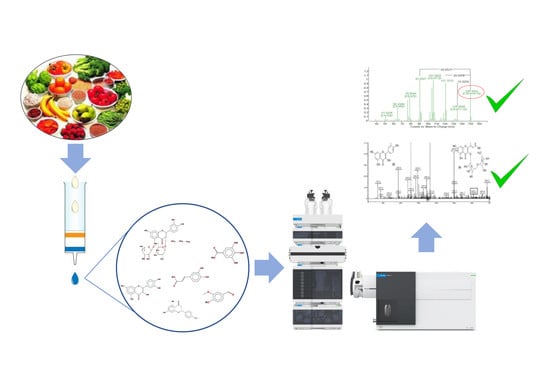

Determination of Polyphenols Using Liquid Chromatography–Tandem Mass Spectrometry Technique (LC–MS/MS): A Review

Abstract

:1. Introduction

2. Extraction and Clean-Up Procedures

2.1. Extraction

| Matrix | Analyte | Extraction (Solvent Extraction) and Purification (Cartridge) | Recovery (%) | LOD (mg/L) | LOQ (mg/L) | Ref |

|---|---|---|---|---|---|---|

| Mutamba (Guazuma ulmifolia Lam.) fruit | Phenolic acids (n = 10) | SLE (1 g + 15 mL methanol/acetone/water (7/7/6, v/v/v), 30 min US, RT) × 3 times | - | - | - | [50] |

| Flavanols (n = 3) | ||||||

| Flavonols (n = 6) | ||||||

| Flavanones (n = 1) | ||||||

| Flavones (n = 1) | ||||||

| Procyanidins (n = 2) | ||||||

| Meiguihua oral solution | Phenolic acids (n = 2) | LLE (dilution 1:100 in methanol) | 92.68–101.45 | 1.09–6.54 | 13.14–3269 | [33] |

| Flavonols (n = 8) | 92.30–102.80 | 0.11–0.87 | 0.44–5.54 | |||

| Wheat pasta chia flour | Phenolic acids (n = 13) | SLE (5 g + 20 mL solvent mixture of acetone/water (4:1), 1 h shaking, RT, darkness) × 2 times | 0.31–0.95 | 0.09–0.28 | [48] | |

| Extra-virgin olive oils, olive fruits and pomaces | Phenolic acids (n = 3) | LLE or SLE (2.5 g + 5 mL ethanol/water, 80/20, v/v, 10 min US at 21 °C) | 10.0–30.0 | 3.0–10–0 | [36] | |

| Flavonols (n = 2) | 10.0 | 3.0 | ||||

| Flavones (n = 1) | 10.0 | 3.0 | ||||

| Flavanones (n = 1) | 10.0 | 4.0 | ||||

| Artemisia campestris | Phenolic acids (n = 3) | SLE (1 g + 10 mL ethanol/water 8/2 v/v, 30 min US at RT) | [51] | |||

| Flavonols (n = 2) | ||||||

| Flavones (n = 1) | ||||||

| Residual brewing yeast | Phenolic acids (n = 6) | MSPD (0. 10 g + 10 mg TiO2 nanoparticles (NPs) and 0.1g diatomaceous earth); mixed 2 min in mortar, add 2 mL ethanol/water 60/40 v/v, 1 min vortex | [1] | |||

| Flavonols (n = 3) | ||||||

| Flavanones (n = 1) | ||||||

| Flavones (n = 1) | ||||||

| Achyrocline satureioides | Phenolic acids (n = 1) | SLE (methanol) and SPE C-18 | - | - | - | [10] |

| Flavones (n = 1) | ||||||

| Flavonols (n = 3) | ||||||

| Fragaria ananassa cv. Camarosa fruits | Anthocyanins (n = 6) | SLE (10 g + 10 mL methanol/formic acid (97/3, v/v), 30 s US, RT and 16 h, orbital shaking, RT) × 2 times and SPE (Oasis MCX cartridges eluted with 15 mL methanol) | - | 0.14 | 0.48 | [32] |

| Flavonols (n = 1) | 0.4 | 1.5 | ||||

| Sweet lupin seed | Phenolic acids (n = 4) | SLE (2 g + 10 mL methanol/water 80/20 v/v, 10 s vortex, 2 h orbital shaking) × 2 times | 97.61–100.76 | 0.001–0.035 | 0.004–0.119 | [49] |

| Isoflavones (n = 1) | 97.89 | 0.004 | 0.013 | |||

| Flavones (n = 1) | 97.72 | 0.030 | 0.100 | |||

| Flavanonol (n = 1) | 104.38 | 0.019 | 0.065 | |||

| Lucerne, goldenrod, phacelia, buckwheat, licorice, and lavender | Phenolic acids (n = 13) | SLE (2.5 g + 10- or 20-mL methanol, automatic shaker 5 h at 900 rpm) and SPE (C18, 6 mL, 500 mg, eluted with 6 mL methanol) | 58.9–95.5 | - | 0.0004–0.02 | [31] |

| Flavonols (n = 3) | 72.6–79.3 | - | 0.0004–0.0008 | |||

| Isoflavones (n = 2) | 56.3–79.5 | - | 0.0004 | |||

| Flavanones (n = 10) | 49.1–95.2 | - | 0.0004–0.0008 | |||

| Commercial herbal dietary supplements | Flavanones (n = 6) | SLE (0.2–0.7 g + 5 mL methanol, 30 min US mL) × 3 times | 64.6–76.8 | 0.00016–0.00025 | 0.0005–0.0008 | [38] |

| Isoflavones (n = 2) | 72.4–81.9 | 0.00022–0.00025 | 0.0007–0.0008 | |||

| Flavonols (n = 2) | 74.6–80.3 | 0.00022–0.00033 | 0.0007–0.001 | |||

| Brown seaweed | Phenolic acids (n = 2) | SLE (5 g + methanol/water 60/40 v/v; under nitrogen atmosphere for 2 h; 40 °C, 100 rpm shaker incubator) and SPE (C18) eluted with 15 mL methanol with 0.1% HCl | 99.3–104.2 | 0.26–0.73 | 0.77–2.50 | [2] |

| Flavonols (n = 2) | 97.2–98.4 | 0.51–0.57 | 1.79–1.82 | |||

| Anthocyanins (n = 1) | 97.7 | 0.34 | 1.14 | |||

| Fruits from Firmiana Simplex (L.) | Phenolic acids (n = 2) | SLE (500 g + 2 L methanol at RT) × 4 times | - | - | - | [52] |

| Flavanols (n = 2) | - | - | - | |||

| Flavones (n = 1) | - | - | - | |||

| Lignans (n = 1) | - | - | - | |||

| Red grapes | Anthocyanins (n = 3) | SLE (0.8 g+ 1 mL methanol (1% formic acid)/water) 60/40, v/v; 72 °C, 100 min 500 rpm | - | 0.003–0.006 | 0.010–0.021 | [34] |

| Phenolic acids (n = 3) | - | 0.002–0.0040 | 0.006–0.135 | |||

| Flavonols (n = 4) | - | 0.003–0.342 | 0.010–1.140 | |||

| Connarus perrottetti var. angustifolius, Cecropia obtusa, Cecropia palmata, and Mansoa alliacea | Phenolic acids (n = 4) | SLE (0.2 g + 70% hydroethanolic, butanol or ethyl acetate, 4 h, US, RT) | 97.6–104.7 | 0.3–0.7 | 0.8–1.0 | [28] |

| Flavonols (n = 2) | 88.2–94.6 | 0.4–0.6 | 0.8–2.4 | |||

| Flavanols (n = 1) | 83.8 | 1.7 | 2.8 | |||

| Lablab purpureus (L.) sweet pods | Anthocyanins (n = 5) | SLE (0.1% HCl in methanol/water; 35/65 v/v) | - | - | - | [53] |

| Syringa vulgaris L. flowers and fruits | Oleuropein | SLE (0.020 g lyophilized sample + 5 mL methanol; stirred 4 h, 200 rpm at RT) × 3 times | 101.0 | 0.0021 | 0.0068 | [37] |

| Acteoside | 97.4 | 0.0008 | 0.0024 | |||

| Rutin | 94.9 | 0.0003 | 0.001 | |||

| Tea | Flavanols (n = 12) | SLE (1 g sample dried + 100 mL hot water, 3 min, mild stirring) × 5 times | 65–115 | 0.12–223.70 | 0.40–745.60 | [54] |

| (pg/injection) | (pg/injection) | |||||

| Euphorbia supina | Phenolic acids (n = 3) | SLE (10 g sample lyophilized + 200 mL ethyl acetate, 20 h, 80 °C) | 79.6–102.8 | 0.030–0.142 | 0.102–0.473 | [30] |

| Flavonols (n = 2) | SPE (silica gel (3 × 1.7 cm i.d.), eluted with 25 mL methanol/dichloromethane 1/5 v/v) | 76.1–100.0 | 0.028–0.037 | 0.094.0.125 | ||

