Abstract

The direct hydrogenation of CO2 into dimethyl-ether (DME) has been studied in presence of zeolite-based hybrid catalysts, prepared through gel-oxalate coprecipitation of copper, zinc and zirconium precursors (in an atomic ratio of 60 : 30 : 10 respectively) in a solution containing different home-made zeolites (i.e., Sil-1, MFI, Y, FER, BEA, MOR), for a final CuZnZr/zeolite weight composition of 1:1. All the samples were properly characterized with different techniques for determining the textural, structural and morphological nature of the catalytic surface. N2 physisorption highlighted a variation both in the specific surface area and in the pore size distribution from the parent zeolites to the hybrid catalyst. TEM analyses disclosed how the pre-formed zeolite architecture affects the distribution of the oxides on the surface, significantly controlling not only the activity-selectivity pattern under the adopted experimental conditions (TR, 200–260°C; PR, 30 bar, GHSV: 8.800 NL/kgcat/h), but also the catalyst stability during time on-stream.

Similar content being viewed by others

1 INTRODUCTION

In the last years, many novel technological approaches are being implemented with the aim of recycling anthropogenic CO2 as a cheap and non-toxic building-block for carbon source synthetic fuels [1–3]. Indeed, the utilization of CO2 represents one of the hot topics of the current International environmental programmes [4, 5] and recent literature report on several studies dealing with CO2 conversion into methane [6–8], methanol [9–16], higher alcohols [17], gasoline [18], dimethyl ether [19–27] as well as liquid fuels [28]. In particular, dimethyl ether (DME) is a promising alternative fuel due to its high efficiency of combustion, high cetane number, sulfur-free property and low emission of NOx [29–31].

The conventional DME synthesis includes a first step of methanol synthesis on copper-based catalyst (Eq. (1)) and a second step of methanol dehydration to DME over solid acid catalyst (Eq. (3)). The reverse water gas shift reaction (RWGS) is an inevitable side reaction under the experimental conditions (Eq. (2)).

Nevertheless, considering the capital and operating expenditures as well as thermodynamic limitations behind a traditional two step process, nowadays several studies report the economic sustainability of producing DME from one-step CO2 hydrogenation processes rather than in traditional multi-step processes.

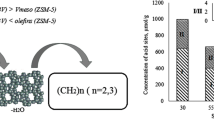

From a catalytic point of view, the direct DME synthesis is boosting an intense research effort in the development and application of novel multi-functional hybrid systems, wherein a mix of different active sites are in close interaction among them to facilitate the rate of mass transfer of a reaction intermediate towards the final product. In particular, it is known that Cu0 provides active sites for H2 dissociation, while some carrier oxides (mainly ZnO, Al2O3, and ZrO2 [32]) possess specific sites generated at the metal-oxide interface, suitable for CO2 adsorption and activation [33–35].

Recently CuO–ZnO–ZrO2 was proposed as an efficient methanol synthesis catalyst from CO2/H2 mixtures due to weak hydrophilicity of ZrO2 in comparison to Al2O3 [36, 37]. Apart from this, the introduction of ZrO2 was also recognized to increase the surface basicity for improving the CO2 adsorption [38]. Accordingly, this system can be advantageously hybridized with an acidic matrix to shift equilibrium towards the formation of DME, by methanol dehydration. Whilst conventional γ-Al2O3 can optimally fulfill this role at atmospheric pressure [39, 40], however its strong affinity to water adsorption during the reaction prevents its potential application in processes carried out at high reaction pressure. For this reason, zeolites appear as more promising crystalline acidic carriers to be integrated with a methanol phase, owing to a tunable system of voids (openings and spatial orientation of channels, size and location of cages, etc.) and concentration, distribution, strength and location of acid sites (both of Brønsted and Lewis type) affecting the overall activity, product selectivity and deactivation of the catalyst [41].

Herein, the catalytic behaviour of hybrid systems characterized by the interaction between metal-oxide sites from an optimized CuZnZr formulation and acidic sites of different home-made zeolites is assessed. Peculiar structure-activity relationships are accordingly defined suitable to understand how a pre-formed zeolite architecture can drive the generation of specific metallic properties for an efficient catalytic system operating in the direct CO2-to-DME hydrogenation reaction.

