Abstract

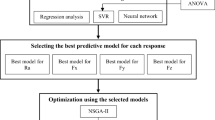

Adhesion strength is one of the most significant quality characteristics for coating performance. Heat treatment and sanding process parameters affect the adhesion strength. The aim of this study was to predict the adhesion strength using machine learning and optimization algorithms. Process factors were selected such as temperature, time, cutting speed, feed rate and grit size while coating performance index was selected as adhesion strength. Adhesion strength values of the specimens were determined by employing pull-off adhesion-type equipment. Firstly, central composite design with analysis of variance was used to create the experimental design and to determine the effective factors. Moreover, the main effect plot was used to determine the values of effective factors. Then, support vector machine (SVR) and extreme learning machine (ELM) were used to predict the adhesion strength. Finally, genetic algorithm was applied to optimize the parameters of SVM and ELM in order to improve the prediction accuracy. The proposed hybrid SVR-GA and ELM-GA approaches were compared with linear regression (LR), SVR and ELM. Experimental results showed that the proposed SVR-GA and ELM-GA approaches outperformed the LR, SVR and ELM in terms of prediction accuracy.

Similar content being viewed by others

References

Bekhta, P.; Krystofiak, T.; Proszyk, S.; Lis, B.: Surface gloss of lacquered medium density fiberboard panels veneered with thermally compressed birch wood. Prog. Org. Coat. 117, 10–19 (2018). https://doi.org/10.1016/j.porgcoat.2017.12.020

Toker, H.; Hiziroglu, S.; Ozcifci, A.: Influence of weathering an adhesion strength of chemically treated and coated scot pine. Prog. Org. Coat. 73, 211–214 (2012). https://doi.org/10.1016/j.porgcoat.2011.11.001

Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M.: Effect of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 12, 40–54 (2017). https://doi.org/10.1080/17480272.2015.1009488

We, Y.; Wang, M.; Zhang, P.; Chen, Y.; Gao, J.; Fan, Y.: The role of phenolic extractives in color changes of Locust Wood (Robinia pseudoacacia) during heat treatment. BioResources 12, 7041–7055 (2017)

Boonstra, M.J.; Tjeerdsma, B.: Chemical analysis of heat treated softwood. Holz als Roh-unWerkstoff 64, 204–211 (2006). https://doi.org/10.1007/s00107-005-0078-4

Dubey, M.K.; Pang, S.; Walker, J.: Oil uptake by wood during heat-treatment and post-treatment cooling, and effects on wood dimensional stability. Eur. J. Wood Wood Prod. 70, 183–190 (2012). https://doi.org/10.1007/s00107-011-0535-1

Huang, X.; Kocaefe, D.; Kocaefe, Y.; Pichette, A.: Combined effect of acetylation and heat treatment on the physical, mechanical and biological behavior of jack pine (Pinus banksiana) wood. Eur. J. Wood Wood Prod. 76, 525–540 (2018). https://doi.org/10.1007/s00107-017-1232-5

Unsal, O.; Korkut, S.; Atik, C.: The effect of heat treatment on some technological properties and color in eucalyptus (Eucalyptus camaldulensis Dehn) wood. Maderas Ciencia Y Technological 5, 145–152 (2003). https://doi.org/10.4067/S0718-221X2003000200006

Bekhta, P.; Krystofiak, T.; Proszyk, S.; Lis, B.: Adhesion strength of thermally compressed and varnished (TCW) substrate. Prog. Org. Coat. 125, 331–338 (2018). https://doi.org/10.1016/j.porgcoat.2018.09.013

Richter, K.; Feist, W.C.; Knaebe, M.T.: The effect of surface roughness on the performance of finishes. Part 1. Roughness characterization and stain performance. For. Prod. J. 45, 91–97 (1995)

Özdemir, T.; Hiziroglu, S.; Kocapınar, M.: Adhesion strength of cellulosic varnish coated wood species as function of their surface roughness. Adv. Mater. Sci. Eng. Int. J. (2015). https://doi.org/10.1155/2015/525496