| Black rice wine | Phenolic acids (n = 8) | LLE (5 mL sample pH 2.0 + 5 mL ethyl acetate, 1 min, vortex) and SPE (Oasis HLB (200 mg, 6 mL), eluted with 8 mL methanol with 0.1% of HCl) | 74–103.0 | 0.008–0.003 | 0.027–0.100 | [29] |

| Flavonols (n = 3) | 63.0–81.0 | 0.008–0.024 | 0.027–0.080 | |||

| Anthocyanins (n = 4) | 62.0–70.0 | 0.010–0.020 | 0.030–0.060 | |||

| Scutellaria baicalensis | Flavones (n = 9) | SLE (10 g lyophilized sample + 200 mL methanol, 24 h, 50 °C) and SPE (silica gel, eluted with 50 mL methanol/dichloromethane, 1/5, v/v) | 82.3–107.7 | 0.007–0.044 | 0.021–0.133 | [3] |

| Flavanones (n = 5) | 80.1–99.0 | 0.11–0.76 | 0.025–0.145 | |||

| Phenolic acids (n = 2) | 104.3–101.7 | 82.3–101.7 | 0.004–0.010 | |||

| Flavonols (n = 1) | 87.6 | 0.017 | 0.052 |

2.2. Clean-Up

3. Chromatographic and Mass Spectrometry Conditions

| Analyte | Matrix | Chromatographic Conditions | Mass Spectrometer Conditions | Ref. |

|---|---|---|---|---|

| Quinic acid; danshensu; caftaric acid; caffeic acid hexoside; salvianolic acid; fertaric acid; caffeic acid; ferulic acid; salviaflaside; rosmarinic acid; salvianolic acid c; methylrosmarinate; methylquercetin | Wheat pasta chia flour | Column: Luna C18 (250 × 4.6 mm, 5 μm) | Capillary voltage: 4500 V | [48] |

| Column temperature: 35 °C | Nebulizer gas: 4.0 bar | |||

| Mobile phase: 0.5% formic acid in water and 0.5% formic acid in methanol (v/v) | Drying gas: 8.0 L/min and 180 °C | |||

| Flow rate: 0.4 mL/min | Nebulizer gas: nitrogen | |||

| Injection volume: 40 µL | Collision gas: argon | |||

| Gallic acid juglanin; quercetin-3-O-sophoroside; ellagic acid; quercitrin; sophoraflavonoloside; hyperoside; astragalin; isoquercitrin; avicularin | Meiguihua oral solution | Column: Hypersil Gold C18 (100 × 2.1 mm, 1.9 μm) | Capillary voltage: −4500 V | [33] |

| Column temperature: 30 °C | Declustering potential: −10 V | |||

| Mobile phase: 0.1% formic acid in water and acetonitrile | Nebulizer gas: 60 Curtain gas: 35 | |||

| Flow rate: 0.3 mL/min | Auxiliary gas: 50 | |||

| Injection volume: 2 µL | Turbo gas temperature: 450 °C | |||

| P-hydroxybenzoic acid; caffeic acid; chlorogenic acid; ellagic acid; ferulic acid; gallic acid; gentisic acid; p-coumaric acid; luteolin; protocatechuic acid; catechin; epicatechin; epigallocatechin; kaempferol; astragalin; nicotiflorin; cynaroside; naringenin; procyanidin dimer b1 y b2; procyanidin trimer c1; quercetin; hyperoside; isorhamnetin; rutin; vanillin | Mutamba (Guazuma ulmifolia Lam.) fruit | Column: Shimpack XR-ODS III column (150 × 2 mm, 2.2 μm) | Capillary voltage: 3.5 kV | [50] |

| Column temperature: 40 °C | Heat block temperature: 300 °C | |||

| Mobile phase: 0.1% formic acid in water and methanol | Desolvation line temperature: 250 °C | |||

| Flow rate: 0.4 mL/min | Nebulizer and drying gas: nitrogen | |||

| Injection volume: 10 µL | Drying flow: 20 L/min | |||

| Nebulizing flow: 3 L/min | ||||

| Collision induced dissociation gas: argon at 224 kPa | ||||

| Protocatechuic acid; 5-O-Caffeoylquinic acid; Quinic acid methyl ester; 3-O-Caffeoylquinic acid; Caffeic acid; 4-O-Feruloylquinic acid; Quercetin-O-glucoside; Rutin; 3,4-Dicaffeoylquinic acid; 4,5-Dicaffeoylquinic acid; 4′,7′-Dimethoxy luteolin | Artemisia campestris | Column: Lichrocart RP-18 column (250 × 4 mm, 5 μm) | Collision gas: argon at 10−4 mbar | [51] |

| Column temperature: 35 °C | Nebulizer and drying gas: nitrogen | |||

| Mobile phase: Formic acid aqueous solution (0.5% v/v) and acetonitrile | ||||

| Flow rate: 0.3 mL/min | ||||

| Injection volume: 10 µL | ||||

| Caffeic, chlorogenic, p-coumaric, 3,4-dihydroxibenzoic, trans-ferulic and gallic acids, kaempferol, myricetin, naringin; quercetin; rutin | Residual brewing yeast | Column: C18 Fusion-RP (150 × 3 mm, 4 µm) | Nebulizer and drying gas: nitrogen | [1] |

| Column temperature: room temperature | Flow nebulizer gas: 1.5 L·min−1 | |||

| Mobile phase: 0.2% formic acid aqueous solution and methanol | Flow drying gas: 15.0 L·min−1 | |||

| Flow rate: 0.50 mL/min | Collision gas: argon at 230 kPa | |||

| Injection volume: 20 µL | Ionization voltage: −4.5 kV | |||

| Verbascoside; Isoverbascoside; Forsythoside A; Leucosceptoside A; Plantainoside C; Purpureaside D; Martynoside | Aloysia polystachya | Column: Ascentis Express C18 (100 × 2.1 mm, 2.7 µm) | Capillary voltage: −4000 V | [35] |

| Column temperature: 30 °C | Drying gas: nitrogen | |||

| Mobile phase: 0.1% formic acid in water and 0.1% formic acid in acetonitrile | Drying gas temperature: 350 °C | |||

| Flow rate: 0.2 mL/min | Flow drying gas: 9 L/min | |||

| Injection volume: 10 µL | Nebulizing gas: 25 psi | |||

| Dicaffeoylquinic acid isomer A and B; iIsoquercitrin; quercetin; luteolin; 3-O-methylquercetin | Achyrocline satureioides | Column: Luna C18 (150 × 4.6 mm, 5 µm) | Capillary voltage: 4000 V | [10] |

| Column temperature: 40 °C | Nebulizer: 40 psi | |||

| Mobile phase: 10 mM formic acid in ultra-pure water and methanol | Dry gas flow: 9.0 L/min at temperature 365 °C | |||

| Flow rate: 0.3 mL/min | Drying and nebulizing gas: nitrogen | |||

| Injection volume: 5 µL | ||||

| Cyanidin-3-glucoside; pelargonidin-3-glucoside; pelargonidin-3 rutinoside; pelargonidin-acetylglucoside; pelargonidin-succinyl-arabinoside; pelargonidin-malonylrhamnoside; quercetin-rhamnoside | Fragaria ananassa var. Camarosa fruits | Column: Kromasil C18 (250 × 4.6 mm, 5 μm) | - | [32] |

| Column temperature: 40 °C | ||||

| Mobile phase: water/acetonitrile/formic acid (87/3/10 v/v/v) and water/acetonitrile/formic acid (40/50/10 v/v/v) | ||||

| Flow rate: 0.8 mL/min | ||||

| Caffeic acid; chlorogenic acid; p-Coumaric acid; ferulic acid; rutin; quercetin; luteolin; naringenin; genistein | Olea europaea L. | Column: Kinetex biphenyl (10 × 2.1 mm, 5 μm) | Nebulizer gas: nitrogen | [36] |

| Column temperature: 35 °C | Capillary voltage: 4000 V | |||

| Mobile phase: 0.1% formic acid in water and 0.1% formic acid in methanol | Inlet pressure: 30 psi and temperature 270 °C | |||

| Flow rate: 0.5 mL/min | ||||

| Injection volume: 5 µL | ||||

| Protocatechuic acid; caffeic acid; vitexin; ferulic acid; taxifolin; trans-cinnamic acid; genistein | Sweet lupin seed | Column: Kinetex XB-C 18 (250 × 4.6 mm, 5 μm) | Nebulizing gas: nitrogen at 45 psi, 300 °C, and 5 L/min | [49] |

| Column temperature: 25 °C | Capillary voltage: 3.5 kV | |||

| Flow rate: 0.5 mL/min | Nozzle voltage: −500 V | |||

| Mobile phase: 0.05% formic acid in water and acetonitrile | Sheath gas: nitrogen at 11 L/min and 250 °C | |||