2 EXPERIMENTAL

2.1 Hybrid Systems for One-step CO2-to-DME Hydrogenation Reaction

The procedure followed for the preparation of the hybrid systems was to generate a methanol phase directly in a solution containing a zeolite finely dispersed (particle size <100 μm). In Table 1, a list of the home-made zeolites used as metal-oxide carriers is reported. All of the molecular sieves were prepared under hydrothermal conditions in a PTFE lined stainless steel autoclaves at 175°C for 10 days in tumbling conditions (20 rpm). Then, the samples were activated in acidic form by calcination at 550°C for 8 h in order to eliminate the structure-directing agent (SDA). Samples synthesized with sodium-containing synthesis gel, were exchanged with NH4Cl solution and calcined again at 550°C for 8 h in order to eliminate ammonia and to obtain catalyst in acid-form.

For the preparation of the hybrid catalysts, the powdered home-made zeolites were dissolved in an ethanolic solution, containing a suitable amount of oxalic acid for quantitative coprecipitation of the CuZnZr nitrate precursors (60/30/10 at %). The solution of metal precursors was added, at room temperature and in a slow and constant mode, to the vigorously stirred ethanolic solution in order to get a final oxide composition of 1 : 1 by weight with the zeolite. The precipitate was stirred for 3 h, aged overnight, then filtered and dried at 110°C for 16 h, before of calcination at 350°C for 4 h.

2.2 Catalyst Characterization

The analytical composition of catalysts was determined by XRF, using a Bruker AXS-S4 Explorer spectrometer, equipped with a rhodium X-ray source (Rh anode and 75 μm Be-window), a LiF 220 crystal analyzer and a 0.12° divergence collimator. Samples were analyzed at the solid state, taking into account the emission value of Cu–Kα1, Zn–Kα1 and Al–Kα1 transitions.

The textural properties of the catalysts were determined from nitrogen adsorption/desorption isotherms at –196°C, using a Micromeritics ASAP 2020 gas adsorption device. The isotherms were elaborated according to the Langmuir method for surface area calculation (SA), while Barrett–Joyner–Halenda (BJH) and Horvath-Kawazoe (HK) methods were used for meso- and micro-porosity evaluation.

Metallic properties were obtained by N2O chemisorption measurements at 90°C, assuming a Cu : N2O = 2 : 1 titration stoichiometry and a surface atomic density of 1.46 × 1019 Cuat/m2. Before “single-pulse” N2O-titration of the metal copper sites, the samples were reduced in situ at 300°C in flowing H2 (100 STP mL/min) for 1 h, then “flushed” at 310°C in nitrogen carrier flow (15 min) and further cooled down at 90°C.

Surface concentrations of base sites were determined by CO2-TPD. The catalysts (≈100 mg) were reduced at 300°C, at atmospheric pressure, by flowing hydrogen (100 STP mL/min) in a linear quartz micro-reactor (l, 200 mm; i.d., 4 mm) for 60 min and then saturated for 60 min in flow of a gas mixture containing 20 vol % of CO2/He (50 mL/min). After purging in helium flow, the measurements were performed in the temperature range 100–600°C, at a rate of 10°C/min using helium (50 STP mL/min) as the carrier flow. The evolved gases were detected by an on-line thermal-conductivity detector, calibrated by the peak area of known pulses of CO2.

TEM images of the hybrid catalysts were acquired and elaborated by a Philips CM12 instrument equipped with a high-resolution camera. Powdered samples were dispersed in 2-propanol under ultrasound irradiation and the resulting suspension put drop-wise on a holey carbon-coated support grid.

2.3 Catalytic Testing

Catalytic testing was carried out in in CO2 hydrogenation at 30 bar (CO2/H2/N2 = 23/69/8), in a tubular fixed catalyst bed reactor (i.d., 4 mm; l., 200 mm), jacketed within a stainless steel rod (o.d., 14 mm; l., 180 mm). The catalytic measurements were performed between 200 and 280°C, at a space velocity of 8.800 NL/kgcat/h. Before the testing, the catalysts were reduced in situ at 300°C under “pure” hydrogen at atmospheric pressure for 1 h. The reaction stream was analyzed by a GC equipped with a double-column system connected to a flame ionized detector (CH4, CH3OH, CH3OCH3) and thermal conductivity detector (H2, N2, CO, CO2) respectively.

