Abstract

Single-mode lasing of quantum-cascade lasers with a distributed Bragg reflector formed by ion-beam etching in layers of the upper waveguide cladding is demonstrated. The active region is formed based on an In0.53Ga0.47As/Al0.48In0.52As solid-alloy heteropair with two-phonon depletion of the lower level in the cascade. Single-mode lasing at a temperature of 280 K corresponds to the emission wavelength of 7.74 μm, and the side-mode suppression ratio is 24 dB.

Similar content being viewed by others

To date, a number of approaches to the designing of single-mode quantum-cascade lasers (QCL) have been presented. The construction of a grating on the waveguide surface providing distributed feedback (DFB) made it possible to implement for the first time the single-mode lasing mode in a QCL [1]. The design of the external cavity allowed for tuning of the lasing wavelength in a wide range [2]. Alternative approaches to selection of higher-order modes are based on the use of photonic crystals [3], Mach–Zehnder interferometers, and ring [4], coupled [5, 6], and monolithic coupled cavities [7–9].

Designs of DFB lasers provide a high side-mode suppression ratio (SMSR). At the same time, it is impossible to accurately set the cavity length at cleavage of mirrors, which leads to an unintentional phase shift. As a consequence, additional modes arise in the lasing spectrum, which reduces the device product yield [10]. The use of distributed Bragg reflectors (DBRs) [11–14] eliminates the effect of spatial hole burning observed in long DFB lasers. The single-mode lasing in a QCL with a DBR was previously implemented in the spectral range of 4.5–5.0 μm [11, 13].

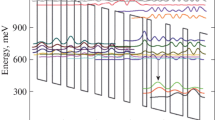

In this Letter, we report the results of designing and studying a QCL with a DBR in the spectral range of 7.5–8.0 μm operating at room temperature. The QCL heterostructure was grown on an InP(001) substrate by Connector Optics LLC on a commercial Riber 49 molecular-beam epitaxy setup [15, 16]. The design of a waveguide with a thin (750 nm) upper cladding based on indium phosphide was used. The active region was formed on the basis of an In0.53Ga0.47As/Al0.48In0.52As solid-alloy heteropair with two-phonon depletion of the lower level in the cascade [17].

The QCL crystal was formed according to the technique similar to that described previously in [18]. The design of deep mesa with a seed in a substrate was used. The ridge width near the heterostructure surface was 20 μm, and the laser cavity length was L = 1.5 mm. High-reflection and antireflection coatings were not deposited on the cleaved laser faces. The crystal was mounted via the substrate on the copper heat sink using indium solder. The DBR grating near the rear facet (Fig. 1) was etched in ultrahigh vacuum by a gallium ion beam with an energy of 30 keV (operating current 450 pA) focused to a spot 40 nm in diameter. The roughness of the etched surface did not exceed 2 nm [19]. The irradiation dose of the DBR region at the etching was 1.75 pC/cm2. The DBR grating period was 1.14 μm. The grating duty cycle was chosen to be 50% [20]. The width of the grating line was 0.57 μm, while its length in the perpendicular direction was 10 μm. A total of 176 lines were deposited with the total length of the DBR grating region equal to 200.64 μm. In the DBR grating region, the upper metallization layer with a thickness of 205 nm, the In0.53Ga0.47As contact layer 120 nm thick, and part of the upper waveguide cladding to a depth of 550 nm were milled. The total depth at the DBR etching was about 875 nm. A scanning electron microscopy (SEM) image of the formed DBR grating is presented in Fig. 1.

The current–voltage characteristics were measured by feeding 125-ns current pulses with a repetition frequency of 15 kHz. Typical shapes of the current–voltage and light intensity-current characteristics of a QCL with DBR measured at 280 K are shown in Fig. 2. The threshold current and its density were 2.65 A and 8.6 kA/cm2, respectively. The laser threshold current before the etching of the DBR grating was 1.7 A. Thus, the fabrication of the DBR grating led to the increase in the threshold current by 55%, which can be related not only to the optical loss introduced by the DBR but also to radiation-induced defects under bombardment of the surface by gallium ions during the DBR etching.