| Injection volume: 20 µL | ||||

| Hesperetin; quercetin; naringenin; benzoic acid; naringin; narirutin; hesperidin; caffeic acid; neohesperidin; pinocembrin; taxifolin; fisetin; glabridin; eriocitrin; eriodictyol; formononetin; liquiritin; liquiritigenin; 3-hydroxybenzoic acid; 3,4-dihydroxybenzoic acid; 3-(4-hydroxyphenyl)propionic acid; 4-hydroxybenzoic acid; 3,4-dihydroxy-phenylacetichippuric acid; α-hydroxyhippuric acid; 3-hydroxyphenylacetic acid; p-coumaric acid; ferulic acid; and 4-hydroxy-3-methoxyphenylacetic acid | Plant materials | Column: Zorbax Eclipse XDB-C18 column (50 × 2.1 mm, 1.8 μm) | Capillary voltage: −4500 V | [31] |

| Column temperature: 30 °C | Temperature: 500 °C | |||

| Mobile phase: 0.1% v/v formic acid in water and acetonitrile | Nebulizer gas: 60 psi | |||

| Flow rate: 0.5 mL/min | Turbo-gas: 50 psi | |||

| Injection volume: 5 µL | Collision activated dissociation gas: 4 psi | |||

| Curtain gas: 20 psi | ||||

| Eriocitrin; taxifolin; naringin; hesperidin; neohesperidin; fisetin; eriodictyol; naringenin; hesperetin; kaempferol; chrysin; glabridin | Commercial herbal dietary supplements | Fusion-RP XDB-C18 (50 × 2.0 mm, 4 μm) | - | [38] |

| Column temperature: 30 °C | ||||

| Mobile phase: 0.1% formic acid in water and acetonitrile | ||||

| Flow rate: 0.3 mL/min | ||||

| Injection volume: 2 µL | ||||

| Phloroglucinol; gallic acid; cyanidin 3-glucoside; chlorogenic acid, rutin; quercetin | Brown seaweed | Column: Atlantis C18 (250 × 4.6 mm, 5 µm) | Capillary voltage: 4000 V | [2] |

| Column temperature: 25 ℃ | Gas nebulizer: nitrogen | |||

| Mobile phase: 0.25% aqueous acetic acid and acetonitrile/water (80/20 v/v) | Pressure gas: 50 psi | |||

| Flow rate: 1.0 mL/min | Flow rate: 10 L/min | |||

| Injection volume: 10 µL | Drying temperature: 350 °C | |||

| Gallic acid; catechin; caffeic acid; rutin; ferulic acid; quercitrin; resveratrol | Connarus perrottetti var. angustifolius, Cecropia obtusa, Cecropia palmata, and Mansoa alliacea | Column: C18 (250 × 4.6 mm, 5 μm) | Capillary voltage: ±2.4 kV | [28] |

| Column temperature: 21 °C | Gas flow: 11 L/min | |||

| Mobile phase: orthophosphoric acid solution (0.1%, w/w) and acetonitrile | Nebulizer: 30 psi | |||

| Flow rate: 0.8 mL/min | Gas temperature: 250 °C | |||

| Drying gas: nitrogen | ||||

| Cis- and trans- resveratrol-3-O-galloylglucoside; methyl-(S)-flavogallonate; quercetin-7-O-di-glucoside; quercetin-7-O-galloyl-glucoside; naringenin-40-methoxy-7-pyranoside; 5,6-dihydroxy-30,40,7-tri-methoxy flavone; terminalin; corilagin derivative; oleanane type triterpenoids | Terminalia brownii (Fresen) | Column: Varian LC–18 (250 × 4.6 mm; 5 µm) | Spray voltage: 5000 V | [76] |

| Column temperature: 30 °C | Capillary temperature: 280 °C | |||

| Mobile phase: acetonitrile and water containing 0.005% formic acid, acetonitrile, and glacial acetic acid | Sheathing gas: nitrogen at 40 U | |||

| Flow rate: 0.5 mL/min | Collision gas: helium at 0.8 mTorr | |||

| Injection volume: 5 µL | ||||

| Gallocatechin; epigallocatechin; catechin; epicatechin; epigallocatechin gallate; gallocatechin gallate; epicatechin gallate; catechin gallate; theaflavin; theaflavin-3-gallate | Tea | Column: Capcellpak C18 MGIII (100 × 2.0 mm, 3 µm) | Nebulizer gas flow: 60 mL/min. | [54] |

| Column temperature: 30 °C | Cone temperature: 200 °C | |||

| Mobile phase: 0.1% aqueous formic acid and methanol | Cone gas flow: 20 mL/min | |||

| Flow rate: 0.3 mL/ min | Heated probe temperature: 300 °C. | |||

| Injection volume: 2 µL | ||||

| Oleuropein; acteoside; rutin | Syringa vulgaris L. flowers and fruits | Column: Zorbax SB-C18 (150 × 3.0 mm, 3.5 μm) | Capillary voltage: 3500 V | [37] |

| Column temperature: 25 °C | Nebulizing and drying gas: nitrogen | |||

| 0.1% (v/v) formic acid and methanol | Nebulizing gas pressure: 45 psi | |||

| Flow rate: 0.7 mL/min | Drying gas flow and temperature: 10 L/min and 300 °C | |||

| Fragmentor voltage: 170 V | ||||

| Nozzle voltage: 500 V | ||||

| Sheath gas flow and temperature: 10 L/min and 300 °C | ||||

| Gallic acid; protocatechuic acid; p-Hydroxybenzoic acid; vanillic acid; caffeic acid; syringic acid; p-coumaric acid; ferulic acid; rutin; quercetin-3-O-glucoside; quercetin; cyanidin-3,5-O-diglucoside; cyanidin-3-O-glucoside; cyanidin-3-O-rutinoside; eonidin-3-O-glucoside | Black rice wine | Column: SHIM-PACK XR-ODS (75 × 3.0 mm, 2.2 μm) | Ion spray voltage: 4400 and –4400 V | [29] |

| Column temperature: 30 °C | Curtain gas (CUR): nitrogen | |||

| Mobile phase: 50% aqueous acetonitrile (v/v) with 0.2% formic acid and water with 0.2% formic acid | Nebulizer gas: air at 50 psi | |||

| Flow rate: 0.3 mL/min | Heater gas: air at 50 psi | |||

| Injection volume: 20 µL | ||||

| Apigenin; Baicalein; chrysin; p-coumaric acid; dihydroxytetramethoxy-flavone; dihydroxytrimethoxy-flavanone; eriodictyol; luteolin; naringenin; norwogonin; oroxylin a; pentahydroxyflavanone; pinocembrin; quercetin; scutellarein; sinapic acid; verbascoside; wogonin | Column: Zorbax Stable Bond Analytical SB-C18 column (250 × 4.6 mm, 5 μm) | Nebulizing and drying gas: nitrogen at 45 psi | [3] | |

| Column temperature: 35 °C | Electron spray voltage: 5.2 kV | |||

| Mobile phase: 0.1% aqueous formic acid and methanol | Source temperature at 500 °C | |||

| Flow rate: 0.5 mL/min | ||||

| Injection volume: 10 µL |

| Analyte | Analyzer/Ionization Mode | Precursor Ion (m/z) | Product Ion (m/z) | Ref |

|---|---|---|---|---|

| 3-(3,4-Dihydroxyphenyl)propionic acid | QqQ/ESI (−) | 181 | 137 | [34] |

| 3-(3-Hydroxyphenyl)propionic acid | QqQ/ESI (−) | 165 | 121 | [34] |

| 3-(4-hydroxy)phenylpropionic acid | QqQ/ESI (−) | 165 | 121 | [34] |

| 3-(4-hydroxyphenyl)propionic acid | QqQ/ESI (−) | 164.9 | 120.5 | [31] |

| 3,4-Dicaffeoylquinic acid | QqQ/ESI (−) | 515 | 353, 235,191, 179, 173, 135 | [51] |

| 3,4-Dihydroxybenzoic acid | QqQ/ESI (−) | 152.9 | 108.9 | [31] |

| 3,4-Dihydroxy-phenylacetic acid | QqQ/ESI (−) | 166.9 | 122.7 | [31] |

| 3-Hydroxybenzoic acid | QqQ/ESI (−) | 137 | 93 | [31,34] |

| 3-Hydroxyphenylacetic acid | QqQ/ESI (−) | 150.9 | 107.0 | [31] |

| 3-Methoxyphenylacetic acid | QqQ/ESI (−) | 180.8 | 136.8 | [31] |

| 3-O-Caffeoylquinic acid | QqQ/ESI (−) | 353 | 191, 173, 85 | [51] |

| 3-O-methylquercetin | QTOF/ESI (−) | 315 | 151, 271 | [10] |

| 4,5-Dicaffeoylquinic acid | QqQ/ESI (−) | 515 | 353, 191, 179, 173, 135 | [51] |