3 RESULTS AND DISCUSSION

According to the graphs displayed in Fig. 1, the textural properties of the hybrid systems are strongly depressed with respect to the parent zeolites, probably due to a partial pore blocking to the presence of CuZnZr particles. It is evident that an extended mesoporosity on the hybrid systems is generated, suggesting that metallic components distribute over the outer surface of the zeolites, giving catalysts characterized by more or less expanded pore volumes depending on the corresponding features of the bare zeolites.

In particular, on the Sil-1, MFI, FER, BEA, and MOR zeolites, the coprecipitation of metal precursors leads to a significant reduction of micropore volume (49–56%), being even more marked on the OX-Y hybrid sample in which the final values of 0.071 cm3/g accounts for a decrease around 75% in respect of the bare zeolite.

As reported in Table 2, the hybrid catalysts obtained by oxalate co-precipitation method are characterized by different metallic, basic and acidic properties. Indeed, the highest value of N2O uptake on silicalite (0.440 mmol/gcat) signals a higher copper surface area and dispersion in the correspondent hybrid sample, as the result of particles with a smaller diameter. On the contrary, ferrierite brings to the lowest value of N2O uptake (0.172 mmol/gcat), accounting for a minor dispersion and larger copper particles generated during preparation.

As for the basic capacity, it can be easily observed as all the hybrid CuZnZr/zeolite systems exhibit a quite variable concentration of surface basic sites, with a maximum CO2 uptake of 0.272 mmol/gcat for the OX/Y sample and the minimum amount of 0.124 mmol/gcat recorded for OX/MOR. Evidently, irrespective of the same metal loading on the zeolite carriers, the zeolite architecture significantly controls the exposure and accessibility of active sites in specific positions, with a direct influence on the CO2 activation process.

Regarding the NH3-TPD measurements, the cumulative acid capacity (with no regard if of Brønsted or Lewis type) was seen to depend on different topology of the zeolites in the hybrid catalysts. Indeed, with an approximately 1 : 1 ratio between the powdered zeolite and the methanol composition, the number of acid sites on the hybrid catalysts should be theoretically 50% lower than the bare zeolites. Instead, the NH3 uptake on the hybrid catalysts appeared even higher than that expected, evidently prompted by water released during catalyst activation/reduction which promotes formation of new strong acid sites on charged metal clusters.

TEM images shown in Fig. 2 clearly display the structural differences among the investigated catalysts. In fact, the procedure adopted for the preparation of the hybrid samples show the existence of metal-oxide clusters of copper-zinc-zirconium (ranging from 5 to 20 nm) well homogenised along the structure of the zeolite. In particular, in the case of OX/MFI, OX/FER catalysts, with a larger size, the metal oxides are randomly deposited over the external surface of the zeolite, evidencing a minor interdispersion among the active sites.

Moreover, when the pore size in the catalysts increases (as for OX/Y), a core-shell type structure is well visible, with a core of Cu–Zn–Zr metal-oxides and an outer shell composed by the zeolite.

The activity pattern over the investigated hybrid catalysts is reported in Fig. 3 as a function of the time on stream at 30 bar and 260°C. No hydrocarbons or coke have been found on the used catalysts under the adopted experimental conditions, the only C-containing products resulting DME, methanol and CO.

From a first analysis, the results show that, with the exception of the OX/Sil-1 catalyst, the initial conversion of CO2 is always quite high (>20%), although it tends to decrease over time mainly in the first phase of reaction (TOS = 0–1200 min). Interestingly, the OX/MOR catalyst is the only one that maintains a high conversion of CO2 even after 100 h of reaction (from 23 to 20%). Instead, the conversion decay of the remaining hybrids is clearly more pronounced, with the OX/Y system that shows the largest decrease in activity over time, with a final conversion value below 13%, recording a net decrease of over 9%.

In terms of yield, on OX/Sil-1 there is practically no DME formation, while on the other hybrid catalysts the trend of DME yield (comprised between 3.5 and 8.5%) over time reflects somewhat the decay of CO2 conversion. Only, on OX/Y the observed trend of DME yield is quite flat, suggesting another mechanism upon DME formation. Obviously, this aspect requires further investigation.