Spectra of the QCL stimulated emission were measured on a Bruker Vertex 80v Fourier spectrometer. The spectral resolution was 0.2 cm–1. The optical signal was detected by a cooled HgCdTe photodetector (operating speed on the order of 10 ns). The signal from the photodetector was measured using an external analog-to-digital converter every 10 s with current-pulse synchronization and averaged over 20 measurements [21]. The pulse width and repetition rate were 125 ns and 15 kHz, respectively.

Figure 3 shows the lasing spectra measured at 280 K. At the pump current of 2.65 A, the lasing spectrum exhibits three longitudinal optical modes near 7.74 μm, spaced by a distance of 5.4–5.8 nm from each other, which corresponds to the fringe distance of the 1.5‑mm-long Fabry–Perot cavity. The SMSR was 7 dB. The full width at half maximum (FWHM) of the lines was 1.7 nm. The increase in the pump current to 2.73 A led to side-mode suppression and occurrence of single-mode lasing with the SMSR at a level of 24 dB (Fig. 3). The FWHM value was 1.7 nm. The increase in the current to 2.8 A reduced the SMSR value to 15 dB. At the pump current of 3 A or higher, additional optical modes near 7.77 μm could be observed in the lasing spectrum.

Thus, we have presented the results of the fabrication of a QCL with a DBR grating in the spectral range of 7.5–8.0 μm and analyzed its parameters. Single-mode lasing at the emission wavelength of 7.74 μm at a temperature of 280 K was demonstrated. The maximum achieved side-mode suppression ratio was 24 dB. The FWHM in the lasing spectrum was 0.3 cm–1, which allows one to design tunable mid-IR lasers based on a linear array of single-mode QCLs with DBR gratings, which are required in spectroscopy and gas analysis.

REFERENCES

J. Faist, C. Gmachl, F. Capasso, C. Sirtori, D. L. Sivco, J. N. Baillargeon, and A. Y. Cho, Appl. Phys. Lett. 70, 2670 (1997).

G. P. Luo, C. Peng, H.Q. Le, S.S. Pei, W.-Y. Hwang, B. Ishaug, J. Um, J. N. Baillargeon, and C.-H. Lin, Appl. Phys. Lett. 78, 2834 (2001).

J. Semmel, L. Nüahle, S. Höfling, and A. Forchel, Appl. Phys. Lett. 91, 071104 (2007).

D. H. Wu and M. Razeghi, APL Mater. 5, 035505 (2017).

Y. Wakayama, S. Iwamoto, and Y. Arakawa, Appl. Phys. Lett. 96, 171104 (2010).

P. Q. Liu, X. Wang, and C. F. Gmachl, Appl. Phys. Lett. 101, 161115 (2012).

M. C. Zheng, Y. M. Zhang, P. Q. Liu, X. Wang, J.-Y. Fan, M. Troccoli, and C. F. Gmachl, Opt. Eng. 57, 011001 (2017).

A. V. Babichev, A. G. Gladyshev, A. S. Kurochkin, V. V. Dyudelev, E. S. Kolodeznyi, G. S. Sokolovskii, V. E. Bugrov, L. Ya. Karachinskii, I. I. Novikov, D. V. Denisov, A. S. Ionov, S. O. Slipchenko, A. V. Lyutetskii, N. A. Pikhtin, and A. Yu. Egorov, Tech. Phys. Lett. 45, 398 (2019).

A. V. Babichev, D. A. Pashnev, D. V. Denisov, A. G. Gladyshev, Yu. K. Bobretsova, S. O. Slipchenko, L. Ya. Karachinskii, I. I. Novikov, D. A. Firsov, L. E. Vorob’ev, N. A. Pikhtin, and A. Yu. Egorov, Opt. Spectrosc. 128 (6), 696–700 (2020).

