Abstract

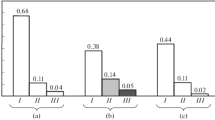

Flow accelerated corrosion (FAC) is considered one of the major causes of damage to heat-recovery steam generators (HRSG) of combined-cycle units. In the last few decades, a great number of papers devoted to this problem have been published in many countries around the world. The results of investigations were analyzed as a rule, on the basis of the flow-averaged thermochemical parameters of the flow, while the features of the near-wall liquid film determining the FAC rate were not taken into account. The indicators in the near-wall region depends on the heat-and-mass transfer conditions, flow hydrodynamics, and the specific of chemicals used to correct the water chemistry (WC). For ammonia and oxygen water treatment chemistries, an equilibrium model is proposed and its validity for HRSG evaporators is substantiated. The rate of the exchange of gas reagents between steam and water is determined by the distribution coefficient Kd. To simplify calculations, simple approximating correlations of Kd for ammonia and oxygen is recommended. For the water chemistry with solid reagents, a diffusion model has been developed to calculate mass transfer on the basis of data on heat transfer in steam-generating tubes. The concentration of reagents near the wall is determined by both the turbulent transport of the liquid between the flow core and the near-wall layer and the coefficient of reagent distribution between the phases. Simple approximating correlations of distribution coefficients for Na3PO4, NaOH, and 90H Turb helamine are proposed. An approximate correlation between the hydraulic resistance coefficient Kh and the geometric parameter Kс of the FAC process has been established. The hydrodynamic fundamentals of the standard HRSG structural members have been studied in more detail than FAC. To estimate Kс, one can use the known value of Kh and the correlation between them. However, this correlation should be used with care since it has been obtained for certain conditions of unambiguity (i.e., specific construction material, water chemistry, flow history, etc.). Under other conditions, this correlation will change somewhat; therefore, it can only be used for rough estimation.

Similar content being viewed by others

REFERENCES

B. Chexal, J. S. Horowitz, R. Jones, B. Dooley, and C. Wood, Flow-Accelerated Corrosion in Power Plants (EPRI, 1996).

J. M. Jevec, S. J. Klimas, P. King, and K. Fruzzetti, Multivariable Assessment of Flow Accelerated Corrosion and Steam Generator Fouling (EPRI, 2003).

J. Otakar, “Control of erosion/corrosion of steels in wet steam,” Power 129, 102–103 (1985).

J. Otakar, “Plant alert: Don’t let erosion/corrosion compromise safety,” Power, February (1996). http:// www.steamcycle.com/plant_alert.pdf

B. Poulson, “Complexities in predicting erosion corrosion,” Wear 233–235, 497–504 (1999). https://doi.org/10.1016/S0043-1648(99)00235-5

Guidelines for Controlling Flow-Accelerated Corrosion in Fossil and Combined Cycle Plants. Final Report, 1008280 (EPRI, 2005).

W. Kastner and K. Riedle, “Empirisches Modell zur Berechnung von Materialabtragen durch Erosionskorrosion,” VGB Kraftwerkstech. 66, 1171–1178 (1986).

J. Schroeder, “Heat recovery steam generator design related influences on flow accelerated corrosion,” in Proc. HRSG Conf. in Nooter/Eriksen, Fenton, MO,2010.

H. Keller, “Erosioncorrosion an Nassdampfturbinen,” VGB Kraftwerktech. 54, 292–295 (1974).

Excel program for calculation of FAC (Flow Assisted Corrosion = Erosion Corrosion) on the basis of the publication of Kastner and Riedle (1986). http://www.studiekern-corrosie.nl/pdf/Lezingen/65%20FACCalculation%20 model%20engels.pdf

G. V. Tomarov, A. V. Mikhailov, E. V. Velichko, and V. A. Budanov, “Extending the erosion-corrosion service life of the tube system of heat-recovery steam generators used as part of combined-cycle plants,” Therm. Eng. 57, 22–27 (2010).