Such catalytic behavior may be explained by considering the cooperation among metal-oxide-acid sites. In fact, as the reactivity of the investigated systems seems to be directly related neither to the metal Cu exposure or surface basicity or surface acidity, it emerges that the direct CO2-to-DME hydrogenation on CuZnZr/zeolite hybrid systems is to be considered a multi-site reaction, where a balanced distribution of different sites on catalyst surface becomes determinant. In particular, mordenite (MOR) is a 12-MR zeolite with only one-dimensional channels that evidently favours not only a certain interdispersion among the active sites, leading to a final relatively higher DME productivity, but also a suitable degree of anchorage of metal-oxides over the zeolite structure, determining a better exposition and accessibility of such sites.

The progressive loss of activity was mainly to be correlated to the “negative” role of water formed during catalytic run, leading to a more and more extensive wetting of catalytic sites, that favours the incipient occupation of oxygen vacancies responsible for CO2 activation with a complete blockage of the active sites. Thus, the occupancy of oxygen vacancies by water leads to a weakened activity in methanol dehydration into DME. This does not exclude that the water formed during the reaction can also be absorbed on the acid sites of the sample, but the absence of coke in the spent catalyst suggests it as a minor phenomenon. After that time, the metal-oxygen pairs and zeolite protons, resulting more available, start to drive competitive reaction pathways finally leading to a dynamic equilibrium that, despite a continuous decrease of the CO2 conversion, maintains unchanged the selectivity values of CO, MeOH and DME, as a result of a balance among the reactions of MeOH/DME formation or decomposition from and to CO.

On the light of the best activity-stability behaviour of the MOR-based hybrid system, a definitive assessment of the catalyst performance is better visible looking at DME productivity (STY), reported in Fig. 4.

As displayed, the OX/MOR catalyst features a steady rise of the DME space-time yield with temperature, from 181 (200°C) to a maximum of 559 gDME/Kgcat/h (280°C).

This result prompts new research efforts to design more hydrophobic and stable catalytic systems for the direct CO2-to-DME hydrogenation reaction where the formation of water certainly represents a critical issue.

4 CONCLUSIONS

Zeolites of different topology were synthesized to be used as carriers on which a CuZnZr methanol phase was coprecipitated to get hybrid catalysts useful for direct DME production via CO2 hydrogenation. BET analysis, N2O chemisorption, TPD results and TEM investigations suggested that the zeolite nature (namely Sil-1, MFI, Y, FER, BEA or MOR) and its specific architecture directly affect not only the metallic properties, but also the basic and acid capacity, by exerting a synergetic role during catalytic runs. Among the prepared zeolites, mordenite revealed to be a very efficient carrier for metal-oxide sites, leading to an active and selective hybrid catalyst under the adopted experimental conditions, attaining a very high DME productivity of ca. 600 gDME/Kgcat/h (TR, 280°C; PR, 3.0 MPa). In terms of stability, the progressive blockage of the active sites due to the formation of water during the catalytic experiments was recognized as the primary cause affecting the catalyst stability.

Change history

22 September 2021

An Erratum to this paper has been published: https://doi.org/10.1134/S0965544121090164