| 4′,7′-Dimethoxy luteolin | QqQ/ESI (−) | 313 | 298, 283, 255, 163, 117 | [51] |

| 4-Hydroxybenzoic acid | QqQ/ESI (−) | 136.9 | 93.0 | [31] |

| 4-O-Feruloylquinic acid | QqQ/ESI (−) | 367 | 191, 173, 134, 93, 87 | [51] |

| Qtrap/ESI (−) | 193, 191, 173 | [52] | ||

| 5-(3,4-Dihydroxyphenyl)-γ-valerolactone | QqQ/ESI (−) | 207 | 85 | [34] |

| 5-(3,4-Dihydroxyphenyl)-γ-valerolactone glucuronide | QqQ/ESI (−) | 383 | 207 | [34] |

| 5,6,7,30,40-Pentahydroxyflavanon | Q-Trap/ESI (−) | 479 | 303, 285, 181, 167, 135 | [3] |

| 5-O-Caffeoylquinic acid | QqQ/ESI (−) | 353 | 191, 179, 173 | [51] |

| 5-O-p-Coumaroylquinic acid | Qtrap/ESI (−) | 337 | 191,173 | [52] |

| 7-O-glucoronide | Q-Trap/ESI (−) | 480 | 303, 285, 181, 167, 136 | [3] |

| Acteoside | QqQ/ESI (−) | 623.2 | 160.9 | [37] |

| Apigenin-7-O-β-apiofuranosyl-6,8-di-C– β-glucopyranoside | QqQ/ESI (−) | 725 | 635, 605, 593, 575, 503 | [49] |

| Aromadendrin-6-C-β-D-glucopyranosyl-7-O-[β-D-apiofuranosyl-(1→2)]-O-β-D-glucopyranoside | QqQ/ESI (−) | 743 | 653, 623, 581, 563 | [49] |

| Astragalin | QqQ/ESI (−) | 447.09 | 284.0 | [33,50] |

| Avicularin | QqQ/ESI (−) | 433.08 | 301.0 | [33] |

| Benzoic acid | QqQ/ESI (−) | 121 | 77 | [31,34] |

| Caffeic acid | QqQ/ESI (−) | 179 | 135 | [1,2,29,31,34,36,50,84] |

| 135, 107, 89 | [51] | |||

| Catechin | QqQ/ESI (−) | 289.1 | 109.20 | [50] |

| 245.1 | [1] | |||

| 203 | [34] | |||

| Catechin glucuronide | QqQ/ESI (−) | 465 | 289 | [34] |

| Catechin | QqQ/ESI (−) | 289.1 | 245.1 | [84] |

| Chlorogenic acid | QqQ/ESI (−) | 353.1 | 191.1 | [1,2,50] |

| 79, 191 | [36] | |||

| Chrysin | QqQ/ESI (−) | 252.9 | 143.0 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Cinnamic acid glucoside | QqQ/ESI (−) | 309 | 291, 247, 180, 128 | [49] |

| Coumarin glycoside ester | Qtrap/ESI (−) | 351 | 307, 145 | [52] |

| Cyanidin-3,5-O-diglucoside | QqQ/ESI (+) | 611.4 | 287.2 | [29] |

| Cyanidin-3-O-glucoside | Qtrap/ESI (+) | 449.2 | 287.2 | [32] |

| QqQ/ESI (+) | [29] | |||

| Cyanidin-3-O-rutinoside | QqQ/ESI (+) | 595.4 | 287.2 | [29] |

| Cynaroside | QqQ/ESI (−) | 446.90 | 285.10 | [50] |

| Dicaffeoylquinic acid | QTOF/ESI (−) | 515 | 353, 191, 179 | [10] |

| QqQ/ESI (−) | 249, 179, 135 | [49] | ||

| Dihydrocaffeic acid glucuronide | QqQ/ESI (−) | 357 | 181 | [34] |

| Dihydroferulic acid glucuronide | QqQ/ESI (−) | 371 | 195 | [34] |

| Dihydro-p-coumaric acid derivative | Qtrap/ESI (−) | 415 | 385, 165 | [52] |

| Dihydroxybenzoic acid | QqQ/ESI (−) | 153.0 | 109.0 | [1] |

| Ellagic acid | QqQ/ESI (−) | 301 | 145 | [33,50] |

| Epicatechin | QqQ/ESI (−) | 289.1 | 109.2 | [50] |

| Epicatechin derivative | Qtrap/ESI (−) | 397 | 365, 289, 207, 151 | [52] |

| Epicatechin glucuronide | QqQ/ESI (−) | 465 | 289 | [34] |

| Epicatechin | QqQ/ESI (−) | 289 | 203 | [34] |

| Epigallocatechin | QqQ/ESI (−) | 305.1 | 125.0 | [50] |

| Qtrap/ESI (−) | 305 | 305, 273, 179 | [52] | |

| Eriocitrin | QqQ/ESI (−) | 595.2 | 286.9 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Eriodictyol | QqQ/ESI (−) | 287.0 | 150.7 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Ferulic acid | QqQ/ESI (−) | 193 | 134 | [31,34,36,50,84] |

| 177.9 | [29] | |||

| 149 | [2] | |||

| Ferulic acid glucoside | QqQ/ESI (-) | 355 | 193, 178, 134 | [49] |

| Fisetin | QqQ/ESI (−) | 284.9 | 134.8 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Formononetin | QqQ/ESI (−) | 266.9 | 251.8 | [31] |

| Gallic acid | QqQ/ESI (−) | 169 | 125 | [1,2,29,33,34,50,84] |

| Qtrap/ESI (−) | [52] | |||

| 169, 125, 97 | [30] | |||

| Gallic acid glycoside | Qtrap/ESI (−) | 331 | 169 | [52] |

| Genistein | QqQ/ESI (−) | 269 | 269, 195, 133 | [49] |

| Gentisic acid | QqQ/ESI (−) | 153.10 | 109.30 | [50] |

| Glabridin | QqQ/ESI (−) | 323.2 | 201.3 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Hesperetin | QqQ/ESI (−) | 300.9 | 163.7 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Hesperidin | QqQ/ESI (−) | 609.0 | 301 | [1,31] |

| Qtrap/ESI (−) | [38] | |||

| Hippuric acid | QqQ/ESI (−) | 178 | 134 | [31,34] |

| Homovanillic | QqQ/ESI (−) | 181 | 163 | [34] |

| Hyperoside | QqQ/ESI (−) | 463.1 | 300.0 | [33,50] |

| Isoquercitrin | QqQ/ESI (−) | 463 | 300.0 | [33] |

| QTOF/ESI (-) | 301, 151 | [10] | ||

| Isorhamnetin | QqQ/ESI (−) | 315.10 | 300.10 | [50] |

| Juglanin | QqQ/ESI (−) | 417.08 | 284.0 | [33] |

| Kaempferol | QqQ/ESI (−) | 285 | 93.1 | [50] |

| 93.4 | [1] | |||

| 239 | [34] | |||

| Qtrap/ESI (-) | 150.7 | [38] | ||

| Q-trap/ (+) | 287 | 287, 258, 165, 153, 121 | [30] | |

| Kaempferol 3-O-hexoside | Q-trap/ (-) | 447 | 447, 285, 255 | [30] |

| Kaempferol 3-O-pentoside | Q-trap/ (+) | 419 | 419, 309, 287, 155 | [30] |

| Liquiritigenin | QqQ/ESI (−) | 255.1 | 118.7 | [31] |

| Liquiritin | QqQ/ESI (−) | 417.2 | 255.0 | [31] |

| Luteolin | QqQ/ESI (−) | 285.10 | 133.20 | [50] |

| QTOF/ESI (-) | 285 | 217, 151 | [10] | |

| Methylcatechin | QqQ/ESI (−) | 303 | 137 | [34] |

| Methylcatechin glucuronide | QqQ/ESI (−) | 479 | 303 | [34] |

| Methylepicatechin glucuronide | QqQ/ESI (−) | 479 | 303 | [34] |

| Methylgallate | Qtrap/ESI (−) | 183 | 169,125 | [52] |

| Methylgallic acid | QqQ/ESI (−) | 183 | 168 | [34] |

| Myricetin | QqQ/ESI (−) | 316.9 | 179 | [2] |

| 317.0 | 151.0 | [1] | ||

| Naringenin | QqQ/ESI (−) | 271 | 151 | [31,36,50] |

| Qtrap/ESI (−) | 270.9 | 118.7 | [38] | |

| Naringin | Qtrap/ESI (−) | 579.2 | 270.9 | [38] |

| QqQ/ESI (−) | 579.0 | 271.1 | [1,31] | |

| Narirutin | QqQ/ESI (−) | 579.3 | 270.9 | [31] |

| Neohesperidin | QqQ/ESI (−) | 609.0 | 300.8 | [31] |

| Qtrap/ESI (−) | [38] | |||

| Nicotiflorin | QqQ/ESI (−) | 593.00 | 285.00 | [50] |

| Nodakenin | Q-trap/ESI(+) | 409 | 409, 391, 353, 389, 247, 229, 203, 185 | [30] |

