Abstract

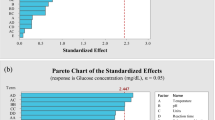

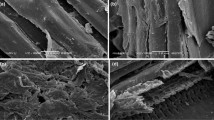

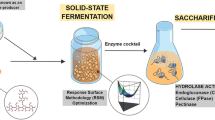

This study focuses on the production of cellulase from a thermophilic bacterium Brevibacillus sp. MT5 and prospects of utilizing the enzyme preparation for the saccharification of sugarcane bagasse (SB). The data revealed that cellulase produced at 70 °C expressed an IFPU (international filter paper unit) of 1.776 when assayed at 60 °C and showed good activity towards SB. Consequently, the conditions affecting saccharification of SB were studied by employing a Plackett–Burman design and reducing sugars were determined by dinitrosalicylic acid method and glucose oxidase kit. The analysis of the design highlighted that the factors affecting the hydrolysis process varies in terms of their significance with respect to the duration of the reaction, however, agitation remained a consistent significant factor throughout the process. Gravimetric analysis displayed a reduction of 49.7 and 22.6% in cellulose content after saccharification of SB from an industry and SB from a fruit juice vendor, respectively. The effect of enzyme action on SB was further visualized by scanning electron microscopy and Fourier transform infra-red spectroscopy that showed increased porosity and a diminished peak for cellulose, indicating degradation of the substrate by the enzyme preparation.

Similar content being viewed by others

Data Availability

Main manuscript and supplementary file contain all the relevant data. The raw dataset can be furnished upon request to the corresponding author.

References

Tariq R, Ansari I, Qadir F et al (2018) Optimization of endoglucanase production from thermophilic strain of Bacillus licheniformis RT-17 and its application for saccharification of sugarcane bagasse. Pak J Bot 50:807–816

Acharya S, Chaudhary A (2012) Bioprospecting thermophiles for cellulase production: a review Brazilian. J Microbiol 43(3):844–856

Hatayama K, Shoun H, Ueda Y, Nakamura A (2014) Brevibacillus fulvus sp. nov., isolated from a compost pile. Int J Syst Evol Microbiol 64:506–512. https://doi.org/10.1099/ijs.0.051052-0

Koutny M, Lemaire J, Delort AM (2006) Biodegradation of polyethylene films with prooxidant additives. Chemosphere 64(8):1243–1252. https://doi.org/10.1016/j.chemosphere.2005.12.060

Narisawa N, Haruta S, Arai H et al (2008) Coexistence of antibiotic-producing and antibiotic-sensitive bacteria in biofilms is mediated by resistant bacteria. Appl Environ Microbiol 74(12):3887–3894. https://doi.org/10.1128/AEM.02497-07

Naseeb S, Sohail M, Ahmad A, Khan SA (2015) Production of xylanases and cellulases by Aspergillus fumigatus MS16 using crude lignocellulosic substrates. Pakistan J Bot 47:779–784

Ejaz U, Muhammad S, Ali FI et al (2019) Methyltrioctylammonium chloride mediated removal of lignin from sugarcane bagasse for themostable cellulase production. Int J Biol Macromol 140:1064–1072. https://doi.org/10.1016/j.ijbiomac.2019.08.206

Arshad M, Ahmed S (2016) Cogeneration through bagasse: A renewable strategy to meet the future energy needs. Renew Sustain Energy Rev 54:732–737. https://doi.org/10.1016/j.rser.2015.10.145

Berezovsky IN, Shakhnovich EI (2005) Physics and evolution of thermophilic adaptation. Proc Natl Acad Sci USA 102(36):12742–12747. https://doi.org/10.1073/pnas.0503890102

Panda AK, Bisht SS, DeMondal S et al (2014) Brevibacillus as a biological tool: A short review. Antonie van Leeuwenhoek, Int J Gen Mol Microbiol 105:623–639. https://doi.org/10.1007/s10482-013-0099-7

Da Silva ASA, Inoue H, Endo T et al (2010) Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour Technol 101(19):7402–7409. https://doi.org/10.1016/j.biortech.2010.05.008

Rabelo SC, da Costa AC, Vaz Rossel CE (2015) Industrial waste recovery. In: Sugarcane: agricultural production, bioenergy and ethanol, pp. 365–381. https://doi.org/10.1016/B978-0-12-802239-9.00017-7

Ejaz U, Ahmed A, Sohail M (2018) Statistical optimization of immobilization of yeast cells on corncob for pectinase production. Biocatal Agric Biotechnol 14:450–456. https://doi.org/10.1016/j.bcab.2018.04.011

Yahya S, Jahangir S, Shaukat SS et al (2016) Production optimization by using plackett-burman design and partial characterization of amylase from Aspergillus tubingensis SY 1. Pakistan J Bot 48:2557–2561

Qadir F, Shariq M, Ahmed A, Sohail M (2018) Evaluation of a yeast co-culture for cellulase and xylanase production under solid state fermentation of sugarcane bagasse using multivariate approach. Ind Crops Prod 123:407–415. https://doi.org/10.1016/j.indcrop.2018.07.021

Rezende CA, De Lima M, Maziero P et al (2011) Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnol Biofuels 4:54. https://doi.org/10.1186/1754-6834-4-54

Kumar RS, Shankar T, Anandapandian KTK, Isaiarasu L (2012) Effect of Bacillus pumilus EWBCM1 whole cell immobilization in various matrices on cellulase enzyme production and saccharification of sugarcane bagasse. Am J Agric Environ Sci 12(1):128–132

Chandel AK, Antunes FAF, Anjos V et al (2014) Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid-base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels 7:63. https://doi.org/10.1186/1754-6834-7-63

Corrales RCNR, Mendes FMT, Perrone CC et al (2012) Structural evaluation of sugar cane bagasse steam pretreated in the presence of CO 2 and SO 2. Biotechnol Biofuels 5:1. https://doi.org/10.1186/1754-6834-5-36

Acknowledgements

The authors are grateful to the Higher Education Commission Pakistan for the grant NRPU 6579 to the MS. Authors also thank to Dr. Firdous from the Department of Chemistry, University of Karachi for rendering TLC and FTIR services available.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khan, M.T., Ejaz, U. & Sohail, M. Evaluation of Factors Affecting Saccharification of Sugarcane Bagasse Using Cellulase Preparation from a Thermophilic Strain of Brevibacillus sp.. Curr Microbiol 77, 2422–2429 (2020). https://doi.org/10.1007/s00284-020-02059-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-020-02059-3