Salca, E.A.; Krystofiak, T.; Lis, B.: Evaluation of selected properties of alder wood as functions of sanding and coating. Coatings 7, 176–182 (2017). https://doi.org/10.3390/coatings7100176

Sogutlu, C.; Nzokou, P.; Koc, I.; Tutgun, R.; Döngel, N.: The effects of surface roughness on varnish adhesion strength of wood materials. J. Coat. Technol. Res. 13, 863–870 (2016). https://doi.org/10.1007/s11998-016-9805-5

Alipanahpour Dil, E.; Ghaedi, M.; Ghaedi, A.M.; Asfaram, A.; Goudarzi, A.; Hajati, S.; Soylak, M.; Agarwal, S.; Gubta, V.K.: Modeling of quaternanaty dyes adsorption onto ZnO-NR-AC artificial neural network: analysis by derivative spectrophotometry. J. Ind. Eng. Chem. 34, 186–197 (2016). https://doi.org/10.1016/j.jiec.2015.11.010

Laha, D.; Ren, Y.; Suganthan, P.N.: Modeling of steelmaking process with effective machining learning techniques. Expert Syst. Appl. 42, 4687–4696 (2015). https://doi.org/10.1016/j.eswa.2015.01.030

Sarikaya, M.; Güllü, A.: Taguchi design and response surface methodology based analysis of machining parameters in CNC turning under MQL. J. Clean. Prod. 65, 604–616 (2016). https://doi.org/10.1016/j.jclepro.2013.08.040

Panigrahi, S.; Behera, H.S.: A study on leading machine learning techniques for high order fuzzy time series forecasting. Eng. Appl. Artif. Intell. (2020). https://doi.org/10.1016/j.engappai.2019.103245

Tiryaki, S.; Aydın, A.: An artificial neural network model for predicting compression strength of heat treated woods and comparison with a multiple linear regression model. Constr. Build. Mater. 62, 102–108 (2014). https://doi.org/10.1016/j.conbuildmat.2014.03.041

Zhang, J.; Qu, L.; Wanh, Z.; Zhao, Z.; He, Z.; Yi, S.: Simulation and validation of heat transfer during wood heat treatment process. Results Phys. 7, 3806–3812 (2017). https://doi.org/10.1016/j.rinp.2017.09.046

Nguyen, T.H.V.; Nguyen, T.T.; Ji, X.; Do, K.T.L.; Guo, M.: Using artificial neural network (ANN) for modeling predicting hardness change of wood during heat treatment. IOP Conf. Ser. Mater. Sci. Eng. 394, 1–7 (2018)

Nguyen, T.H.V.; Nguyen, T.T.; Ji, X.; Guo, M.: Predicting color change in wood heat treatment using an artificial neural network model. BioResources 11, 6250–6264 (2018). https://doi.org/10.15376/biores.13.3.6250-6264

Ozsahin, S.; Murat, M.: Prediction of equilibrium moisture content and specific gravity of heat treated wood by artificial neural networks. Eur. J. Wood Prod. 76, 563–572 (2018). https://doi.org/10.1007/s00107-017-1219-2

Cool, J.; Hernandez, R.E.: Effects of peripheral planning on surface characteristics and adhesion of a waterborne acrylic coating to black spruce wood. For. Prod. J. 62, 124–133 (2012). https://doi.org/10.13073/0015-7473-62.2.124

Ugulino, B.; Hernandez, R.E.: Assessment of surface properties and solvent-borne coating performance of red oak wood produced by peripheral planning. Eur. J. Wood Prod. 75, 581–593 (2017). https://doi.org/10.1007/s00107-016-1090-6

Salca, E.A.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S.: Some coating properties of black alder wood as a function of varnish type and application method. BioResources 11, 7580–7594 (2016). https://doi.org/10.15376/biores.11.3.7580-7594