| Oleuropein | QqQ/ESI (−) | 539.2 | 275.1 | [37] |

| p-Coumaric acid | QqQ/ESI (−) | 163 | 119 | [1,29,31,34,36,50] |

| p-coumaric acid glucoside | QqQ/ESI (−) | 325 | 163, 119 | [49] |

| Pelargonidin-3 rutinoside | Qtrap/ESI (+) | 579.2 | 433.1, 271.1 | [32] |

| Pelargonidin-3-glucoside | Qtrap/ESI (+) | 433.2 | 271.6 | [32] |

| Pelargonidin-acetylglucoside | Qtrap/ESI (+) | 475.2 | 271.2 | [32] |

| Pelargonidin-malonylrhamnoside | Qtrap/ESI (+) | 503.2 | 271.1 | [32] |

| Pelargonidin-succinyl-arabinoside or | Qtrap/ESI (+) | 503.2 | 271.1 | [32] |

| Pentahydroxyflavanone | Q-Trap/(-) | 303 | 257, 219, 167, 141, 129, 113 | [3] |

| Pentahydroxyflavone | Q-Trap/(+) | 303 | 303, 285, 257, 247, 235, 229, 179, 165, 153, 149, 137, 127 | [3] |

| Peonidin-3-O-glucoside | QqQ/ESI (+) | 463.0 | 301.2 | [29] |

| Phenylpropionic acid | QqQ/ESI (−) | 149 | 105 | [34] |

| Phloroglucinol | QqQ/ESI (−) | 125 | 57 | [34] |

| 97 | [2] | |||

| p-Hydroxybenzoic acid | QqQ/ESI (−) | 137 | 93 | [29,50] |

| Pinocembrin | QqQ/ESI (−) | 254.8 | 150.7 | [31] |

| Pinoresinol rhamnoside | Qtrap/ESI (−) | 503 | 357 | [52] |

| Procyanidin dimer | QqQ/ESI (−) | 557 | 425 | [34] |

| Procyanidin dimer B1and B2 | QqQ/ESI (−) | 577.10 | 407.20 | [50] |

| Procyanidin trimer C1 | QqQ/ESI (−) | 865.00 | 289.00 | [50] |

| Protocatechuic acid | QqQ/ESI (−) | 153 | 109. | [29,34,50] |

| 141, 109 | [51] | |||

| 135, 109 | [49] | |||

| Q-trap/ (-) | 153, 109, 108 | [30] | ||

| Quercetin | QqQ/ESI (−) | 301 | 151 | [1,29,31,34,36,50] |

| 179 | [2] | |||

| QTOF/ESI (-) | 151, 179, 121 | [10] | ||

| Q-trap/ (+) | 301, 273, 179, 153 | [30] | ||

| Quercetin 3-O-hexoside | Q-trap/ (−) | 463 | 463, 301, 300, 283, 271, 255, 151 | [30] |

| Quercetin 3-O-pentoside | Q-trap/ (−) | 433 | 433, 300, 273, 271, 255, 179, 151 | [30] |

| Quercetin derivative | Qtrap/ESI (−) | 657 | 493, 327, 301, 255 | [52] |

| Quercetin-3-O-glucoside | QqQ/ESI (−) | 463.1 | 300.7 | [29] |

| Quercetin-3-O-sophoroside | QqQ/ESI (−) | 625.2 | 299.8 | [33] |

| Quercetin-O-glucoside | QqQ/ESI (−) | 463 | 301, 179, 151 | [51] |

| Quercitrin | Qtrap/ESI (+) | 447.0 | 301.0 | [32,33,84] |

| QqQ/ESI (−) | ||||

| Quinic acid butyl ester | Qtrap/ESI (−) | 247 | 247, 191 | [52] |

| Quinic acid derivative | QqQ/ESI (−) | 405 | 191, 111 | [49] |

| Quinic acid methyl ester | QqQ/ESI (−) | 205 | 143, 129, 114 | [51] |

| Resveratrol | QqQ/ESI (−) | 227.1 | 143.1 | [1,34] |

| Rutin | QqQ/ESI (−) | 609.0 | 300.1 | [1,29,31,36,37,50,51,84] |

| Sinapoyl hexoside | Q-Trap/(−) | 385 | 223, 205, 190, 179, 175, 163 | [3] |

| Sophoraflavonoloside | QqQ/ESI (−) | 609.20 | 284.0 | [33] |

| Syringic acid | QqQ/ESI (−) | 197.0 | 181.9 | [29] |

| Taxifolin | QqQ/ESI (−) | 303.2 | 284.7 | [31] |

| Qtrap/ESI (−) | [38] | |||

| trans-Ferulic acid | QqQ/ESI (−) | 193.2 | 134.0 | [1] |

| Tricin | Qtrap/ESI (−) | 329 | 329, 189, 137 | [52] |

| Tricin O-(syringyl alcohol) ether O-hexoside | Qtrap/ESI (−) | 659 | 497, 329 | [52] |

| Valeric acid | QqQ/ESI (−) | 225 | 163 | [34] |

| Vanillic acid | QqQ/ESI (−) | 167 | 108 | [29,34] |

| Vanillin | QqQ/ESI (−) | 151.10 | 136.20 | [50] |

| Vicenin | QqQ/ESI (−) | 593 | 503, 473, 383, 353, 297 | [49] |

| α-Hydroxyhippuric acid | QqQ/ESI (−) | 193.9 | 72.8 | [31] |

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gómez-Mejía, E.; Rosales-Conrado, N.; León-González, M.E.; Madrid, Y. Determination of phenolic compounds in residual brewing yeast using matrix solid-phase dispersion extraction assisted by titanium dioxide nanoparticles. J. Chromatogr. A 2019, 1601, 255–265. [Google Scholar] [CrossRef] [PubMed]

- Rajauria, G. Optimization and validation of reverse phase HPLC method for qualitative and quantitative assessment of polyphenols in seaweed. J. Pharm. Biomed. Anal. 2018, 148, 230–237. [Google Scholar] [CrossRef] [PubMed]

- Seo, O.N.; Kim, G.S.; Kim, Y.H.; Park, S.; Jeong, S.W.; Lee, S.J.; Jin, J.S.; Shin, S.C. Determination of polyphenol components of Korean Scutellaria baicalensis Georgi using liquid chromatography-tandem mass spectrometry: Contribution to overall antioxidant activity. J. Funct. Foods 2013, 5, 1741–1750. [Google Scholar] [CrossRef]

- Manach, C.; Williamson, G.; Morand, C.; Scalbert, A.; Rémésy, C. Bioavailability and bioefficacy of polyphenols in humans. I. Review of 97 bioavailability studies. Am. J. Clin. Nutr. 2005, 81, 230S–242S. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Belščak-Cvitanović, A.; Durgo, K.; Huđek, A.; Bačun-Družina, V.; Komes, D. Overview of polyphenols and their properties. In Polyphenols: Properties, Recovery, and Applications; Galanakis, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–44. ISBN 9780128135723. [Google Scholar]

- Larrauri, M.; Zunino, M.P.; Zygadlo, J.A.; Grosso, N.R.; Nepote, V. Chemical characterization and antioxidant properties of fractions separated from extract of peanut skin derived from different industrial processes. Ind. Crops Prod. 2016, 94, 964–971. [Google Scholar] [CrossRef]

- Grosso, G.; Stepaniak, U.; Topor-Madry, R.; Szafraniec, K.; Pajak, A. Estimated dietary intake and major food sources of polyphenols in the Polish arm of the HAPIEE study. Nutrition 2014, 30, 1398–1403. [Google Scholar] [CrossRef] [Green Version]

- Hollman, P.C.H. Evidence for health benefits of plant phenols: Local or systemic effects? J. Sci. Food Agric. 2001, 81, 842–852. [Google Scholar] [CrossRef]

- Morand, C.; Crespy, V.; Manach, C.; Besson, C.; Demigné, C.; Rémésy, C. Plasma metabolites of quercetin and their antioxidant properties. Am. J. Physiol. Regul. Integr. Comp. Physiol. 1998, 275, 212–219. [Google Scholar] [CrossRef]

- Martínez-Busi, M.; Arredondo, F.; González, D.; Echeverry, C.; Vega-Teijido, M.A.; Carvalho, D.; Rodríguez-Haralambides, A.; Rivera, F.; Dajas, F.; Abin-Carriquiry, J.A. Purification, structural elucidation, antioxidant capacity and neuroprotective potential of the main polyphenolic compounds contained in Achyrocline satureioides (Lam) D.C. (Compositae). Bioorganic Med. Chem. 2019, 27, 2579–2591. [Google Scholar] [CrossRef]

