Abstract

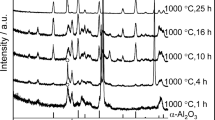

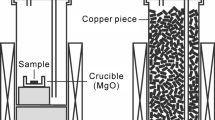

On-site analysis of the composition, morphology, and thickness of surface scale on heat-resistant alloys helps to efficiently prevent serious problems such as failure and corrosion during their operation and to predict their remaining life. Currently, there are no analytical methods available that satisfy the requirements for the on-site analysis of oxide scale, which include short measurement time, nondestructive measurement, and portability of the analyzer. This study proposes a nondestructive analytical method to simultaneously identify alumina scale, which is one the most important protective oxide scales for base alloys, and to evaluate its morphology and thickness within 10 s by obtaining X-ray-excited optical luminescence (XEOL) images of the alloy surfaces. This was verified on Fe–25%Al, Fe–15%Al–10%Cr, and NiAl alloys heated at 900 or 1000 °C for different holding times. The XEOL images allow identifying alumina scale and observing its morphology from the infrared luminescence at 695 nm. The alumina scale thickness can be determined from the R value of the XEOL images in the range of 0.20–1.50 μm. The XEOL measurement can be performed in the air, and the setup primarily requires a digital camera and an X-ray tube used in portable analyzers such as X-ray fluorescence analyzer. The results suggest that the XEOL imaging method is suitable for the on-site evaluation of oxide scales on practical heat-resistant alloys.

Similar content being viewed by others

References

H. Hindam and D. P. Whittle, Oxidation of Metals18, 245 (1982).

F. H. Stott, G. C. Wood and J. Stringer, Oxidation of Metals44, 113 (1995).

D. J. Young, High Temperature Oxidation and Corrosion of Metals, vol. 1, (Elsevier, Amsterdam, 2016).

P. Kofstand, High Temperature Corrosion, (Elsevier, London, 1988).

K. Loeffel, L. Anand and Z. M. Gasem, Acta Materialia61, 399 (2013).

S. Chevalier, in Shreir’s Corrosion, eds. R. A. Cottis, et al. (Elsevier, Amsterdam, 2010), p. 132.

C. A. C. Sequeira, High Temperature Corrosion: Fundamentals and Engineering, (Wiley, Hoboken, 2019).

H. Chen, M. M. Rogalski and J. N. Anker, Physical Chemistry Chemical Physics14, 13469 (2012).

D. Benza, U. Uzair, Y. Raval, T. J. Tzeng, C. J. Behrend, and J. N. Anker, in Proceedings of SPIE—The International Society for Optical Engineering (2017), p. 10081.

M. K. Burdette, et al., Langmuir35, 171 (2019).

W. Fan, et al., Advanced Materials31, e1806381 (2019).

M. Udayakantha, P. Schofield, G. R. Waetzig and S. Banerjee, Journal of Solid State Chemistry270, 569 (2019).

W. Sun, Z. Zhou, G. Pratx, X. Chen and H. Chen, Theranostics10, 1296 (2020).

S. Imashuku and K. Wagatsuma, Corrosion Science154, 226 (2019).

C. Houngniou, S. Chevalier and J. P. Larpin, Oxidation of Metals65, 409 (2006).

Z. G. Zhang, F. Gesmundo, P. Y. Hou and Y. Niu, Corrosion Science48, 741 (2006).

G. Y. Lai, High-Temperature Corrosion and Materials Applications, (ASM International, Novelty, 2007).

B. A. Pint, in Shreir’s Corrosion, eds. R. A. Cottis, et al. (Elsevier, Amsterdam, 2010), p. 606.

S. Imashuku, K. Ono and K. Wagatsuma, Microscopy and Microanalysis23, 1143 (2017).

S. Imashuku and K. Wagatsuma, X‐Ray Spectrometry48, 522 (2019).

S. Imashuku and K. Wagatsuma, Metallurgical and Materials Transactions B (2020): submitted.

S. Imashuku, K. Ono, R. Shishido, S. Suzuki and K. Wagatsuma, Materials Characterization131, 210 (2017).

S. Imashuku, H. Tsuneda and K. Wagatsuma, Metallurgical and Materials Transactions B51B, 28 (2020).

S. Imashuku and K. Wagatsuma, Minerals Engineering151, 106317 (2020).

S. Imashuku and K. Wagatsuma, Oxidation of Metals93, 175 (2019).

S. Imashuku, H. Tsuneda and K. Wagatsuma, Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy229, 117952 (2020).

S. Imashuku and K. Wagatsuma, Metallurgical and Materials Transactions B.51B, 79 (2020).

K. Sato, S. Shimada, H. Toyoda, T. Yanai and N. Hori, Journal of The Remote Sensing Society of Japan36, 131 (2016).

B. G. Yacobi, and D. B. Holt, in Cathodoluminescence Microscopy of Inorganic Solids (New York: Plenum Press; 1990), p. 151.

Q. Wen, D. M. Lipkin and D. R. Clarke, Journal of the American Ceramic Society81, 3345 (1998).

L. Shen, C. Hu, S. Zhou, A. Mukherjee and Q. Huang, Optical Materials35, 1268 (2013).

A. Rastorguev, M. Baronskiy, A. Zhuzhgov, A. Kostyukov, O. Krivoruchko and V. Snytnikov, RSC Advances5, 5686 (2015).

Acknowledgements

This work was supported by Iketani Science and Technology Foundation (Grant No. 0311066-A). We thank Dr. Nagasako for preparing NiAl alloy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Imashuku, S., Wagatsuma, K. X-ray-Excited Optical Luminescence Imaging for On-Site Analysis of Alumina Scale. Oxid Met 94, 27–36 (2020). https://doi.org/10.1007/s11085-020-09976-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09976-5