Abstract—

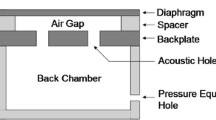

The market for MEMS microphones is growing every year. The aggregate average annual growth rate is 11.7%. This is due to the increase in devices using voice control, the increase in the number of microphones in smartphones, and the increasing role of MEMS microphones in the Internet of Things. A MEMS microphone consists of a MEMS element for converting acoustic pressure, a preamplification chip, a board with an acoustic inlet, and a cover. The MEMS conversion element is a variable capacitor with polysilicon plates. The main parameters of MEMS microphones are the signal-to-noise (S/N) ratio, non-linear distortion coefficient, and non-uniformity of the amplitude-frequency characteristics. When developing a MEMS microphone, computer simulation is used in the ANSYS software package. Using the ANSYS Mechanical program, the design is calculated and optimized to achieve the necessary sensitivity parameters of the MEMS conversion element. Using electrostatic analysis, the CV characteristics are calculated to determine the active capacitance and collapse voltage of MEMS-CE membranes. The influence of the housing dimensions, position, size and number of acoustic holes, the sizes above the membrane and under membrane volumes of the microphone frequency response is calculated in order to determine the effect of the housing parameters on the MEMS microphone’s characteristics. An experimental prototype of the first domestic MEMS microphone is developed and manufactured at the NPK Technological Center. New designs are being actively designed to improve the technical characteristics of MEMS microphones.

Similar content being viewed by others

REFERENCES

Apple iPhone X—MEMS Microphones Complete Teardown Report 2018. www.businesswire.com/news/ home/20180725005343/en/. Accessed April 3, 2019.

MEMS Microphone Market Outlook to 2024. www.businesswire.com/news/home/20180702005421/ en/MEMS-Microphone-Market-Outlook-2024-Global-2.9. Accessed April 3, 2019.

Godovitsyn, I.V., Generalov, C.C., Polomoshnov, S.A., Syvorotkin, P.A., and Amelichev, V.V., Integrated condenser acoustic pressure transducer for a miniature MEMS-microphone, Nano- Mikrosist. Tekh., 2014, no. 4, pp. 43–50.

Amelichev, V.V. and Il’kov, A.V., Konstruktivno-tekhnologicheskii bazis sozdaniya elektroakusticheskikh preobrazovatelei (Structural and Technological Basis for the Creation of Electro-Acoustic Transducers), Moscow: Tekhnosfera, 2012.

GOST (State Standard) no. R 53576-2009, Microphones, methods for measuring electroacoustic parameters, 2010.

J. Lewis, Microphone specifications explained, Application Note, AN-1112, San Jose, CA, USA: Invensense Inc., 2016. www.invensense.com/wp-content/uploads/ 2015/02/AN-1112-v1.1.pdf. Accessed April 3, 2019.

STMicroelectronics Total Parts for MEMS Microphones. www.st.com/content/st_com/en/product-selector2.html. Accessed April 3, 2019.

Lee, H.H., Finite element simulations with ANSYS workbench 18, SDC Publ., 2018.

Amelichev, V.V., Grigor’ev, D.M., and Reznev, A.A., Finite element modeling of membrane module, Izv. Vyssh. Uchebn. Zaved.,Elektron., 2018, vol. 23, no. 3, pp. 277–284.

Grigor’ev, D.M., Godovitsyn, I.V., Amelichev, V.V., Generalov, S.S., and Polomoshnov, S.A., The use of finite element modeling for calculating the C-V curve of capacitor MEMS microphone, Russ. Microelectron., 2017, vol. 46, no. 6, pp. 396–403.

Grigor’ev, D.M., Godovitsyn, I.V., Amelichev, V.V., and Generalov, S.S., Finite element simulation of frequency response of MEMS-microphone, Russ. Microelectron., 2018, vol. 47, no. 3, pp. 211–216.

Grigor’ev, D.M., Godovitsyn, I.V., Amelichev, V.V., and Il’kov, A.V., The influence of acoustic port parameters on frequency response of MEMS-Microphone, Nano- Mikrosist.Tekh., 2018, vol. 20, no. 8, pp. 491–497.

TDK InvenSense MEMS Microphones (Microphone). https://product.tdk.com/en/search/sw_piezo/mic/ mems-mic/list#pn=*&psts%5B%5D=0&psts%5B%5 D=-20&psts%5B%5D=-10&8snr_nom=72&_l=20&_ p=1&_c=part_no-part_no&_d=0 0. Accessed April 3, 2019.

Anzinger, S., Manz, J., Dehe, A., and Schrag, G., A comb-based capacitive MEMS microphone with high signal-to-noise ratio: modeling and noise-level analysis, in Multidisciplinary Digital Publishing Institute Proceedings, 2017, vol. 1, no. 4, pp. 1–5.

Dehé, A., MEMS microphone innovations towards high signal to noise ratios, in Proceedings of the SPIE Conference on Smart Sensors, Actuators, and MEMS VIII,2017.

Dehé, A., Wurzer, M., Füldner, M., and Krumbein, U., The infineon silicon MEMS microphone, in Proceedings of the AMA Conference,2013, pp. 95–99.

Author information

Authors and Affiliations

Corresponding author

Additional information

Abbreviation: PA microcircuits, preamplification microcircuits; SE, sensor element; AFR, amplitude-frequency response; S/N, signal-to-noise ratio; NDC, coefficient of nonlinear distortion; CE, conversion element.

Rights and permissions

About this article

Cite this article

Grigoriev, D.M., Generalov, S.S., Polomoshnov, S.A. et al. Condenser MEMS Microphone. Russ Microelectron 49, 37–42 (2020). https://doi.org/10.1134/S1063739720010084

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739720010084