Reduction-Responsive Molecularly Imprinted Poly(2-isopropenyl-2-oxazoline) for Controlled Release of Anticancer Agents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Instruments

2.3. Synthesis of Poly(2-Isopropenyl-2-Oxazoline) (PiPOx)

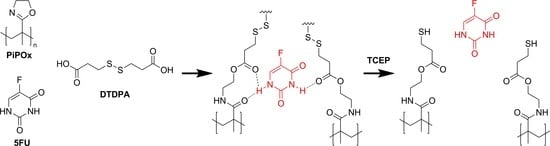

2.4. PiPOx Molecularly Imprinted Polymers (MIPs) Synthesis

2.5. Adsorption Experiments

2.6. In Vitro 5-Fluorouracil (5-FU) Release Studies

2.7. Statistical Analysis

3. Results and Discussion

3.1. Polymer Synthesis and Characterization

3.2. Adsorption Kinetics

3.3. Adsorption Isotherms

3.4. In Vitro Release Studies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wong, H.L.; Bendayan, R.; Rauth, A.M.; Li, Y.; Wu, X.Y. Chemotherapy with anticancer drugs encapsulated in solid lipid nanoparticles. Adv. Drug Deliv. Rev. 2007, 59, 491–504. [Google Scholar] [CrossRef] [PubMed]

- Durán, J.D.G.; Arias, J.L.; Gallardo, V.; Delgado, A.V. Magnetic Colloids As Drug Vehicles. J. Pharm. Sci. 2008, 97, 2948–2983. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Yin, Y.; Xu, S.J.; Chen, W.S. 5-Fluorouracil: Mechanisms of resistance and reversal strategies. Molecules 2008, 13, 1551–1569. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arias, J.L.; Ruiz, M.A.; López-Viota, M.; Delgado, Á.V. Poly(alkylcyanoacrylate) colloidal particles as vehicles for antitumour drug delivery: A comparative study. Colloids Surf. B 2008, 62, 64–70. [Google Scholar] [CrossRef]

- Arias, J.L. Novel strategies to improve the anticancer action of 5-fluorouracil by using drug delivery systems. Molecules (Baselswitzerland) 2008, 13, 2340–2369. [Google Scholar] [CrossRef] [Green Version]

- Arıca, B.; Çalış, S.; Kaş, H.S.; Sargon, M.F.; Hıncal, A.A. 5-Fluorouracil encapsulated alginate beads for the treatment of breast cancer. Int. J. Pharm. 2002, 242, 267–269. [Google Scholar] [CrossRef]

- Martini, L.G.; Collett, J.H.; Attwood, D. The Release of 5-Fluorouracil from Microspheres of Poly(ε-Caprolactone-co-ethylene Oxide). Drug Dev. Ind. Pharm. 2000, 26, 7–12. [Google Scholar] [CrossRef]

- Fabiano, A.; Piras, A.M.; Guazzelli, L.; Storti, B.; Bizzarri, R.; Zambito, Y. Impact of Different Mucoadhesive Polymeric Nanoparticles Loaded in Thermosensitive Hydrogels on Transcorneal Administration of 5-Fluorouracil. Pharmaceutics 2019, 11, 623. [Google Scholar] [CrossRef] [Green Version]

- Rață, D.M.; Cadinoiu, A.N.; Atanase, L.I.; Bacaita, S.E.; Mihalache, C.; Daraba, O.-M.; Gherghel, D.; Popa, M. “In vitro” behaviour of aptamer-functionalized polymeric nanocapsules loaded with 5-fluorouracil for targeted therapy. Mater. Sci. Eng. C 2019, 103, 109828. [Google Scholar] [CrossRef]

