Abstract

Formation of the honeycomb-like electrodes of copper by the regime of reversing current (RC) in the second range has been investigated. Morphological and structural characteristics of this electrode type obtained by various parameters of RC regimes were examined by the techniques of scanning electron and optical microscopies, while the amount of hydrogen produced during electrodeposition process was quantified by determination of the average current efficiency for hydrogen evolution reaction. To optimize the process of formation of the honeycomb-like electrodes, the following parameters of square wave RC regimes were analyzed: the cathodic current density, the same anodic to cathodic time ratios but various durations of the cathodic and the anodic pulses, and the various values of the anodic to cathodic time ratios. The minimal amount of hydrogen spent for formation of the honeycomb-like electrodes with maximal number of holes formed from detached hydrogen bubbles is obtained with the anodic to cathodic time ratio of 0.50 and duration of the cathodic and anodic pulses of 2 and 1 s, respectively. To explain formation of the honeycomb-like electrodes of optimal morphological and structural characteristics, the upgraded mathematical model defining the RC regime in the second range was proposed and discussed.

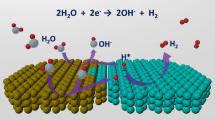

Graphical Abstract

Similar content being viewed by others

Introduction

The honeycomb-like or the 3D foam structures formed by electrolysis represent a relatively new type of metal electrodes which investigation has been extensively commenced by the beginning of this century [1,2,3]. The advantage of these 3D electrodes relative to 2D ones is its very developed surface area achieved by simultaneous processes of metal electrodeposition and vigorous hydrogen evolution, making them very suitable for application in batteries, sensors, and fuel cells. The method of formation of the honeycomb-like or the 3D foam structures is known as gas bubble dynamic template method or dynamic hydrogen bubble template (DHBT) method where hydrogen bubbles generated by electrodeposition in the hydrogen co-deposition range act as dynamic template around which metal electrodeposition occurs [4,5,6]. Thinking to electrolytically generated hydrogen bubbles, morphology of the honeycomb-like structures is determined by holes formed from detached hydrogen bubbles and dendrites or cauliflower-like particles around them. Almost all metals which can be electrodeposited from aqueous electrolytes can be produced in the honeycomb-like form. Some of technologically important metals obtained in the form of the honeycomb-like or the 3D foam structures are Cu [1, 3, 5, 7,8,9,10,11,12], Ni [13,14,15], Ag [16, 17], Au [18], Pd [19], Pt [20], Ru [21], Pb [22], etc. These structures can be also obtained by molten salt electrolysis [23, 24]. Although both potentiostatic and galvanostatic regimes of electrolysis can be used for their production, galvanostatic regime is more important than potentiostatic from point of view of commercial application.

The surface area of the honeycomb-like structure is determined by the number and size of holes, and distances among them (or so-called wall width) [7]. Regarding the strong effect of evolved hydrogen on morphological and structural characteristics of the honeycomb-like electrodes, the largest challenges in their development for commercial application lie in an increase of number of holes formed from detached hydrogen bubbles and in an improvement of their structural stability. In the case of copper, the increase of number of holes is achieved either by an addition of additives to electrodeposition baths, such as acetic acid [7], chloride ions [7], (NH4)+, polyethylene glycol, and 3-mercapto-1-propane sulfonic acid [25] or by application of periodically changing regimes of electrolysis in the millisecond range, such as pulsating [26,27,28,29] and reversing current [29, 30] regimes. Simultaneously, the significant improvement of the structural stability was achieved by application of the regimes of pulsating (PC) and reversing currents (RC) [28, 30]. This is attained by a decrease of amount of evolved hydrogen spent for formation of the honeycomb-like structures with maximal number of the holes. Also, energy saving in formation of the honeycomb-like structures can be realized by application of the PC regime [28]. The increase of the surface area, improvement of the structural stability, and energy savings just make periodically changing regimes of electrolysis very suitable for the formation of the honeycomb-like structures.