- Bakkali, F.; Averbeck, S.; Averbeck, D.; Idaomar, M. Biological effects of essential oils—A review. Food Chem. Toxicol. 2008, 46, 446–475. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, A.K. Chemistry and Biological Activities of Flavonoids: An Overview. Sci. World J. 2013, 2013, 162750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, C.S.; Landau, J.M.; Huang, M.T.; Newmark, H.L. Inhibition of Carcinogenesis by Dietary Polyphenolic Compounds. Annu. Rev. Nutr. 2001, 21, 381–406. [Google Scholar] [CrossRef] [Green Version]

- Chong, J.; Poutaraud, A.; Hugueney, P. Metabolism and roles of stilbenes in plants. Plant Sci. 2009, 177, 143–155. [Google Scholar] [CrossRef]

- Arranz, S.; Chiva-Blanch, G.; Valderas-Martínez, P.; Medina-Remón, A.; Lamuela-Raventós, R.M.; Estruch, R. Wine, beer, alcohol and polyphenols on cardiovascular disease and cancer. Nutrients 2012, 4, 759–781. [Google Scholar] [CrossRef] [Green Version]

- Manach, C.; Scalbert, A.; Morand, C.; Rémésy, C.; Jiménez, L. Polyphenols: Food sources and bioavailability. Am. J. Clin. Nutr. 2004, 79, 727–747. [Google Scholar] [CrossRef] [Green Version]

- Scalbert, A.; Manach, C.; Morand, C.; Rémésy, C.; Jiménez, L. Dietary polyphenols and the prevention of diseases. Crit. Rev. Food Sci. Nutr. 2005, 45, 287–306. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.Y. Challenges in providing credible scientific evidence of health benefits of dietary polyphenols. J. Funct. Foods 2013, 5, 524–526. [Google Scholar] [CrossRef]

- Domínguez, R.; Gullón, P.; Pateiro, M.; Munekata, P.E.S.; Zhang, W.; Lorenzo, J.M. Tomato as potential source of natural additives for meat industry. A review. Antioxidants 2020, 9, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lorenzo, J.M.M.; Pateiro, M.; Domínguez, R.; Barba, F.J.F.J.; Putnik, P.; Kovačević, D.B.B.D.B.; Shpigelman, A.; Granato, D.; Franco, D. Berries extracts as natural antioxidants in meat products: A review. Food Res. Int. 2018, 106, 1095–1104. [Google Scholar] [CrossRef] [PubMed]

- Munekata, P.E.S.; Rocchetti, G.; Pateiro, M.; Lucini, L.; Domínguez, R.; Lorenzo, J.M. Addition of plant extracts to meat and meat products to extend shelf-life and health-promoting attributes: An overview. Curr. Opin. Food Sci. 2020, 31, 81–87. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pateiro, M.; Vargas, F.C.; Chincha, A.A.I.A.; Sant’Ana, A.S.; Strozzi, I.; Rocchetti, G.; Barba, F.J.; Domínguez, R.; Lucini, L.; do Amaral Sobral, P.J.; et al. Guarana seed extracts as a useful strategy to extend the shelf life of pork patties: UHPLC-ESI/QTOF phenolic profile and impact on microbial inactivation, lipid and protein oxidation and antioxidant capacity. Food Res. Int. 2018, 114, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Vargas, F.C.; Strozzi, I.; Pateiro, M.; Furtado, M.M.; Sant’Ana, A.S.; Rocchetti, G.; Barba, F.J.; Dominguez, R.; Lucini, L.; et al. Influence of pitanga leaf extracts on lipid and protein oxidation of pork burger during shelf-life. Food Res. Int. 2018, 114, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Munekata, P.E.S.; Domínguez, R.; Campagnol, P.C.B.; Franco, D.; Trindade, M.A.; Lorenzo, J.M. Effect of natural antioxidants on physicochemical properties and lipid stability of pork liver pâté manufactured with healthy oils during refrigerated storage. J. Food Sci. Technol. 2017, 54, 4324–4334. [Google Scholar] [CrossRef]

- Naczk, M.; Shahidi, F. Extraction and analysis of phenolics in food. J. Chromatogr. A 2004, 1054, 95–111. [Google Scholar] [CrossRef]

- Naczk, M.; Shahidi, F. Phenolics in cereals, fruits and vegetables: Occurrence, extraction and analysis. J. Pharm. Biomed. Anal. 2006, 41, 1523–1542. [Google Scholar] [CrossRef]

- Pires, F.B.; Dolwitsch, C.B.; Dal Prá, V.; Faccin, H.; Monego, D.L.; de Carvalho, L.M.; Viana, C.; Lameira, O.; Lima, F.O.; Bressan, L.; et al. Qualitative and quantitative analysis of the phenolic content of connarus var. Angustifolius, cecropia obtusa, cecropia palmata and mansoa alliacea based on HPLC-DAD and UHPLC-ESI-MS/MS. Braz. J. Pharmacogn. 2017, 27, 426–433. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Xiao, C.; Liu, L.; Hao, M.; Wang, J.; Liu, X. Simultaneous Determination of 15 Phenolic Constituents of Chinese Black Rice Wine by HPLC-MS/MS with SPE. J. Food Sci. 2014, 79, C1100–C1105. [Google Scholar] [CrossRef]

- Song, Y.; Jeong, S.W.; Lee, W.S.; Park, S.; Kim, Y.H.; Kim, G.S.; Lee, S.J.; Jin, J.S.; Kim, C.Y.; Lee, J.E.; et al. Determination of polyphenol components of Korean prostrate spurge (Euphorbia supina) by using liquid chromatography—Tandem mass spectrometry: Overall contribution to antioxidant activity. J. Anal. Methods Chem. 2014, 2014. [Google Scholar] [CrossRef] [Green Version]

- Bajkacz, S.; Baranowska, I.; Buszewski, B.; Kowalski, B.; Ligor, M. Determination of Flavonoids and Phenolic Acids in Plant Materials Using SLE-SPE-UHPLC-MS/MS Method. Food Anal. Methods 2018, 11, 3563–3575. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, A.; Sanhueza, M.; Gómez, F.; Tereucán, G.; Valenzuela, T.; García, S.; Cornejo, P.; Hermosín-Gutiérrez, I. Changes in the content of anthocyanins, flavonols, and antioxidant activity in Fragaria ananassa var. Camarosa fruits under traditional and organic fertilization. J. Sci. Food Agric. 2019, 99, 2404–2410. [Google Scholar] [PubMed]

- Nijat, D.; Abdulla, R.; Liu, G.Y.; Luo, Y.Q.; Aisa, H.A. Identification and quantification of Meiguihua oral solution using liquid chromatography combined with hybrid quadrupole-orbitrap and triple quadrupole mass spectrometers. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2020, 1139, 121992. [Google Scholar] [CrossRef] [PubMed]

- Iglesias-Carres, L.; Mas-Capdevila, A.; Bravo, F.I.; Aragonès, G.; Arola-Arnal, A.; Muguerza, B. A comparative study on the bioavailability of phenolic compounds from organic and nonorganic red grapes. Food Chem. 2019, 299, 125092. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, L.; Pellati, F.; Graziosi, R.; Brighenti, V.; Pinetti, D.; Bertelli, D. Identification and determination of bioactive phenylpropanoid glycosides of Aloysia polystachya (Griseb. et Moldenke) by HPLC-MS. J. Pharm. Biomed. Anal. 2019, 166, 364–370. [Google Scholar] [CrossRef]

- Tamasi, G.; Baratto, M.C.; Bonechi, C.; Byelyakova, A.; Pardini, A.; Donati, A.; Leone, G.; Consumi, M.; Lamponi, S.; Magnani, A.; et al. Chemical characterization and antioxidant properties of products and by-products from Olea europaea L. Food Sci. Nutr. 2019, 7, 2907–2920. [Google Scholar] [CrossRef] [Green Version]

- Tótha, G.; Barabás, C.; Tóth, A.; Kéry, Á.; Béni, S.; Boldizsár, I.; Varga, E.; Noszál, B. Characterization of antioxidant phenolics in Syringa vulgaris L. flowers and fruits by HPLC-DAD-ESI-MS. Biomed. Chromatogr. 2016, 30, 923–932. [Google Scholar] [CrossRef]

- Baranowska, I.; Bajkacz, S. A new UHPLC-MS/MS method for the determination of flavonoids in supplements and DPPH[rad]-UHPLC-UV method for the evaluation of the radical scavenging activity of flavonoids. Food Chem. 2018, 256, 333–341. [Google Scholar] [CrossRef]