- Nazeri, M.T.; Javanbakht, S.; Shaabani, A.; Ghorbani, M. 5-aminopyrazole-conjugated gelatin hydrogel: A controlled 5-fluorouracil delivery system for rectal administration. J. Drug Deliv. Sci. Technol. 2020, 57, 101669. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, H.; Zhu, H.; Jiang, L.; Yang, H. Self-healing gelatin-based shape memory hydrogels via quadruple hydrogen bonding and coordination crosslinking for controlled delivery of 5-fluorouracil. J. Biomater. Sci. Polym. Ed. 2020, 31, 712–728. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Subuddhi, U. Guar gum–poly(N-isopropylacrylamide) smart hydrogels for sustained delivery of 5-fluorouracil. Polym. Bull. (Berl.) 2019, 76, 2945–2963. [Google Scholar] [CrossRef]

- Gao, F.; Wu, X.; Wu, D.; Yu, J.; Yao, J.; Qi, Q.; Cao, Z.; Cui, Q.; Mi, Y. Preparation of degradable magnetic temperature- and redox-responsive polymeric/Fe3O4 nanocomposite nanogels in inverse miniemulsions for loading and release of 5-fluorouracil. Colloid Surf. A 2020, 587, 124363. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Christa, J. Temperature and pH sensitive multi-functional magnetic nanocomposite for the controlled delivery of 5-fluorouracil, an anticancer drug. J. Drug Deliv. Sci. Technol. 2020, 55, 101476. [Google Scholar] [CrossRef]

- Keyvan Rad, J.; Alinejad, Z.; Khoei, S.; Mahdavian, A.R. Controlled Release and Photothermal Behavior of Multipurpose Nanocomposite Particles Containing Encapsulated Gold-Decorated Magnetite and 5-FU in Poly(lactide-co-glycolide). Acs Biomater. Sci. Eng. 2019, 5, 4425–4434. [Google Scholar] [CrossRef]

- Harikrishnan, S.; Sedev, R.; Beh, C.C.; Priest, C.; Foster, N.R. Loading of 5-fluorouracil onto Halloysite nanotubes for targeted drug delivery using a subcritical gas antisolvent process (GAS). J. Supercrit. Fluids 2020, 159, 104756. [Google Scholar] [CrossRef]

- Golubeva, O.Y.; Alikina, Y.A.; Brazovskaya, E.Y.; Ugolkov, V.V. Peculiarities of the 5-fluorouracil adsorption on porous aluminosilicates with different morphologies. Appl. Clay Sci. 2020, 184, 105401. [Google Scholar] [CrossRef]

- Gârea, S.A.; Mihai, A.I.; Ghebaur, A.; Nistor, C.; Sârbu, A. Porous clay heterostructures: A new inorganic host for 5-fluorouracil encapsulation. Int. J. Pharm. 2015, 491, 299–309. [Google Scholar] [CrossRef]

- Tuwahatu, C.A.; Yeung, C.C.; Lam, Y.W.; Roy, V.A.L. The molecularly imprinted polymer essentials: Curation of anticancer, ophthalmic, and projected gene therapy drug delivery systems. J. Control. Release. 2018, 287, 24–34. [Google Scholar] [CrossRef]

- Madadian-Bozorg, N.; Zahedi, P.; Shamsi, M.; Safarian, S. Poly (methacrylic acid)-based molecularly imprinted polymer nanoparticles containing 5-fluourouracil used in colon cancer therapy potentially. Polym. Adv. Technol. 2018, 29, 2401–2409. [Google Scholar] [CrossRef]

- Oliveira, D.; Gomes, C.P.; Dias, R.C.S.; Costa, M.R.P.F.N. Molecular imprinting of 5-fluorouracil in particles with surface RAFT grafted functional brushes. React. Funct. Polym. 2016, 107, 35–45. [Google Scholar] [CrossRef]

- Cegłowski, M.; Kurczewska, J.; Ruszkowski, P.; Schroeder, G. Application of paclitaxel-imprinted microparticles obtained using two different cross-linkers for prolonged drug delivery. Eur. Polym. J. 2019, 118, 328–336. [Google Scholar] [CrossRef]