From all periodically changing regimes of electrolysis, the reversing current is the only regime used in the second range [5]. This fact makes this regime suitable for commercial application, owing to lower price and easier construction of pulse rectifiers in the second mode from those working in the millisecond mode. The first investigation of the formation of the honeycomb-like structures by the RC regime in the second range has been performed recently [31]. It was shown that the mechanism of formation of this structure type was completely different from that in the millisecond range. In the millisecond range, electrodeposition process always occurs at the average current density, and morphological and structural characteristics of the honeycomb-like structures are just determined by this current value. On the other hand, an effective time of electrodeposition in the hydrogen co-deposition range during the cathodic pulses determines the same characteristics of the honeycomb-like structures obtained by electrodeposition by the RC regime in the second range.

In this study, regarding the high potential of the RC regime in the second range on the formation of technologically important honeycomb-like or the 3D foam structures, we continue an investigation of formation of these structures with the aim to find conditions enabling formation of the honeycomb-like structures of maximal surface area and the improved structural stability. For that reason, various parameters of this regime, such as the cathodic current density values, the anodic to cathodic time ratios, and the same anodic to cathodic time ratios but attained by various durations of the cathodic and the anodic pulses, will be investigated.

Experimental

Copper was electrodeposited from 0.15 M CuSO4 in 0.50 M H2SO4 in open cell at a temperature of 21.0 ± 0.50 °C under the following conditions:

-

(I)

jc = 240 mA cm−2, ja = 80 mA cm−2, tc = 10 s, ta = 5 s,

-

(II)

jc = 320 mA cm−2, ja = 80 mA cm−2, tc = 10 s, ta = 5 s,

-

(III)

jc = 400 mA cm−2, ja = 80 mA cm−2, tc = 10 s, ta = 5 s,

-

(IV)

jc = 320 mA cm−2, ja = 80 mA cm−2, tc = 2 s, ta = 1 s,

-

(V)

jc = 320 mA cm−2, ja = 80 mA cm−2, tc = 20 s, ta = 10 s,

-

(VI)

jc = 320 mA cm−2, ja = 80 mA cm−2, tc = 10 s, ta = 2 s, and

-

(VII)

jc = 320 mA cm−2, ja = 80 mA cm−2, tc = 10 s, ta = 6.7 s.

The p.a. reagents and ultra pure water were used for a preparation of the electrolyte. The working and counter electrodes were of copper. The working electrode was the cylindrical shape of the surface area of 0.25 cm2 and positioned in the middle of the cell. The counter electrode was in the form of foil situated close to wall of the cell. The honeycomb-like structures were produced with a deposition charge of 10 mA h cm−2.

Morphology of the obtained deposits was examined by a scanning electron microscope (SEM) using Tescan Digital Microscopy - model VEGA3.

Cross-sectional analysis was performed using an optical microscope (Olympus CX41) connected to the computer. Preparation of the samples for cross-sectional analysis is described elsewhere [30].

The average current efficiency of hydrogen evolution, ηI,av(H2), values were determined using an electrolytic cell with the same arrangement of Cu electrodes as that used for the preparation of Cu deposits for morphological and structural analyses. In this case, the electrodes were situated under a burette with the surface facing up so that the total amount of electrolytically generated hydrogen went into the burette.

The current efficiency for hydrogen evolution reaction in a time ti, ηI,i(H2), in %, is presented by Eq. (1):

where

and neF is the number of Faradays per mole of consumed ions, V is the molar volume of a gas at a temperature of 21.0 °C (i.e., 24120 cm3), S0 is the surface of working electrode, and jc is the cathodic current density in the RC regimes.

The average current efficiency of hydrogen evolution, ηI,av(H2), is determined after graphical integration ηI,i(H2) − t as \( {\eta}_{\mathrm{I},\mathrm{av}}\left({\mathrm{H}}_2\right)=\left(1/t\right)\underset{0}{\overset{t}{\int }}{\eta}_{\mathrm{I},\mathrm{i}}\left({\mathrm{H}}_2\right)\mathrm{d}t \).

