Abstract

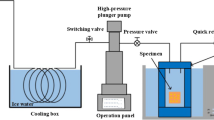

The foaming behavior of poly(ε-caprolactone)/poly (lactic-co-glycolic acid) (PCL/PLGA) blends and the effect of composition on porous structure, compression property and biocompatibility are investigated. Various portions of PLGA are added into matrix PCL at dispersion phase by melt blending. A solid-state batch foaming process is used based on supercritical CO2 as a physical blowing agent. With the PLGA content increased from 5 to 30 wt%, storage modulus and complex viscosity of PCL from rheological tests are improved significantly. Foaming tests reveal that incorporation of PLGA facilitates foaming of PCL by increasing viscosity. With an increase of PLGA content, pore size clearly decreases, and the open–cell content first increases and then decreases slightly. The maximum open-cell content value is greater than 86% for foamed 10 wt% PLGA. Moreover, uni-axial compression testing shows that dispersed PLGA improves the compressive stress distinctly. Cell structure evolutions at linear elasticity, plateau, and densification stages in compression tests are also investigated. Cell viability results demonstrate that there are more and denser live HUVECs detected on scaffold with increase of PLGA content. Compression strength of PCL/PLGA scaffold has more contributions to cell viability than that of porosity and open-cell content.

Similar content being viewed by others

References

Jin F-L, Zhao M, Park M, Park S-J (2019) Recent trends of foaming in polymer processing: a review. Polymers 11(6):953

Jacobsen K, Kragl J (2001) Microcellular foam molding: advantages and application examples. In: Structural Plastics 2001: 29th Annual Conference and New Product Design Competition of SPI's Structural Plastics Division

Kuang T, Chang L, Chen F, Sheng Y, Fu D, Peng X (2016) Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 105:305–313

Okolieocha C, Raps D, Subramaniam K, Altstädt V (2015) Microcellular to nanocellular polymer foams: progress (2004–2015) and future directions–a review. Eur Polymer J 73:500–519

Lv Z, Zhao N, Wu Z, Zhu C, Li Q (2018) Fabrication of novel open-cell foams of poly (ε-caprolactone)/poly (lactic acid) blends for tissue-engineering scaffolds. Ind Eng Chem Res 57(39):12951–12958

Wang X, Salick MR, Gao Y, Jiang J, Li X, Liu F, Cordie T, Li Q, Turng L-S (2018) Interconnected porous poly (ɛ-caprolactone) tissue engineering scaffolds fabricated by microcellular injection molding. J Cell Plast 54(2):379–397

Kuang T, Chen F, Chang L, Zhao Y, Fu D, Gong X, Peng X (2017) Facile preparation of open-cellular porous poly (l-lactic acid) scaffold by supercritical carbon dioxide foaming for potential tissue engineering applications. Chem Eng J 307:1017–1025

Nam YS, Park TG (1999) Biodegradable polymeric microcellular foams by modified thermally induced phase separation method. Biomaterials 20(19):1783–1790

Chen G, Weng W, Wu D, Wu C, Lu J, Wang P, Chen X (2004) Preparation and characterization of graphite nanosheets from ultrasonic powdering technique. Carbon 42(4):753–759

Zhang K, Wang Y, Jiang J, Wang X, Hou J, Sun S, Li Q (2019) Fabrication of highly interconnected porous poly (ɛ-caprolactone) scaffolds with supercritical CO2 foaming and polymer leaching. J Mater Sci 54(6):5112–5126

Livshin S, Silverstein MS (2008) Cross-linker flexibility in porous crystalline polymers synthesized from long side-chain monomers through emulsion templating. Soft Matter 4(8):1630–1638

Chen C, Peng H, Guan Y, Yao S (2019) Morphological study on the pore growth profile of poly (ε-caprolactone) bi-modal porous foams using a modified supercritical CO2 foaming process. J Supercrit Fluids 143:72–81

Chen C, Liu Q, Xin X, Guan Y, Yao S (2016) Pore formation of poly (ε-caprolactone) scaffolds with melting point reduction in supercritical CO2 foaming. J Supercrit Fluids 117:279–288

Kong W-l, Bao J-B, Wang J, Hu G-H, Xu Y, Zhao L (2016) Preparation of open-cell polymer foams by CO2 assisted foaming of polymer blends. Polymer 90:331–341

Shim J-H, Yoon M-C, Jeong C-M, Jang J, Jeong S-I, Cho D-W, Huh J-B (2014) Efficacy of rhBMP-2 loaded PCL/PLGA/β-TCP guided bone regeneration membrane fabricated by 3D printing technology for reconstruction of calvaria defects in rabbit. Biomed Mater 9(6):065006

Thi Hiep N, Chan Khon H, Dai Hai N, Byong-Taek L, Van Toi V, Thanh Hung L (2017) Biocompatibility of PCL/PLGA-BCP porous scaffold for bone tissue engineering applications. J Biomater Sci Polym Ed 28(9):864–878

Xin X, Liu Q, Chen C, Guan Y, Yao S (2016) Fabrication of bimodal porous PLGA scaffolds by supercritical CO2 foaming/particle leaching technique. J Appl Polymer Sci. https://doi.org/10.1002/app.43644

Peng C, Zheng J, Chen D, Zhang X, Deng L, Chen Z, Wu L (2018) Response of hPDLSCs on 3D printed PCL/PLGA composite scaffolds in vitro. Mol Med Rep 18(2):1335–1344

Sánchez-Pech JC, Rosales-Ibáñes R, Cauich-Rodriguez JV, Carrillo-Escalante HJ, Rodríguez-Navarrete A, Avila-Ortega A, Hernández-Sánchez F (2019) Design, synthesis, characterization, and cytotoxicity of PCL/PLGA scaffolds through plasma treatment in the presence of pyrrole for possible use in urethral tissue engineering. J Biomater Appl. https://doi.org/10.1177/0885328219882638