- Zhang, L.-P.; Tang, S.-H.; Mo, C.-E.; Wang, C.; Huang, Y.-P.; Liu, Z.-S. Synergistic effect of liquid crystal and polyhedral oligomeric silsesquioxane to prepare molecularly imprinted polymer for paclitaxel delivery. Eur. Polym. J. 2018, 98, 226–236. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, Y.; Chen, L.; Yan, H.; Zhang, C.; Liu, L.; Xu, X. Synthesis and characterization of paclitaxel-imprinted microparticles for controlled release of an anticancer drug. Mater. Sci. Eng. Cmaterials Biol. Appl. 2018, 92, 338–348. [Google Scholar] [CrossRef] [PubMed]

- Suksuwan, A.; Lomlim, L.; Rungrotmongkol, T.; Nakpheng, T.; Dickert, F.L.; Suedee, R. The composite nanomaterials containing (R)-thalidomide-molecularly imprinted polymers as a recognition system for enantioselective-controlled release and targeted drug delivery. J. Appl. Polym. Sci. 2015, 132, 41930. [Google Scholar] [CrossRef]

- Jaiswal, L.; Rakkit, S.; Pochin, K.; Jaisamut, P.; Tanthana, C.; Tanmanee, N.; Srichana, T.; Suedee, R. A thalidomide templated molecularly imprinted polymer that promotes a biologically active chiral entity tagged in colon carcinoma cells and protein-related immune activation. Process Biochem. (Amst. Neth.) 2015, 50, 2035–2050. [Google Scholar] [CrossRef]

- Scrivano, L.; Parisi, O.I.; Iacopetta, D.; Ruffo, M.; Ceramella, J.; Sinicropi, M.S.; Puoci, F. Molecularly imprinted hydrogels for sustained release of sunitinib in breast cancer therapy. Polym. Adv. Technol. 2019, 30, 743–748. [Google Scholar] [CrossRef]

- Mo, C.-E.; Chai, M.-H.; Zhang, L.-P.; Ran, R.-X.; Huang, Y.-P.; Liu, Z.-S. Floating molecularly imprinted polymers based on liquid crystalline and polyhedral oligomeric silsesquioxanes for capecitabine sustained release. Int. J. Pharm. 2019, 557, 293–303. [Google Scholar] [CrossRef]

- Lin, F.; Chen, J.; Lee, M.; Lin, B.; Wang, J. Multi-Responsive Ibuprofen-Imprinted Core–Shell Nanocarriers for Specific Drug Recognition and Controlled Release. Acs Appl. Nano Mater. 2020, 3, 1147–1152. [Google Scholar] [CrossRef]

- Chen, L.; Wang, X.; Lu, W.; Wu, X.; Li, J. Molecular imprinting: Perspectives and applications. Chem. Soc. Rev. 2016, 45, 2137–2211. [Google Scholar] [CrossRef]

- Luliński, P. Molecularly imprinted polymers based drug delivery devices: A way to application in modern pharmacotherapy. A review. Mater. Sci. Eng. C 2017, 76, 1344–1353. [Google Scholar] [CrossRef]

- Singh, B.; Chauhan, N. Preliminary evaluation of molecular imprinting of 5-fluorouracil within hydrogels for use as drug delivery systems. Acta Biomater. 2008, 4, 1244–1254. [Google Scholar] [CrossRef] [PubMed]

- Puoci, F.; Iemma, F.; Cirillo, G.; Picci, N.; Matricardi, P.; Alhaique, F. Molecularly Imprinted Polymers for 5-Fluorouracil Release in Biological Fluids. Molecules 2007, 12, 805–814. [Google Scholar] [CrossRef] [PubMed]

- Zaidi, S.A. Molecular imprinting: A useful approach for drug delivery. Mater. Sci. Energy Technol. 2020, 3, 72–77. [Google Scholar] [CrossRef]

- Zhang, N.; Salzinger, S.; Soller, B.S.; Rieger, B. Rare Earth Metal-Mediated Group-Transfer Polymerization: From Defined Polymer Microstructures to High-Precision Nano-Scaled Objects. J. Am. Chem. Soc. 2013, 135, 8810–8813. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Changez, M.; Hong, K.; Mays, J.W.; Kang, N.-G. 2-Isopropenyl-2-oxazoline: Well-Defined Homopolymers and Block Copolymers via Living Anionic Polymerization. Macromolecules 2017, 50, 54–62. [Google Scholar] [CrossRef]