Results and discussion

Basic facts and the determination of the average current efficiency for hydrogen evolution reaction (ηI,av(H2))

The reversing current (RC) regime consists of periodic repetition of square wave cathodic and anodic pulses and is defined in Eq. (3) [5]:

In Eq. (3), jav is the average current density, jc is the cathodic current density, ja is the anodic current density, and tc and ta are durations of the cathodic and the anodic pulses, respectively.

Equation (3) can be given in the form of Eq. (4):

where r is the anodic to cathodic time ratio, and is defined by Eq. (5):

The RC regime in the second range gives optimal results for tc/ta ratios between 1.5 and 5 [5], i.e., for r ratios between 0.67 and 0.20.

Since formation of the honeycomb-like structures occurs deep in the hydrogen co-deposition range, the current efficiency for Cu electrodeposition is less than 1, and Eq. (4) can be given in the form of Eq. (6) as [30, 31]:

where jav* is the average current density when electrodeposition of Cu occurs parallel with hydrogen evolution, and ηI,c (Cu) is the current efficiency for Cu electrodeposition during the cathodic pulses.

During electrodeposition process, hydrogen evolution occurs during the cathodic pulses, while there is no any gas evolution during anodic pulses [30, 31]. Figure 1 shows the dependencies of volume of hydrogen generated during the cathodic pulses on electrolysis time for the honeycomb-like structures obtained with the cathodic current density, jc, values of 240 and 400 mA cm−2 (Fig. 1a), for the same anodic to cathodic time ratios (r = 0.50) but various durations of both the cathodic and the anodic pulses (Fig. 1b), and for various values of r, i.e., with r of 0.20 and 0.67 (Fig. 1c). The average values of the current efficiency for hydrogen evolution reaction, ηI,av(H2), are determined by graphical integration of the obtained dependencies ηI,i(H2) − t as, \( {\eta}_{\mathrm{I},\mathrm{av}}\left({\mathrm{H}}_2\right)=\left(1/t\right)\underset{0}{\overset{t}{\int }}{\eta}_{\mathrm{I},\mathrm{i}}\left({\mathrm{H}}_2\right)\mathrm{d}t \) and presented in Table 1.

The dependencies of the volume of evolved hydrogen and the current efficiency of hydrogen evolution on the time of electrodeposition obtained by various RC regimes: (a) jc = 240 mA cm−2 and jc = 400 mA cm−2, (b) tc = 2 s; ta = 1 s, and tc = 20 s; ta = 10 s, and (c) tc = 10 s; ta = 2 s, and tc = 10 s; ta = 6.7 s

Intensification of hydrogen evolution reaction occurred with the increase of the cathodic current density from 240 to 400 mA cm−2, and with the decrease of the anodic to cathodic time ratios from 0.67 to 0.20 (i.e., for the decrease of the length of anodic pulse from 6.7 to 2 s for the same length of the cathodic pulse of 10 s). It is interesting to note by analysis of data from Table 1 that the values of ηI,av(H2) obtained for the same r but with various lengths of the cathodic and the anodic pulses were different, indicating the strong effect of the anodic to the cathodic time ratios on hydrogen evolution reaction. At the first sight, it was very surprising and requires additional analysis, what will be performed later.

Morphological and structural analysis of the honeycomb-like structures obtained by various RC regimes

Figure 2 shows morphologies of Cu deposits obtained with the cathodic current density values of 240 (Fig. 2a), 320 (Fig. 2b), and 400 mA cm−2 (Fig. 2c). Although the honeycomb-like structures, determined by holes formed from the detachment of hydrogen bubbles and cauliflower-like agglomerates of Cu grains around them, were formed with all three the RC regimes, deeper analysis performed at the higher magnifications showed a difference among them. This difference was especially visible in size and shape of holes formed from detached hydrogen bubbles. The numbers of holes formed from detached hydrogen bubbles were 125 ± 5, 215 ± 5, and 200 ± 5 holes/mm2 surface area for the honeycomb-like structures obtained with jc of 240, 320, and 400 mA cm−2, respectively.

