Abstract

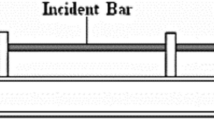

The concept of brittle crack arrest has recently become an internationally focused issue for container ships. The International Association of Classification Society (IACS) also prescribed the unified requirement (UR) for brittle crack arrest design, and brittle crack arrest design has been internationally authorized. As one of the methods to evaluate brittle crack arrestability, the crack arrest temperature (CAT) concept, by isothermal crack arrest test, has been proposed since the 1990s. The concept has been applied mainly for tank design. However, no standard has been specified to describe the detailed evaluation procedure. This means that only limited organizations can evaluate CAT and it is considered to be a problem when arrest evaluation is mandated as an international standard. In the background of such circumstances, Japanese research groups including the Japan Welding Engineering Society (JWES) and Nippon Kaiji Kyokai (ClassNK) started the standardization for CAT test in 2016. In the research programme, various aspects of control factors have been investigated based on the test results from many experiments and numerical calculations. The CAT test shall include the embrittled zone to initiate a brittle crack. Either electron beam (EB) line remelting or a local temperature gradient (LTG) can be applied to the embrittled zone. Even if we focus on EB welding only, welding defects in the embrittled zone can be an influencing factor. In this report, we investigate the effects of residual stress by EB welding on the crack driving force, which is quantified as the K value using a 3D finite element method (FEM). As a result, we confirmed the existence of the residual stress which cannot be ignored that is formed on the surface of the EB-welded portion; however, the influence of that on the K value is considered to be small if the CAT test conditions can sufficiently secure the arrest crack length. This result shows that the driving force at the arrested point in the CAT test can be simply evaluated by the LEFM formula without consideration of the residual stress of the EB weld for embrittlement.

Similar content being viewed by others

References

Stout RD, Wiersma SJ (1986) Crack-arrest properties of 9% nickel steels used in LNG storage vessels, 8th International Conference of Liquefied Natural Gas, Session3, Paper No.5

Hirota K, Nakagawa T, Takeda S, Hashi Y, Tada M (2007) World’s first application of 47 kgf/mm2 higher tensile strength steel for large-scale container ships and realization of safety design to respond to trend for supersizing, Mitsubishi Heavy Industries, Ltd. Tech Rev 44(3)

Kanninen MH, Popelar CH (1985) Advance fracture mechanics. Oxford University Press, Oxford

Willoughby AA (1987) Crack arrest concepts: part 1 and 2. T.W.I. Research Bulletin, 28, 235–240 and 275–277

Kanawzawa T, Koshiga F (1977) Brittle fracture 2, fracture toughness testing, Baifu-kan

Robertson TS (1953) Propagation of brittle fracture in steel. J Iron Steel Inst 175:361–374

Feely FJ, Northup MS, Kleppe SR, Gensamer M (1955) Studies on the brittle failure of tankage steel plates. Welding J 34:596–607

Yoshiki M, Kanazawa T (1957) On the mechanism of propagation of brittle fracture in mild steel (in Japanese). J Zosen Kiokai 1957(102):39–45. https://doi.org/10.2534/jjasnaoe1952.1957.102_39

Koshiga F, Imazawa O, Takehana S (1963) Arrest-transition of brittle crack in steel plate. J Zosen Kiokai 1963(114):200–209

WES2815 (2014) Test method for brittle crack arrest toughness, Kca, explanation, Japan Welding Engineering Society

International Organization for Standardization (ISO20064) (2019) Method of test for the determination of brittle crack arrest toughness, Kca

Wiesner CW, Hayes B, Willoughby AA (1993) Crack arrest in modern steels and their weldments—comparison between small and large scale experiments. Int J Press Vessel Pip 56:369–385

Crosley PB, Ripling EJ (1977) In: Hahn GT, Kanninen MF (eds) Towards development of a standard test for measuring KIa, Fast fracture and crack arrest, ASTM STP627. ASTM International, West Conshohocken, pp 372–401

ASTM E1221-96 (Reapproved 2002): Standard test method for determining plane-strain crack-arrest fracture toughness, Kia, of ferritic steels