- Reyes, F.T.; Malins, E.L.; Becer, C.R.; Kelland, M.A. Non-Amide Kinetic Hydrate Inhibitors: Performance of a Series of Polymers of Isopropenyloxazoline on Structure II Gas Hydrates. Energy Fuels 2013, 27, 3154–3160. [Google Scholar] [CrossRef]

- Raus, V.; Hološ, A.; Kronek, J.; Mosnáček, J. Well-Defined Linear and Grafted Poly(2-isopropenyl-2-oxazoline)s Prepared via Copper-Mediated Reversible-Deactivation Radical Polymerization Methods. Macromolecules 2020, 53, 2077–2087. [Google Scholar] [CrossRef]

- Rehfeldt, F.; Tanaka, M.; Pagnoni, L.; Jordan, R. Static and Dynamic Swelling of Grafted Poly(2-alkyl-2-oxazoline)s. Langmuir 2002, 18, 4908–4914. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, T. Facile Fabrication of Bio- and Dual-Functional Poly(2-oxazoline) Bottle-Brush Brush Surfaces. Chemistry 2020, 26, 2749–2753. [Google Scholar] [CrossRef]

- Weber, C.; Neuwirth, T.; Kempe, K.; Ozkahraman, B.; Tamahkar, E.; Mert, H.; Becer, C.R.; Schubert, U.S. 2-Isopropenyl-2-oxazoline: A Versatile Monomer for Functionalization of Polymers Obtained via RAFT. Macromolecules 2012, 45, 20–27. [Google Scholar] [CrossRef]

- Jerca, V.V.; Nicolescu, F.A.; Trusca, R.; Vasile, E.; Baran, A.; Anghel, D.F.; Vasilescu, D.S.; Vuluga, D.M. Oxazoline-functional polymer particles graft with azo-dye. React. Funct. Polym. 2011, 71, 373–379. [Google Scholar] [CrossRef]

- Nishikubo, T.; Kameyama, A.; Tokai, H. Synthesis of Polymers in Aqueous Solutions. Selective Addition Reaction of Poly(2-isopropenyl-2-oxazoline) with Thiols and Carboxylic Acids in Aqueous Solutions. Polym. J. (Tokyojpn.) 1996, 28, 134–138. [Google Scholar] [CrossRef] [Green Version]

- Jerca, F.A.; Jerca, V.V.; Anghelache, A.M.; Vuluga, D.M.; Hoogenboom, R. Poly(2-isopropenyl-2-oxazoline) as a versatile platform towards thermoresponsive copolymers. Polym. Chem. 2018, 9, 3473–3478. [Google Scholar] [CrossRef]

- Zhang, N.; Luxenhofer, R.; Jordan, R. Thermoresponsive Poly(2-oxazoline) Molecular Brushes by Living Ionic Polymerization: Kinetic Investigations of Pendant Chain Grafting and Cloud Point Modulation by Backbone and Side Chain Length Variation. Macromol. Chem. Phys. 2012, 213, 973–981. [Google Scholar] [CrossRef]

- Kroneková, Z.; Mikulec, M.; Petrenčíková, N.; Paulovičová, E.; Paulovičová, L.; Jančinová, V.; Nosál’, R.; Reddy, P.S.; Shimoga, G.D.; Chorvát, D., Jr.; et al. Ex Vivo and In Vitro Studies on the Cytotoxicity and Immunomodulative Properties of Poly(2-isopropenyl-2-oxazoline) as a New Type of Biomedical Polymer. Macromol. Biosci. 2016, 16, 1200–1211. [Google Scholar] [CrossRef]