- Catalán, Ú.; Barrubés, L.; Valls, R.M.; Solà, R.; Rubió, L. In vitro Metabolomic Approaches to Investigating the Potential Biological Effects of Phenolic Compounds: An Update. Genom. Proteom. Bioinform. 2017, 15, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Rocchetti, G.; Bhumireddy, S.R.; Giuberti, G.; Mandal, R.; Lucini, L.; Wishart, D.S. Edible nuts deliver polyphenols and their transformation products to the large intestine: An in vitro fermentation model combining targeted/untargeted metabolomics. Food Res. Int. 2019, 116, 786–794. [Google Scholar] [CrossRef]

- Rocchetti, G.; Lucini, L.; Giuberti, G.; Bhumireddy, S.R.; Mandal, R.; Trevisan, M.; Wishart, D.S. Transformation of polyphenols found in pigmented gluten-free flours during in vitro large intestinal fermentation. Food Chem. 2019, 298, 125068. [Google Scholar] [CrossRef]

- Merken, H.M.; Beecher, G.R. Liquid chromatographic method for the separation and quantification of prominent flavonoid aglycones. J. Chromatogr. A 2000, 897, 177–184. [Google Scholar] [CrossRef]

- Ignat, I.; Volf, I.; Popa, V.I. A critical review of methods for characterisation of polyphenolic compounds in fruits and vegetables. Food Chem. 2011, 126, 1821–1835. [Google Scholar] [CrossRef] [PubMed]

- Hasbay, I.; Galanakis, C.M. Recovery technologies and encapsulation techniques. In Polyphenols: Properties, Recovery, and Applications; Galanakis, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 233–264. [Google Scholar]

- Jokić, S.; Velić, D.; Bilić, M.; Bucić-Kojić, A.; Planinić, M.; Tomas, S. Modelling of solid-liquid extraction process of total polyphenols from soybeans. Czech J. Food Sci. 2010, 28, 206–212. [Google Scholar] [CrossRef] [Green Version]

- Plaza, M.; Domínguez-Rodríguez, G.; Castro-Puyana, M.; Marina, M.L. Polyphenols analysis and related challenges. In Polyphenols: Properties, Recovery, and Applications; Galanakis, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 177–232. [Google Scholar]

- Stalikas, C.D. Extraction, separation, and detection methods for phenolic acids and flavonoids. J. Sep. Sci. 2007, 30, 3268–3295. [Google Scholar] [CrossRef]

- Pigni, N.B.; Aranibar, C.; Lucini Mas, A.; Aguirre, A.; Borneo, R.; Wunderlin, D.; Baroni, M.V. Chemical profile and bioaccessibility of polyphenols from wheat pasta supplemented with partially-deoiled chia flour. LWT 2020, 124, 109134. [Google Scholar] [CrossRef]

- Zhong, L.; Wu, G.; Fang, Z.; Wahlqvist, M.L.; Hodgson, J.M.; Clarke, M.W.; Junaldi, E.; Johnson, S.K. Characterization of polyphenols in Australian sweet lupin (Lupinus angustifolius) seed coat by HPLC-DAD-ESI-MS/MS. Food Res. Int. 2019, 116, 1153–1162. [Google Scholar] [CrossRef] [Green Version]

- Pereira, G.A.; Arruda, H.S.; de Morais, D.R.; Peixoto Araujo, N.M.; Pastore, G.M. Mutamba (Guazuma ulmifolia Lam.) fruit as a novel source of dietary fibre and phenolic compounds. Food Chem. 2020, 310, 125857. [Google Scholar] [CrossRef]

- Bakchiche, B.; Gherib, A.; Bronze, M.R.; Ghareeb, M.A. Identification, quantification, and antioxidant activity of hydroalcoholic extract of artemisia campestris from Algeria. Turk. J. Pharm. Sci. 2019, 16, 234–239. [Google Scholar] [CrossRef]

- Ghareeb, M.A.; Mohamed, T.; Saad, A.M.; Refahy, L.A.G.; Sobeh, M.; Wink, M. HPLC-DAD-ESI-MS/MS analysis of fruits from Firmiana simplex (L.) and evaluation of their antioxidant and antigenotoxic properties. J. Pharm. Pharmacol. 2018, 70, 133–142. [Google Scholar] [CrossRef]

- Cui, B.; Hu, Z.; Zhang, Y.; Hu, J.; Yin, W.; Feng, Y.; Xie, Q.; Chen, G. Anthocyanins and flavonols are responsible for purple color of Lablab purpureus (L.) sweet pods. Plant Physiol. Biochem. 2016, 103, 183–190. [Google Scholar] [CrossRef]

- Tao, W.; Zhou, Z.; Zhao, B.; Wei, T. Simultaneous determination of eight catechins and four theaflavins in green, black and oolong tea using new HPLC–MS–MS method. J. Pharm. Biomed. Anal. 2016, 131, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Ajila, C.M.; Brar, S.K.; Verma, M.; Tyagi, R.D.; Godbout, S.; Valéro, J.R. Extraction and Analysis of Polyphenols: Recent trends. Crit. Rev. Biotechnol. 2011, 31, 227–249. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant phenolics: Extraction, analysis and their antioxidant and anticancer properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef] [PubMed]

- Iglesias-Carres, L.; Mas-Capdevila, A.; Sancho-Pardo, L.; Bravo, F.I.; Mulero, M.; Muguerza, B.; Arola-Arnal, A. Optimized extraction by response surface methodology used for the characterization and quantification of phenolic compounds in whole red grapes (Vitis vinifera). Nutrients 2018, 10, 1931. [Google Scholar] [CrossRef] [Green Version]

- Tabaraki, R.; Nateghi, A. Optimization of ultrasonic-assisted extraction of natural antioxidants from rice bran using response surface methodology. Ultrason. Sonochem. 2011, 18, 1279–1286. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Jiang, J.G.; Li, W.F.; Chen, J.; Wang, D.Y.; Zhu, L. Optimum extraction process of polyphenols from the bark of Phyllanthus emblica L. based on the response surface methodology. J. Sep. Sci. 2009, 32, 1437–1444. [Google Scholar] [CrossRef] [PubMed]

- Karacabey, E.; Mazza, G. Optimisation of antioxidant activity of grape cane extracts using response surface methodology. Food Chem. 2010, 119, 343–348. [Google Scholar] [CrossRef]

- Luque de Castro, M.D.; Priego-Capote, F. Ultrasound-assisted crystallization (sonocrystallization). Ultrason. Sonochem. 2007, 14, 717–724. [Google Scholar] [CrossRef]

- Al Khawli, F.; Pateiro, M.; Domínguez, R.; Lorenzo, J.M.; Gullón, P.; Kousoulaki, K.; Ferrer, E.; Berrada, H.; Barba, F.J. Innovative green technologies of intensification for valorization of seafood and their by-products. Mar. Drugs 2019, 17, 689. [Google Scholar] [CrossRef] [Green Version]

- Adjé, F.; Lozano, Y.F.; Lozano, P.; Adima, A.; Chemat, F.; Gaydou, E.M. Optimization of anthocyanin, flavonol and phenolic acid extractions from Delonix regia tree flowers using ultrasound-assisted water extraction. Ind. Crops Prod. 2010, 32, 439–444. [Google Scholar] [CrossRef]

- Altemimi, A.; Choudhary, R.; Watson, D.G.; Lightfoot, D.A. Effects of ultrasonic treatments on the polyphenol and antioxidant content of spinach extracts. Ultrason. Sonochem. 2015, 24, 247–255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prá, V.D.; Dolwitsch, C.B.; Lima, F.O.; de Carvalho, C.A.; Viana, C.; do Nascimento, P.C.; da Rosa, M.B. Ultrasound-assisted extraction and biological activities of extracts of Brassica oleracea var. capitata. Food Technol. Biotechnol. 2015, 53, 102–109. [Google Scholar]

- Azwanida, N. Citation: Azwanida NN (2015) A Review on the Extraction Methods Use in Medicinal Plants, Principle, Strength and Limitation. Med. Aromat. Plants 2015, 4, 196. [Google Scholar]

- Shi, J.; Nawaz, H.; Pohorly, J.; Mittal, G.; Kakuda, Y.; Jiang, Y. Extraction of polyphenolics from plant material for functional foods—Engineering and technology. Food Rev. Int. 2005, 21, 139–166. [Google Scholar] [CrossRef]

- Castañeda-Ovando, A.; de Pacheco-Hernández, M.L.; Páez-Hernández, M.E.; Rodríguez, J.A.; Galán-Vidal, C.A. Chemical Studies of Anthocyanins: A Review; Elsevier: Amsterdam, The Netherlands, 2009; Volume 113, pp. 859–871. [Google Scholar]

- Lucci, P.; Saurina, J.; Núñez, O. Trends in LC-MS and LC-HRMS analysis and characterization of polyphenols in food. TrAC Trends Anal. Chem. 2017, 88, 1–24. [Google Scholar] [CrossRef]