Y. Liu, J. Zhang, F. Yan, Z. Jia, F. Liu, P. Liang, N. Zhuo, S.-Q. Zhai, L.-J. Wang, J.-Q. Liu, S.-M. Liu, and Z. Wang, Opt. Express 24, 19545 (2016).

A. Bismuto, Y. Bidaux, S. Blaser, R. Terazzi, T. Gresch, M. Rochat, A. Muller, C. Bonzon, and J. Faist, Opt. Express 24, 10694 (2016).

S. Song, S. S. Howard, Z. Liu, A. O. Dirisu, C. F. Gmachl, and C. B. Arnold, Appl. Phys. Lett. 89, 041115 (2006).

A. Sadeghi, P. Q. Liu, X. Wang, J. Fan, M. Troccoli, and C. F. Gmachl, Opt. Express 21, 31012 (2013).

I. Sergachev, R. Maulini, T. Gresch, S. Blaser, A. Bismuto, A. Müller, Y. Bidaux, T. Sudmeyer, and S. Schilt, Opt. Express 25, 11027 (2017).

A. V. Babichev, G. A. Gusev, A. N. Sofronov, D. A. Firsov, L. E. Vorob’ev, A. A. Usikova, Yu. M. Zadiranov, N. D. Il’inskaya, V. N. Nevedomskii, V. V. Dyudelev, G. S. Sokolovskii, A. G. Gladyshev, L. Ya. Karachinsky, I. I. Novikov, and A. Yu. Egorov, Tech. Phys. 63, 1511 (2018).

A. V. Babichev, A. S. Kurochkin, E. S. Kolodeznyi, A. V. Filimonov, A. A. Usikova, V. N. Nevedomsky, A. G. Gladyshev, L. Ya. Karachinsky, I. I. Novikov, and A. Yu. Egorov, Semiconductors 52, 745 (2018).

A. V. Babichev, A. G. Gladyshev, D. V. Denisov, L. Ya. Karachinskii, I. I. Novikov, L. Boulley, A. Bousseksou, N. A. Pikhtin, and A. Yu. Egorov, Opt. Spectrosc. 127, 279 (2019).

A. V. Babichev, A. Bousseksou, N. A. Pikhtin, I. S. Tarasov, E. V. Nikitina, A. N. Sofronov, D. A. Firsov, L. E. Vorobjev, I. I. Novikov, L. Ya. Karachinsky, and A. Yu. Egorov, Semiconductors 50, 1299 (2016).

G. Pozina, K. A. Ivanov, M. I. Mitrofanov, M. A. Kaliteevski, K. M. Morozov, I. V. Levitskii, G. V. Voznyuk, V. P. Evtikhiev, and S. N. Rodin, Phys. Status Solidi B 256, 1800631 (2019).

A. Bousseksou, V. Moreau, R. Colombelli, C. Sirtori, G. Patriarche, O. Mauguin, L. Largeau, G. Beaudoin, and I. Sagnes, Electron. Lett. 44, 807 (2008).

A. V. Babichev, D. A. Pashnev, A. G. Gladyshev, A. S. Kurochkin, E. S. Kolodeznyi, L. Ya. Karachinskii, I. I. Novikov, D. V. Denisov, L. Boulley, D. A. Firsov, L. E. Vorobjev, N. A. Pikhtin, A. Bousseksou, and A. Yu. Egorov, Tech. Phys. Lett. 45, 1136 (2019).

Funding

This study was supported by the Russian Foundation for Basic Research, project no. 16-29-03289. D.A. Firsov and L.E. Vorob’ev acknowledge the partial support of the Ministry of Science and Higher Education of the Russian Federation, state contract no. 3.933.2017/4.6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Sin’kov

Rights and permissions

About this article

Cite this article

Babichev, A.V., Pashnev, D.A., Gladyshev, A.G. et al. Quantum-Cascade Lasers with a Distributed Bragg Reflector Formed by Ion-Beam Etching. Tech. Phys. Lett. 46, 312–315 (2020). https://doi.org/10.1134/S1063785020040033

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785020040033