Abstract

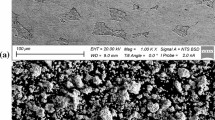

This article discusses the influence of carbonyl iron powder, grade VK, on compactability, sintering, and mechanical properties of samples made of atomized iron powder, grade PZhRV 2.200.26, produced on commercial scale in Russia. It is demonstrated that the relative density of compacted samples made of dispersed PZhRV 2.200.26 iron powder can be increased by addition of particles of carbonyl iron powder, grade VK, which are predominantly located in pores between the particles of atomized powder. Additional introduction of solid lubricants in PZhRV 2.200.26 and VK mixture does not lead to further increase in relative density of pressed samples (more than 90%). It is established that addition of the VK carbonyl powder to the atomized PZhRV 2.200.26 powder in the amount of 15–20 wt % atomized the bending strength of green compacted pieces because of difficulties of plastic deformation of atomized particles into pores, but it increases the bending strength of the material after sintering owing to more developed contacts.

Similar content being viewed by others

REFERENCES

Kuz’mina, Yu.K., Koshelev, A.V., and Syrkin, V.G., Physicomechanical characteristics of parts produced from mixtures of an atomized and a carbonyl iron powder, Sov. Powder Metall. Met. Ceram., 1990, vol. 29, no. 10, pp. 761–766.

Belivin, K.E., Min’ko, D.V., D’yachkova, L.N., and Pinchuk, T.I., Features of electro-pulse compaction of iron-based multicomponent powders, Materialy 10-go Mezhdunarodnogo simpoziuma “Poroshkovaya metallurgiya: inzheneriya poverkhnosti, novye poroshkovye kompozitsionnye materialy. Svarka” (Proc. 10th Int. Symp. “Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding”), Minsk, 2017, pp. 56–67.

Narva, V.K., Eremeeva, Zh.V., Korobov, N.P., and Pfening, D.A., Effect of the addition of nanodispersed iron powders and iron oxides on the processes of pressing and sintering of powder steels, Materialy 10-go Mezhdunarodnogo simpoziuma “Poroshkovaya metallurgiya: inzheneriya poverkhnosti, novye poroshkovye kompozitsionnye materialy. Svarka” (Proc. 10th Int. Symp. “Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding”), Minsk, 2017, pp. 196–204.

Korznikov, O.V., Fedina, T.V., Eremeeva, Zh.V., and Lopatin, V.Yu., Comparative characteristics of powders obtained by the method of melt spraying with a jet of energy carrier, Materialy 10-go Mezhdunarodnogo simpoziuma “Poroshkovaya metallurgiya: inzheneriya poverkhnosti, novye poroshkovye kompozitsionnye materialy. Svarka” (Proc. 10th Int. Symp. “Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding”), Minsk, 2017, pp. 156–162.

Fomina, O.N., Poroshkovaya metallurgiya. Entsiklopediya mezhdunarodnykh standartov (Powder Metallurgy: Encyclopedia of International Standards), Moscow: Protektor, 2015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Moshkin

Rights and permissions

About this article

Cite this article

Lopatin, V.Y., Eremeeva, Z.V. & Nguyen, N.D. The Influence of Carbonyl Iron Powder, Grade VK, on Compactability and Strength Properties of Sintered Atomized Iron Powder, Grade PZhRV 2.200.26. Inorg. Mater. Appl. Res. 11, 403–407 (2020). https://doi.org/10.1134/S2075113320020239

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320020239