Abstract

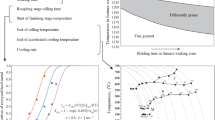

This study presents computing parameter techniques for the cold rolling of steel wide strip in a continuous five-stand mill 1700. The reduction of the required power for the main drives during rolling is shown. The characteristic effects of reduction and tension of the steel strip and steel-type, as well as profile assortment on the energy consumption, is established. An algorithm for computing the rolling parameters is proposed. The results lay the foundation for the computer-aided design (CAD) software of continuous rolling modes. This technique application contributes to the basic principles for determining the technological parameters in the five-stand mill.

Similar content being viewed by others

REFERENCES

Storck, J., Product variety, flexibility and energy use in hot rolling mills, Proc. 4th Int. Conf. on Changeable, Agile, Reconfigurable and Virtual production (CARV2011) “Enabling Manufacturing Competitiveness and Economic Sustainability,” Montreal, Canada, October 2–5,2011, New York: Springer-Verlag, 2011. P. 80–85.

Shilov, V.A. and Ponomarev, A.A., Optimization of technological modes of rolling by criteria of mechanical properties, Proizvod. Prokata, 2013, no. 2, pp. 14–19.

Genkin, A.L., Energy conservation in a furnace-mill sheet-rolling system, Steel Transl., 2011, vol. 41, no. 3, pp. 236–242.

Rumyantsev, M.I., The method to improve the sheet rolling technological systems, Vestn. Magnitogorsk. Gos. Tekh. Univ. im. G.I. Nosova, 2017, vol. 15, no. 1, pp. 45–55.

Rumyantsev, M.I., Improvement of rolling production for sheet rolling systems, Teor. Tekhnol. Metall. Proizvod., 2017, no. 4 (23), pp. 26–36.

Garber, E.A., Shalaevskii, D.L., Mitrofanov, A.V., et al., Energy saving modes of hot rolling of broad steel strips, Chern. Metall., 2016, no. 5, pp. 38–43.

Kozhevnikov, A., Kozhevnikova, I., Bolobanova, N., and Shalaevskii, D., Methodology of design of thin steel strip cold rolling energy efficient technology, Metallurgja, 2018, vol. 57, no. 4, pp. 337–340.

Kuznetsov, V.V., Garber, E.A., Yusupov, V.S., and Shalaevskii, D.D., Production of cold rolling automobile sheets from new corrosion-resistant economically efficient steel with BH effect, Proizvod. Prokata, 2007, no. 11, pp. 9–12.

Garber, E.A., Shadrunova, I.A., and Traino, A.I., Determination of energy power parameters of cold rolling of thinnest strips, Chern. Metall., 2002, no. 2, p. 47.

Kozhevnikova, I.A. and Garber, E.A., Energy power calculations of thin-sheet rolling: discussion paper, Proizvod. Prokata, 2010, no. 12, pp. 16–24.

Funding

The work was carried out within the State Task of the Ministry of Science and Higher Education of the Russian Federation (project no. 11.3943.2017/4.6).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by E. Oborin

About this article

Cite this article

Shalaevskii, D.L., Kozhevnikov, A.V. Computer-Aided Design (CAD) of Energy-Efficient Cold Rolling Technology. Steel Transl. 50, 36–41 (2020). https://doi.org/10.3103/S0967091220010106

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220010106