Abstract

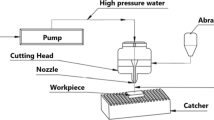

Since fabric-polymer laminates are being used in several engineering applications, it is imperative to compute and analyse the performance of any novel fabric reinforced polymer laminates while machining. Given these perspectives, an endeavor has been made to formulate a polymer sandwich laminate by incorporating industrial by-product & natural fibres and to machine the sandwich laminate using Abrasive Water Jet (AWJ) machining. For enhancing the machining process, a multi-objective optimisation is employed. In this study 2 wt.% fumed silica added epoxy reinforced with linen fabric (3 layers) & jute fabric (2 layers) sandwich laminate is machined using AWJ machining and the optimal combination of machining parameters are predicted using Taguchi-grey relational technique for multi-response characteristics such as Material Removal Rate (MRR) and Kerf Inclination (KI). For multi-response optimisation the traverse speed, the standoff distance, and the abrasive flow rate are considered as input machining parameters. In AWJ machining, the MRR increases with traverse speed and abrasive flow rate. Whereas, passing of higher abrasive particles at higher traverse speed causes reduction in kerf inclination. Using Taguchi-grey relational analysis (GRA), the optimal combination of AWJ machining process parameters for maximum MRR and minimum kerf inclination is attained. For determining the greatest significant parameter in optimisation, ANOVA is carried out. The standoff distance has the highest influence on multi performance characteristics of AWJ machining of laminate followed by traverse speed and abrasive flow rate. The confirmation test revealed that the grey relation grade value has improved by 1.81% from predicted grey relation grade value.

Similar content being viewed by others

References

Baba ZU, Shafi WK, Haq MIU, Raina A (2019) Towards sustainable automobiles-advancements and challenges. Prog Ind Ecol – An International Journal 13(4):315–331. https://doi.org/10.1504/pie.2019.102840

Parthipan N, Ilangkumaran M, Maridurai T, Prasanna SC (2020) Effect of Silane treated silicon (IV) oxide nanoparticle addition on mechanical, impact damage and drilling characteristics of Kenaf fibre-reinforced epoxy composite. Silicon 12:459–467

Kumar R, Ul Haq MI, Raina A, Anand A (2019) Industrial applications of natural fibre-reinforced polymer composites – challenges and opportunities. Int J Sustain Eng 12(3):212–220. https://doi.org/10.1080/19397038.2018.1538267

Pandian A, Jailani S (2019) Development and investigation of jute/linen fibre reinforced polymer composite. SAE technical paper 2019-28-0171. https://doi.org/10.4271/2019-28-0171

Pandian CKA, Jailani HS (2019) Dynamic and vibrational characterization of natural fabrics incorporated hybrid composites using industrial waste silica fumes. Int J Polym Anal Charact 4(8):721–730

Saravanan S, Vijayan V, Suthahar STJ, Balan AV, Sankar S, Ravichandran M (2020) A review on recent progresses in machining methods based on abrasive water jet machining. Mater Today-Proc 21:116–122. https://doi.org/10.1016/j.matpr.2019.05.373

Prajapati HJ, Kumar P, Kumar S, Kant R (2020) Experimental investigation on influence of process parameters of abrasive water jet machining on kerf taper of glass Fiber-reinforced polymer composites. In: Shunmugam MS, Kanthababu M (eds) Advances in unconventional machining and composites, lecture notes on multidisciplinary industrial engineering. Springer, Singapore. https://doi.org/10.1007/978-981-32-9471-4_59

Karataş MA, Motorcu AR, Gökkaya H (2020) Optimization of machining parameters for kerf angle and roundness error in abrasive water jet drilling of CFRP composites with different fiber orientation angles. J Braz Soc Mech Sci 42(4). https://doi.org/10.1007/s40430-020-2261-2

Prabu VA, Kumaran ST, Uthayakumar M (2017) Performance evaluation of abrasive water jet machining on banana fiber reinforced polyester composite. J Nat Fibers 14(3):450–457

Jayakumar K (2017) Abrasive water jet machining studies on kenaf/E-glass fiber polymer composite. Proceedings of International Conference on Precision, Meso, Micro and Nano Engineering 396–399

Jani SP, Kumar AS, Khan MA, Kumar MU (2016) Machinablity of hybrid natural fiber composite with and without filler as reinforcement. Mater Manuf Process 31:1393–1399

Koronis G, Silva A, Foong S (2017) Predicting the flexural performance of woven flax reinforced epoxy composites using design of experiments. Mater Today Commun 13:317–324

Pawade RS, Joshi SS (2011) Multi-objective optimization of surface roughness and cutting forces in high-speed turning of Inconel 718 using Taguchi grey relational analysis (TGRA). Int J Adv Manuf Technol 56:47–62

Kumar PN, Rajadurai A, Muthuramalingam T (2018) Multi-response optimization on mechanical properties of silica fly ash filled polyester composites using Taguchi-Grey relational analysis. Silicon 10:1723–1729

Manickam C, Kumar J, Athijayamani A, Karthik K (2015) Modeling and multiresponse optimization of the mechanical properties of roselle fiber-reinforced vinyl ester composite. Polym–Plast Technol 54(16):1694–1703

Navaneethakrishnan S, Athijayamani A (2017) Taguchi method for optimization of fabrication parameters with mechanical properties in sisal fibre–vinyl ester composites. Aust J Mech Eng 15(2):74–83

Pattanaik A, Satpathy MP, Mishra SC (2016) Dry sliding wear behavior of epoxy fly ash composite with Taguchi optimization. Eng Sci Technol 19(2):710–716

Kalirasu S, Rajini N, Jappes JTW, Uthayakumar M, Rajesh S (2015) Mechanical and machining performance of glass and coconut sheath fibre polyester composites using AWJM. J Reinf Plast Compos 34:564–580

Pandian CKA, Jailani HS, Rajadurai A (2017) Natural fabric sandwich laminate composites: development and investigation. Bull Mater Sci 40:139–146

Pandian CKA, Jailani HS (2018) Investigation of viscoelastic attributes and vibrational characteristics of natural fabrics-incorporated hybrid laminate beams. Polym Bull 75:1997–2014

Tarrío-Saavedra J, López-Beceiro J, Naya S, Artiaga R (2008) Effect of silica content on thermal stability of fumed silica/epoxy composites. Polym Degrad Stab 93(12):2133–2137

Kalirasu S, Rajini N, Rajesh S, Jappes JTW, Karuppasamy K (2017) AWJM performance of jute/polyester composite using moora and analytical models. Mater Manuf Process 32(15):1730–1739

Wang J (1999) A machinability study of polymer matrix composites using abrasive water jet cutting technology. J Mater Process Technol 94(1):30–35

Tsao CC (2009) Grey–Taguchi method to optimize the milling parameters of aluminum alloy. Int J Adv Manuf Technol 40(1–2):41–48

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandian, C.K.A., Jailani, H.S. Linen Fabric-Jute Fabric-Fumed Silica-Epoxy Sandwich Laminate: AWJ Machining and Multi-Response Optimisation. Silicon 13, 1239–1248 (2021). https://doi.org/10.1007/s12633-020-00515-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00515-0