- Valls, J.; Millán, S.; Martí, M.P.; Borràs, E.; Arola, L. Advanced separation methods of food anthocyanins, isoflavones and flavanols. J. Chromatogr. A 2009, 1216, 7143–7172. [Google Scholar] [CrossRef] [PubMed]

- Carrasco-Pancorbo, A.; Cerretani, L.; Bendini, A.; Segura-Carretero, A.; Gallina-Toschi, T.; Fernández-Gutiérrez, A. Analytical determination of polyphenols in olive oils. J. Sep. Sci. 2005, 28, 837–858. [Google Scholar] [CrossRef]

- Alonso-Carrillo, N.; de los Aguilar-Santamaría, M.Á.; Vernon-Carter, E.J.; Jiménez-Alvarado, R.; Cruz-Sosa, F.; Román-Guerrero, A. Extraction of phenolic compounds from Satureja macrostema using microwave-ultrasound assisted and reflux methods and evaluation of their antioxidant activity and cytotoxicity. Ind. Crop. Prod. 2017, 103, 213–221. [Google Scholar] [CrossRef]

- M’hiri, N.; Ioannou, I.; Mihoubi Boudhrioua, N.; Ghoul, M. Effect of different operating conditions on the extraction of phenolic compounds in orange peel. Food Bioprod. Process. 2015, 96, 161–170. [Google Scholar] [CrossRef]

- Montero, L.; Herrero, M.; Prodanov, M.; Ibáñez, E.; Cifuentes, A. Characterization of grape seed procyanidins by comprehensive two-dimensional hydrophilic interaction× reversed phase liquid chromatography coupled to diode array detection and tandem mass spectrometry. Anal. Bioanal. Chem. 2013, 405, 4627–4638. [Google Scholar] [CrossRef] [Green Version]

- Pyrzynska, K.; Sentkowska, A. Recent Developments in the HPLC Separation of Phenolic Food Compounds. Crit. Rev. Anal. Chem. 2015, 45, 41–51. [Google Scholar] [CrossRef]

- Salih, E.Y.A.; Fyhrquist, P.; Abdalla, A.M.A.; Abdelgadir, A.Y.; Kanninen, M.; Sipi, M.; Luukkanen, O.; Fahmi, M.K.M.; Elamin, M.H.; Ali, H.A. LC-MS/MS tandem mass spectrometry for analysis of phenolic compounds and pentacyclic triterpenes in antifungal extracts of Terminalia brownii (Fresen). Antibiotics 2017, 6, 37. [Google Scholar] [CrossRef] [Green Version]

- Pereira, A.M.; Fernández-Tajes, J.; Gaspar, M.B.; Méndez, J. Identification of the wedge clam Donax trunculus by a simple PCR technique. Food Control 2012, 23, 268–270. [Google Scholar] [CrossRef]

- Hughey, C.A.; Wilcox, B.; Minardi, C.S.; Takehara, C.W.; Sundararaman, M.; Were, L.M. Capillary liquid chromatography-mass spectrometry for the rapid identification and quantification of almond flavonoids. J. Chromatogr. A 2008, 1192, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Tong, C.; Peng, M.; Tong, R.; Ma, R.; Guo, K.; Shi, S. Use of an online extraction liquid chromatography quadrupole time-of-flight tandem mass spectrometry method for the characterization of polyphenols in Citrus paradisi cv. Changshanhuyu peel. J. Chromatogr. A 2018, 1533, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Quatrin, A.; Pauletto, R.; Maurer, L.H.; Minuzzi, N.; Nichelle, S.M.; Carvalho, J.F.C.; Maróstica, M.R.; Rodrigues, E.; Bochi, V.C.; Emanuelli, T. Characterization and quantification of tannins, flavonols, anthocyanins and matrix-bound polyphenols from jaboticaba fruit peel: A comparison between Myrciaria trunciflora and M. jaboticaba. J. Food Compos. Anal. 2019, 78, 59–74. [Google Scholar] [CrossRef]

- Hilary, S.; Tomás-Barberán, F.A.; Martinez-Blazquez, J.A.; Kizhakkayil, J.; Souka, U.; Al-Hammadi, S.; Habib, H.; Ibrahim, W.; Platat, C. Polyphenol characterisation of Phoenix dactylifera L. (date) seeds using HPLC-mass spectrometry and its bioaccessibility using simulated in-vitro digestion/Caco-2 culture model. Food Chem. 2020, 311, 125969. [Google Scholar] [CrossRef]

- Mannino, G.; Perrone, A.; Campobenedetto, C.; Schittone, A.; Margherita Bertea, C.; Gentile, C. Phytochemical profile and antioxidative properties of Plinia trunciflora fruits: A new source of nutraceuticals. Food Chem. 2020, 307, 125515. [Google Scholar] [CrossRef]

- Jin, Q.; Yang, J.; Ma, L.; Wen, D.; Chen, F.; Li, J. Identification of polyphenols in mulberry (genus Morus) cultivars by liquid chromatography with time-of-flight mass spectrometer. J. Food Compos. Anal. 2017, 63, 55–64. [Google Scholar] [CrossRef]

- Liu, S.; Xu, Q.; Li, X.; Wang, Y.; Zhu, J.; Ning, C.; Chang, X.; Meng, X. Effects of high hydrostatic pressure on physicochemical properties, enzymes activity, and antioxidant capacities of anthocyanins extracts of wild Lonicera caerulea berry. Innov. Food Sci. Emerg. Technol. 2016, 36, 48–58. [Google Scholar] [CrossRef]

- Ivanova-Petropulos, V.; Hermosín-Gutiérrez, I.; Boros, B.; Stefova, M.; Stafilov, T.; Vojnoski, B.; Dörnyei, Á.; Kilár, F. Phenolic compounds and antioxidant activity of Macedonian red wines. J. Food Compos. Anal. 2015, 41, 1–14. [Google Scholar] [CrossRef]

- Nematallah, K.A.; Ayoub, N.A.; Abdelsattar, E.; Meselhy, M.R.; Elmazar, M.M.; El-Khatib, A.H.; Linscheid, M.W.; Hathout, R.M.; Godugu, K.; Adel, A.; et al. Polyphenols LC-MS2 profile of Ajwa date fruit (Phoenix dactylifera L.) and their microemulsion: Potential impact on hepatic fibrosis. J. Funct. Foods 2018, 49, 401–411. [Google Scholar] [CrossRef]

- Rocchetti, G.; Lucini, L.; Rodriguez, J.M.L.; Barba, F.J.; Giuberti, G. Gluten-free flours from cereals, pseudocereals and legumes: Phenolic fingerprints and in vitro antioxidant properties. Food Chem. 2019, 271, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Rocchetti, G.; Giuberti, G.; Busconi, M.; Marocco, A.; Trevisan, M.; Lucini, L. Pigmented sorghum polyphenols as potential inhibitors of starch digestibility: An in vitro study combining starch digestion and untargeted metabolomics. Food Chem. 2020, 312, 126077. [Google Scholar] [CrossRef] [PubMed]

- Rocchetti, G.; Senizza, B.; Giuberti, G.; Montesano, D.; Trevisan, M.; Lucini, L. Metabolomic Study to Evaluate the Transformations of Extra-Virgin Olive Oil’s Antioxidant Phytochemicals during In Vitro Gastrointestinal Digestion. Antioxidants 2020, 9, 302. [Google Scholar] [CrossRef] [Green Version]

- Cuadrado-Silva, C.; Pozo-Bayón, M.; Osorio, C. Targeted Metabolomic Analysis of Polyphenols with Antioxidant Activity in Sour Guava (Psidium friedrichsthalianum Nied.) Fruit. Molecules 2016, 22, 11. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Fernández, O.; Domínguez, R.; Pateiro, M.; Munekata, P.E.S.; Rocchetti, G.; Lorenzo, J.M. Determination of Polyphenols Using Liquid Chromatography–Tandem Mass Spectrometry Technique (LC–MS/MS): A Review. Antioxidants 2020, 9, 479. https://doi.org/10.3390/antiox9060479

López-Fernández O, Domínguez R, Pateiro M, Munekata PES, Rocchetti G, Lorenzo JM. Determination of Polyphenols Using Liquid Chromatography–Tandem Mass Spectrometry Technique (LC–MS/MS): A Review. Antioxidants. 2020; 9(6):479. https://doi.org/10.3390/antiox9060479

Chicago/Turabian StyleLópez-Fernández, Olalla, Rubén Domínguez, Mirian Pateiro, Paulo E.S. Munekata, Gabriele Rocchetti, and José M. Lorenzo. 2020. "Determination of Polyphenols Using Liquid Chromatography–Tandem Mass Spectrometry Technique (LC–MS/MS): A Review" Antioxidants 9, no. 6: 479. https://doi.org/10.3390/antiox9060479