Abstract

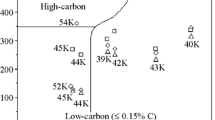

The influence of aluminum (5–10%) and carbon (0.04–1.7%) contents on phase transformations, structure formation processes and mechanical properties of Fe–25 Mn–5 Ni–Al–C steels was studied theoretically and experimentally. The authors have estimated intervals of optimal crystallization regimes and subsequent deformation-thermal effects for obtaining austenitic steels with high specific strength. Hardness measurements on the sample section and mechanical tests in a wide interval of temperatures of cold, warm and hot deformation were performed, as well as the phase structure assessment of steels (alloys) on the basis of Fe–25 Mn–5 Ni–Al–C. In a cast state, an alloy with 5% of Al was non-magnetic, i.e., it had austenitic structure; alloys with 10–15% of Al were magnetic with two-phase structure (γ + α). Aluminum considerably increases deformation resistance. At the same time, values σ1 and σmax grow, i.e., also deformation hardening grows and softening processes are slowed down. With deformation rate growth, the Al influence becomes stronger. Austenitic high-manganese alloys with 5% of Al, both with low and high carbon content, have rather high plasticity and durability, and differ in high austenite stability. Alloying with nickel increases plasticity. Alloys with Al less than 10% are rather plastic also in a cast state. High-manganese (from 25% of Mn) alloys with Al content to 5–7% can be considered as high-strength cold-resistant and heat-resistant with thermally and mechanically stable austenite up to carbon content ~1.5%.

Similar content being viewed by others

REFERENCES

Moor, E.D., Gibbs, P.J., Speer, J.G., and Matlock, D., Strategies for third-generation advanced high-strength steel development, Iron Steel Technol., 2010, vol. 7, no. 11, pp. 133–144.

Kim, S., Kim, G., and Chin, K., Development of high manganese TWIP steel with 980 MPa tensile strength, Proc. Int. Conf. on New Developments in Advanced High-Strength Sheet Steels, Orlando, USA, June 15–18,2008, Orlando, 2008, pp. 249–256.

Svyazhin, A.G. and Kaputkina, L.M., High nitrogen steels: today and tomorrow, Proc. 11th Int. Conf. on High Nitrogen Steels and Interstitial Alloys (HNS 2012), September 27–29,2012, Chennai, India, Chennai: VRK, 2013, pp. 11–22.

Frommeyer, G. and Bruex, U., Microstructures and mechanical properties of high-strength Fe–Mn–Al–C light-weight TRIPLEX steels, Steel Res. Int., 2006, vol. 77, no. 9, pp. 627–633.

Ishida, K., Ohtani, H., Satoh, N., Kainuma, R., and Nishizawa, T., Phase equilibria in Fe–Mn–Al–C alloys, ISIJ Int., 1990, vol. 30, no. 8, pp. 680–686.

Goretskii, G.P. and Gorev, K.V., Phase equilibria in Fe–Mn–Al–C alloys, Izv. Akad. Nauk SSSR, Metall., 1990, no. 2, pp. 218–222.

Acselrad, O., Kalashnikov, I.S., Silva, E.M., Simao, R.A., Achete, C.A., and Pereira, L.C., Phase transformation in Fe–Mn–Al–C austenite steels with Si addition, Metall. Mater. Trans. A, 2002, vol. 33, no. 11, pp. 3569–3573.

Storchak, N.A. and Drachinskaya, A.G., Strengthening of Fe–Mn–Al–C alloys during ageing, Phys. Met. Metallogr., 1977, vol. 44, no. 2, pp. 123–130.

Sato, K., Tagawa, K., and Inoue, Y., Modulated structure and magnetic properties of age-hardenable Fe–Mn–Al–C alloys, Metall. Trans. A, 1990, vol. 21, no. 1, pp. 5–11.

Han, K.H., Choo, W.K., Choi, D.Y., and Hong, S.P., Age Hardening in Fe-Mn-Al-C. Austenitic Alloys, Warrendale, PA: Miner., Met. Mater. Soc., 1987, pp. 91–106.

Han, H.N., Oh, C.-S., Kim, G., and Kwon, O., Design method for TRIP-aided multiphase steel based on a microstructure-based modeling for transformation-induced plasticity and mechanically induced martensitic transformation, Mater. Sci. Eng., A, 2009, vol. 499, no. 1, pp. 462–468.

Pottore, N., Fonstein, N., Gupta, I., and Bhattacharya, D., A family of 980 MPa tensile strength advanced high strength steels with various mechanical property attributes, Proc. of the Int. Conf. on Advanced High Strength Sheet Steels for Automotive Applications, Colorado, USA, June 6–9,2004, Winter Park, CO: Assoc. Iron Steel Technol., 2004, pp. 119–129.

Kimura, Y., Handa, K., Hayashi, K., and Mishima, Y., Microstructure control and ductility improvement of the two-phase γ-Fe/κ-(Fe, Mn)3AlC alloys in the Fe–Mn–Al–C quaternary system, Intermetallics, 2004, vol. 12, no. 6, pp. 607–617.