Ghasemi, E.; Kalhori, H.; Bagherpour, R.: A new hybrid ANFIS-PSO model for prediction of peak particle velocity due to bench blastik. Eng. Comput. 32, 607–614 (2016). https://doi.org/10.1007/s00366-016-0438-1

Kazem, A.; Sharifi, E.; Hussain, F.K.; Saberi, M.; Hussain, O.K.: Support vector regression with chaos-based firefly algorithm for stock market price forecasting. Appl. Soft Comput. 13, 947–958 (2013). https://doi.org/10.1016/j.asoc.2012.09.02

Esfa, M.H.; Ahangar, M.R.H.; Rejvani, M.; Toghraire, D.; Hajmohammad, M.H.: Designing an artificial neural network to predict dynamic viscosity of aqueous nanofluid of TiO2 using experimental data. Int. Commun. Heat Mass Transf. 75, 192–196 (2016). https://doi.org/10.1016/j.icheatmasstransfer.2016.04.002

Patel, J.; Shah, S.; Thakkar, P.; Kotecha, K.: Predicting stock market index using fusion of machine learning techniques. Expert Syst. Appl. 42, 2162–2172 (2015). https://doi.org/10.1016/j.eswa.2014.10.031

Vapnik, V.: The Nature of Statistical Learning Theory. Springer, Berlin (1999)

Huang, G.B.; Zhu, Q.Y.; Siev, C.K.: Extreme learning machine: theory and applications. Neurocomputing 70, 489–501 (2006). https://doi.org/10.1016/j.neucom.2005.12.126

Cao, J.; Zhang, K.; Luo, M.; Yin, C.; Lai, X.: Extreme learning machine and adaptive sparse representation for image classification. Neural Netw. 81, 91–102 (2016). https://doi.org/10.1016/j.neunet.2016.06.001

Qin, L.; Yi, Z.; Zhang, Y.: Enhanced surface roughness discrimination with optimized features bio-inspired tactile sensor. Sens. Actuators A 264, 133–140 (2017). https://doi.org/10.1016/j.sna.2017.07.054

Rafiei, M.; Niknam, T.; Khooban, M.H.: Probabilistic forecasting of hourly electricity price by generalization of ELM for usage improved wavelet neural network. IEEE Trans. Ind. Inf. 13, 71–79 (2017). https://doi.org/10.1109/tii.2016.2585378

Holland, J.M.: Adaptation in Natural and Artificial Systems. University of Michigan Press, Ann Arbor (1975)

Hazir, E.; Ozcan, T.: Response surface methodology integrated with desirability function and genetic algorithm approach for the optimization of CNC machining parameters. Arab. J. Sci. Eng. 44, 2795–2809 (2019). https://doi.org/10.1007/s13369-018-3559-6

Falkenauer, E.: Applying genetic algorithms to real-world problems. Evolut. Algorithms 111, 65–88 (1999). https://doi.org/10.1007/978-1-4612-1542-4_4

Kadri, R.L.; Boctor, F.F.: An efficient genetic algorithm to solve the resource-constrained Project scheduling problem with transfer times: the single mode case. Eur. J. Oper. Res. 265, 454–462 (2018). https://doi.org/10.1016/j.ejor.2017.07.027

Armaghani, D.J.; Hasanipanah, M.; Mahdiyari, A.; Majid, M.A.; Amnieh, H.B.; Tahir, M.M.D.: Airblast prediction through a hybrid genetic algorithm-ANN model. Neural Comput. Appl. 29, 619–629 (2018). https://doi.org/10.1007/s00521-016-2598-8

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Hazir, E., Ozcan, T. & Koç, K.H. Prediction of Adhesion Strength Using Extreme Learning Machine and Support Vector Regression Optimized with Genetic Algorithm. Arab J Sci Eng 45, 6985–7004 (2020). https://doi.org/10.1007/s13369-020-04625-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04625-0