Abstract

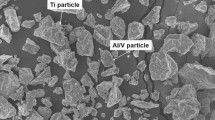

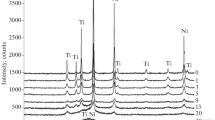

Shock-induced chemical transformations in Ti–B–Ni and Ti–C–Ni powder blends were explored by XRD and EDS methods (flyer velocities 1000 and 1500 m/s). The blends based on Ti–C showed lower sensitivity to shock compression compared to those based on Ti–B. Synthesized products comprised of TiC or TiB2 grains in a Ti–Ni binder. Preliminary mechanical alloying of reactive mixtures was found to elevate their sensitivity to shock compression. The obtained results may turn helpful in designing and optimizing the processes for fabrication of layered cermets.

Similar content being viewed by others

REFERENCES

Filimonov, V.Yu., Korchagin, M.A., Afanas’ev, A.V., Sitnikov, A.A., Yakovlev, V.I., Terekhin, S.V., Baryshnikov, I.V., and Lyakhov, N.Z., Critical regimes of volume ignition of mechanically activated Ti–C–Ni mixtures, Combust. Explos. Shock Waves, 2010, vol. 46, no. 1, pp. 30–35. https://doi.org/10.1007/s10573-010-0005-9

Amosov, A.P., Samboruk, A.R., Yatsenko, I.V., and Yatsenko, V.V., TiC–Fe powders by coupled SHS reactions: An overview, Int. J. Self-Propag. High-Temp. Synth., 2019, vol. 28, no. 1, pp. 10–17. https://doi.org/10.3103/S1061386219010023

Yong, P., Wang, H., Wang, W., Zhang, J., Wang, Y.C., Wang, H., and Zhang, Q., Welding of Ti–6Al–4V and TiB2–Ni cermet using pulsed current heating, Sci. Technol. Weld. Joining, 2008, vol. 13, no. 5, pp. 456–461. https://doi.org/10.1179/174329308X341898

Liu, G., Li, J., and Chen, K., Combustion synthesis of refractory and hard materials: A review, Int. J. Refract. Met. Hard Mater., 2013, vol. 39, pp. 90–102. https://doi.org/10.1016/j.ijrmhm.2012.09.002

Alsawat, M., Altalhi, T., Alotaibi, N.F., and Zakia, Z.I., Titanium carbide–titanium boride composites by self-propagating high-temperature synthesis approach: Influence of zirconia additives on the mechanical properties, Results Phys., 2019, vol. 13. https://doi.org/10.1016/j.rinp.2019.102292

Vallauri, D. and Deorsola, F.A., Synthesis of TiC–TiB2–Ni cermets by thermal explosion under pressure, Mater. Res. Bull., 2009, vol. 44, no. 7, pp. 1528–1533. https://doi.org/10.1016/j.materresbull.2009.02.009

Zhang, J., Pan, C., Zhang, Y., and Cheng, Zh., Synthesis mechanism of TiB2–TiC–Ni composites produced by combustion reaction of Ti–Ni–B4C system in the high gravity field, IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 381, no. 1. https://doi.org/10.1088/1757-899X/381/1/012055

Batsanov, S.S., Features of solid-phase transformations induced by shock compression, Russ. Chem. Rev., 2006, vol. 75, no. 7, pp. 601–616, https://doi.org/10.1070/RC2006v075n07ABEH003613

Batsanov, S.S., Gavrilkin, S.M., Gordopolov, A.Yu., and Gordopolov, Yu.A., Spalling phenomena in shock-recovery capsules during shock compression of inert and reactive mixtures, Combust. Explos. Shock Waves, 2004, vol. 40, no. 5, pp. 605–611. https://doi.org/10.1023/B:CESW.0000041414.23884.48

Merzhanov, A.G., Combustion and explosion processes in physical chemistry and technology of inorganic materials, Russ. Chem. Rev., 2003, vol. 72, no. 4, pp. 289–310. https://doi.org/10.1070/RC2003v072n04ABEH000766

Meyers, M.A., Batsanov, S.S., Gavrilkin, S.M., Chen, H.C., LaSalvia, J.C., and Marquis, F.D.S., Effect of shock pressure and plastic strain on chemical reactions in Nb–Si and Mo–Si systems, Mater. Sci. Eng. A, 1995, vol. 201, no. 1, pp. 150–158.