Yoon JJ, Park TG (2001) Degradation behaviors of biodegradable macroporous scaffolds prepared by gas foaming of effervescent salts. J Biomed Mater Res 55(3):401–408

Goimil L, Jaeger P, Ardao I, Gómez-Amoza JL, Concheiro A, Alvarez-Lorenzo C, García-González CA (2018) Preparation and stability of dexamethasone-loaded polymeric scaffolds for bone regeneration processed by compressed CO2 foaming. J CO2 Utilization 24:89–98

Song C, Li S, Zhang J, Xi Z, Lu E, Zhao L, Cen L (2019) Controllable fabrication of porous PLGA/PCL bilayer membrane for GTR using supercritical carbon dioxide foaming. Appl Surf Sci 472:82–92

Naguib HE, Park CB, Lee PC (2003) Effect of talc content on the volume expansion ratio of extruded PP foams. J Cell Plast 39(6):499–511

Kwon Y, Cooke R, Park C (2003) Representative unit-cell models for open-cell metal foams with or without elastic filler. Mater Sci Eng, A 343(1–2):63–70

Yang J, Zhang Y, Zheng S, Huang L, Chen F, Fan P, Zhong M (2014) Probing structure–heterogeneous nucleation efficiency relationship of mesoporous particles in polylactic acid microcellular foaming by supercritical carbon dioxide. J Supercrit Fluids 95:228–235

Fu D, Chen F, Kuang T, Li D, Peng X, Chiu DY, Lin CS, Lee LJ (2016) Supercritical CO2 foaming of pressure-induced-flow processed linear polypropylene. Mater Des 93:509–513

Li R, Yu W, Zhou C (2006) Rheological characterization of droplet-matrix versus co-continuous morphology. J Macromol Sci Part B 45(5):889–898

Wang X, Li Y, Jiao Y, Zhou H, Wang X (2019) Microcellular foaming behaviors of poly (lactic acid)/low-density polyethylene blends induced by compatibilization effect. J Polym Environ 27(8):1721–1734

Zhou H, Zhao M, Qu Z, Mi J, Wang X, Deng Y (2018) Thermal and rheological properties of poly (lactic acid)/low-density polyethylene blends and their supercritical CO2 foaming behavior. J Polym Environ 26(9):3564–3573

Wang X, Mi J, Zhou H, Wang X (2019) Transition from microcellular to nanocellular chain extended poly (lactic acid)/hydroxyl-functionalized graphene foams by supercritical CO2. J Mater Sci 54(5):3863–3877

Qu Z, Yin D, Zhou H, Wang X, Zhao S (2019) Cellular morphology evolution in nanocellular poly (lactic acid)/thermoplastic polyurethane blending foams in the presence of supercritical N2. Eur Polymer J 116:291–301

Zhao J, Wang G, Zhang L, Li B, Wang C, Zhao G, Park CB (2019) Lightweight and strong fibrillary PTFE reinforced polypropylene composite foams fabricated by foam injection molding. Eur Polymer J 119:22–31

Wang G, Zhao G, Zhang L, Mu Y, Park CB (2018) Lightweight and tough nanocellular PP/PTFE nanocomposite foams with defect-free surfaces obtained using in situ nanofibrillation and nanocellular injection molding. Chem Eng J 350:1–11

Li Y, Zhou H, Wen B, Chen Y, Wang X (2019) A Facile and Efficient Method for Preparing Chain Extended Poly (lactic acid) Foams with High Volume Expansion Ratio. J Polym Environ 28:1–15

Sun S, Li Q, Zhao N, Jiang J, Zhang K, Hou J, Wang X, Liu G (2018) Preparation of highly interconnected porous poly (ε-caprolactone)/poly (lactic acid) scaffolds via supercritical foaming. Polym Adv Technol 29(12):3065–3074

Shutov FA (1983) Foamed polymers. Cellular structure and properties. Industrial developments. Springer, Berlin, pp 155–218

Ameli A, Nofar M, Wang S, Park CB (2014) Lightweight polypropylene/stainless-steel fiber composite foams with low percolation for efficient electromagnetic interference shielding. ACS Appl Mater Interfaces 6(14):11091–11100

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Li T, Zhao G, Wang G, Zhang L, Hou J (2019) Thermal-insulation, electrical, and mechanical properties of highly-expanded PMMA/MWCNT nanocomposite foams fabricated by supercritical CO2 foaming. Macromol Mater Eng 304:1800789

Sun M, Chi G, Li P, Lv S, Xu J, Xu Z, Xia Y, Tan Y, Xu J, Li L (2018) Effects of matrix stiffness on the morphology, adhesion, proliferation and osteogenic differentiation of mesenchymal stem cells. Int J Med Sci 15(3):257

Wells RG (2008) The role of matrix stiffness in regulating cell behavior. Hepatology 47(4):1394–1400

Acknowledgements

This work is sponsored by the International Technological Cooperation Project (2015DFA30550), Scientific and technological research project of Henan Province (202102210028, 172102210489), Key scientific research project plan of Henan high education institutions (17A430032) and College students' innovation and entrepreneurship projects of Zhengzhou University (2019cxcy661). Zhengzhou University Doctoral Talent Program for corresponding author is also appreciated.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author declares that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, H., Jiang, J., Li, Z. et al. Solid-State Supercritical CO2 Foaming of PCL/PLGA Blends: Cell Opening and Compression Behavior. J Polym Environ 28, 1880–1892 (2020). https://doi.org/10.1007/s10924-020-01732-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01732-9