REFERENCES

W. Wang, S. P. Wang, X. B. Ma, and J. L. Gong, Chem. Soc. Rev. 40, 3703 (2011).

M. Aresta, A. Dibenedetto, and E. Quaranta, J. Catal. 343, 2 (2016).

G. A. Olah, Angew. Chem. Int. Ed. Engl. 52, 104 (2013).

S. Brynolf, M. Taljegard, M. Grahn, and J. Hansson, Renew. Sust. Energy Rev. 81, 1887 (2018).

S. Kar, J. Kothandaraman, A. Goeppert, and G.K.S. Prakash, J. CO2 Util. 23, 212 (2018).

H. H. Shin, L. Lu, C. J. Yang, et al., ACS Catal. 6, 2811 (2016).

F. Frusteri, L. Frusteri, F. Costa, et al., Appl. Catal., A, 545C, 24 (2017).

Y. Li, Z. Wang, Z. He, et al., Bioresourc. Technol. 295, 122296 (2020).

K. Kobl, L. Angelo, Y. Zimmermann, et al., C. R. Chim. 18, 302 (2015),

J. Graciani, K. Mudiyanselage, F. Xu, et al., Science 345, 546 (2014).

F. Arena, K. Barbera, G. Italiano, et al., J. Catal. 249, 185 (2007).

F. Arena, G. Italiano, K. Barbera, et al., Appl. Catal., A 350, 16 (2008).

F. Arena, G. Italiano, K. Barbera, et al., Catal. Today 143, 80 (2009),

G. Bonura, M. Cordaro, C. Cannilla, et al., Appl. Catal., B 152–153, 152 (2014).

G. Bonura, A. A. Khassin, T. M. Yurieva, et al., Catal. Today (2018). https://doi.org/10.1016/j.cattpd.2018.10.038

G. Bonura, C. Cannilla, L. Frusteri, et al., Catal. Today. (2019). https://doi.org/10.1016/j.cattpd.2019.08.014

J. H. He, Q. L. Qian, J. Ma, et al., Angew. Chem., Int. Ed. Engl. 55, 737 (2016).

J. Wei, Q. J. Ge, R. W. Yao, et al., Nat. Commun. 8, 15174 (2017).

R. W. Liu, Z. Z. Qin, H. D. Ji, and T. M. Su, Ind. Eng. Chem. Res. 52, 16648 (2013).

G. Bonura, M. Cordaro, L. Spadaro, et al., Appl. Catal., B 140–141, 16 (2013).

G. Bonura, M. Cordaro, C. Cannilla, et al., Catal. Today 228, 51 (2014).

F. Frusteri, M. Cordaro, C. Cannilla, and G. Bonura, Appl. Catal., B 162, 57 (2015).

F. Frusteri, G. Bonura, C. Cannilla, et al., Appl. Catal., B 176–177, 522 (2015).

G. Bonura, F. Frusteri, C. Cannilla, et al., Catal. Today 277, 48 (2016).

G. Bonura, C. Cannilla, L. Frusteri, et al., Catal. Today 281, 337 (2017).

F. Frusteri, M. Migliori, C. Cannilla, et al., J. CO2 Util. 18, 353 (2017).

E. Catizzone, G. Bonura, M. Migliori, et al., Molecules 23, 31 (2018).

T. Numpilai, T. Witoon, N. Chanlek, et al., Appl. Catal., A 547, 219 (2017),

G. Bonura, M. Migliori, L. Frusteri, et al., J. CO2 Util. 24, 398 (2018).

I. Miletto, E. Catizzone, G. Bonura, et al., Materials 11, 2275 (2018).

E. Catizzone, G. Bonura, M. Migliori, et al., Ann. Chim.–Sci. Mat. 43, 141 (2019).

G. Bonura, C. Cannilla, L. Frusteri, and F. Frusteri, Appl. Catal., A, 544C, 21 (2017).

M. Gentzen, W. Habicht, D. E. Doronkin, et al., Catal. Sci. Technol. 6, 1054 (2016).

C. Tisseraud, C. Comminges, T. Belin, et al., J. Catal. 330, 533 (2015).

O. Martin, C. Mondelli, D. Curulla-Ferre, et al., ACS Catal. 5, 5607 (2015).

K. Kobl, S. Thomas, Y. Zimmermann, et al., Catal. Today 270, 31 (2016).

L. Angelo, M. Girleanu, O. Ersen, et al., Catal. Today 270, 59 (2016).

X. S. Dong, F. Li, N. Zhao, et al., Appl. Catal., B 191, 8 (2016).

E. Catizzone, A. Aloise, M. Migliori, and G. Giordano, Microporous Mesoporous Mater. 243, 102 (2017).

E. Catizzone, A. Aloise, M. Migliori, and G. Giordano, Appl. Catal., A 502, 215 (2015).

A. Corma, J. Catal. 216, 298 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

The original online version of this article was revised: due to a retrospective Open Access order.

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Frusteri, L., Bonura, G., Cannilla, C. et al. Promoting Direct CO2 Conversion to DME over Zeolite-based Hybrid Catalysts. Pet. Chem. 60, 508–515 (2020). https://doi.org/10.1134/S0965544120040076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544120040076