The honeycomb-like structure with an average hole size of 110 μm (Fig. 3a) and small dendrites at its bottom (Fig. 3b) was formed with jc of 240 mA cm−2. The hole size decreases with the increasing jc, reaching a value of 75 μm for the honeycomb-like structures obtained with jc of 320 and 400 mA cm−2 (Fig. 3 c and d, respectively). The numerous small cauliflower-like agglomerates of Cu grains were formed at the bottom of these holes (Fig. 3e). As a result of intensification of hydrogen evolution caused by the increased jc value, an enhanced coalescence of neighboring hydrogen bubbles was observed, as shown in Fig. 3f. The size of the coalesced holes was about 90 μm, and it was for about 20% larger than individual (non-coalesced) holes. The coalescence process is a just reason of smaller number of holes formed with jc of 400 mA cm−2 than with jc of 320 mA cm−2. The values of number and size of holes obtained for these, as well as all other electrodeposition conditions, are summarized in Table 2.

The honeycomb-like structures obtained with jc of 320 mA cm−2 and the same r (r = 0.5), but with various durations of the cathodic and the anodic pulses, are shown in Fig. 4. The honeycomb-like structure obtained with tc of 2 s and ta of 1 s is shown in Fig. 4a, while the one obtained with tc of 20 s and ta of 10 s is shown in Fig. 4b. The number of formed holes was 225 ± 5 holes/mm2 surface area for the honeycomb-like structure obtained with tc of 2 s and ta of 1 s, and 150 ± 5 holes/mm2 surface area for the one obtained with tc of 20 s and ta of 10 s.

The typical hole obtained with tc of 2 s and ta of 1 s is shown in Fig. 4c. The hole size was approximately same as those obtained with tc of 10 s and ta of 5 s (Fig. 3c). The small cauliflower-like agglomerates of Cu grains are formed at the bottom of holes obtained with this RC regime (Fig. 4d). On the other hand, analysis of holes obtained with tc of 20 s and ta of 10 s showed that the formed holes were larger than those obtained with tc of 2 s and ta of 1 s, and tc of 10 s and ta of 5 s. The size of holes obtained with tc of 20 s and ta of 10 s was about 95 μm, as seen from Fig. 4e. The small cauliflower-like agglomerates of Cu grains, similar to those shown in Fig. 4d, were also formed at the bottom of these holes. The noticeable coalescence of neighboring hydrogen bubbles is observed leading to a decrease of the overall number of holes formed with tc of 20 s and ta of 10 s relative to the numbers of holes formed with tc of 10 s and ta of 5 s, and tc of 2 s and ta of 1 s. The typical coalesced hole obtained with tc of 20 s and ta of 10 s is shown in Fig. 4f. On the other hand, the coalesced process was almost suppressed with tc of 2 s and ta of 1 s, causing formation of the honeycomb-like structures with the larger number of holes.

The honeycomb-like structures obtained with r of 0.20 and 0.67 are shown in Fig. 5 a and b, respectively. The number of holes formed from detached hydrogen bubbles was 200 ± 5 holes/mm2 surface area for the honeycomb-like structure obtained with r of 0.20 and 170 ± 5 holes/mm2 surface area for the honeycomb-like structure obtained with r of 0.67. Holes constructing the honeycomb-like structure produced with r of 0.20 were very disperse in size with a dominant presence of coalesced holes (Fig. 5a). The size of holes changed from 65 μm (Fig. 5c) for individual to 90 μm (Fig. 5d) for those obtained by a coalescence of neighboring hydrogen bubbles. The bottom of these holes consisted of small cauliflower-like agglomerates of Cu grains (Fig. 5e). The smaller number of larger holes was formed with r of 0.67 (Fig. 5b). The size of the holes obtained under these RC conditions was up to 100 μm (Fig. 5f). The mixture of small cauliflower-like and dendritic particles was formed at the bottom of these holes (Fig. 5g).

