Abstract

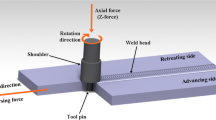

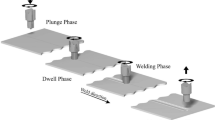

Friction stir welding (FSW) is a solid-state welding technology which is frequently used for welding of thermoplastic and metallic alloys in the automobile and aerospace industries. Polylactic acid (PLA) is a biodegradable thermoplastic polymer. PLA can replace petroleum-based polymer in many applications if the FSW process can be used for welding of PLA-based engineering components. In the present study, FSW process was carried out to join PLA sheets to investigate the influence of input parameters such as tool speed and transverse speed on the tensile strength of the welded specimens using different pin profiles. The tool speeds of 700, 1400, and 2000 rpm and traverse speeds of 20, 30, and 40 mm/min were selected to perform the welding. The pin profiles such as cylindrical, threaded, and conical pins of the tool were used to study their effect on the joint strength and efficiency. Visual inspection of the welded specimens was carried out to find the defects in welding. The temperature that is induced during welding and the load-displacement behavior of the welded specimens were also studied to understand the welding behavior of biodegradable PLA.

Similar content being viewed by others

References

Joost WJ (2012) Reducing vehicle weight and improving US energy efficiency using integrated computational materials engineering. Jom 64(9):1032–1038

Patil A, Patel A, Purohit R (2017) An overview of polymeric materials for automotive applications. Mater Today 4:3807–3815

Shanelec DA (1991) U.S. Patent No. 5,073,444. U.S. Patent and Trademark Office, Washington, DC

Sasaki T, Ito T, Toyota Y, Kumagai N (2010) U.S. Patent No. 7,825,166. U.S. Patent and Trademark Office, Washington, DC

Štrumberger N, Gospočić A, BartulićČn (2005) Polymeric materials in automobiles. Promet-Zagreb 17:149–160

Yang C, Gong C, Peng T, Deng K, Zan L (2010) High photocatalytic degradation activity of the polyvinyl chloride (PVC)-vitamin C (VC)-TiO2 nano-composite film. J Hazard Mater 178:152–156

Rusu D, Boyer SAE, Lacrampe MF, Krawczak P (2011) Bioplastics and vegetal fiber reinforced bioplastics for automotive applications. In: Handbook of bioplastics and biocomposites engineering applications. Wiley, p 397–452

Yousefpour A, Hojjati M, Immarigeon JP (2004) Fusion bonding/welding of thermoplastic composites. J Thermoplast Compos Mater 17:303–341

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer-metal hybrid structures: recent developments and trends. PolymEngSci 49:1461–1476

Mishra D, Sahu SK, Mahto RP, Pal SK., Pal K (2019) Friction stir welding for joining of polymers. In: Strengthening and joining by plastic deformation, Springer, p 123–162

Pirizadeh M, Azdast T, Ahmadi SR, Shishavan SM, Bagheri (2014) A friction stir welding of thermoplastics using a newly designed tool. Mater Des 54:342–347

Sahu SK, Mishra D, Mahto RP, Sharma VM, Pal SK, Pal K, Banerjee S, Dash P (2018) Friction stir welding of polypropylene sheet. EngSciTechnolInt J 21:245–254

Derazkola HA, Simchi (2018) A experimental and thermomechanical analysis of the effect of tool pin profile on the friction stir welding of poly (methyl methacrylate) sheets. J Manuf Process 34:412–423

Inaniwa S, Kurabe Y, Miyashita Y, Hori H (2013) Application of friction stir welding for several plastic materials. In: Proceedings of the 1st International Joint Symposium on Joining and Welding. Woodhead Publishing, p 137–142

Panneerselvam K, Lenin K (2014) Joining of nylon 6 plate by friction stir welding process using threaded pin profile. Mater Des 53:302–307

Simões F, Rodrigues DM (2014) Material flow and thermo-mechanical conditions during friction stir welding of polymers: literature review, experimental results and empirical analysis. Mater Des 59:344–351

Hoseinlaghab S, Mirjavadi SS, Sadeghian N, Jalili I, Azarbarmas M, Givi MKB (2015) Influences of welding parameters on the quality and creep properties of friction stir welded polyethylene plates. Mater Des 67:369–378

Thomas W, Nicholas ED, Staines D, Tubby PJ, Gittos MF (2005) FSW process variants and mechanical properties. Weld World 49:4–11

Akinlabi ET, Akinlabi SA (2012) Friction stir welding process: a green technology. IJMME 6:2514–2516

Kumar R, Singh R, Ahuja IPS, Penna R, Feo L (2018) Weldability of thermoplastic materials for friction stir welding-a state of art review and future applications. Compos Part B 137:1–15

Singh JIP, Singh S, Dhawan V (2018) Mechanical and biodegradation behaviour of jute/polylactic acid green composites. AJEAT 7:52–57

Sharma V, Prakash U, Kumar BM (2015) Surface composites by friction stir processing: a review. J Mater ProcessTechnol 224:117–134

Biswas P, Mandal NR (2011) Effect of tool geometries on thermal history of FSW of AA1100. Weld J 90:129–135

Reza-E-Rabby M, Reynolds AP (2014) Effect of tool pin thread forms on friction stir weldability of different aluminum alloys. ProcediaEng 90:637–642

Chiteka K (2013) Friction stir welding/processing tool materials and selection. IJERT 2:8–18

Barmouz M, Shahi P, Asadi P (2014) Friction stir welding/processing of polymeric materials. In: Advances in friction stir welding and processing. Woodhead Publishing Limited, Elsevier, p 601–668

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Sharma, A.K.R., Roy Choudhury, M. & Debnath, K. Experimental investigation of friction stir welding of PLA. Weld World 64, 1011–1021 (2020). https://doi.org/10.1007/s40194-020-00890-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00890-7