Abstract

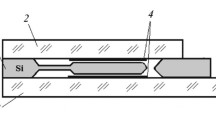

The article presents the features of using the through reactive ion etching of quartz membranes with a thickness of 20 μm or more in the technology of the group manufacturing of pendulums of Q-flex accelerometers. A comparative analysis of the thin-film masking material (aluminum, chromium, titanium, copper, nickel) for the through reactive ion etching of quartz by the selectivity parameters and the temperature stresses introduced into the membrane is carried out. The mechanism of interaction of a copper mask with a fluorine-containing plasma, namely, the formation of copper fluorides on the masking surface and the subsequent increase in the total thickness of the mask with the etching time, are considered. The effect of a local increase in the etching rate of quartz in the region of thermal stresses of the membrane near the masking metal pattern is revealed. To study the effect, a method is developed for decorating a quartz surface with microneedles using an etching mode with an increased bias voltage.

Similar content being viewed by others

REFERENCES

Sagatelyan, G.R., Novoselov, K.L., Shishlov, A.V., and Shchukin, S.A., The application of nanotechnology methods for manufacturing of a plate of a pendulous accelerometer, Inzh. Zh.: Nauka Innov., 2013, no. 6 (18).

Kozlov, D.V., Smirnov, I.P., Korpukhin, A.S., Zapet-lyaev, V.M., and Isakova, G.A., A method of manufacturing a sensitive element of the accelerometer, RF Patent no. 2656109 C1, Byull. Izobret., 2018, no. 16.

Bom, S.Dzh., Optimization of parameters and modeling of operating modes in compensation accelerometers of the Q-flex and Si-flex type, Cand. Sci. (Tech. Sci.) Dissertation, Moscow, 2012.

Jung, H.C., Design and fabrication of microfluidic devices for electrokinetic studies, Master’s Thesis, Ohio: Ohio State Univ., 2008.

Kim, D.W., Lee, H.Y., Park, B.J., Kim, H.S., Sung, Y.J., Chae, S.H., Ko, Y.W., and Yeom, G.Y., High rate etching of 6H-SiC in SF6-based magnetically-enhanced inductively coupled plasmas, Thin Solid Films, 2004, nos. 447–448, pp. 100–104.

Park, J.H., Lee, N.-E., Jaechan Lee, Park, J.S., and Park, H.D., Deep dry etching of borosilicate glass using SF6 and SF6/Ar inductively coupled plasmas, Microelectron. Eng., 2005, no. 82, pp. 119–128.

Chen, H., An investigation into the characteristic of deep reactive ion etching of quartz using SU-8 as a mask, J. Micromec. Microeng., 2008, no. 18, p. 105001-1–8.

Ujile, T., Kikuchi, T., Ichiki, T., and Horiike, Y., Fabrication of quartz microcapillary electrophoresis chips using plasma etching, J. Appl. Phys., 2000, vol. 39, no. 6A, pp. 3677–3682.

Makarchuk, M.V. and Korolev, A.P., Fizika tonkikh plenok: konspekt lektsii (Thin Film Physics, Lecture Course), Tambov: VPO TGTU, 2013.

Abe, T. and Esashi, M., One-chip multi channel quartz crystal microbalance (QCM) fabricated by Deep RIE, Sens. Actuators, 2000, no. 82, pp. 139–143.

Lallement, L. et al., Etching studies of silica glasses in SF6/Ar inductively coupled plasmas: implications for microfluidic devices fabrication, J. Vac. Scl. Technol. A, 2010, vol. 28, no. 2, pp. 277–286.

Dunaev, A.V. and Murin, D.B., Copper etching kinetics in a high-frequency discharge of freon R12, Russ. Microelectron., 2017, vol. 46, no. 4, pp. 261–266.

Youtsey, C., Romano, L.T., and Adesida, I., Gallium nitride whiskers formed by selective photoenhanced wet etching dislocations, Appl. Phys. Lett., 1998, vol. 73, no. 6, pp. 797–799.

Albert, J. et al., Maskless writing of submicrometer gratings in fused silica by focused ion beam implantation and differential wet etching, Appl. Phys. Lett., 1993, vol. 63, p. 11.

Blum, A.E., Yund, R.A., and Lasaga, A.C., The effect of dislocation density on the dissolution rate of quartz, Geochim. Cosmochim. Acta, 1989, vol. 54, pp. 283–297.

Emaletdinov, A.K. and Nurullaev, R.L., The line defects and micromechanisms deformation of amorphous materials, Vestn. TGU, 2003, vol. 8, no. 4, pp. 762–765.

Volynskii, A.L. and Bakeev, N.F., Structural aspects of inelastic strain in glassy polymers, Polymer Sci., Ser. C, 2005, vol. 47, no. 1, p. 74.

Grigor’ev, F.I., Plazmokhimicheskoe i ionno-khimicheskoe travlenie v tekhnologii mikroelektroniki: Uchebnoe posobie (Plasma-Chemical and Ion-Chemical Etching in Microelectronics Technology, The School-Book), Moscow: Mosk. Gos. Inst. Elektron. Mat., 2003.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Abbreviations: MEMS, microelectromechanical systems; LCE, liquid chemical etching; RIE, reactive ion etching; PCE, plasma chemical etching; SEM, scanning electron microscopy; EDS, energy dispersive spectrometry; AFM, atomic force microscopy; TCLE, temperature coefficient of linear expansion.

Rights and permissions

About this article

Cite this article

Kharlamov, M.S., Guseva, O.S. & Konovalov, S.F. Features of the Application of Reactive Ion Etching of Quartz in the Production of Pendulums of Q-Flex Accelerometers. Russ Microelectron 49, 184–194 (2020). https://doi.org/10.1134/S1063739720020055

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739720020055