater Sci Eng A 616:281–287

Maletta C, Sgambitterra E, Niccoli F (2016) Temperature dependent fracture properties of shape memory alloys: novel findings and a comprehensive model. Sci Rep 6(1):17

Morin C, Moumni Z, Zaki W (2011a) A constitutive model for shape memory alloys accounting for thermomechanical coupling. Int J Plast 27(5):748–767

Morin C, Moumni Z, Zaki W (2011b) Thermomechanical coupling in shape memory alloys under cyclic loadings: experimental analysis and constitutive modeling. Int J Plast 27(12):1959–1980

Oral A, Lambros J, Anlas G (2008) Crack initiation in functionally graded materials under mixed mode loading: experiments and simulations. J Appl Mech 75(5):051110

Özerim G, Anlaş G, Moumni Z (2018) On crack tip stress fields in pseudoelastic shape memory alloys. Int J Fract 212(2):205–217

Pieczyska E, Gadaj S, Nowacki W, Tobushi H (2006) Phase-transformation fronts evolution for stress-and strain-controlled tension tests in tini shape memory alloy. Exp Mech 46(4):531–542

Prahlad H, Chopra I (2003) Development of a strain-rate dependent model for uniaxial loading of SMA wires. J Intellig Mater Syst Struct 14(7):429–442

Qian H, Li H, Song G, Guo W (2013) A constitutive model for superelastic shape memory alloys considering the influence of strain rate. Mathematical problems in engineering

Reedlunn B, Churchill CB, Nelson EE, Shaw JA, Daly SH (2014) Tension, compression, and bending of superelastic shape memory alloy tubes. J Mech Phys Solids 63:506–537

Robertson S, Mehta A, Pelton A, Ritchie R (2007) Evolution of crack-tip transformation zones in superelastic nitinol subjected to in situ fatigue: a fracture mechanics and synchrotron x-ray microdiffraction analysis. Acta Mater 55(18):6198–6207

Robertson S, Pelton A, Ritchie R (2012) Mechanical fatigue and fracture of nitinol. Int Mater Rev 57(1):1–37

Robertson SW (2006) On the mechanical properties and microstructure of nitinol forbiomedical stent applications. Tech. rep., Lawrence Berkeley National Lab. (LBNL), Berkeley, CA (United States)

Robertson SW, Ritchie RO (2007) In vitro fatigue-crack growth and fracture toughness behavior of thin-walled superelastic nitinol tube for endovascular stents: a basis for defining the effect of crack-like defects. Biomaterials 28(4):700–709

Roh JH (2014) Thermomechanical modeling of shape memory alloys with rate dependency on the pseudoelastic behavior. Mathematical problems in engineering 2014

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of niti. J Mech Phys Solids 43(8):1243–1281

Stebner AP, Paranjape HM, Clausen B, Brinson LC, Pelton AR (2015) In situ neutron diffraction studies of large monotonic deformations of superelastic nitinol. Shape Memory Superelast 1(2):252–267

Tobushi H, Shimeno Y, Hachisuka T, Tanaka K (1998) Influence of strain rate on superelastic properties of tini shape memory alloy. Mech Mater 30(2):141–150

Vitiello A, Giorleo G, Morace RE (2004) Analysis of thermomechanical behaviour of nitinol wires with high strain rates. Smart Mater Struct 14(1):215

Wang G (2007) Effect of martensite transformation on fracture behavior of shape memory alloy niti in a notched specimen. Int J Fract 146(1–2):93–104

Wang G, Xuan F, Tu S, Wang Z (2010) Effects of triaxial stress on martensite transformation, stress–strain and failure behavior in front of crack tips in shape memory alloy niti. Mater Sci Eng A 527(6):1529–1536

Wang X, Wang Y, Baruj A, Eggeler G, Yue Z (2005) On the formation of martensite in front of cracks in pseudoelastic shape memory alloys. Mater Sci Eng A 394(1–2):393–398

Wayman CM, Ōtsuka K (1998) Shape memory materials. Cambridge University Press, Cambridge

Xiong F, Liu Y (2007) Effect of stress-induced martensitic transformation on the crack tip stress-intensity factor in ni-mn-ga shape memory alloy. Acta Mater 55(16):5621–5629

Yan W, Wang CH, Zhang XP, Mai YW (2002) Effect of transformation volume contraction on the toughness of superelastic shape memory alloys. Smart Mater Struct 11(6):947

Yi S, Gao S (2000) Fracture toughening mechanism of shape memory alloys due to martensite transformation. Int J Solids Struct 37(38):5315–5327

You Y, Zhang Y, Moumni Z, Anlas G, Zhang W (2017) Effect of the thermomechanical coupling on fatigue crack propagation in niti shape memory alloys. Mater Sci Eng A 685:50–56

You Y, Gu X, Zhang Y, Moumni Z, Anlaş G, Zhang W (2019) Effect of thermomechanical coupling on stress-induced martensitic transformation around the crack tip of edge cracked shape memory alloy. Int J Fract 1:11

Yu C, Kang G, Kan Q, Zhu Y (2015) Rate-dependent cyclic deformation of super-elastic niti shape memory alloy: thermo-mechanical coupled and physical mechanism-based constitutive model. Int J Plast 72:60–90

Zaki W, Moumni Z (2007) A three-dimensional model of the thermomechanical behavior of shape memory alloys. J Mech Phys Solids 55(11):2455–2490

Zhang X, Feng P, He Y, Yu T, Sun Q (2010) Experimental study on rate dependence of macroscopic domain and stress hysteresis in niti shape memory alloy strips. Int J Mech Sci 52(12):1660–1670

Zhang Y, Zhu J, Moumni Z, Van Herpen A, Zhang W (2016) Energy-based fatigue model for shape memory alloys including thermomechanical coupling. Smart Mater Struct 25(3):035042

Zhu S, Zhang Y (2007) A thermomechanical constitutive model for superelastic SMA wire with strain-rate dependence. Smart Mater Struct 16(5):1696

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mutlu, F., Anlaş, G. & Moumni, Z. Effect of loading rate on fracture mechanics of NiTi SMA. Int J Fract 224, 151–165 (2020). https://doi.org/10.1007/s10704-020-00450-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00450-6