Wilkowski GM, Maxey MA, Eiber RJ (1985) AGA/API drop weight tear test round robin testing program, A G A Catalog No L5147

API recommended practice for conducting drop-weight tear test on line pipe (1978)

Deguchi A, Tada M, Yajima H (1990) A consideration on brittle crack arrestability and new impact test for 9% Ni steel. J Soc Naval Architects Japan 167:271–277. https://doi.org/10.2534/jjasnaoe1968.1990.271

Hasebe S, Kawaguchi Y (1975) Study on the brittle fracture propagation-arrest characteristics of low C-Ni steel plates by tapered double cantilever beam test (in Japanese). Tetsu-to-Hagane 61(6):875–883. https://doi.org/10.2355/tetsutohagane1955.61.6_875

Soya I, Sato M, Nakamura Y, Taniguchi N (1976) On a modified three point bend test for determining brittle fracture arresting properties (in Japanese). J Soc Naval Archit Jpn 1976(139):274–283. https://doi.org/10.2534/jjasnaoe1968.1976.274

Nishizono Y, Aihara S, Okawa T, Kawabata T (2019) Development of simplified method for evaluation of brittle crack arrest toughness of steels in small-scale bending tests. Eng Fract Mech 215:99–111. https://doi.org/10.1016/j.engfracmech.2019.03.047

Pellinim WS, Puzak PP, Eschbacher EW (1954) Procedures for NRL drop weight test, NRL Memo Report 316. National Research Laboratory, Washington

ASTM International, Standard test method for conducting drop-weight test to determine nil-ductility transition temperature of ferritic steels, ASTM E208-17

Wiesner CS, Hayes B, Smith SD, Willoughby AA (1994) Investigations into the mechanics of crack arrest in large plates of 1.5 %Ni TMCP steel. Fatigue Fract Eng Mater Struct 17(2):221–233. https://doi.org/10.1111/ffe.1994.17.issue-2

Britich Standard, Alternative steel selection and its effect on design and testing of tanks to BS 7777, PD 7777:2000

Shimada Y, Inoue T, Kawabata T, Aihara S (2017) Effect of specimen size, applied stress and temperature gradient on brittle crack arrest toughness test. Int J Fract 204(2):245–260

Kawabata T, Kaneko M, Aihara S (2018) Effect of impact energy in ESSO test (part 1: basic experiments and validation of FEM analysis). J Test Eval 46(5). https://doi.org/10.1520/JTE20170045

Kaneko M, Kawabata T, Aihara S (2018) Effect of impact energy in the ESSO test (part 2: proposal of validity criteria of impact condition in ESSO test by FEM crack propagation analysis). J Test Eval 46(5). https://doi.org/10.1520/JTE20170151

Kaneko M, Kawabata T, Aihara S (2018) Effect of impact energy in the ESSO test (part 3: experimental validation for new validity criteria of impact condition giving constant evaluation in ESSO test). J Test Eval 46(5). https://doi.org/10.1520/JTE20170150

International Association of Classification Society, Application of YP47 steel plates, UR W31 rev.1 (2015)

Wiesner CS, Leggatt RH, B. Hayes, Residual stress in crack starter sections of double tension crack arrest specimens, Proceedings of 10th European Conference of Fracture, ECF10, structural integrity; experiments, models and applications, pp.589–601

Abaqus theory guide, Dassault Systems. SIMULIA Abaqus6.14

Iron-steel handbook 5th edition, The Iron and Steel Institute of Japan (2014)

Tada H, Paris PC, Irwin G (1985) The stress analysis of cracks handbook, Del Research. Corporation

Acknowledgements

In this study, the authors are very grateful to the members of JWES and analysis technician of KOBELCO RESEARCH, and also the authors wish to thank researcher of POSCO and Lloyd’s Register for fruitful discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Iwatake, C., Kaneko, M., Matsumoto, K. et al. Effects of residual stress by EB welds on assessment of crack arrest temperature (CAT). Weld World 64, 1161–1174 (2020). https://doi.org/10.1007/s40194-020-00905-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00905-3