Figure 6 shows the cauliflower-like agglomerates of Cu grains formed around holes obtained with jc of 240 (Fig. 6a) and 400 mA cm−2 (Fig. 6b), tc = 2 s and ta = 1 s (Fig. 6c), tc = 20 s and ta = 10 s (Fig. 6d), r of 0.2 (Fig. 6e) and 0.67 (Fig. 6f). Unlike size and shape of holes, it is very clear that the applied RC regimes do not affect morphology of cauliflower-like agglomerates of Cu grains formed around them. Numerous irregular channels originating from evolved hydrogen were also formed around small agglomerates inside the large cauliflower-like agglomerates of Cu grains.

Cross-sectional analysis of the obtained structures showed that the depth of holes did not depend on the applied parameters of the RC regimes (Fig. 7). In all cases, the depth of holes was about 100 μm. This can be ascribed to fact that dissolution effect is primarily determined by the anodic current density value, while an influence of length of anodic pulse was less significant. Namely, the anodic current density was 80 mA cm−2 in all applied RC regimes. The very porous interior structure constructed from numerous intertwined channels, not dependent on the applied RC regime, was also observed.

Discussion of the presented results

Analyzing the effect of the anodic current density values on the formation of the honeycomb-like structures, it was shown recently [31] that this structure type obtained with jc of 320 mA cm−2, ja of 80 mA cm−2, tc of 10 s, and ta of 5 s showed the maximum surface area determined by the number and size of holes. This honeycomb-like structure was obtained with the average current efficiency of hydrogen evolution (ηI,av(H2)) of 20.5% [31]. As already mentioned, the honeycomb-like structures were formed with both smaller (jc = 240 mA cm−2) and larger (jc = 400 mA cm−2) value than this jc value (jc = 320 mA cm−2). It is understandable because cathodic potential responses of 1060–1150 mV for 240 mA cm−2, 1150–1250 mV for 320 mA cm−2, and 1180–1280 for 400 mA cm–2 were all deep in the hydrogen co-deposition range enabling formation of deposits with the honeycomb-like structure. The final morphological and structural characteristics of the honeycomb-like electrodes were determined by the other parameters defining this regime, such as duration of the anodic pulse (various r) and the same r, but with various durations of the cathodic and the anodic pulses.

The increase of ηI,av(H2), i.e., intensification of hydrogen evolution reaction with increasing the jc values, as well as with decreasing ta values is expected. However, the dependence of volume of evolved hydrogen, and hence ηI,av(H2) values, on the anodic to cathodic time ratios (r) was unexpected, and for that reason, it required additional analysis of the RC regime in the second range on the process of formation of the honeycomb-like structures in the hydrogen co-deposition range, and it can be considered as follows:

The first cathodic pulse with cathodic potential response deep in the hydrogen co-deposition range represents a template for a formation of the honeycomb-like structures. The dissolution process only occurs during anodic pulses, and the value of anodic potential response is exclusively determined by the anodic current density value [31]. For an anodic current density, ja of 80 mA cm−2, anodic potential response was in the 108–122 mV range. Starting from the second cathodic pulse, the initial cathodic potential response corresponds to the final anodic potential response, and it increases with time reaching the value in the hydrogen co-deposition range after some time. The time needed to reach the value in the hydrogen co-deposition range is denoted with tc,est, and during this time there is no hydrogen evolution. Since the value of the anodic potential response is only determined by the anodic current density value, the value of this part of the cathodic pulse does not depend on overall duration of the cathodic pulse, and for ja of 80 mA cm−2, tc,est is 0.82 s [31]. The rest of the cathodic pulse, denoted with tc,eff, corresponds to electrodeposition in the hydrogen co-deposition range, since tc,est + tc,eff = tc. For better understanding, this is schematically presented in Fig. 8 for the same r, but various tc and ta values.

