Abstract

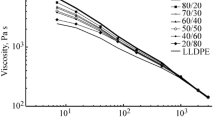

The results of the study of the rheological characteristics of low- and high-density polyethylene blend in the ratio of 50 : 50 and its composites filled with aluminum hydroxide are presented. The influence of the concentration of aluminum hydroxide, temperature, and shear stress on the regularity of changes in the effective viscosity and shear rate has been established. Rheograms of low- and high-density polyethylene blend in the ratio of 50 : 50 and composites based on it are presented. The dependence of viscosity on temperature in Arrhenius coordinates is determined, according to which the “apparent” activation energy of viscous flow for the initial low- and high-density polyethylene blend and its composites filled with aluminum hydroxide varies in the range of 6–19 and 11–31 kJ/mol, respectively. A universal temperature-invariant characteristic of the viscosity properties of low-and high- density polyethylene blend in the ratio of 50 : 50 and its composites filled with aluminum hydroxide, which makes it possible to predict the change in the melt viscosity of composites in a wide range of shear rates and stresses, is drawn. It is shown that, with an increase in the concentration of aluminum hydroxide in the polymer mixture to 5 wt %, the value of the shear rate remains almost unchanged relative to the initial low- and high-density polyethylene blend (50/50). Rheological studies of the melt of polymer materials have been carried out in accordance with the standard ASTM D1238 on a CEAST MF50 capillary rheometer (INSTRON, Italy) in the temperature range of 190–250°C and in the load range of 3.8–21.6 kg.

Similar content being viewed by others

REFERENCES

Zhang, W., Camino, G., and Yang, R., Polymer/polyhedral oligomeric silsesquioxane (POSS) nanocomposites: an overview of fire retardance, Prog. Polym. Sci., 2017, vol. 67, pp. 77–125.

Georlette, P., Simons, J., and Costa, L., Halogen-containing fire-retardant compounds, in Fire Retardancy of Polymeric Materials, Grand, A.F. and Wilkie, C.A., Eds., New York: Marcel Dekker, 2000, pp. 245–284.

Rothon, R. and Hornsby, P., Fire retardant fillers for polymers, in Polymer Green Flame Retardants, Amsterdam: Elsevier, 2014, chap. 9, pp. 289–321.

Su, Z., Jiang, P., Li, Q., Wei, P., and Zhang, Y., Toughening of polypropylene highly filled with aluminumhydroxide, Polym. Polym. Compos., 2005, vol. 13, no. 2, pp. 139–150.

Pilarska, A., Bula, K., Myszka, K., Rozmanowski, T., Szwarc-Rzepka, K., Pilarski, K., Chrzanowski, L., Czaczyk, K., and Jesionowsk, T., Functional polypropylene composites filled with ultra-fine magnesium hydroxide, Open Chem., 2015, vol. 13, pp. 161–171.

Hoseini, M., Haghtalab, A., and Family, N., Influence of compounding methods on rheology and morphology of linear low-density polyethylene/poly lactic acid, Appl. Rheol., 2016, vol. 26, no. 6, pp. 64746–64523.

ASTM D1238-10: Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer, West Conshohocken, PA: ASTM Int., 2010.

Moore, D.S., Notz, W.I., and Fligner, M.A., The Basic Practice of Statistics, New York: W.H. Freeman, 2010.

Kakhramanly, Yu.N., Nesovmestimye polimernye smesi i kompozitsionnye materialy na ikh osnove (Incompatible Polymer Blends and Composite Materials Based on Them), Baku: Elm, 2013.

Zhang, Z., Li, M., Wu, L., Zhang, Y., and Mai, K., Preparation and crystallization of aluminum hydroxide-filled β-polypropylene composites, J. Therm. Anal. Calorim., 2017, vol. 130, no. 2, pp. 773–780.

Kakhramanov, N.T., Arzumanova, N.B., Osipchik, V.S., and Guliev, A.M., Rheological properties of composite materials based on random polypropylene and vesuviane, Perspekt. Mater., 2017, no. 4, pp. 35–43.

Kakhramanov, N.T., Arzumanova, N.B., Alieva, F.M., and Gadzhieva, R.Sh., Rheological properties of nanocomposites based on vesuviane and propylene block-copolymer with ethylene, Plast. Massy, 2018, nos. 11–12, pp. 3–6.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Arzumanova, N.B., Mustafayeva, F.A. & Kakhramanov, N.T. Rheological Properties of Composites Based on Aluminum Hydroxide and Low- and High-Density Polyethylene Blends. Inorg. Mater. Appl. Res. 11, 429–434 (2020). https://doi.org/10.1134/S2075113320020045

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320020045