Adadurov, G.A., Borovinskaya, I.P., Gordopolov, Yu.A., and Merzhanov, A.G., Technological fundamentals of SHS compacting, J. Eng. Phys. Thermophys., 1992, vol. 63, no. 5, pp. 1075–1081. https://doi.org/10.1007/BF0085350

Kamynina, O.K., Vadchenko, S.G., and Shchukin, A.S., SHS Joining of Ti–C–Si ceramics with tantalum, Int. J. Self-Propag. High-Temp. Synth., 2018, vol. 27, no. 3, pp. 192–194. https://doi.org/10.3103/S1061386218030056

Saikov, I.V., Alymov, M.I., Vadchenko, S.G., and Gulyaev, P.Yu., Shock-wave synthesis in powder mixtures, J. Phys. Conf. Ser., 2018, vol. 1115, no. 4. https://doi.org/10.1088/1742-6596/1115/4/042012

Alymov, M.I., Vadchenko, S.G., Gordopolova, I.S., Saikov, I.V., and Milyukova, I.V., Effect of mechanical activation on thermally and shock wave initiated reactions of refractory metals with Teflon, Inorg. Mater., 2018, vol. 54, pp. 1175–1182. https://doi.org/10.1134/S0020168518110018

Vlasova, M., Bykov, A., Kakazey, M., Aguilar, P.A.M., Melnikov, I., Rosales I., and Tapia, R.G., Formation and properties of TiB2–Ni composite ceramics, Sci. Sinter., 2016, vol. 48, pp. 137–146. https://doi.org/10.2298/SOS1602137V

Pacheco, M.M., Bouma, R.H.B., and Katgerman, L., Combustion synthesis of TiB2-based cermets: Modeling and experimental results, Appl. Phys. A, 2008, vol. 90, pp. 159–163. https://doi.org/10.1007/s00339-007-4245-9

Kochetov, N.A., Rogachev, A.S., Emel’yanov, A.N., Illarionova, E.V., and Shkiro, V.M., Microstructure of heterogeneous mixtures for gasless combustion, Heat Transf. Res., 2007, vol. 38, no. 2, pp. 95–106. https://doi.org/10.1615/HeatTransRes.v38.i2.10

Zhu, G., Wang, W., Wang, R., Zhao, C., Pan, W., Huang, H., Du, D., Wang, D., Shu, D., Dong, A., Sun, B., Jiang, S., and Pu, Y., Formation mechanism of spherical TiC in Ni–Ti–C system during combustion synthesis. Materials, 2017, vol. 10, pp. 1007–1015. https://doi.org/10.3390/ma10091007

Zhang, X.H., Han, J.C., He, X.D., and Kvanin, V.L., Combustion synthesis and thermal stress analysis of TiC–Ni functionally graded materials, J. Mater. Synth. Process., 2000, vol. 8, no. 1, pp. 29–34. https://doi.org/10.1023/A:1009469610918

ACKNOWLEDGMENTS

This study was performed by using the set of modern scientific instruments available for multiple accesses at ISMAN.

Funding

This work was financially supported by the Russian Foundation for Basic Research (project no. 19-08-00754).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Scheck

About this article

Cite this article

Saikov, I.V., Salamatov, V.G., Malakhov, A.Y. et al. Shock-Induced Chemical Transformations in Ti–B–Ni and Ti–C–Ni Powder Blends. Int. J Self-Propag. High-Temp. Synth. 29, 10–14 (2020). https://doi.org/10.3103/S1061386220010100

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386220010100