V. I. Baranenko and A. A. Prosvirnov, System Requirements for Future Nuclear Power Plants and Factors of Erosion-Corrosion Wear (ProAtom, 2012) [in Russian]. http://www.proatom.ru/modules.php?file=article&name= News&sid=3552

M. M. Naftal’, V. I. Baranenko, and O. M. Gulina, “Use of software tools for calculating flow accelerated corrosion of nuclear power plant equipment and pipelines,” Therm. Eng. 61, 456–463 (2014). https://doi.org/10.1134/S0040601514060081

T. I. Petrova and F. V. Dyachenko, “A review of studies on the use of film-forming amines for corrective water treatment,” Presented at The Use of Film-Forming Amines in Power Generation, Sci.-Pract. Conf., Moscow, Nov. 10,2016. https://docplayer.ru/60241671-Obzor-issledovaniy-po-primeneniyu-plenkoobrazuyushchihaminov-dlya-korrekcionnoy-obrabotki-vody.html

N. S. Galetskii and A. L. Shvarts, “Features of erosion-corrosion wear in low-pressure evaporators of combined-cycle plant heat-recovery steam generators at high steam quality,” Therm. Eng. 60, 917–920 (2013). https://doi.org/10.1134/S0040601513120082

V. I. Nikitin, I. I. Belyakov, and V. I. Breus, “Damage to steam-generating tubes of low-pressure circuit of drum-type heat recovery steam generator used in the PGU-450 combined-cycle unit at Severozapadnaya cogeneration plant,” Therm. Eng. 56, 124–128 (2009).

M. A. Styrikovich, V. S. Polonsky, and G. V. Tsiklauri, Heat and Mass Transfer and Hydrodynamics in Two-Phase Flows in Nuclear Power Plants (Nauka, Moscow, 1982; Hemisphere, New York, 1986).

VGB-S-010-T-00 (VGB-Standard). Feed Water, Boiler Water and Steam Quality for Power Plants/Industrial Plants, 3rd ed. (2011–2012).

V. S. Polonsky, I. L. Mostinskii, N. P. Afanas’ev, V. I. Zalkind, V. F. Krapivnyi, K. N. Proskuryakov, O. G. Stonik, and L. A. Shatenѐv, “Steam and gas abrasive cutters. Design basics, Prospects for use,” Preprint IVTAN No. 1–393 (High Temperature Inst., Russian Academy of Sciences, Moscow, 1996).

O. M. Baldina, V. A. Lokshin, D. F. Peterson, I. E. Semenovker, and A. L. Shvarts, Hydraulic Calculation of Boiler Units (Normative Method) (Energiya, Moscow, 1978) [in Russian].

I. E. Idel’chik, Handbook of Hydraulic Resistance, Ed. by M. O. Shteinberg, 3rd ed. (Mashinostroenie, Moscow, 1992; CRC, Boca Raton, FL, 1994).

Cycle Chemistry Guidelines for Combined Cycle/Heat Recovery Steam Generators (HRSG’s), Electric Power Research Institute Report No. 1010438 (EPRI, 2006).

R. Turyna and V. Svarc, “Beitrag zur Ueberpruefung einiger Gleichungen der Dissoziationskoeffizienten von Ammoniak und Wasser sowie des Verteilungskoeffizienten von Ammoniak im Wasser-Damofkreislauf von Kemkraftwerken,” VGB Kraftwerkstech. 74, 408 (1994).

T. Kh. Margulova and O. I. Martynova, Water Chemistries Used at Thermal and Nuclear Power Plants, 2nd ed. (Vysshaya Shkola, Moscow, 1987) [in Russian].

V. N. Voronov and T. I. Petrova, Water Chemistries of Thermal and Nuclear Power Plants: Study Aid, Ed. by A. P. Pil’shchikov (Mosk. Energ. Inst., Moscow, 2009).

IAPWS G7-04, Guideline on the Henry’s Constant and Vapor–Liquid Distribution Constant for Gases in H2O and D2O at High Temperatures (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Krasnoshchekova

Rights and permissions

About this article

Cite this article

Polonsky, V.S., Tarasov, D.A. & Gorr, D.A. The Effect of Heat-and-Mass Transfer and Flow Hydrodynamics on the Flow Accelerated Corrosion Rate in Evaporators of Combined-Cycle Unit Heat-Recovery Steam Generators. Therm. Eng. 67, 396–404 (2020). https://doi.org/10.1134/S0040601520060105

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520060105