Schematic presentation of electrodeposition processes by the RC regime in the second range. The same anodic to cathodic time ratio, but various durations of the cathodic and the anodic pulses. In both cases, tc,est is the same: (a) the longer durations of the cathodic and the anodic pulses, and (b) the shorter durations of the cathodic and the anodic pulses

Regarding this consideration, a correction of Eq. (6) is necessary on the way presented by Eq. (7):

where n is number of the cycles starting from the second cycle. Equation (7) can be re-written in the form:

i.e.,

where

and

and

Hence, \( {j}_{\mathrm{av},\mathrm{I}}^{\ast } \) is the average current density in the hydrogen co-deposition range during the first cycle. \( {j}_{\mathrm{av},\mathrm{eff}}^{\ast } \) is the average current density in the hydrogen co-deposition range during the n cycles starting from the second cycle, and \( {j}_{\mathrm{av},\mathrm{est}}^{\ast } \) is the average current density during the n cycles starting from the second cycle in which there is no hydrogen evolution.

The final morphology of the honeycomb-like structure is determined by contribution of these three average current densities. The length of one cycle is defined by the duration of the cathodic and the anodic pulse, and for the same deposition charge, the overall number of cycles is different for the same r. All surface morphologies presented in this investigation are obtained with a deposition charge of 10 mA h cm−2. Hence, for the same r of 0.50, the numbers of cycles to reach this amount of the electricity were 56 for tc/ta = 2 s/1 s, 11 cycles for tc/ta = 10 s/5 s, and 6 cycles for tc/ta = 20 s/10 s.

Formation of the honeycomb-like structure occurs during the first cathodic pulse, since the lengths of the cathodic pulses in all three cases were enough to initiate a formation of this structure type. Since time needed to reach electrodeposition in the hydrogen co-deposition range is only determined by the value of the anodic current density and it does not depend on the length of the cathodic pulse (in these cases, tc,est = 0.82 s [31]), a contribution of \( {j}_{\mathrm{av},\mathrm{est}}^{\ast } \) increases with increasing the number of cycles. Hence, the contribution of \( {j}_{\mathrm{av},\mathrm{est}}^{\ast } \) grows in the following row: 20 s/10 s < 10 s/5 s < 2 s/1 s. On the other hand, it is easy to show that a contribution of electrodeposition in the hydrogen co-deposition range (\( {j}_{\mathrm{av},\mathrm{eff}}^{\ast } \)) increases in the following row: 2 s/1 s < 10 s/5 s < 20 s/10 s. In this way, the effect of the same anodic to cathodic time ratios (the same r), but various durations of the cathodic and the anodic pulses on formation of the honeycomb-like structures are proved.

On the basis of the abovementioned results, the process of formation of the honeycomb-like structures by the RC regime in the second range can be optimized as follows: the increase of the cathodic current density from 240 to 320 and 400 mA cm−2 intensifies hydrogen evolution reaction. Firstly, the increase of number of holes, and hence the increase of the surface area, was observed with a change of jc from 240 to 320 mA cm−2. The further change of jc from 320 to 400 mA cm−2 led to the decrease of number of holes due to coalescence of closely formed hydrogen bubbles. Analyzing the same r, but various durations of the cathodic and the anodic pulses, the decrease of the amount of evolved hydrogen was found with the shortening of durations of tc and ta. This can be ascribed to a decrease of effective time for deposition in the hydrogen co-deposition range during the cathodic pulses. Hence, the use of shorter tc and ta values represents a benefit in formation of the honeycomb-like structures, since the smaller amount of hydrogen is then generated, resulting in an improvement of their structural stability. The decrease of r (the shorter duration ta for the same tc) intensifies hydrogen evolution reaction leading to a coalescence of neighboring hydrogen bubbles and worsening of the structural stability of the honeycomb-like structures. Finally, the honeycomb-like structure with the maximal number of holes (the largest surface area), and minimal amount of hydrogen spent for its formation is obtained with jc of 320 mA cm−2, ja of 80 mA cm−2, tc of 2 s, and ta of 1 s.