- Jerca, F.A.; Anghelache, A.M.; Ghibu, E.; Cecoltan, S.; Stancu, I.-C.; Trusca, R.; Vasile, E.; Teodorescu, M.; Vuluga, D.M.; Hoogenboom, R.; et al. Poly(2-isopropenyl-2-oxazoline) Hydrogels for Biomedical Applications. Chem. Mater. 2018, 30, 7938–7949. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Jerca, F.A.; Van Hecke, K.; Jerca, V.V.; Hoogenboom, R. High compression strength single network hydrogels with pillar [5] arene junction points. Mater. Horiz. 2020, 7, 566–573. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Jerca, F.A.; Jerca, V.V.; Hoogenboom, R. Covalent Poly(2-Isopropenyl-2-Oxazoline) Hydrogels with Ultrahigh Mechanical Strength and Toughness through Secondary Terpyridine Metal-Coordination Crosslinks. Adv. Funct. Mater. 2019, 29, 1904886. [Google Scholar] [CrossRef] [Green Version]

- Chujo, Y.; Sada, K.; Naka, A.; Nomura, R.; Saegusa, T. Synthesis and redox gelation of disulfide-modified polyoxazoline. Macromolecules 1993, 26, 883–887. [Google Scholar] [CrossRef]

- Zhang, P.; Wu, J.; Xiao, F.; Zhao, D.; Luan, Y. Disulfide bond based polymeric drug carriers for cancer chemotherapy and relevant redox environments in mammals. Med. Res. Rev. 2018, 38, 1485–1510. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.M.; Jani, R.H.; Patel, C.N. Design and evaluation of colon targeted modified pulsincap delivery of 5-fluorouracil according to circadian rhythm. Int. J. Pharm. Investig. 2011, 1, 172–181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, P.; Tyagi, G.; Mehrotra, R.; Bakhshi, A.K. Thermal stability studies of 5-fluorouracil using diffuse reflectance infrared spectroscopy. Drug Test. Anal. 2009, 1, 240–244. [Google Scholar] [CrossRef] [PubMed]

- Haghseresht, F.; Lu, G.Q. Adsorption Characteristics of Phenolic Compounds onto Coal-Reject-Derived Adsorbents. Energy Fuels 1998, 12, 1100–1107. [Google Scholar] [CrossRef]

- Fytianos, K.; Voudrias, E.; Kokkalis, E. Sorption–desorption behaviour of 2,4-dichlorophenol by marine sediments. Chemosphere 2000, 40, 3–6. [Google Scholar] [CrossRef]

- Bashir, S.; Teo, Y.Y.; Naeem, S.; Ramesh, S.; Ramesh, K. pH responsive N-succinyl chitosan/Poly (acrylamide-co-acrylic acid) hydrogels and in vitro release of 5-fluorouracil. Plos ONE 2017, 12, e0179250. [Google Scholar] [CrossRef]

- Ayyavu, M.; Shanmugarathinam, A.; Kandasamy, R. Synthesis and characterization of cystamine conjugated chitosan-SS-mPEG based 5-Fluorouracil loaded polymeric nanoparticles for redox responsive drug release. Eur. J. Pharm. Sci. 2018, 116, 37–47. [Google Scholar] [CrossRef]

| Polymer | Pseudo-First-Order Kinetic Model | Pseudo-Second-Order Kinetic Model | ||

|---|---|---|---|---|

| k1 [h−1] | R2 | k2 [g mg−1 h−1] | R2 | |

| PiPOx-MIP | 0.47 ± 0.08 | 0.963 | 0.022 ± 0.004 | 0.984 |

| PiPOx-NIP | 0.38 ± 0.06 | 0.994 | 0.015 ± 0.003 | 0.900 |

| Polymer | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|

| qm [mg g−1] | K [L mg−1] | R2 | Kf [mg g−1 (L mg−1)1/n] | 1/n | R2 | |

| PiPOx-MIP | 85.3 ± 1.6 | 12.4 ± 0.4 | 0.998 | 102 ± 6 | 0.53 ± 0.08 | 0.910 |

| PiPOx-NIP | 66.1 ± 1.3 | 7.94 ± 0.36 | 0.996 | 74 ± 5 | 0.59 ± 0.07 | 0.919 |

| Polymer | Medium | Zero Order | First Order | Higuchi | Hixson-Crowell | ||||

|---|---|---|---|---|---|---|---|---|---|

| k0 [h−1] | R2 | k1 [h−1] | R2 | kH [h−1/2] | R2 | kHC [h−1/3] | R2 | ||

| PiPOx-MIP | pH 7.4 | 2.73 ± 0.29 | 0.676 | 0.123 ± 0.014 | 0.471 | 10.4 ± 1.6 | 0.838 | 0.112 ± 0.013 | 0.543 |