Kimura, Y., Hayashi, K., Handa, K., and Mishima, Y., Microstructural control for strengthening the γ‑Fe/E21–(Fe, Mn)3AlCx alloys, Mater. Sci. Eng., A, 2002, vols. 329–331, pp. 680–685.

Choo, W.K. and Kim, J.H., Microstructural and mechanical property changes on precipitation of intermetallic k' cubic carbide phase in the Fe–Mn(Ni)–Al–C solid solution, Proc. Int. Conf. on Thermomechanical Processing of Steels and Other Materials (THERMEC'97), Wollongong, Australia, July 7–11,1997, Warrendale, PA: Miner., Met. Mater. Soc., 1997, pp. 1631–1637.

Kalashnikov, I., Shalkevich, A., Acselrad, O., and Pereira, L.C., Chemical composition optimization for austenitic steels of the Fe–Mn–Al–C system, J. Mater. Eng. Perform., 2000, vol. 9, no. 6, pp. 597–602.

Kalashnikov, I.S., Acselrad, O., Shalkevich, A., Chumakova, L.D. and Pereira, L.C., Heat treatment and thermal stability of Fe–Mn–Al–C alloys, J. Mater. Process. Technol., 2003, vol. 136, nos. 1–3, pp. 72–79.

Acselrad, O., Kalashnikov, I.S., Silva, E.M, Kha-dyev, M.S., and Simao, R.A., Diagram of phase transformations in the austenite of hardened alloy Fe–28% Mn–8.5% Al–1% C–1.25% Si as a result of aging due to isothermal heating, Met. Sci. Heat Treat., 2006, vol. 48, nos. 11–12, pp. 543–553.

Tian, X., Tian, R., Wei, X., and Zhang, Y., Effect of Al content on work hardening in austenitic Fe–Mn–Al–C alloys, Can. Metall. Quart., 2004, vol. 43, no. 2, pp. 183–192.

Chiou, S.-T., Cheng, W.-C., and Lee, W.-S., Strain rate effects on the mechanical properties of a Fe–Mn–Al alloy under dynamic impact deformations, Mater. Sci. Eng., A, 2005, vol. 392, nos. 1–2, pp. 156–162.

Acselrad, O., Pereira, L.C., Dille, J., and Delplancke, J.-L., Room-temperature cleavage fracture of Fe–Mn–Al–C steels, Metall. Mater. Trans. A, 2004, vol. 35, no. 12, pp. 3863–3866.

Hallstedt, B., Khvan, A.V., Lindahl, B.B., Selleby, M., and Liu, S., PrecHiMn-4—A thermodynamic database for high-Mn steels, Calphad, 2017, vol. 56, pp. 49–57.

Zheng, W., He, S., Selleby, M., He, Y., Li, L., Lu, X.-G., and Agren, J., Thermodynamic assessment of the Al‒C–Fe system, Calphad, 2017, vol. 58, pp. 34–49.

Zheng, W., Lu, X.-G., Mao, H., He, Y., Selleby, M., Li, L., and Agren, J., Thermodynamic modeling of the Al–C–Mn system supported by ab initio calculations, Calphad, 2018, vol. 60, pp. 222–230.

Bronz, A.V., Kaputkin, D.E., Kaputkina, L.M., Kindop, V.E., and Svyazhin, A.G., Effect of chemical composition on the crystal lattice and physical properties of iron-manganese alloys with high content of aluminum, Met. Sci. Heat Treat., 2014, vol. 55, nos. 11–12, pp. 647–651.

Svyazhin, A.G., Bazhenov, V.E., Kaputkina, L.M., Smarygina, I.V., and Kindop, V.E., Nitrogen in Fe–Mn–Al–C-based system, CIS Iron Steel Rev., 2016, vol. 12, pp. 13–17.

Kaputkina, L.M., Svyazhin, A.G., Kaputkin, D.E., Bazhenov, V.E., Bronz, A.V., and Smarygina, I.V., Effect of Mn, Al, Ni and C content on the equilibrium phase composition of alloys based on the Fe–Mn–Al–C system, Metallurgist, 2016, vol. 59, nos. 11–12, pp. 1075–1080.

Kaputkina, L.M., Svyazhin, A.G., and Smarygina, I.V., Hardening of austenitic nitrogen high-manganese aluminum alloys under heat and thermomechanical treatment, Met. Sci. Heat Treat., 2016, vol. 57, no. 11, pp. 705–712.

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V., and Kindop, V.E., Strength of “light” ferritic and austenitic steels based on the Fe–Mn–Al–C system, Met. Sci. Heat Treat., 2017, vol. 58, nos. 9–10, pp. 515–519.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Gumerov

About this article

Cite this article

Kaputkina, L.M., Svyazhin, A.G., Smarygina, I.V. et al. Light Non-Magnetic Steels Based on the Fe–25 Mn–5 Ni–Al–C System. Steel Transl. 50, 22–30 (2020). https://doi.org/10.3103/S0967091220010039

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220010039