Conclusion

The process of formation of the honeycomb-like structures by the RC regime in the second range is optimized by selection of parameters defining this regime. The following conclusions can be derived:

-

Intensification of hydrogen evolution reaction increases number of holes (the surface area) in the honeycomb-like structures up to a certain value of the cathodic current density (up to jc of 320 mA cm−2). After this value, the number of holes decreased due to enhanced coalescence of closely formed hydrogen bubbles caused by the further intensification of hydrogen evolution reaction with increasing jc value.

-

For the same anodic to cathodic time ratios (r), application of the short cathodic and anodic pulses realizes benefits in the formation of the honeycomb-like structures. Application of the shorter tc and ta values leads to a decrease of the overall time of electrodeposition in the hydrogen co-deposition range. As a result of this, the overall amount of produced hydrogen was smaller than with the longer tc and ta values. The final consequences of applied shorter tc and ta pulses are the improved structural stability and the increased number of holes due to additional suppression of coalescence process.

-

The decreasing r values (the shortening of duration of ta pulse) intensify hydrogen evolution reaction enhancing a coalescence of neighboring hydrogen bubbles, and consequently, decreasing the number of holes formed from detached hydrogen bubbles.

-

The upgraded mathematical model defining the RC regime in the second range in the hydrogen co-deposition range is proposed and discussed.

-

The best performance from morphological and structural point of view showed the honeycomb-like structure produced with jc of 320 mA cm−2, ja of 80 mA cm−2, tc of 2 s, and ta of 1 s.

References

Shin HC, Dong J, Liu M (2003) Nanoporous structures prepared by an electrochemical deposition process. Adv Mater 15(19):1610–1614

Shin HC, Liu M (2005) Three-dimensional porous copper-tin alloy electrodes for rechargeable lithium batteries. Adv Funct Mater 15(4):582–586

Nikolić ND, Popov KI, Pavlović LjJ, Pavlović MG (2006) The effect of hydrogen codeposition on the morphology of copper electrodeposits. I. The concept of effective overpotential. J Electroanal Chem 588:88–98

Plowman BJ, Jones LA, Bhargava SK (2015) Building with bubbles: the formation of high surface area honeycomb-like films via hydrogen bubble templated electrodeposition. Chem Commun 51(21):4331–4346

Popov KI, Djokić SS, Nikolić ND, Jović VD (2016) Morphology of electrochemically and chemically deposited metals. Springer, Berlin

Wang M, Yu X, Wang Z, Guo Z, Dai L (2017) Hierarchically 3D porous films electrochemically constructed on gas-liquid-solid three-phase interface for energy application. J Mater Chem A 5(20):9488–9513

Shin HC, Liu M (2004) Copper foam structures with highly porous nanostructured walls. Chem Mater 16(25):5460–5464

Li Y, Jia W-Z, Song Y-Y, Xia X-H (2007) Superhydrophobicity of 3D porous copper films prepared using the hydrogen bubble dynamic template. Chem Mater 19(23):5758–5764

Zhang W, Ding C, Wang A, Zeng Y (2015) 3-D Network pore structures in copper foams by electrodeposition and hydrogen bubble templating mechanism. J Electrochem Soc 162(8):D365–D370

Singh H, Dheeraj PB, Singh YP, Rathore G, Bhardwaj M (2017) Electrodeposition of porous copper as a substrate for electrocatalytic material. J Electroanal Chem 785:1–7

Rosa-Ortiz SM, Khorramshahi F, Takshi A (2019) Study the impact of CuSO4 and H2SO4 concentrations on lateral growth of hydrogen evolution assisted copper electroplating. J Appl Electrochem 49(12):1203–1210

Nikolić ND, Pavlović LjJ, Pavlović MG, Popov KI (2007) Formation of dish-like holes and a channel structure in electrodeposition of copper under hydrogen co-deposition. Electrochim Acta 52(28):8096–8104

Yu X, Wang M, Wang Z, Gong X, Guo Z (2016) The structure evolution mechanism of electrodeposited porous Ni films on NH4Cl concentration. Appl Surf Sci 360:502–509

Sengupta S, Patra A, Jena S, Das K, Das S (2018) A study on the effect of electrodeposition parameters on the morphology of porous nickel electrodeposits. Metall Mater Trans A 49(3):920–937