| pH 7.4 + TCEP | 3.53 ± 0.37 | 0.491 | 0.114 ± 0.013 | 0.361 | 14.2 ± 1.5 | 0.677 | 0.116 ± 0.013 | 0.406 | |

| pH 6.5 | 4.11 ± 0.43 | 0.770 | 0.175 ± 0.019 | 0.530 | 12.7 ± 1.3 | 0.924 | 0.163 ± 0.018 | 0.622 | |

| pH 6.5 + TCEP | 5.43 ± 0.56 | 0.765 | 0.162 ± 0.018 | 0.567 | 16.9 ± 1.8 | 0.922 | 0.171 ± 0.019 | 0.641 | |

| pH 2.0 | 1.41 ± 0.15 | 0.475 | 0.094 ± 0.010 | 0.363 | 5.72 ± 0.59 | 0.659 | 0.075 ± 0.009 | 0.402 | |

| pH 2.0 + TCEP | 2.92 ± 0.30 | 0.569 | 0.116 ± 0.013 | 0.401 | 11.5 ± 1.6 | 0.747 | 0.110 ± 0.012 | 0.459 | |

| PiPOx-NIP | pH 7.4 | 4.75 ± 0.49 | 0.545 | 0.256 ± 0.027 | 0.460 | 13.0 ± 1.3 | 0.785 | 0.222 ± 0.024 | 0.491 |

| pH 7.4 + TCEP | 5.71 ± 0.59 | 0.440 | 0.305 ± 0.032 | 0.375 | 14.5 ± 1.5 | 0.690 | 0.265 ± 0.028 | 0.399 | |

| pH 6.5 | 3.57 ± 0.37 | 0.437 | 0.283 ± 0.029 | 0.308 | 11.9 ± 1.3 | 0.661 | 0.205 ± 0.022 | 0.350 | |

| pH 6.5 + TCEP | 3.39 ± 0.35 | 0.390 | 0.267 ± 0.028 | 0.295 | 11.6 ± 1.3 | 0.617 | 0.195 ± 0.021 | 0.327 | |

| pH 2.0 | 4.20 ± 0.43 | 0.454 | 0.211 ± 0.023 | 0.396 | 12.3 ± 1.4 | 0.702 | 0.187 ± 0.019 | 0.419 | |

| pH 2.0 + TCEP | 4.07 ± 0.41 | 0.430 | 0.192 ± 0.020 | 0.386 | 12.0 ± 1.4 | 0.677 | 0.176 ± 0.018 | 0.404 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cegłowski, M.; Jerca, V.V.; Jerca, F.A.; Hoogenboom, R. Reduction-Responsive Molecularly Imprinted Poly(2-isopropenyl-2-oxazoline) for Controlled Release of Anticancer Agents. Pharmaceutics 2020, 12, 506. https://doi.org/10.3390/pharmaceutics12060506

Cegłowski M, Jerca VV, Jerca FA, Hoogenboom R. Reduction-Responsive Molecularly Imprinted Poly(2-isopropenyl-2-oxazoline) for Controlled Release of Anticancer Agents. Pharmaceutics. 2020; 12(6):506. https://doi.org/10.3390/pharmaceutics12060506

Chicago/Turabian StyleCegłowski, Michał, Valentin Victor Jerca, Florica Adriana Jerca, and Richard Hoogenboom. 2020. "Reduction-Responsive Molecularly Imprinted Poly(2-isopropenyl-2-oxazoline) for Controlled Release of Anticancer Agents" Pharmaceutics 12, no. 6: 506. https://doi.org/10.3390/pharmaceutics12060506