Yu X, Yuan Z (2019) The structure evolution mechanism of Ni films depending on hydrogen evolution property during electrodeposition process. Metall Mater Trans B Process Metall Mater Process Sci 50(2):587–594

Cherevko S, Xing X, Chung C-H (2010) Electrodeposition of three-dimensional porous silver foams. Electrochem Commun 12(3):467–470

Cherevko S, Chung C-H (2010) Impact of key deposition parameters on the morphology of silver foams prepared by dynamic hydrogen template deposition. Electrochim Acta 55(22):6383–6390

Cherevko S, Chung C-H (2011) Direct electrodeposition of nanoporous gold with controlled multimodal pore size distribution. Electrochem Commun 13(1):16–19

Cherevko S, Kulyk N, Chung C-H (2012) Nanoporous palladium with sub-10 nm dendrites by electrodeposition for ethanol and ethylene glycol oxidation. Nanoscale 4(1):103–105

Ott A, Jones LA, Bhargava SK (2011) Direct electrodeposition of porous platinum honeycomb structures. Electrochem Commun 13(11):1248–1251

Oppedisano DK, Jones LA, Junk T, Bhargava SK (2014) Ruthenium electrodeposition from aqueous solution at high cathodic overpotential. J Electrochem Soc 161(10):D489–D494

Cherevko S, Xing X, Chung C-H (2011) Hydrogen template assisted electrodeposition of sub-micrometer wires composing honeycomb-like porous Pb films. Appl Surf Sci 257:8054–8061

Cvetković VS, Vukićević NM, Nikolić ND, Branković G, Barudžija TS, Jovićević JN (2018) Formation of needle-like and honeycomb-like magnesium oxide/hydroxide structures by electrodeposition from magnesium nitrate melts. Electrochim Acta 268:494–502

Cvetković VS, Vukićević NM, Nikolić ND, Baščarević Z, Barudžija TS, Jovićević JN (2019) A possible mechanism of formation of flower-like MgO/Mg(OH)2 structures by galvanostatic molten salt electrolysis: the concept of local diffusion fields. J Electroanal Chem 842:168–175

Kim J-H, Kim R-H, H-Sang K (2008) Preparation of copper foam with 3-dimensionally interconnected spherical pore network by electrodeposition. Electrochem Commun 10(8):1148–1151

Nikolić ND, Branković G (2010) Effect of parameters of square-wave pulsating current on copper electrodeposition in the hydrogen co-deposition range. Electrochem Commun 12(6):740–744

Nikolić ND, Branković G, Maksimović VM (2012) Morphology and internal structure of copper deposits electrodeposited by the pulsating current regime in the hydrogen co-deposition range. J Solid State Electrochem 16(1):321–328

Nikolić ND, Branković G, Popov KI (2011) Optimization of electrolytic process of formation of open and porous copper electrodes by the pulsating current (PC) regime. Mater Chem Phys 125(3):587–594

Nikolić ND, Branković G (2012) Comparison of open porous copper structures obtained by the different current regimes of electrolysis. Mater Lett 70:11–15

Nikolić ND, Branković G, Maksimović VM (2011) Effect of the anodic current density on copper electrodeposition in the hydrogen co-deposition range by the reversing current (RC) regime. J Electroanal Chem 661(2):309–316

Berkesi K, Živković PM, Elezović N, Lačnjevac U, Hristoforou E, Nikolić ND (2019) Mechanism of formation of the honeycomb-like structures by the regime of the reversing current (RC) in the second range. J Electroanal Chem 833:401–410

Funding

This work was financially supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia (Grant No. 451-03-68/2020-14/200026).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nikolić, N.D., Živković, P.M., Elezović, N. et al. Optimization of process of the honeycomb-like structure formation by the regime of reversing current (RC) in the second range. J Solid State Electrochem 24, 1615–1624 (2020). https://doi.org/10.1007/s10008-020-04658-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04658-3